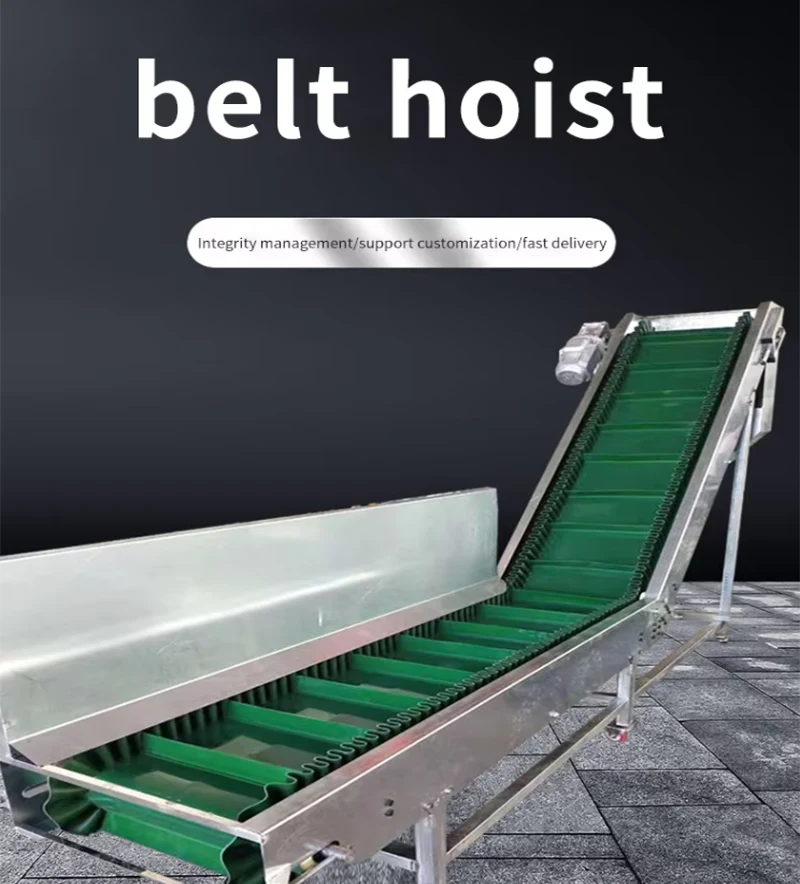

As the core equipment in the field of large-angle material transportation, the climbing belt conveyor breaks the limitations of traditional horizontal transportation. With its unique structural design and powerful conveying performance, it realizes stable and efficient transmission of materials on steep slopes or even in a nearly vertical direction. It is widely used in various industrial scenarios and logistics links, and is a key equipment for improving production efficiency.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

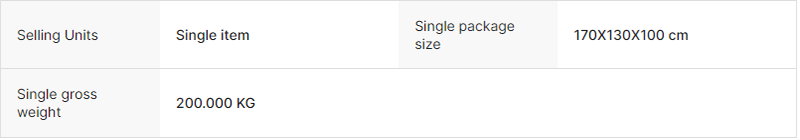

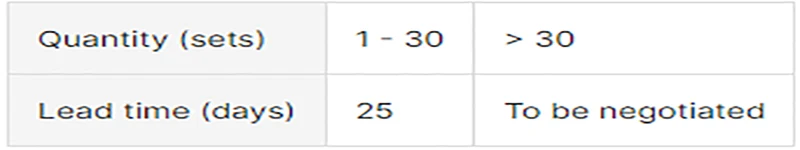

Packaging and delivery

Lead time

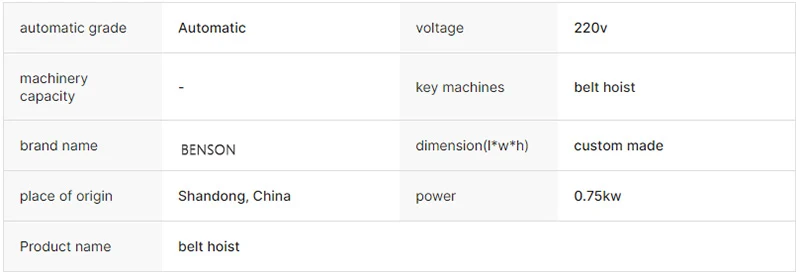

Product descriptions from the supplier

Climbing belt conveyor: an intelligent solution for efficient vertical transportation

Core advantages and technical highlights of climbing belt conveyor

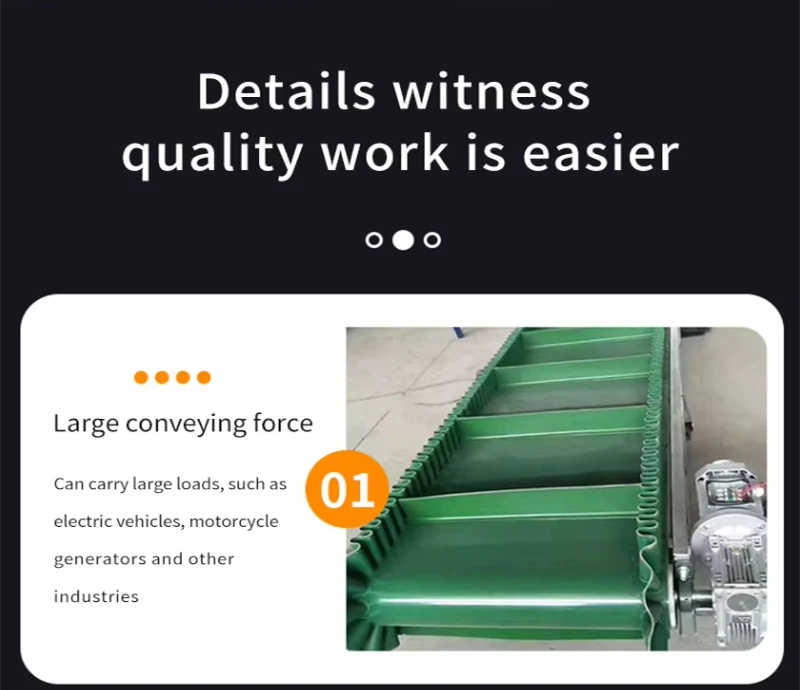

- Super strong conveying capacity: It can continuously convey powder, granular, block and even packaged materials. The conveying capacity of a single device can reach up to 500 tons/hour, meeting the needs of large-scale production.

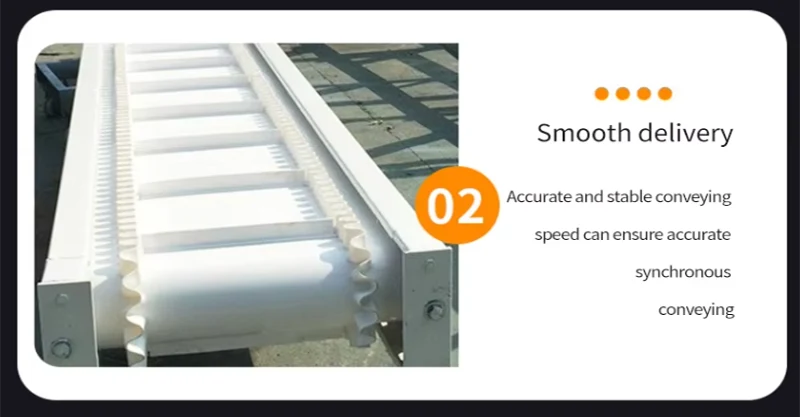

- Anti-leakage and anti-slip design: The integrated design of skirt and block forms a closed conveying space to prevent material spillage; the special texture treatment on the surface of the conveyor belt enhances friction and ensures the safe transportation of materials.

- Energy-saving and low-consumption operation: The use of high-efficiency variable frequency motors and optimized transmission systems can save more than 20% energy compared with traditional conveying equipment, reducing the operating costs of enterprises.

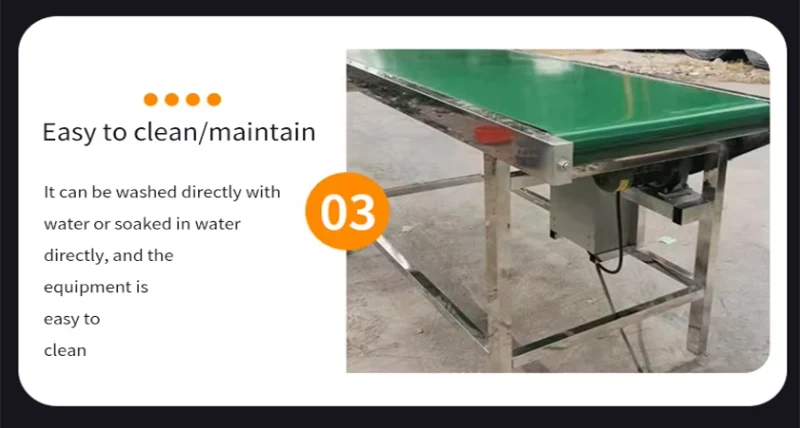

- Strong durability: The conveyor belts made of wear-resistant rubber, polyurethane and other materials are selected, and the stainless steel or high-strength carbon steel frame is used to adapt to harsh environments such as high temperature, humidity and corrosion, with a service life of up to 8-10 years.

Climbing belt conveyor has multiple industry application scenarios

1. Mines and quarries: used for long-distance climbing transportation of heavy materials such as ore, sand and gravel, replacing traditional step-type transportation, reducing floor space and transfer links, and improving mining efficiency.

2. Grain and agricultural product processing: in granaries, flour mills, and feed mills, vertical lifting and transfer of granular materials such as wheat, corn, and rice are realized to avoid material damage and meet food-grade hygiene standards.

3. Chemical and building materials industry: for powdery or block materials such as cement, fertilizers, and chemical raw materials, it has a fully enclosed dust-proof design to ensure a safe and environmentally friendly production environment and reduce material loss.

4. Logistics and warehousing: in e-commerce warehouses and express sorting centers, complete the rapid transfer of goods from the ground to high-rise shelves and sorting lines, seamlessly connect with the automated warehousing system, and optimize space utilization.

Full process customization and service guarantee

We provide one-stop services from solution design, production and manufacturing to installation and commissioning. The professional team tailors exclusive solutions based on the customer's material characteristics, conveying volume, installation space and budget. The equipment supports remote monitoring and intelligent early warning functions, real-time monitoring of operating status, and avoidance of failure risks in advance. The 7×24-hour after-sales response mechanism ensures that technicians can arrive at the site quickly, provide repair, maintenance and operation training services, and escort the company's production. Choose our climbing belt conveyor to unlock a new experience of efficient, intelligent and reliable vertical transportation!

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry