AI visual perception and adaptive operation of automated industrial collaborative robots

Integrated with high-resolution 3D visual cameras and deep learning algorithms, it can identify the position, posture and surface features of workpieces in real time. It supports functions such as disordered sorting, weld tracking, defect detection, etc., automatically adjusts the operation path, and can adapt to different materials and tasks without complex programming.

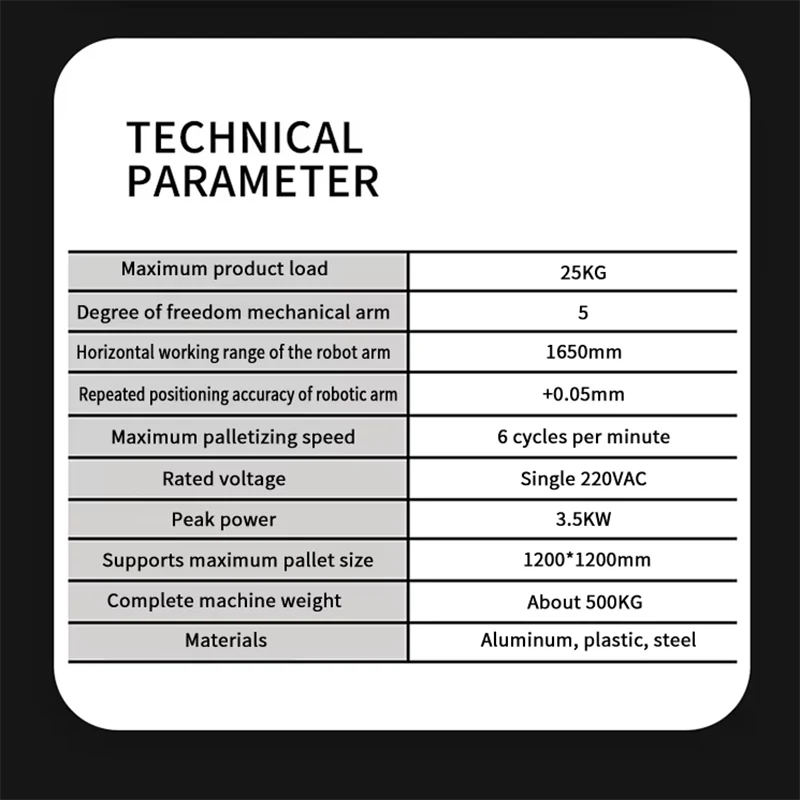

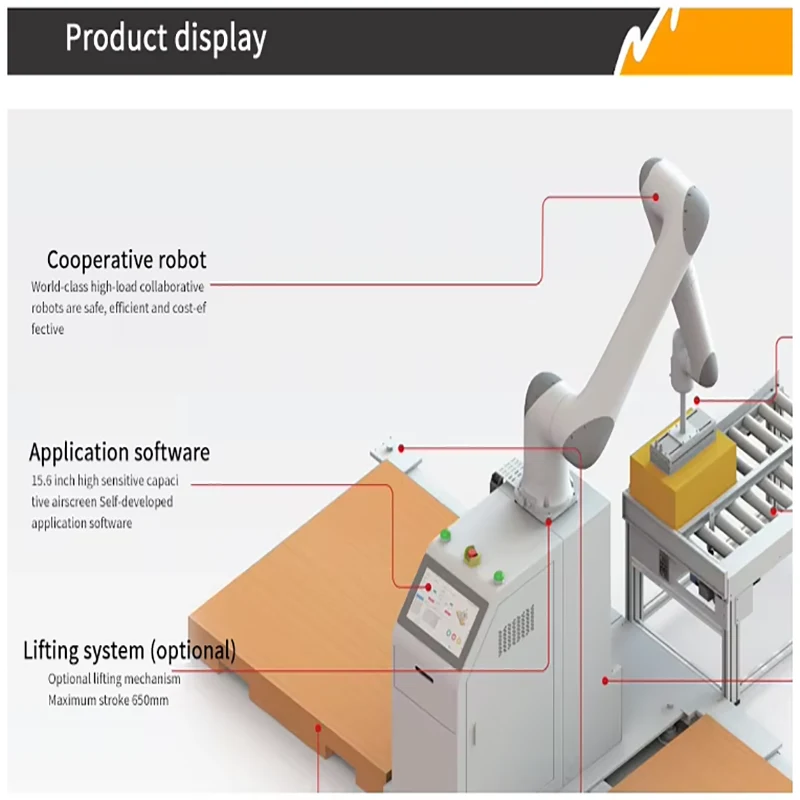

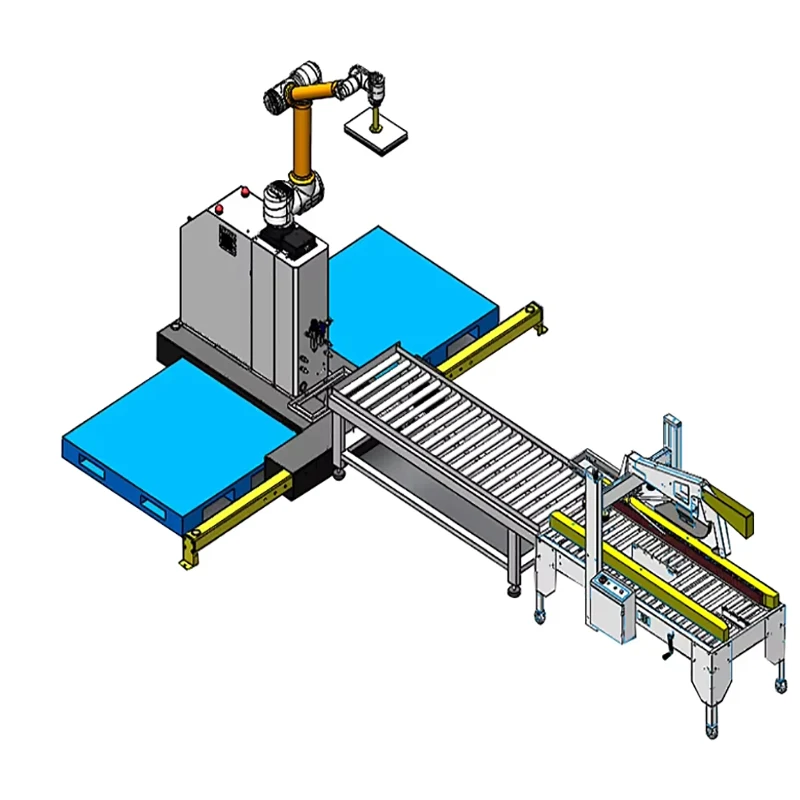

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Intelligent industrial collaborative robots have a human-machine safe collaboration mode

- Dynamic obstacle avoidance: Through laser radar and infrared sensing, real-time monitoring of the surrounding environment, intelligent detour around obstacles, and ensuring the safety of human-machine collaboration.

Edge computing and cloud collaboration

Equipped with edge computing modules to achieve local and rapid data processing; support access to the industrial cloud platform, remote monitoring of equipment status, analysis of operating data, optimization of operation strategies, and remote upgrade of the system through OTA to reduce operation and maintenance costs.

Low-code/no-code programming

Provides a graphical programming interface and a modular instruction library, and users can complete task settings by dragging and dropping and configuring parameters; supports offline simulation, reduces on-site debugging time, and lowers the programming threshold.

Modular configuration scheme

Hardware expansion

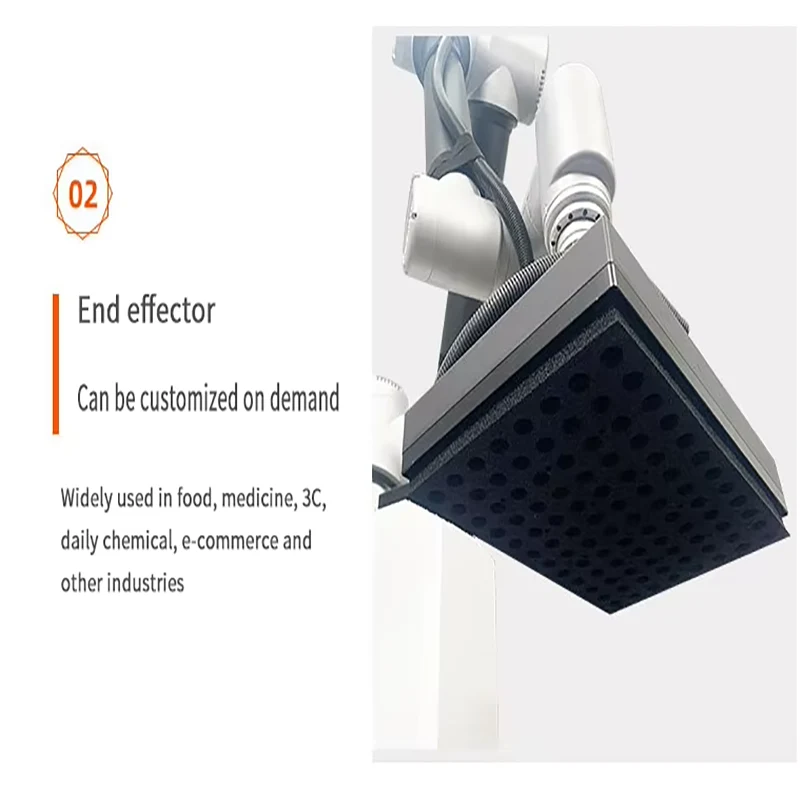

- End effector: adapts to a variety of tools such as suction cups, grippers, welding guns, spray heads, grinding tools, etc., and supports quick-change interfaces;

- Mobile chassis: AGV/AMR chassis are optional to achieve autonomous robot movement and expand the scope of operation.

Software system

- Intelligent scheduling platform: supports multi-robot collaborative operation, automatically assigns tasks, and optimizes paths;

- Data dashboard: real-time display of key indicators such as equipment operation status, production efficiency, and fault warning.

Products Description

Company Profile

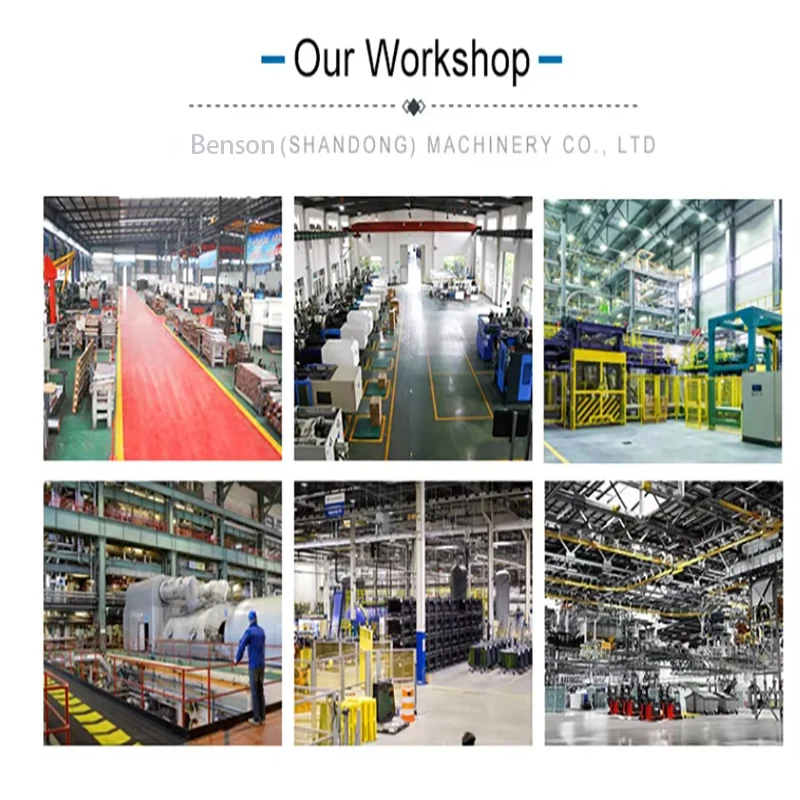

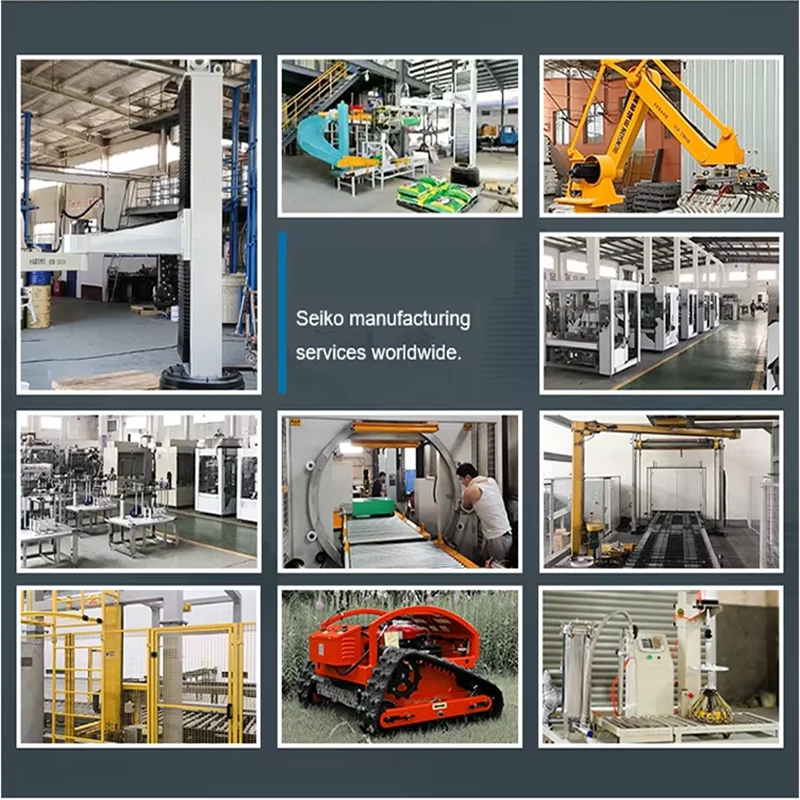

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

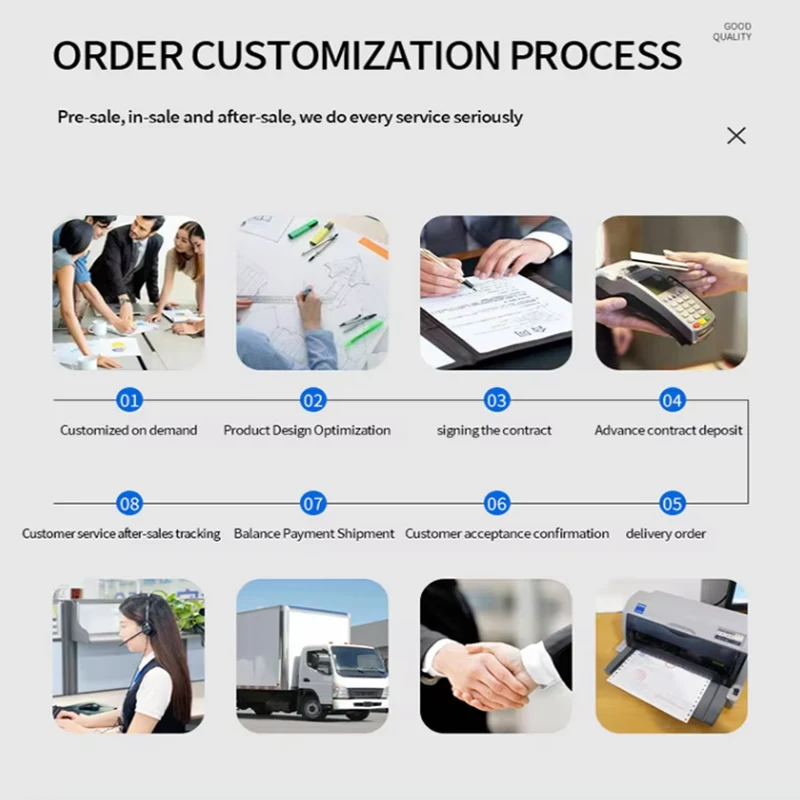

Product Inquiry