Industrial collaborative robot arms can accurately repeat positioning: the repeat positioning accuracy can reach ±0.02mm, which can accurately control the welding and spraying positions and trajectories, ensure product quality consistency, and reduce the defective rate. For example, in the welding of electronic components, it can accurately complete the operation of tiny solder joints; when spraying, it can also ensure the uniform thickness of the coating.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

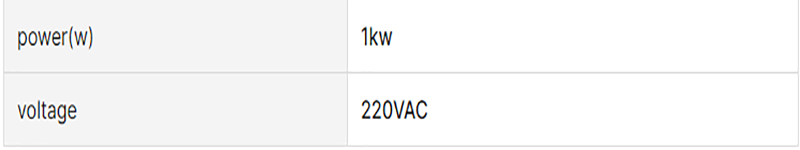

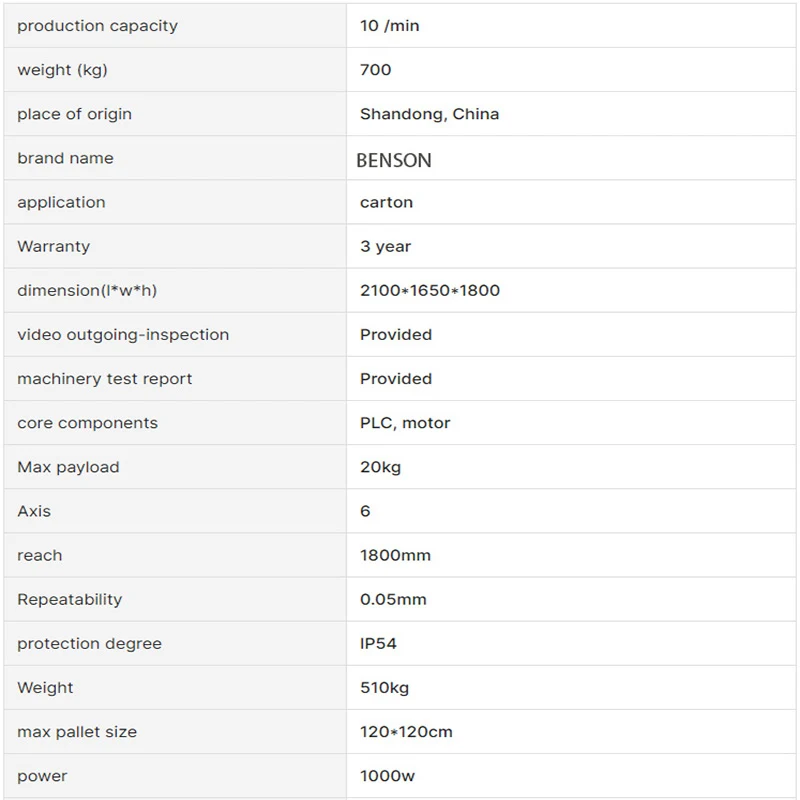

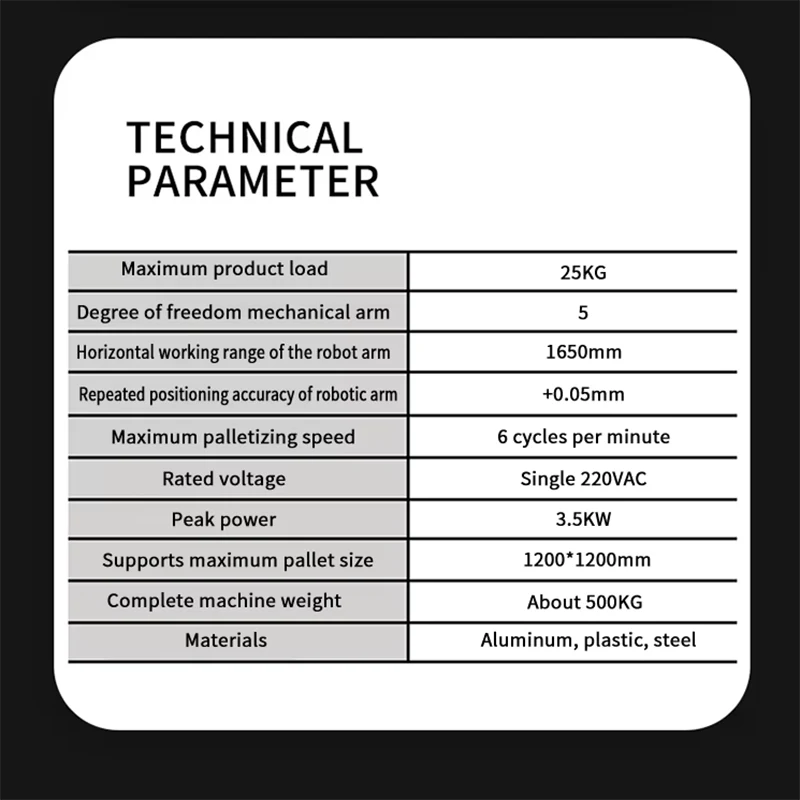

This collaborative robot has a maximum load capacity of 20 kg, a repeatability of 0.05 mm and a P54 protection level. It is suitable for palletizing, welding and spraying tasks. It is equipped with a powerful programmable logic controller (PLC) and motor to ensure accuracy and reliability. The product comes with a 12-month warranty, mechanical test report and video shipment inspection to ensure quality.

Products Description

- Industrial collaborative robot arm has strong real-time deviation correction capability: With the help of arc tracking, laser visual weld tracking and other technologies, it can sense deviations in real time and adjust automatically. During welding, the welding gun can always be in the center of the weld, even if the workpiece has a certain tolerance or the welding process is deformed, the welding quality can be ensured.

- Complex trajectory operation: Unique arm structure (such as double joint module design), flexible movement, can achieve complex spatial trajectory movement, adapt to various complex workpieces and welding and spraying requirements.

- Fast operation: fast movement speed and quick action response, compared with manual, it can greatly shorten the welding and spraying time of a single workpiece and improve production efficiency.

- Welding collaborative robot arm works continuously and stably: It can work stably and continuously for 24 hours without rest and fatigue, ensuring a stable and continuous production rhythm.

- Human-machine collaboration safety: equipped with collision detection and other sensors, it can automatically slow down or stop when it senses contact or collision with personnel to ensure the safety of operators.

- Fault protection mechanism: It has perfect fault diagnosis and protection functions. When an abnormality occurs, it will alarm in time and take measures to avoid danger. For example, the electromagnetic brake will lock in place and not fall when the power is off.

- Convenient teaching: It supports smooth dragging, visual teaching and other methods. Operators can easily drag welding guns and spray guns to the target position, quickly set parameters to establish tasks, and reduce programming difficulty and operation threshold.

- Friendly operation interface: The human-computer interaction interface design is intuitive and easy to understand. Operators can operate proficiently after simple training, which is convenient for daily use and task switching.

- Spraying collaborative robot arm reduces labor costs: It replaces manual repetitive and high-intensity welding and spraying work, reduces manpower requirements, and can avoid quality problems and rework costs caused by unskilled manual operation.

- Low maintenance cost: Some robots adopt modular design, quick component maintenance, and self-diagnosis function, which can quickly locate faults, shorten downtime and maintenance time, and reduce maintenance costs.

<img src="/uploads/allimg/20250502/1-250502161351b6.webp" title="Collaborative robot arm" " alt="4.jpg"/>

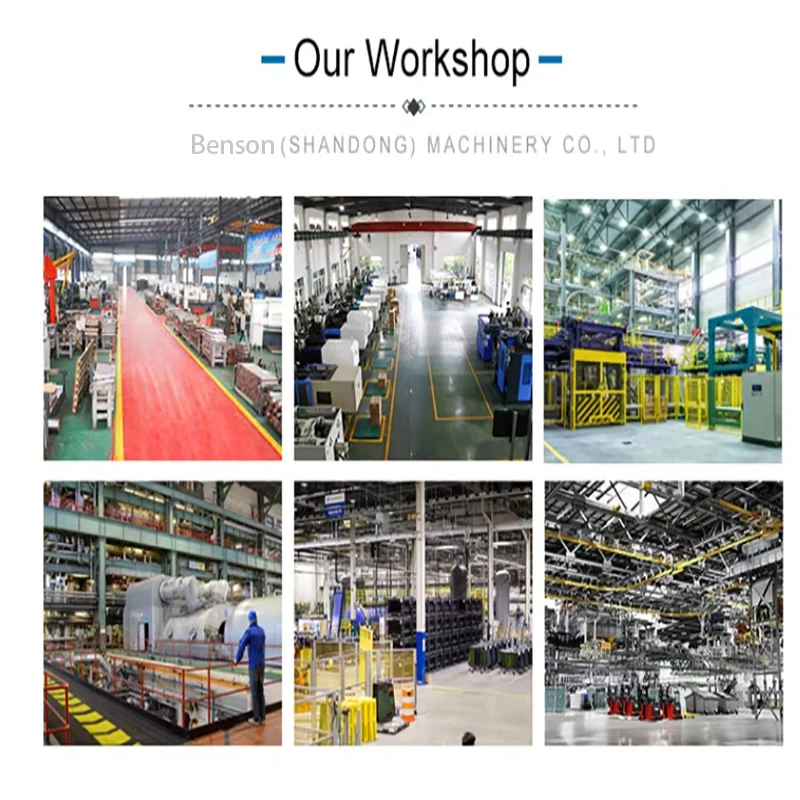

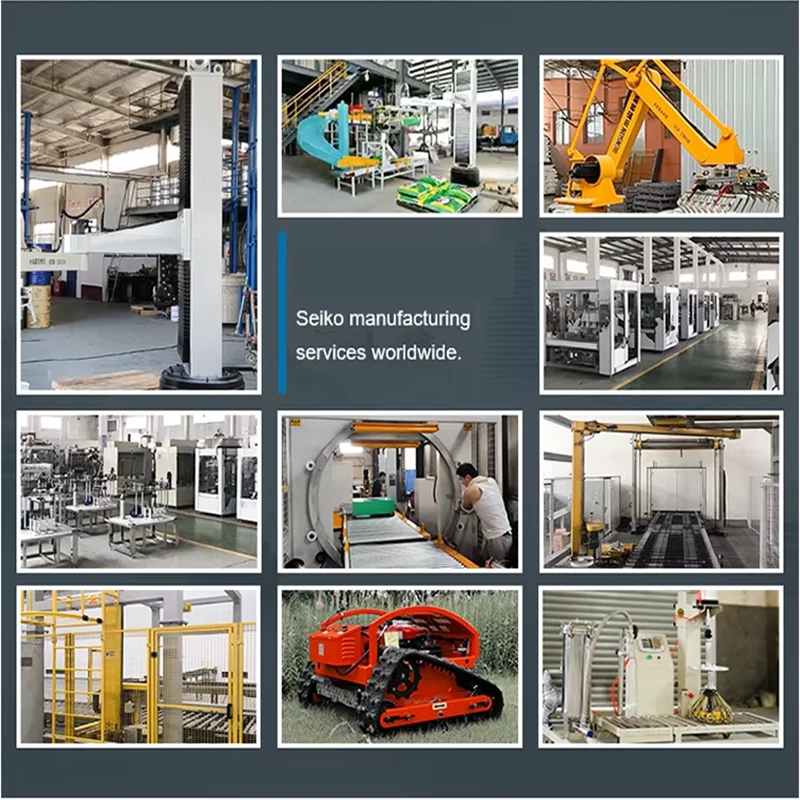

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

FAQ

Product Inquiry