Automated production collaborative robots - opening a new era of intelligent production

In today's highly competitive manufacturing industry, automated production collaborative robots are becoming the core force to promote the efficient development of enterprises. It breaks the limitations of traditional production models and provides innovative solutions for various production scenarios with excellent performance, high safety and wide applicability.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

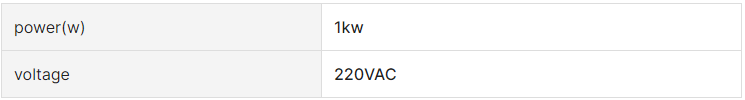

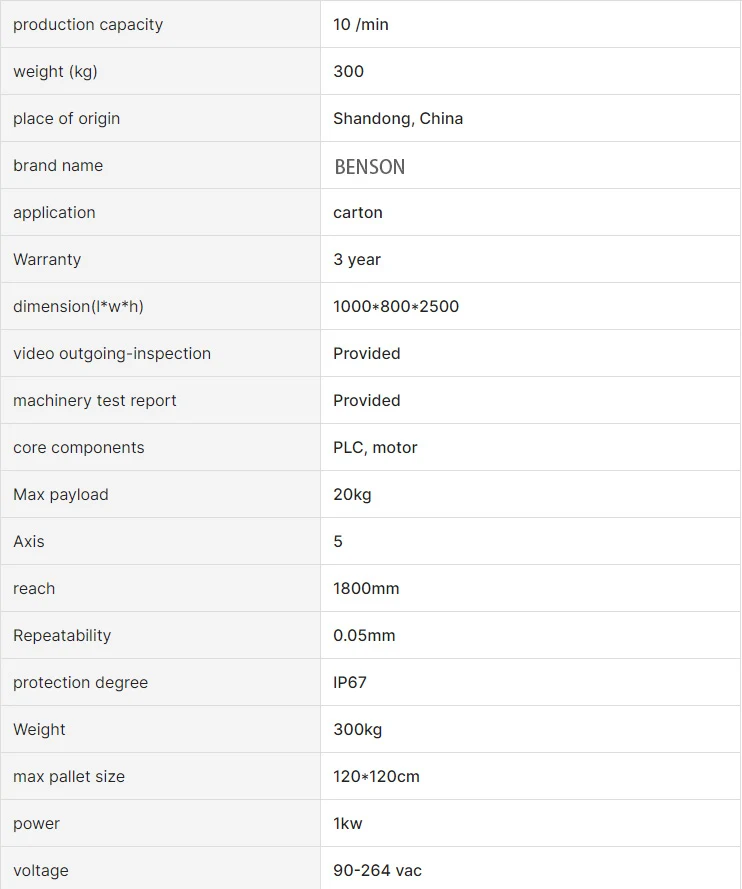

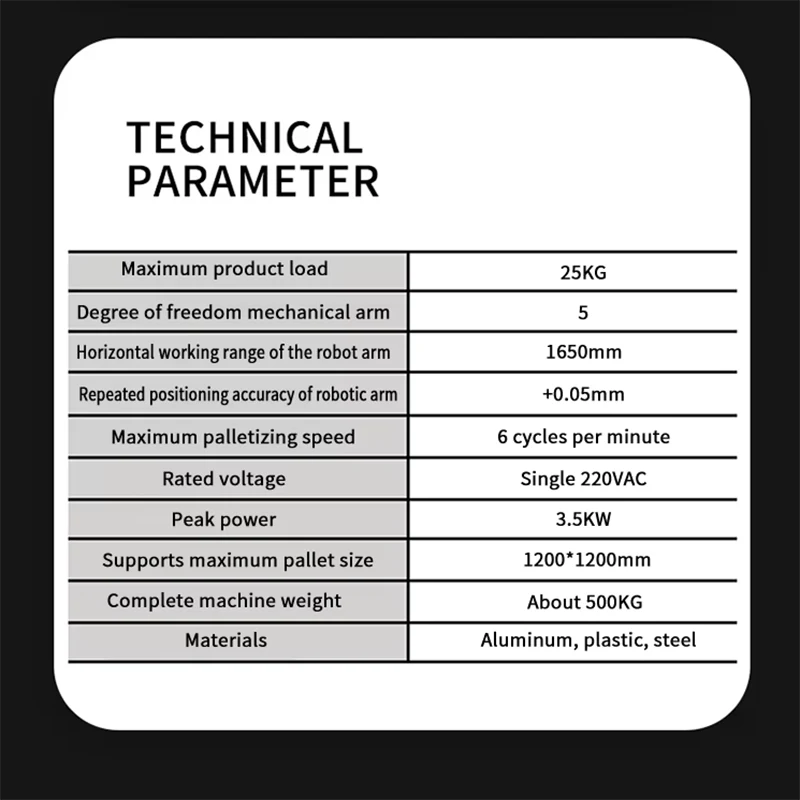

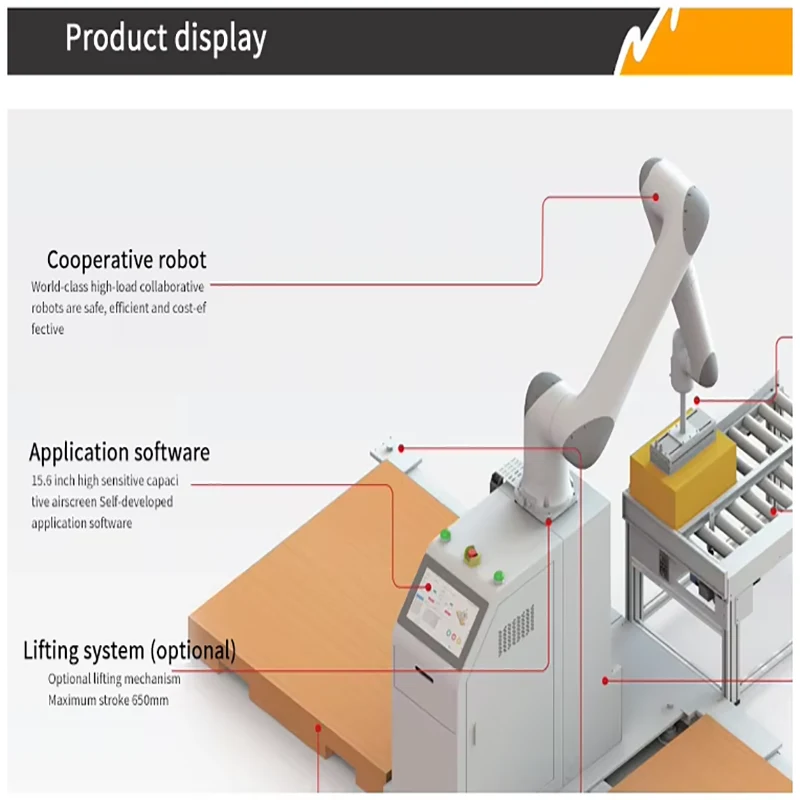

Feature highlights: This collaborative robotic arm palletizing system boasts a repeatability of 0.05mm and an IP67 protection degree, ensuring precision and durability in demanding industrial environments. Equipped with a 5 - axis design, 20kg max payload, and 1800mm reach, it is ideal for automated production lines. The product includes a machinery test report and core components like motor and PLC, backed by a 2 - year warranty on core parts.

Our automated production collaborative robot has high-precision motion control capabilities, which can achieve precise operations in complex production tasks and ensure the stability and consistency of product quality. Whether it is the assembly of precision parts or the processing of tiny parts, it can meet production needs with excellent performance.

The robot has a fast response speed and efficient operation rhythm, which can complete a large amount of repetitive work in a short time and greatly improve production efficiency. Its operating speed can be flexibly adjusted according to task requirements, effectively shortening the production cycle and enhancing the market competitiveness of the enterprise.

Safety is the design core of the automated production collaborative robot. It is equipped with advanced collision detection system and intelligent sensing technology. When it detects the risk of collision with the human body or other objects, it can stop movement instantly to avoid accidental injuries. At the same time, the robot also has multiple safety protection mechanisms, such as emergency stop button, safety light curtain, etc., to provide all-round safety protection for operators.

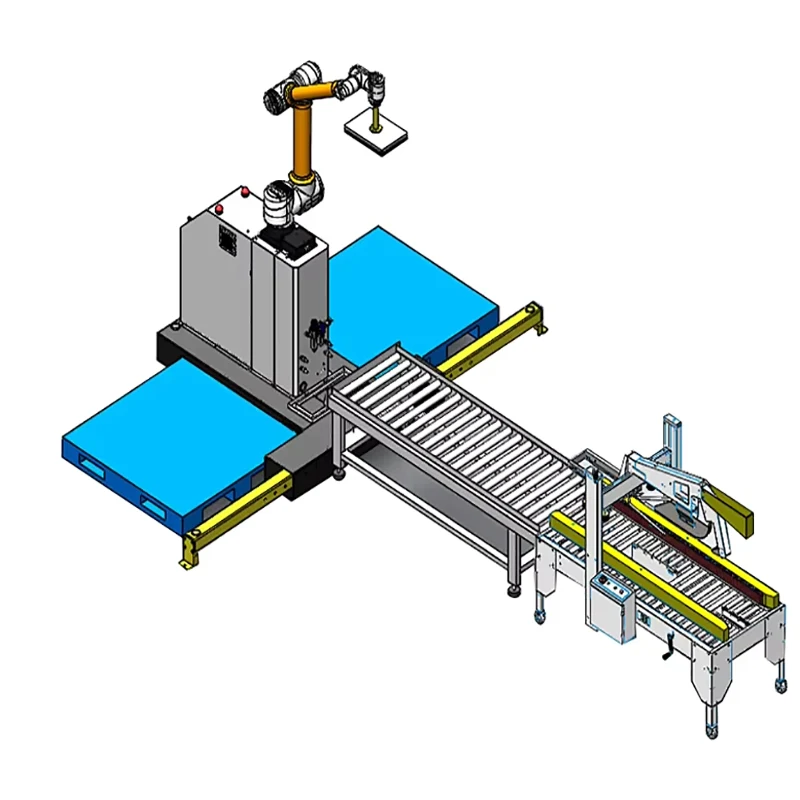

The robot supports the human-machine collaborative working mode and can work with human employees in the same workspace. Through intelligent programming and teaching functions, operators can easily set tasks and operate robots, realize seamless cooperation between people and robots, give full play to their respective advantages, and jointly complete complex production tasks.

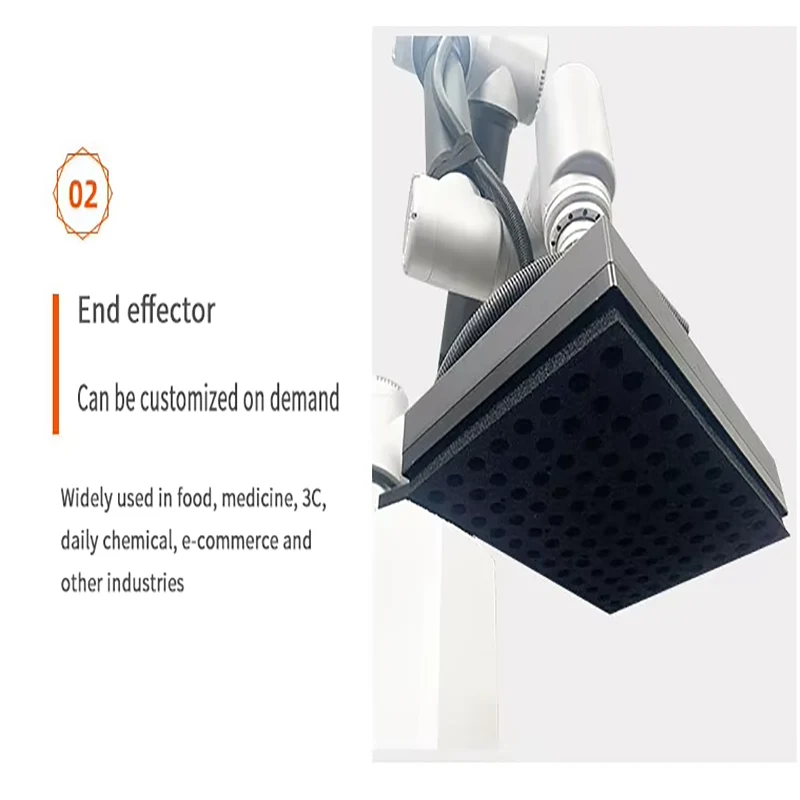

The robot has a high degree of flexibility and scalability, and can be customized according to different production needs. It can be equipped with various types of end effectors, such as grippers, suction cups, spray guns, etc., to adapt to the operation of workpieces of different shapes, sizes and materials; it can also be seamlessly integrated with other automation equipment and production lines to build a complete automated production system and realize the intelligence and automation of the production process.

The automated production collaborative robot adopts an advanced intelligent control system and an intuitive operation interface. Operators do not need to have professional programming knowledge, and can complete task programming and parameter settings through simple drag and click operations. At the same time, the robot also supports remote monitoring and diagnosis functions. Managers can understand the robot's operating status and working data in real time through mobile phones, computers and other terminal devices, and promptly discover and solve potential problems to ensure the continuity and stability of production.

Products Description

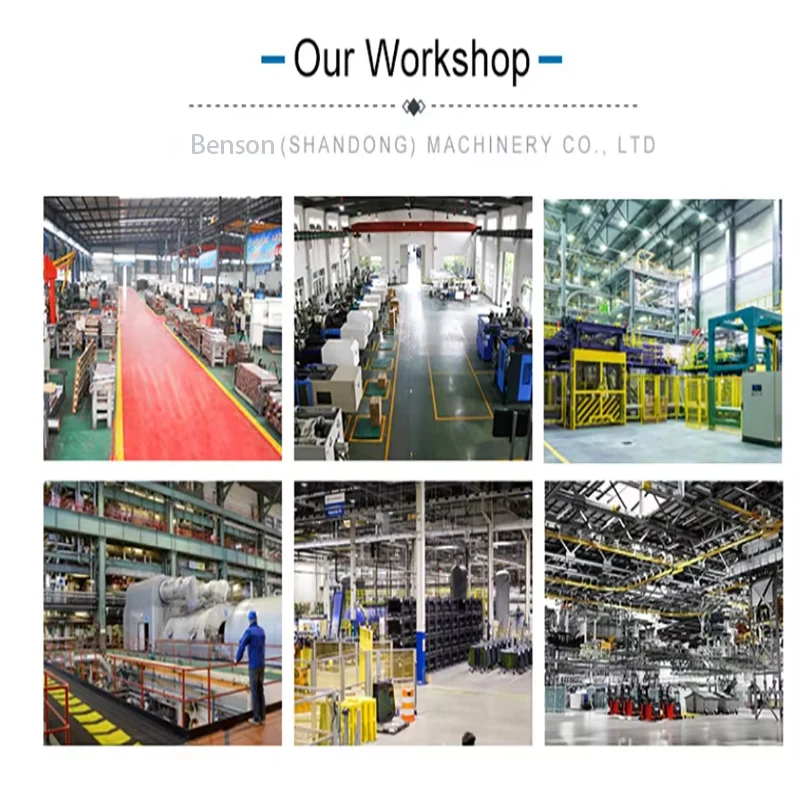

Company Profile

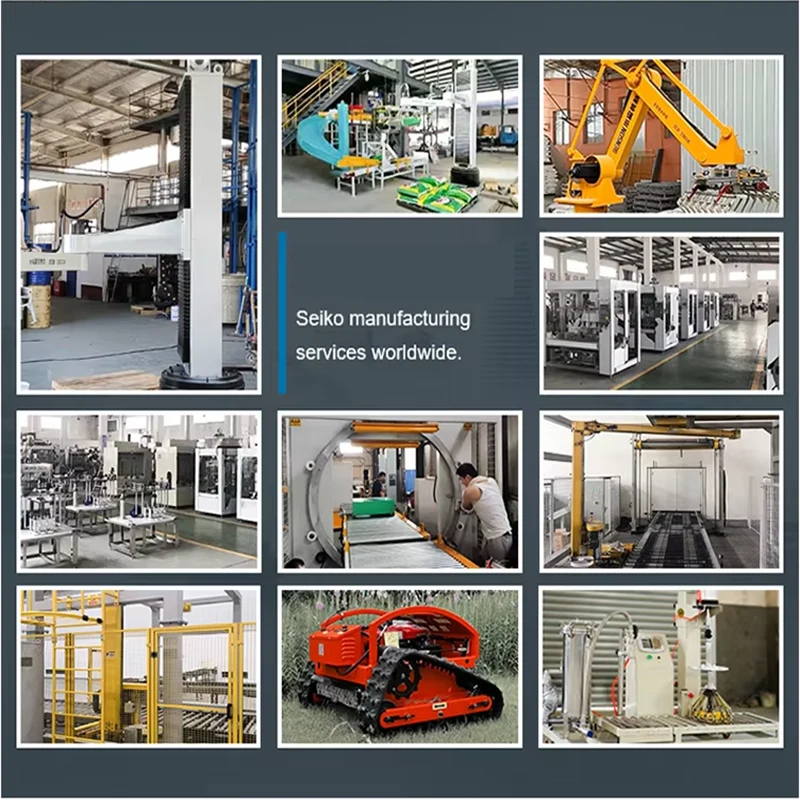

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry