Industrial automation collaborative robot arm, opening a new era of intelligent production

At the moment when Industry 4.0 and intelligent manufacturing are booming, industrial automation collaborative robot arm has become a powerful assistant for many companies to improve production efficiency and optimize production processes. It integrates advanced technology, realizes human-machine collaboration, and brings changes to industrial production.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

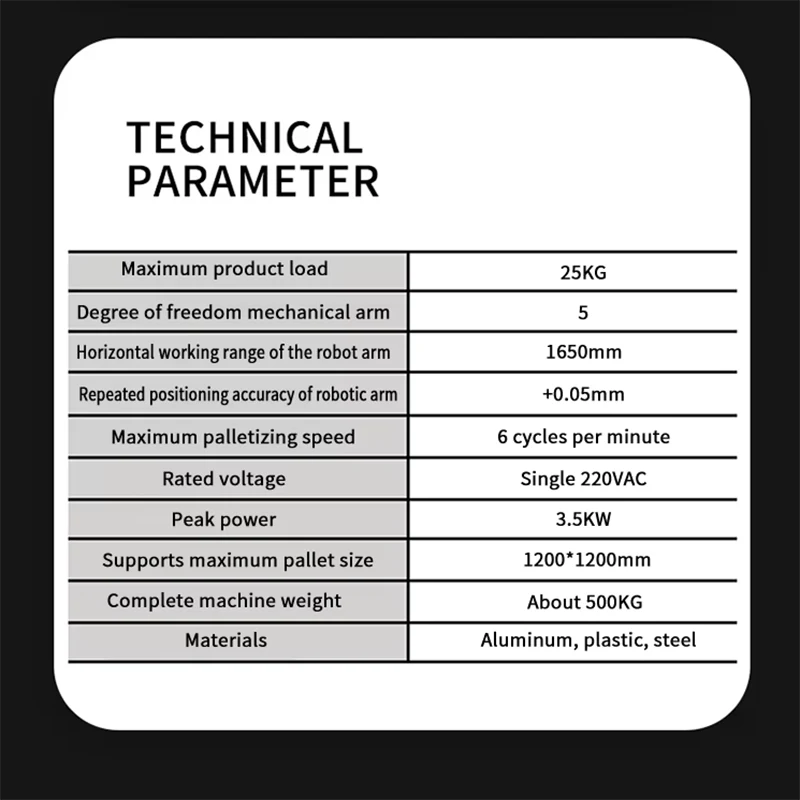

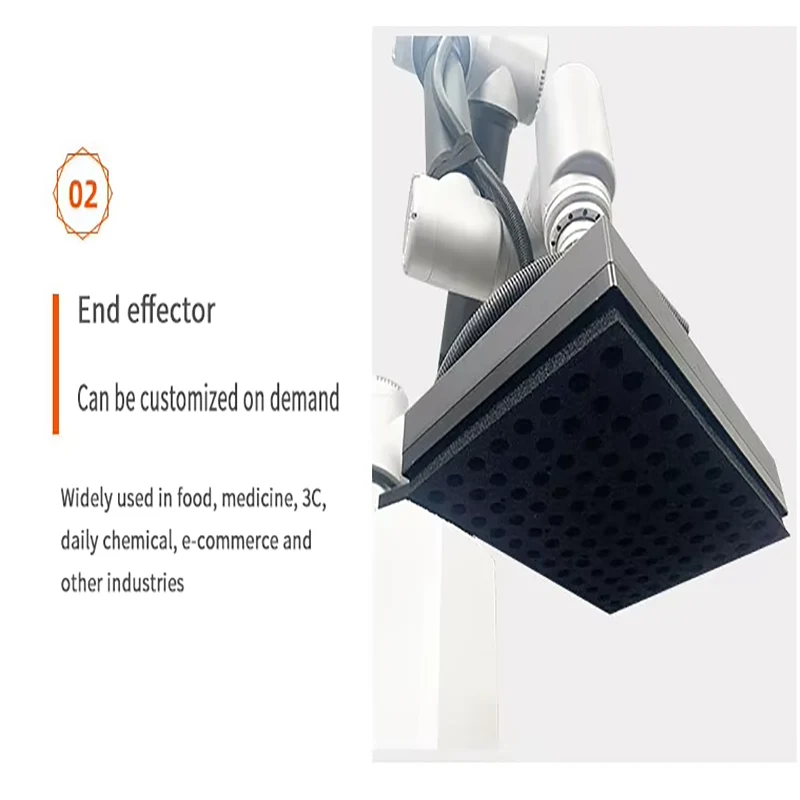

Flexible collaborative robot arm with outstanding features, leading the new trend of industry

Highly flexible: With multi-axis design, it generally has 6 axes or even more degrees of freedom, which is as flexible as human arms. It can move freely in complex spaces and complete various difficult actions, such as assembly in narrow spaces and multi-angle welding.

High-precision operation: The positioning accuracy is ±0.02mm - ±0.05mm, and the repeated positioning accuracy is extremely high, ensuring the accurate grasping, placement and processing of parts in the production process, effectively improving product quality and reducing the defective rate.

Safe collaboration: Equipped with advanced force sensors and intelligent algorithms, it can keenly perceive the surrounding environment. When it comes into contact with people or detects abnormalities, it can quickly stop or adjust the action to ensure the safety of personnel, realize the side-by-side operation of man and machine, and complete the task together.

Diverse loads: With a wide range of loads, it can handle everything from light operations of a few kilograms to heavy handling of hundreds of kilograms, and adapt to different production needs. Whether it is the operation of tiny components in the electronics industry or the handling of large parts in automobile manufacturing, you can find a robot arm with a suitable load.

Adjustable speed: The running speed can be flexibly adjusted according to the task. It is fast and efficient when transporting materials at high speed, and stable and accurate in tasks such as fine assembly, meeting the diversified production rhythm.

Widely used, empowering multiple industries

Automotive manufacturing: On the automotive production line, collaborative robot arms are very useful. Car body welding ensures uniform and firm solder joints with high precision; assists in engine assembly and accurately installs various parts; can also complete the handling of automotive parts and improve production efficiency.

Electronic manufacturing: It is essential for precision production in the electronics industry. It can achieve high-speed and high-precision placement of tiny components such as chips, resistors and capacitors; in the assembly of electronic products, it can accurately complete the splicing of parts and ensure product quality.

Metal processing: used for metal cutting, grinding, polishing and other processes. When cutting, it cuts accurately according to the preset path to improve material utilization; when grinding and polishing, it ensures the flatness and smoothness of the metal surface and improves the appearance quality of the product.

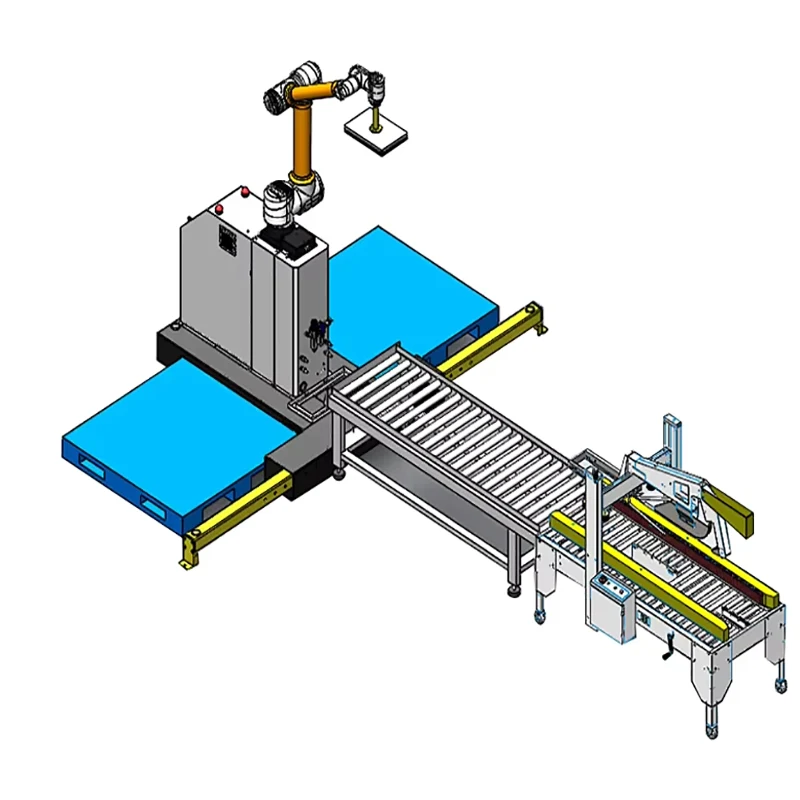

Logistics warehousing: It plays an important role in the logistics field. Carry out cargo sorting, quickly identify and classify cargo; perform stacking tasks, neatly stack cargo, and improve storage space utilization; it can also complete cargo handling and reduce manual labor intensity.

Flexible collaborative robot arm intelligent collaboration, human-machine co-creation efficiency

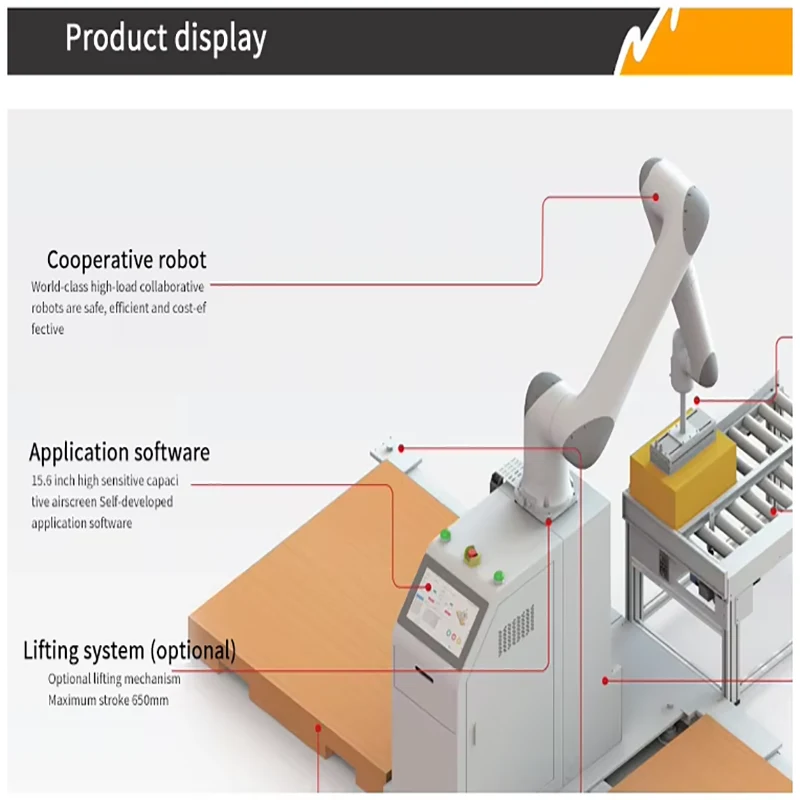

Easy programming: With a graphical programming interface, operators do not need a deep programming foundation. By simply dragging and setting parameters, they can complete complex task programming, lower the threshold for use, and shorten programming time.

Easy to deploy: Small size, easy installation, can be quickly integrated into existing production lines, without large-scale transformation of production facilities, saving time and cost.

Strong scalability: Supports a variety of communication interfaces and protocols, convenient for seamless connection with other equipment such as AGV carts, automated production lines, visual systems, etc., to achieve more complex production process automation and build smart factories.

Intelligent interaction: Operators can easily interact with robot arms through teaching pendants, gesture recognition, voice control and other methods. For example, with gesture recognition, when the operator makes specific gestures, the robot arm can understand and perform corresponding actions, making the operation more convenient and efficient.

Products Description

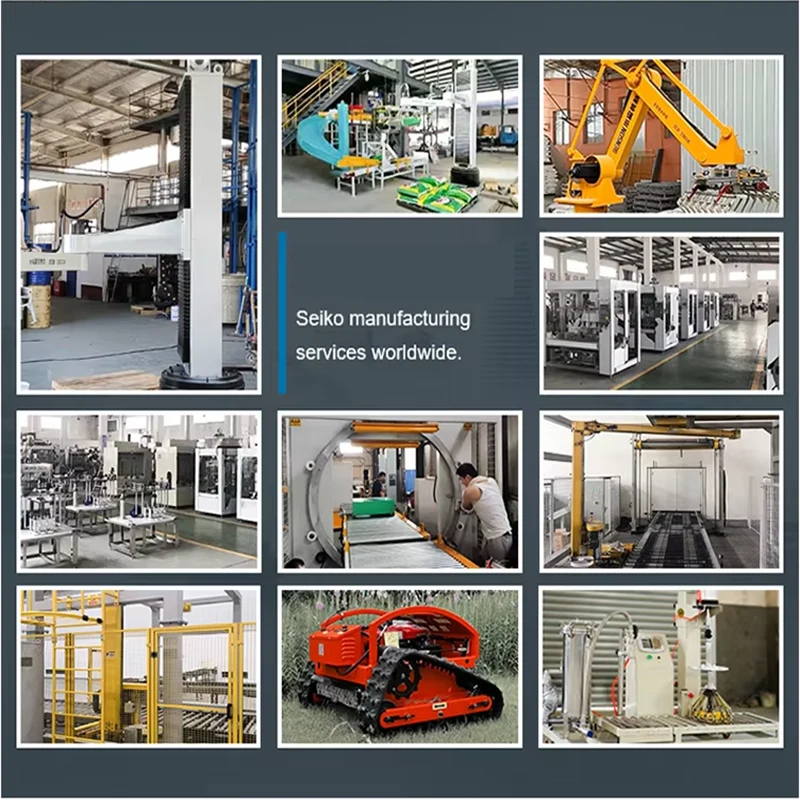

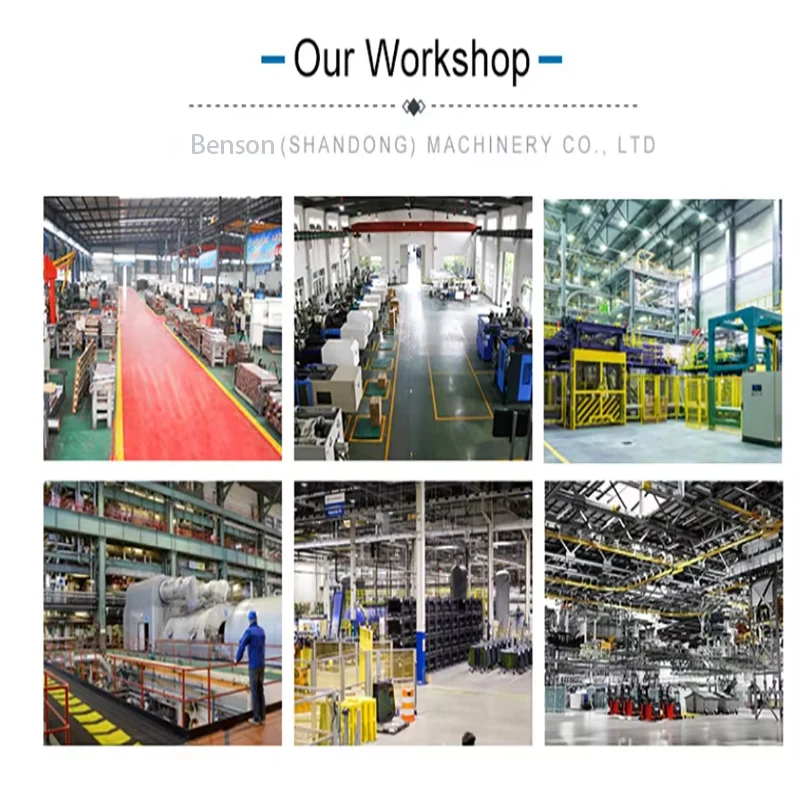

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry