In modern industrial production, palletizing is a key process after product packaging, and its efficiency and quality directly affect the overall operating costs and benefits of the enterprise. Zhongji Benson palletizing collaborative robot arm came into being. With its excellent performance, advanced technology and flexible application, it has become an ideal choice for many companies to achieve palletizing automation upgrades.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

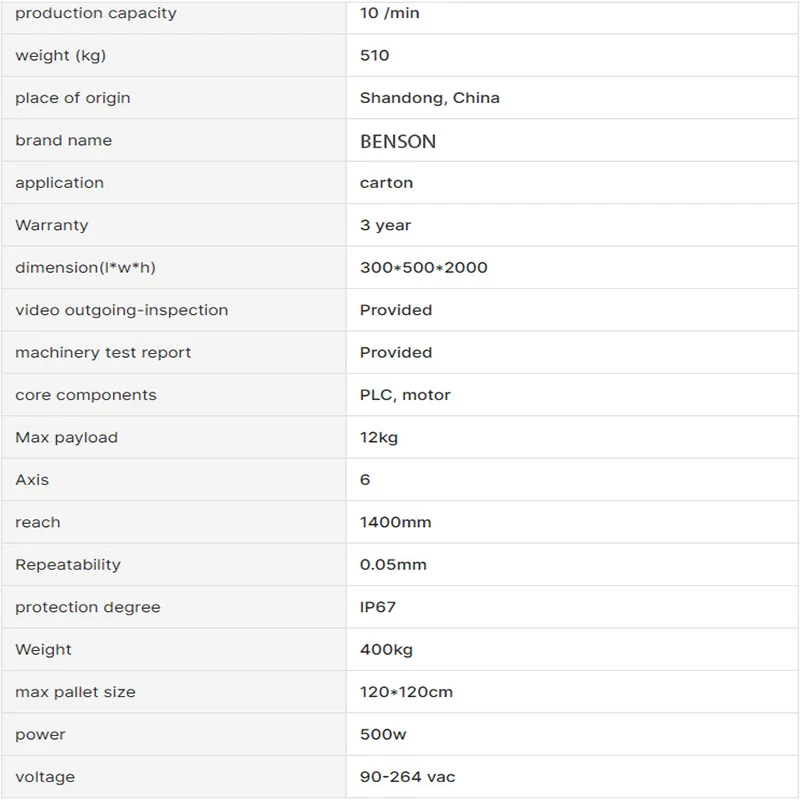

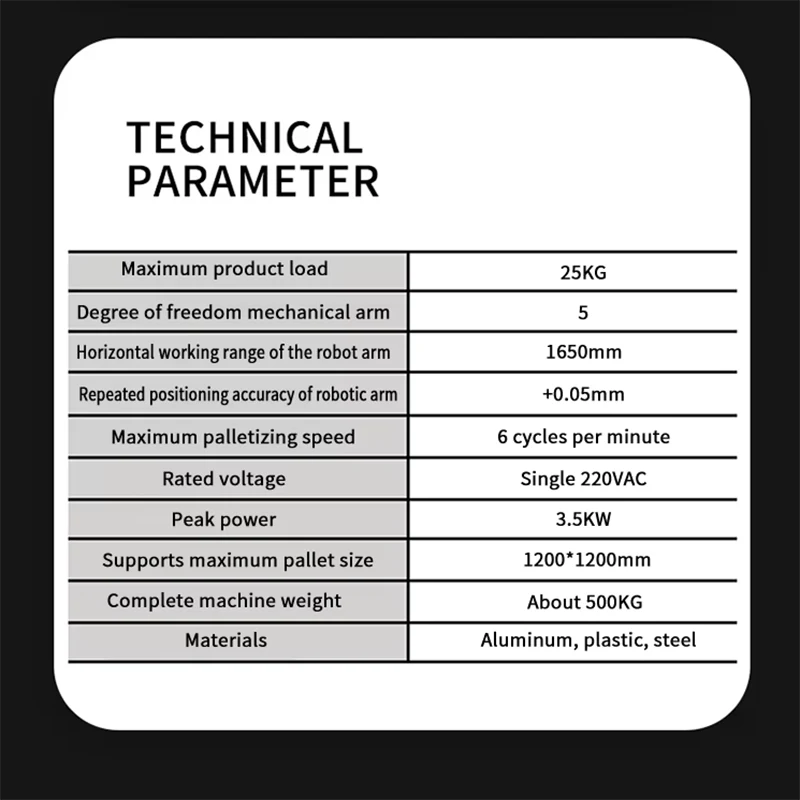

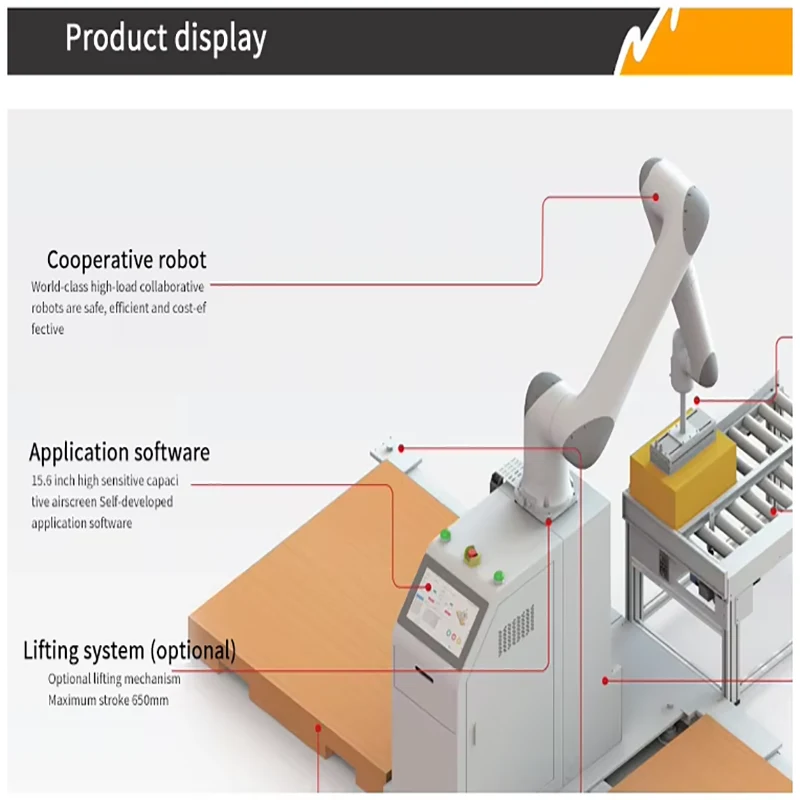

1.Excellent performance of collaborative packaging robot arm, accurate and efficient

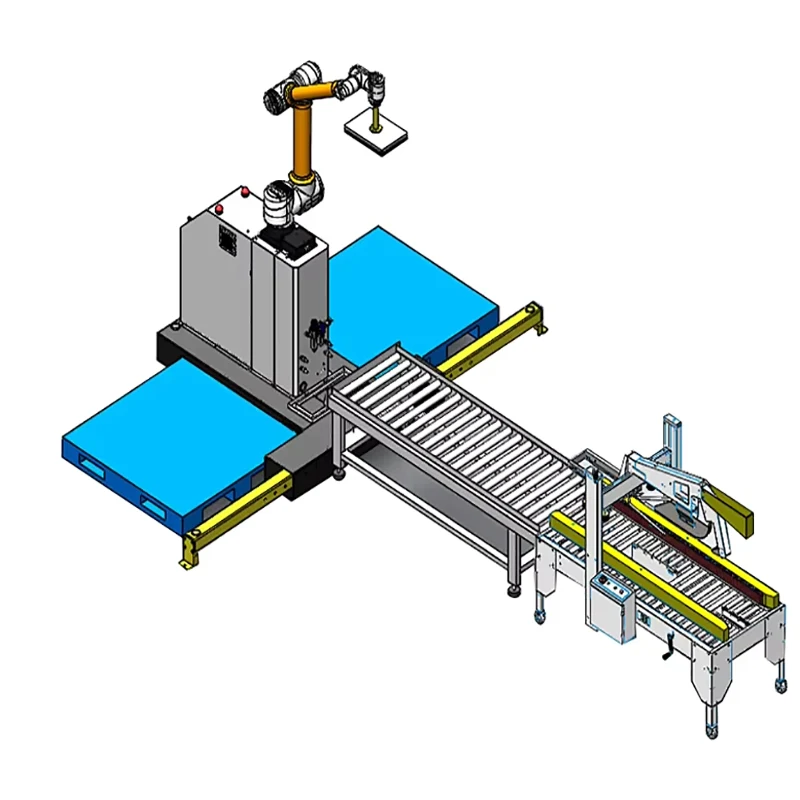

Extremely long working radius: effectively expands the operating range, reduces the frequency of robot movement, and improves palletizing efficiency. In large warehouses or production workshops, it can cover a larger working area, flexibly shuttle between different pallets and production lines, and achieve efficient material handling and palletizing.

High speed and high precision: fast running speed, greatly shortening the palletizing cycle, and increasing the palletizing output per unit time. At the same time, ensure that every grab and place is accurate, so that the stacked products are neat and orderly, avoid safety hazards and space waste caused by irregular palletizing, and provide strong guarantees for subsequent storage and transportation links.

2.Intelligent technology of packaging collaborative robot arm, flexible collaboration

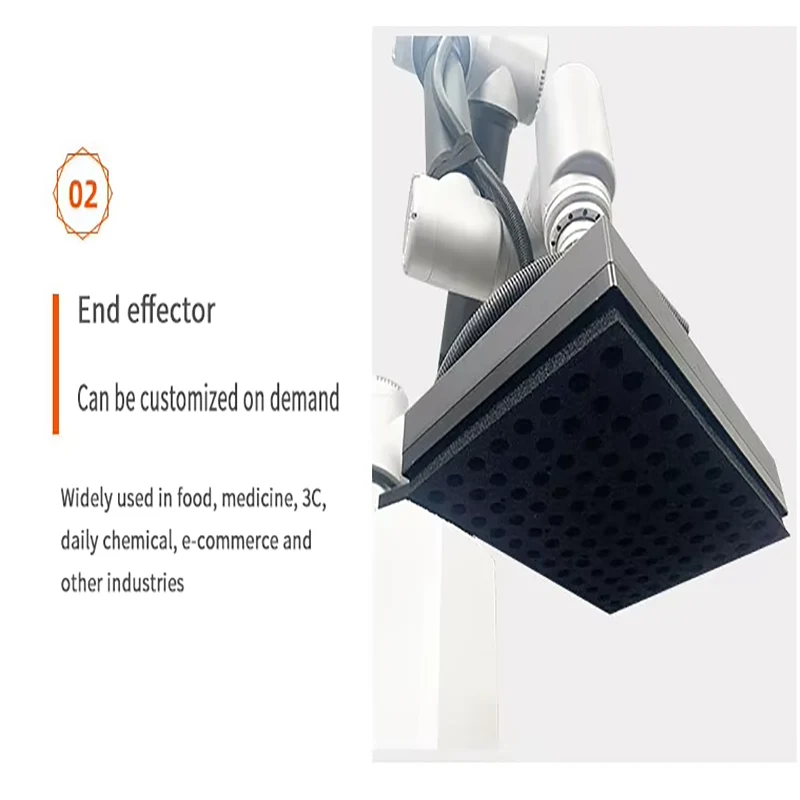

Advanced visual recognition system: Equipped with an advanced visual recognition system, it can quickly and accurately identify the shape, size, position and posture of the product. Even in a complex production environment, it can easily cope with mixed palletizing of products of different specifications, and realize automatic sorting and precise palletizing. The visual system also has a dynamic tracking function, which can track the movement of products on the conveyor belt in real time, plan the grabbing path in advance, ensure efficient grabbing, and effectively improve the efficiency and accuracy of palletizing.

Safety guarantee of human-machine collaboration: Fully consider the safety of human-machine collaboration and equip with a variety of safety protection measures. Force sensors are distributed in each joint of the robot arm. When a collision with a person is detected, the movement can be stopped instantly to avoid harm to the person. At the same time, a safety light curtain and an emergency stop button are set. Once someone enters a dangerous area or an emergency occurs, the protection mechanism can be triggered immediately to ensure a safe and reliable working environment and realize harmonious coexistence and collaborative operation between people and robots.

Flexible programming and teaching function: The operation is simple and convenient, and supports a variety of programming methods, such as graphical programming, teaching and reproduction programming, etc. Through the graphical programming interface, users can complete complex palletizing task programming by simply dragging icons and setting parameters, without the need for professional programming knowledge. Teaching and reproducing programming is more intuitive. The operator can manually guide the robot arm to complete a series of actions, and the robot automatically records the action trajectory and generates a program. It is convenient and fast, and can quickly adapt to the changes of different products and pallet types to meet the needs of small batch and multi-variety production.

3.The packaging collaborative robot arm is durable, stable and reliable

High-quality materials and structural design: The main body of the robot arm is made of high-strength aluminum alloy and high-quality steel. After careful structural design and optimization, it has excellent rigidity and stability. In a long-term high-intensity working environment, it can still maintain precise motion control and reliable performance, effectively reduce equipment failures and downtime, and provide strong support for the company's continuous and stable production.

Advanced drive and control system: Equipped with advanced servo drive system and high-performance control system, it has fast response speed and high control accuracy, and can achieve smooth start, stop and high-speed operation of the robot arm. The drive system has functions such as overload protection and overheating protection, which effectively extends the service life of the equipment. The control system adopts modular design, which is easy to maintain and upgrade. It can flexibly expand functions according to enterprise needs and adapt to changing production needs.

Strict quality inspection and certification: During the production process, strictly follow the international quality management system standards, and conduct strict inspection and debugging of multiple processes for each stacking collaborative robot arm to ensure reliable product quality.

4.The packaging collaborative robot arm is widely used and adapted to multiple scenarios

Food and beverage industry: suitable for packaging and palletizing of various foods and beverages, such as snacks in cartons, bottled beverages, canned beer, etc. It can quickly move products from the production line to the pallet, and neatly stack them according to specific pallet types to avoid product squeezing and damage, improve packaging efficiency and product quality, and help food and beverage companies meet the rapidly growing market demand.

Electronic and electrical industry: In view of the small size, light weight and high precision requirements of electronic and electrical products, the robot arm can perform fine palletizing of electronic product parts and finished products with its high-precision grasping and placement capabilities. In the electronic product production line, it seamlessly connects with other automated equipment to improve production efficiency, reduce labor costs, and help electronic and electrical enterprises improve their market competitiveness.

Products Description

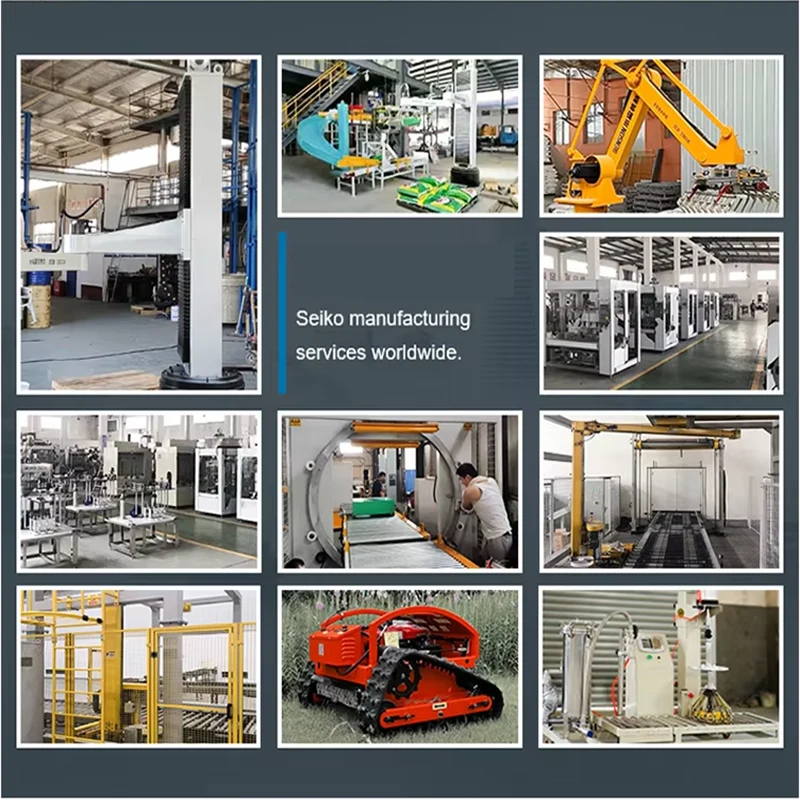

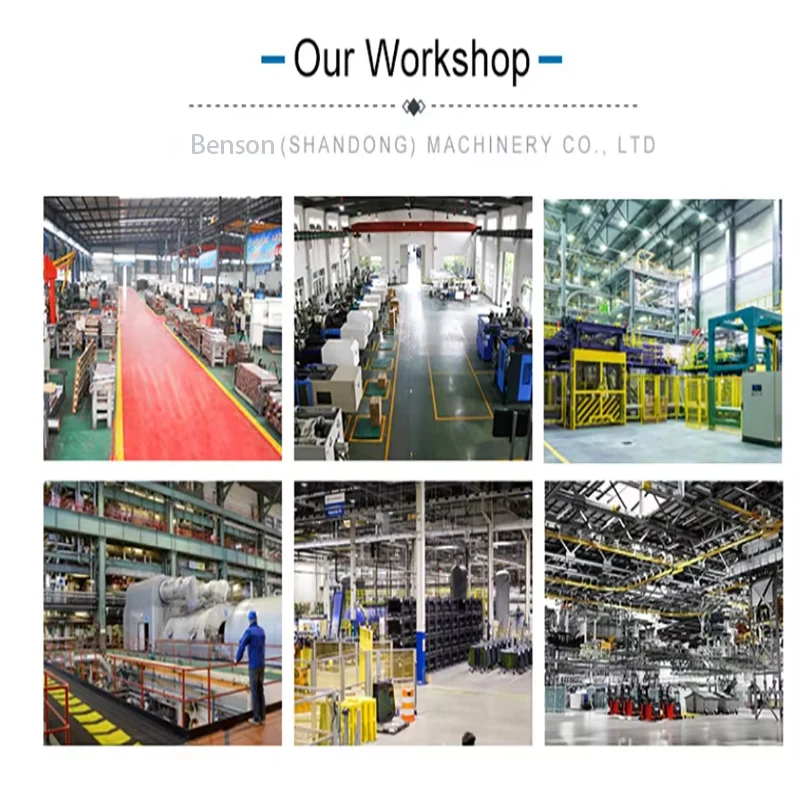

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry