- 5Kg load industrial collaborative robot is flexible and agile: the six-axis linkage design gives the robot excellent flexibility, and each joint can respond to instructions quickly to achieve high-speed and smooth movement. In tasks such as electronic component assembly and small parts handling that require high speed and flexibility, it can complete operations efficiently and accurately, greatly shortening the production cycle.

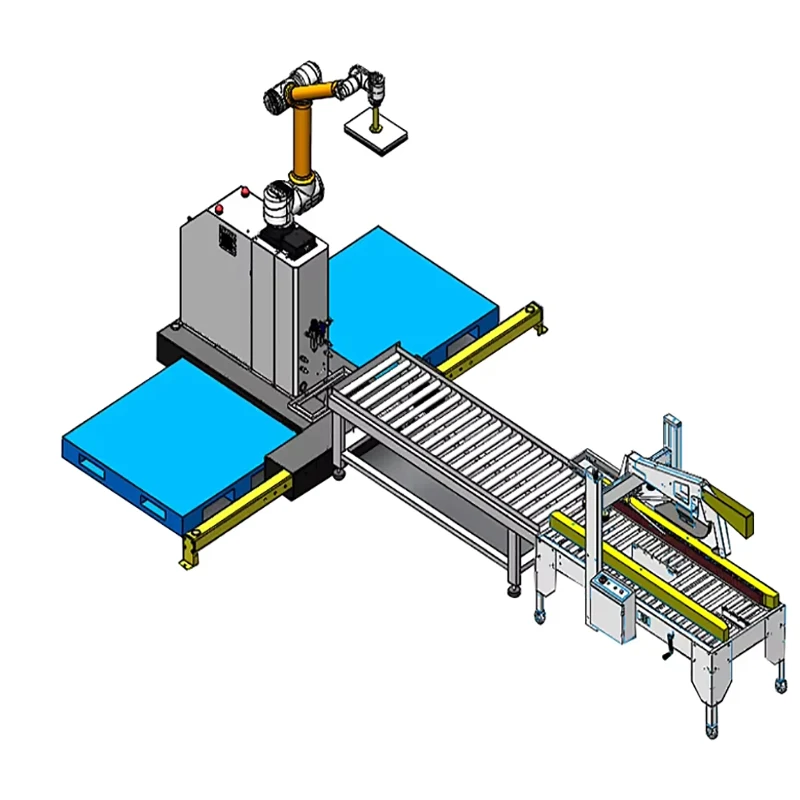

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

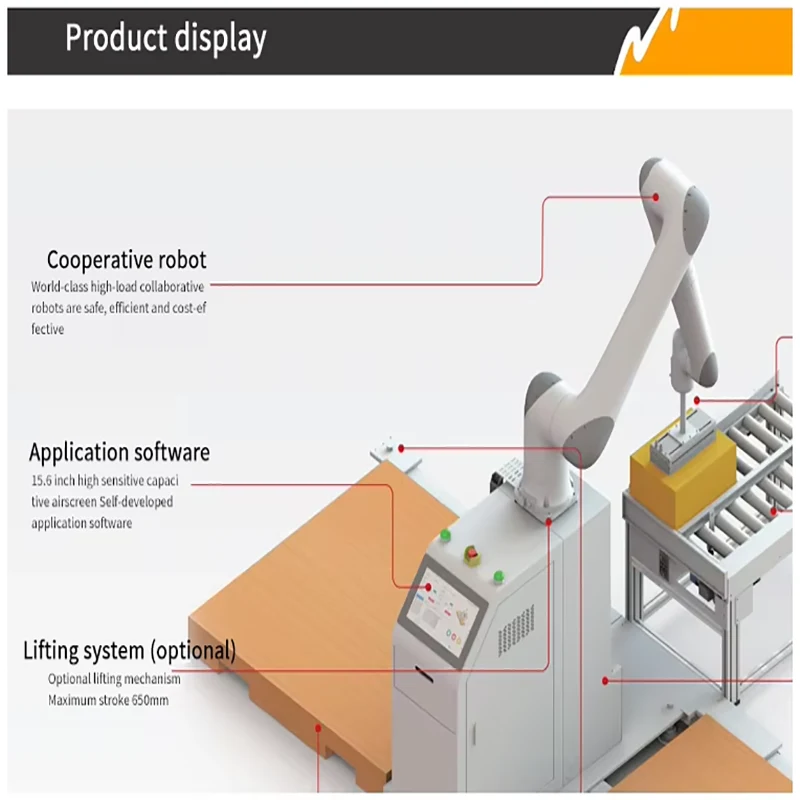

Appearance and basic parameters of automated packaging industrial collaborative robots

- Appearance design: The overall design is compact and lightweight, made of lightweight materials, which reduces its own weight while ensuring mechanical strength, making it easy to install and move. Its structural layout is reasonable, the joints are smoothly connected, and the mechanical arm is flexible and changeable, which can easily adapt to the spatial layout of various industrial scenes.

- Basic parameters: The load capacity is 5kg, which can stably carry tools or workpieces of corresponding weight; the working radius is usually around 800-1000mm (different brands and models have differences), and can cover a certain range of working areas; the repeat positioning accuracy can reach ±0.02-±0.1mm, ensuring high precision of operation; with 6 degrees of freedom, it can achieve multi-dimensional flexible movement and simulate human hand movements in all directions.

Performance characteristics of automated packaging industrial collaborative robots

Motion performance

- Stable and reliable: By optimizing the mechanical structure and transmission system, combined with high-precision servo motors and reducers, the vibration and noise during operation are effectively reduced, ensuring the stability of the robot under long-term and high-frequency working conditions, reducing downtime caused by mechanical failures, and improving equipment utilization.

Intelligent control

- Advanced control system: Equipped with a high-performance controller, it has powerful data processing and computing capabilities, and can quickly parse and execute complex instructions. At the same time, it adopts advanced motion control algorithms, which can accurately plan and adjust the robot's motion trajectory in real time to ensure the accuracy and consistency of operations.

- Multiple programming methods: Supports teaching programming. The operator can manually guide the movement of the robot arm through the teach pendant, record key points and actions, and quickly generate operation programs; it also supports offline programming, with the help of professional software for virtual simulation on the computer, planning the best operation path in advance, reducing on-site debugging time, and improving programming efficiency and safety. In addition, some robots can also be programmed through a graphical programming interface or simple code instructions, reducing the difficulty of programming and facilitating operation by personnel of different skill levels.

Safety protection

- Multiple safety mechanisms: Equipped with collision detection sensors, when the robot collides with obstacles or personnel during operation, it can quickly detect changes in external forces and stop movement immediately to avoid equipment damage or personal injury; equipped with hardware protection measures such as safety fences and emergency stop buttons, operators can quickly trigger emergency stops in emergency situations to ensure on-site safety; at the same time, the robot can also set a safe working area, and automatically slow down or stop running when it exceeds the preset area.

- Human-machine collaboration safety: In line with human-machine collaboration safety standards, it can work collaboratively with operators in the same workspace. Through advanced force control technology, the robot can sense the contact force with personnel, while ensuring operational accuracy, achieving safe and harmonious human-machine interaction, and is suitable for production scenarios that require a combination of manual assistance and robot automation.

Application areas

Electronic manufacturing industry,Automotive parts manufacturing,Food and pharmaceutical industry.

Advantages of automated packaging industrial collaborative robots

Cost-effectiveness

- Reduce labor costs: It can work 24 hours a day, replace manual labor to complete repetitive and high-intensity tasks, reduce the company's dependence on labor, and reduce labor cost expenditure. At the same time, the stability and consistency of robot operation can effectively reduce the defective rate and rework rate, and further save production costs.

- Improve return on investment: Although the initial purchase cost is relatively high, in the long run, its efficient production capacity, low maintenance cost and long service life can bring significant economic benefits to the company and improve the return on investment. In addition, with the continuous advancement of technology and the intensification of market competition, the price of robots has gradually become reasonable, and the cost performance has continued to improve.

Production flexibility

- Fast switching tasks: Due to its flexible programming and easy operation, it can complete the switching of different tasks in a short time, and adapt to the production mode of multiple varieties and small batches. Enterprises can quickly adjust production tasks according to changes in market demand, realize rapid reorganization and optimization of production lines, and improve production flexibility and response speed.

- Easy to integrate: It can be integrated with various industrial equipment, sensors, visual systems, etc. to build intelligent production units or production lines. Through interconnection with other equipment, data sharing and collaborative operations can be achieved, further improving the level of automation and intelligence of production and meeting the needs of digital transformation of enterprises.

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

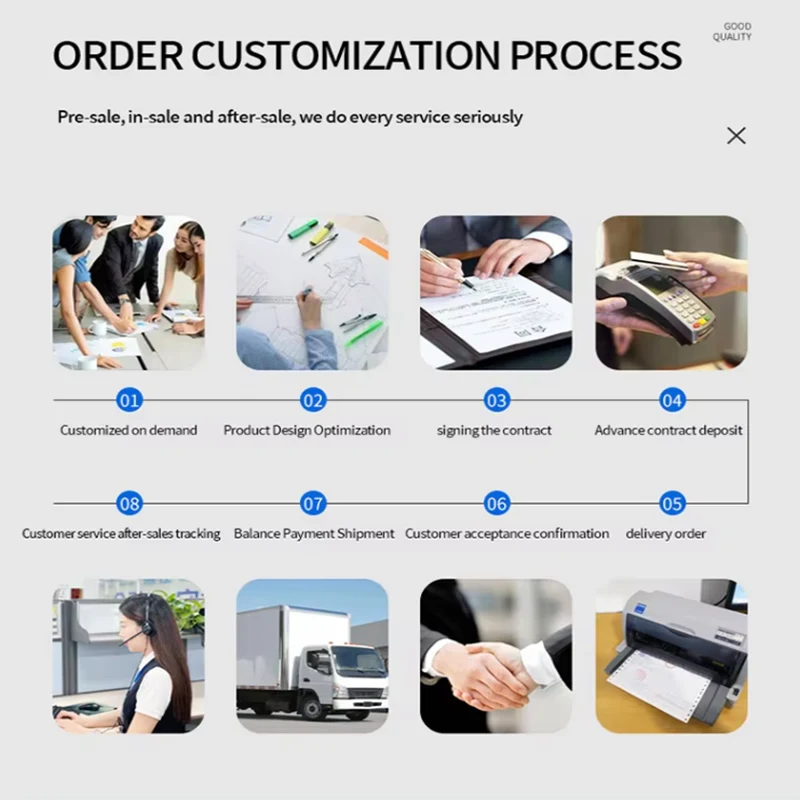

Product Inquiry