In modern manufacturing, the accuracy, efficiency and safety of the spraying process play a key role in product quality and corporate competitiveness. With its excellent multi-axis design, intelligent control and outstanding collaboration capabilities, the multi-axis spraying collaborative robot has brought new spraying solutions to various industries, helping companies achieve efficient and high-quality production goals.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Multi-axis spraying collaborative robot has excellent multi-axis design and flexible and precise operation

Rich number of axes and full coverage: breaking through the motion limitations of traditional spraying equipment. From basic translation and rotational motion to complex multi-angle and multi-posture adjustment, each axis works closely together to ensure that the spray gun can fully cover the surface of the workpiece. Whether it is a simple plane structure or a complex curved surface or special-shaped workpiece, it can achieve dead-angle spraying and provide uniform and perfect coating effects for all kinds of products.

High-precision motion control: equipped with advanced servo drive system and precision reducer, during the spraying process, the robot can accurately control the movement trajectory, speed and angle of the spray gun to ensure that each spraying is stable and consistent, effectively avoiding quality problems such as sag and leakage caused by uneven spraying, and greatly improving the product's yield and appearance quality.

Large working range and high load capacity: with a large working space, it can easily cope with the spraying needs of large workpieces, reduce the movement frequency of the robot, and improve production efficiency. At the same time, it can stably carry various types of spray guns and related tools, adapt to spraying tasks of different weights and specifications, and provide enterprises with a wider range of application options.

Intelligent control system of multi-axis spraying collaborative robot to optimize the spraying process

Advanced visual recognition and path planning: Integrating advanced visual recognition system, through 3D visual scanning, image analysis and other technologies, it can quickly and accurately identify the shape, size, position and posture of the workpiece. According to the recognition results, the robot automatically generates the optimal spraying path and parameters, and can complete complex spraying tasks without human intervention. At the same time, the visual system also has real-time monitoring function, which can dynamically track the spraying process, adjust the spraying path in time, ensure uniform coating, and improve spraying quality and efficiency.

Intelligent parameter adjustment and adaptive spraying: Equipped with intelligent control system, it can automatically adjust the flow rate, atomization effect, fan width and other parameters of the spray gun according to factors such as coating characteristics, workpiece material, and spraying environment. Using machine learning algorithms, the robot can also achieve adaptive spraying, automatically adjust the spraying thickness and speed according to the actual situation of the workpiece surface, ensure stable and reliable coating quality, and meet the personalized spraying needs of different products and processes.

Remote monitoring and data analysis: Support remote monitoring function. Through network connection, users can view the robot's operating status, spraying parameters and work progress in real time on mobile phones, computers and other terminal devices anytime and anywhere. At the same time, the robot also has powerful data collection and analysis functions, which can record various data in the spraying process, such as spray gun flow, spraying time, coating thickness, etc. Through the analysis of these data, users can promptly discover problems in the production process, optimize the spraying process, and improve production efficiency and product quality.

Multi-axis spraying collaborative robot safety collaboration characteristics to ensure human-machine collaboration

Multiple safety protection measures: Fully consider the safety of human-machine collaboration and equip with a variety of safety protection devices. Force sensors are distributed in each joint of the robot arm. When a collision with a person is detected, the movement can be stopped instantly to avoid harm to the person. At the same time, safety light curtains, emergency stop buttons, collision detection systems, etc. are set up. Once someone enters the dangerous area or an emergency occurs, the protection mechanism can be triggered immediately to ensure a safe and reliable working environment.

Friendly human-machine interaction interface: The operation is simple and convenient, and it adopts an intuitive graphical programming interface and teaching function. Users can easily complete the programming and operation of the robot through touch screens, handles and other devices without professional programming knowledge. At the same time, the robot also supports interactive methods such as voice control and gesture recognition to further improve the efficiency and convenience of human-machine collaboration.

Flexible collaboration mode: It can work in collaboration with manual operation and flexibly adjust the working mode according to production needs. In some links that require manual assistance, such as loading and unloading of workpieces, local fine spraying, etc., the robot can accurately cooperate with manual work to complete tasks and achieve efficient human-machine interaction. At the same time, multiple robots can also work together to complete large and complex spraying projects and improve production efficiency and capacity.

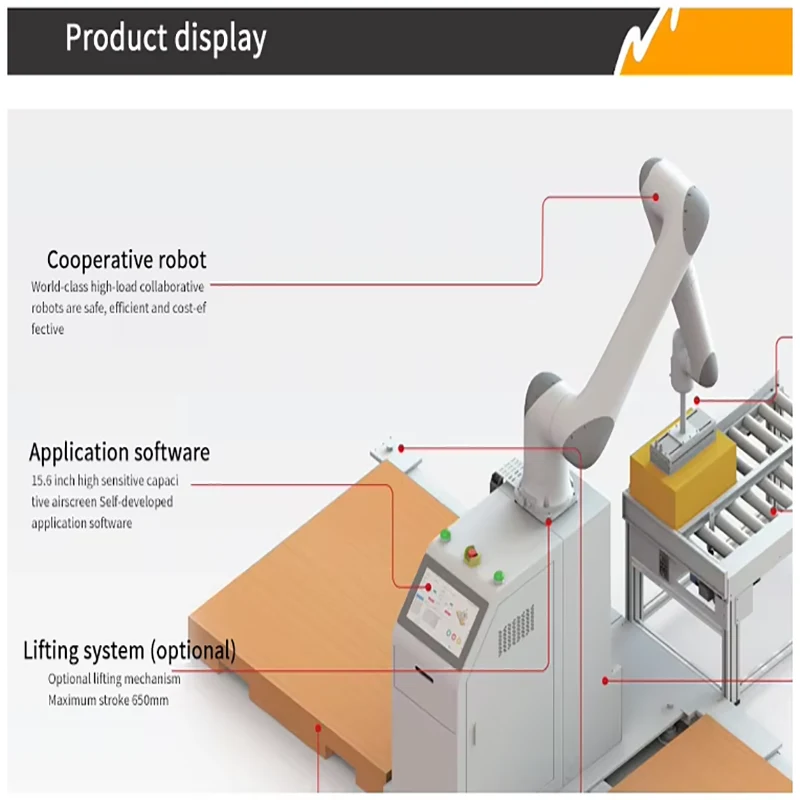

Products Description

Company Profile

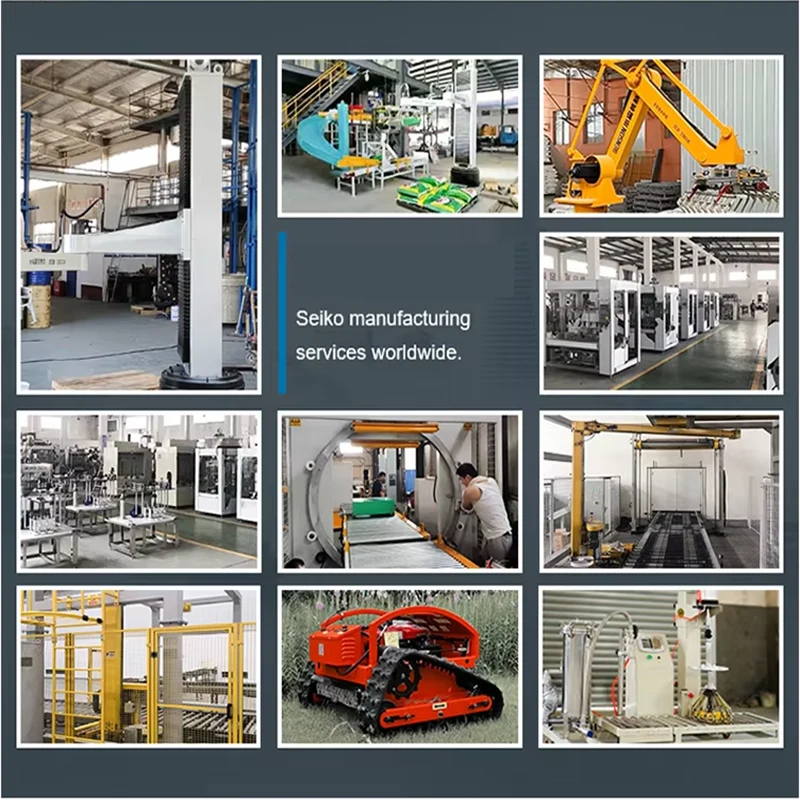

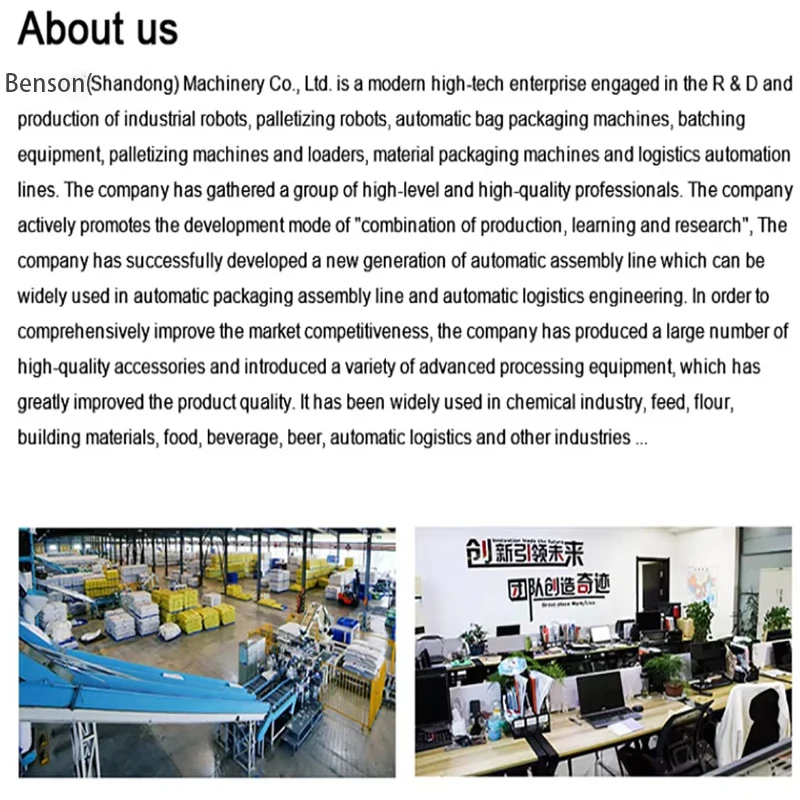

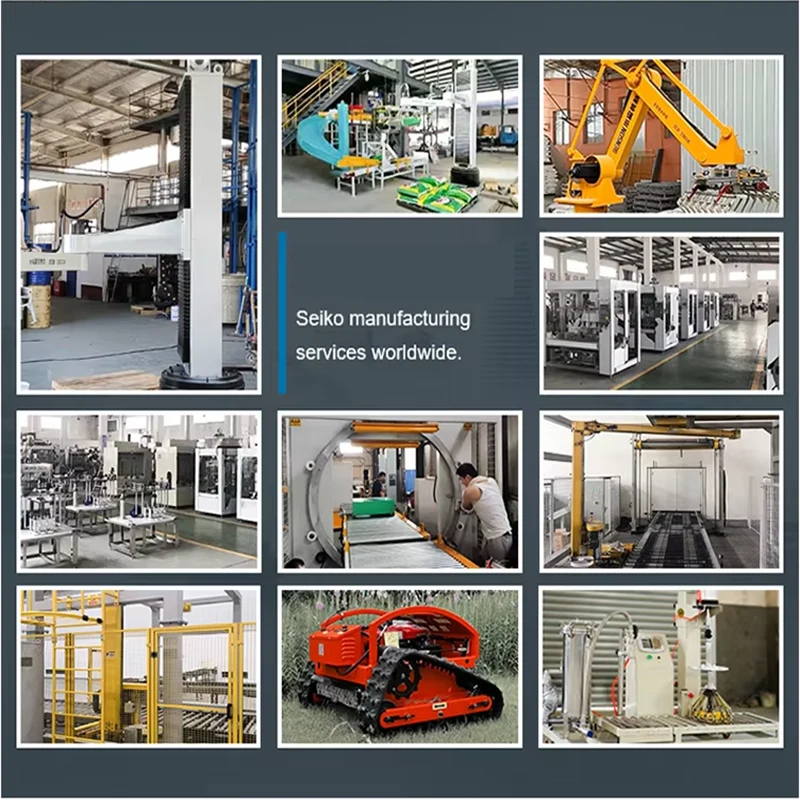

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

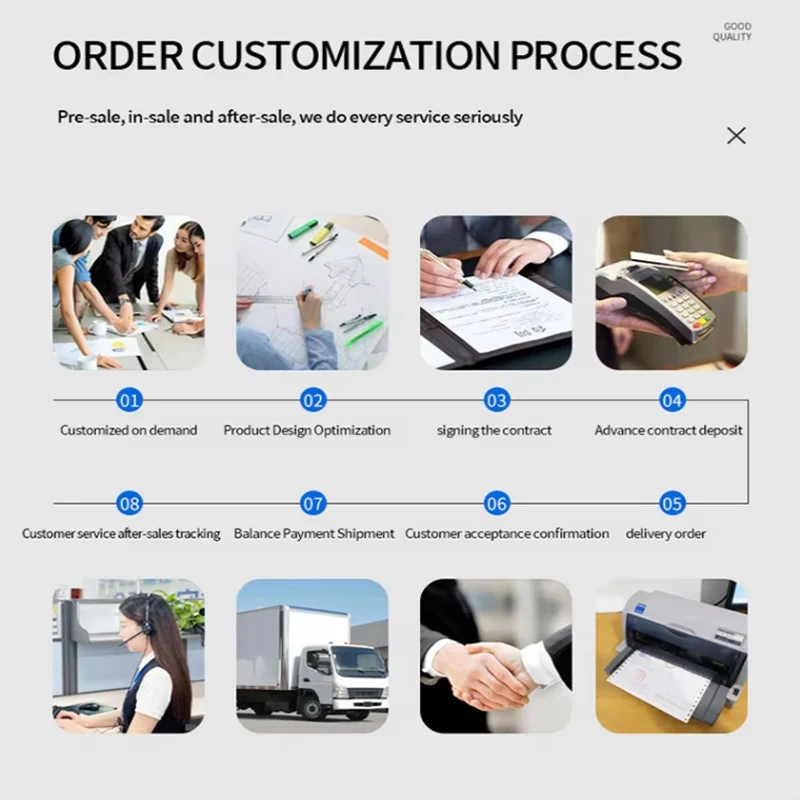

Product Inquiry