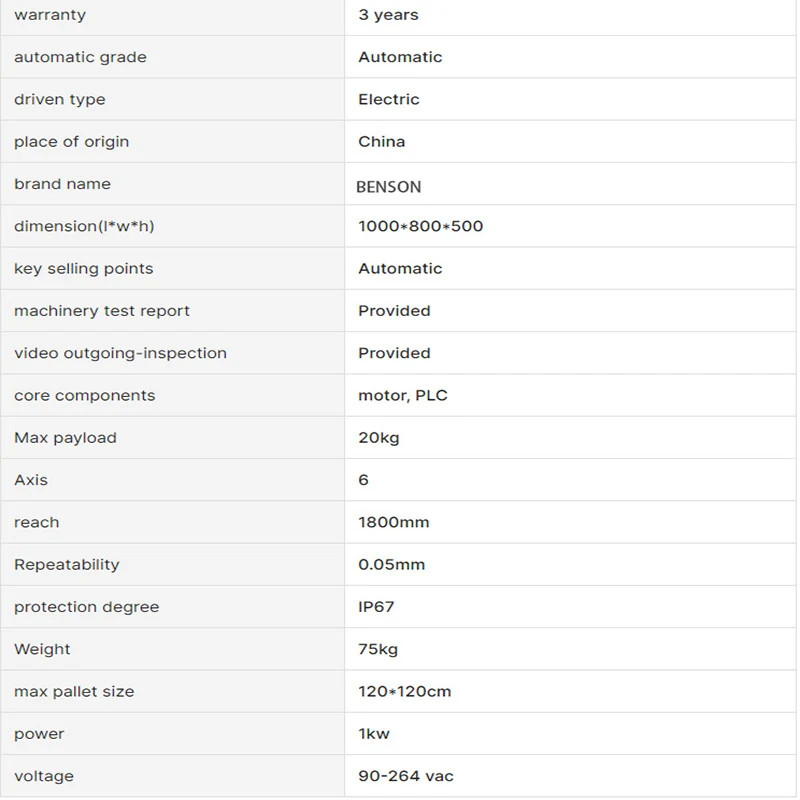

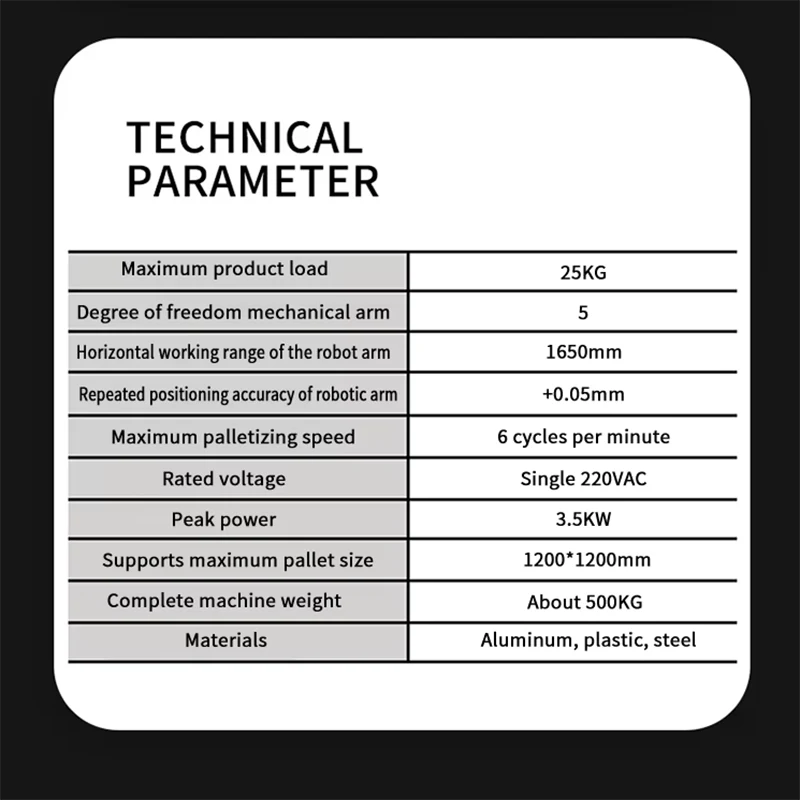

- High-precision operation of the automated plastic pallet collaborative robot: It has high repeatability positioning accuracy, such as up to 0.05mm, and can accurately complete actions such as grabbing and placing to ensure the regularity and consistency of palletizing.

- Load capacity adaptation: It has a certain load limit, such as some models can reach 20kg, which meets the needs of various cargo palletizing.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

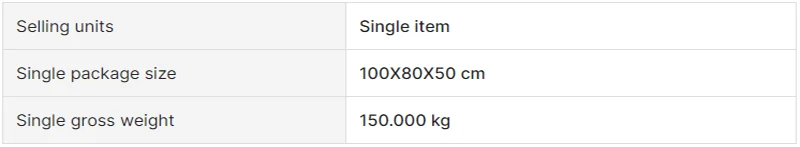

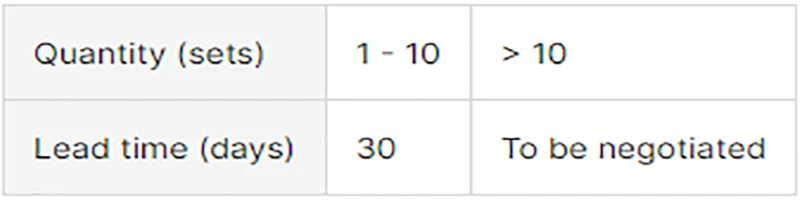

Feature highlights: This Collaborative Robotic Arm Plastic Palletizer offers high precision with a repeatability of 0.05mm and a max payload of 20kg, suitable for industries like food, beverage, and manufacturing. It features an IP67 protection degree, electric - driven operation, and a 3 - year warranty on core components. The product is supported by a comprehensive after - sales service system and meets diverse packaging needs.

Competitive pricing Growing customer interest

Lower than 100% of similar items +150% from last month 10 views

Products Description

Functional features of automated plastic pallet collaborative robots

- Good protection performance: often with IP67 protection level, can effectively prevent dust and water, and adapt to complex industrial environments.

- High efficiency of electric drive: adopts electric drive mode, stable operation, quick response, can achieve fast operation cycle, and improve work efficiency.

- Safe collaborative design: in line with relevant safety standards, equipped with sensors and other devices, can work safely with workers, and adjust the operation status or stop in time when abnormal situations such as people approaching are detected to avoid safety accidents.

Automated plastic pallet collaborative robot workflow

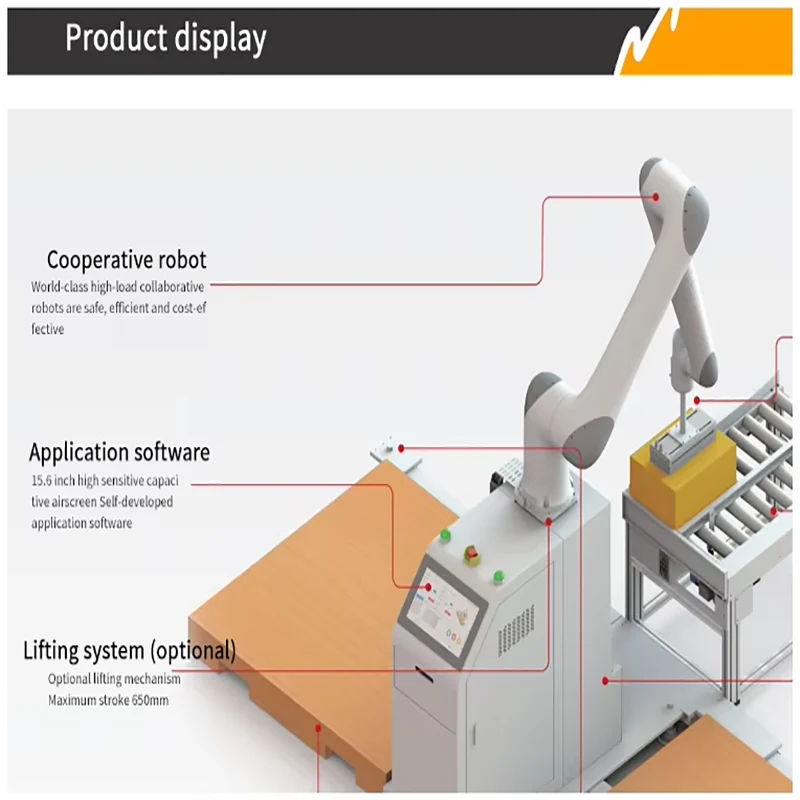

Cargo transportation: Cargo arrives at the designated location in sequence through conveying equipment such as conveyor belts.

Visual recognition and positioning: Use the built-in visual system to identify and locate the shape, position, posture, etc. of the goods, and provide information for accurate grasping.

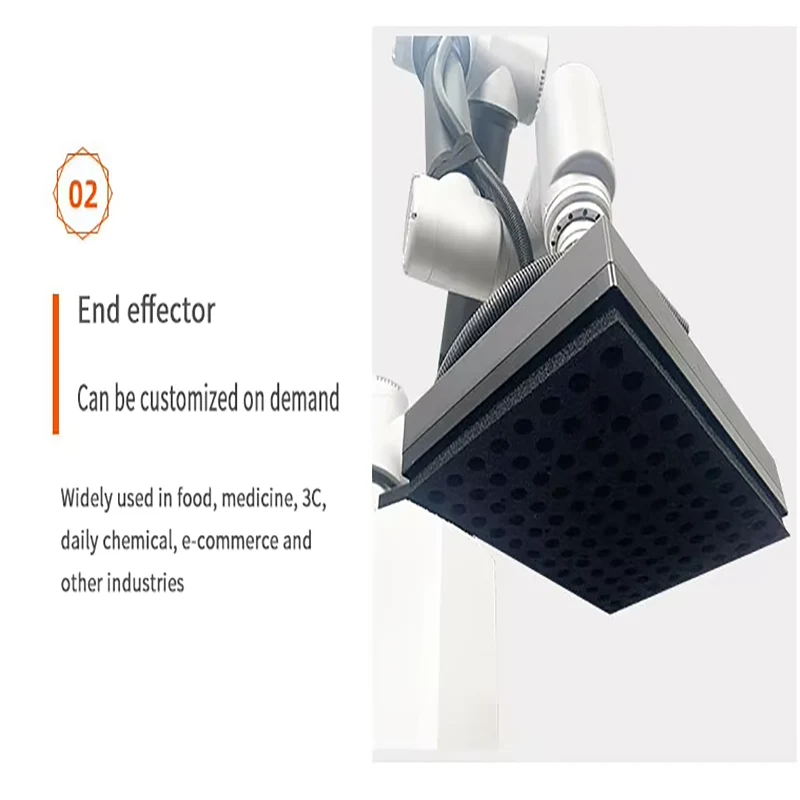

Grasping and handling: The collaborative robot grabs the goods through the end effector (such as grippers, suction cups, etc.) according to the visual feedback information, and moves them to the top of the plastic pallet.

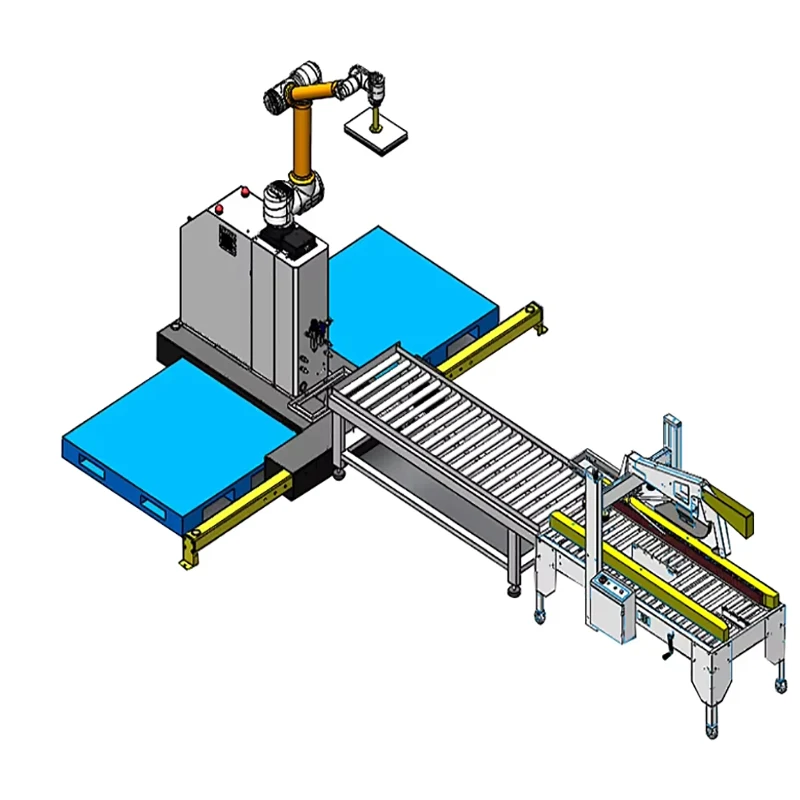

Palletizing: Place the goods accurately on the plastic pallet according to the preset palletizing mode (such as neatly arranged rows and columns, staggered stacking, etc.). After completing one layer of palletizing, continue the next layer of operation until the predetermined height or quantity is reached.

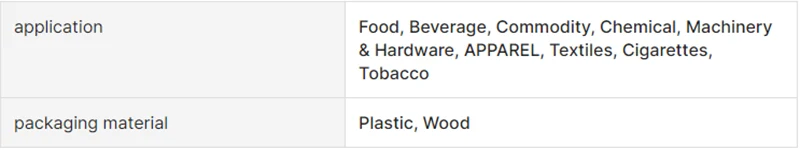

Application fields of automated plastic pallet collaborative robots

- Food and beverage industry: Palletize packaged food and beverage products, such as bottled beverages, boxed food, etc., to meet the requirements of hygienic and efficient production.

- Manufacturing industry: In the production links of parts and finished products, it is used to stack products on plastic pallets for storage, transportation and subsequent processing.

- Logistics and warehousing industry: All kinds of goods can be palletized and sorted, which is convenient for the utilization of storage space and the loading and unloading of goods, and improves the efficiency of logistics turnover.

Advantages and value of automated plastic pallet collaborative robots

- Improve production efficiency: Compared with manual palletizing, automated operations are fast and continuous, which can greatly shorten the operation time and increase the output per unit time.

- Reduce labor costs: Reduce dependence on a large number of manual labor, alleviate the problems of difficulty in recruiting workers and high labor costs.

- Improve product quality: Precise operation can avoid collision and damage of goods caused by manual handling, and the palletizing quality is stable and regular, which is conducive to subsequent storage and transportation.

- Flexible production: Through simple programming adjustments, it can adapt to different sizes, weights and diversified palletizing needs, meeting the company's small batch and multi-variety production mode.

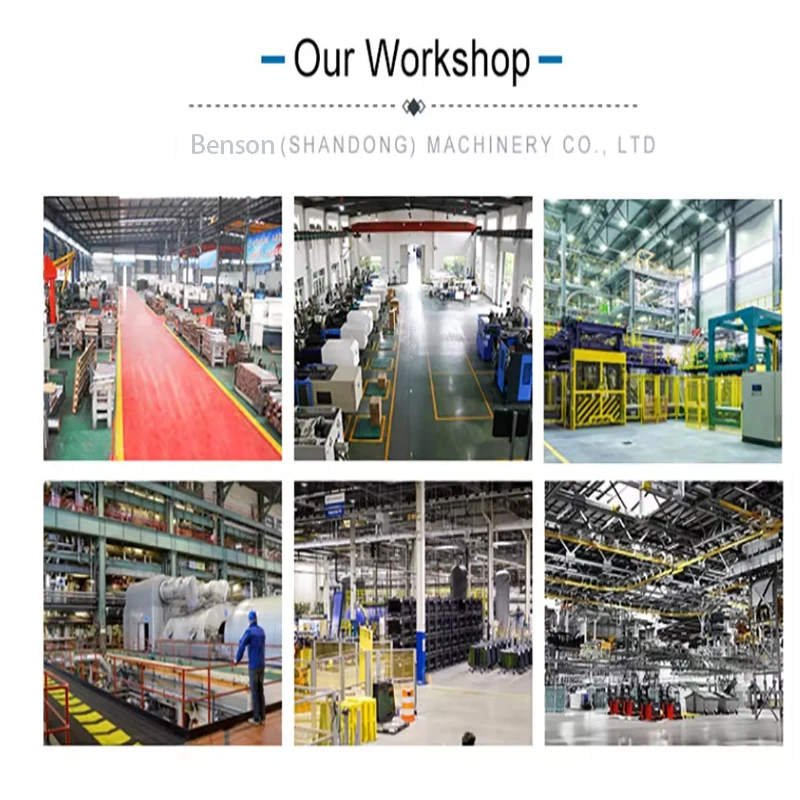

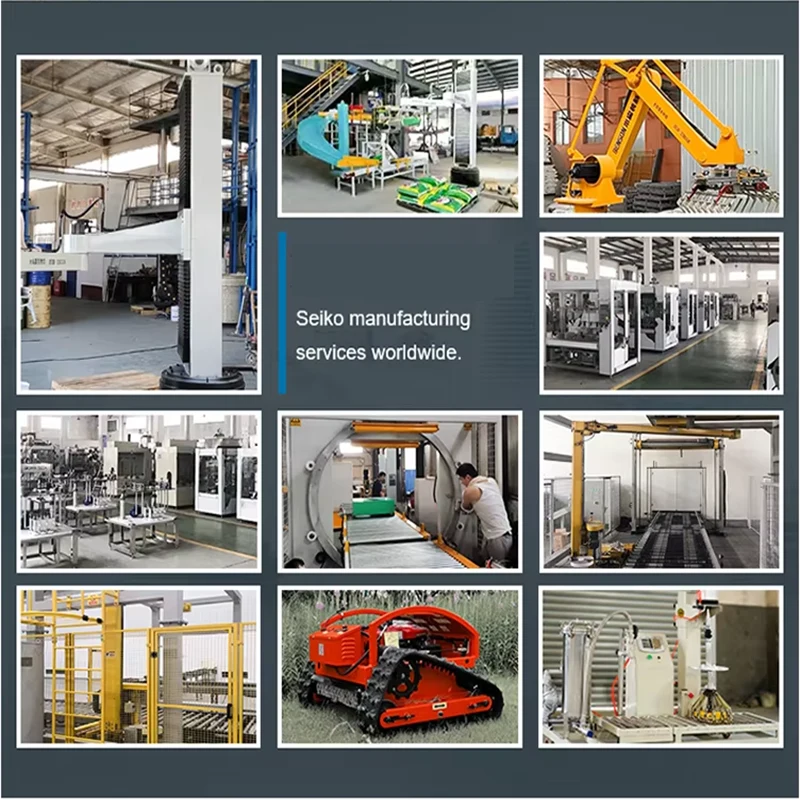

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry