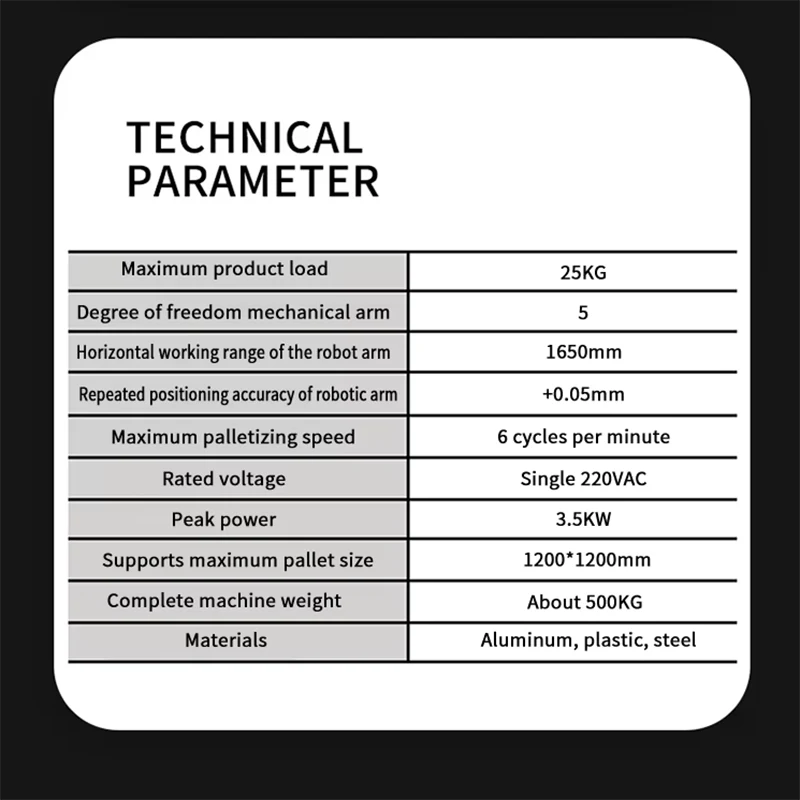

Automated carton pallet machine robots are widely used in many industries such as food, beverage, medicine, electronics, and daily necessities. For example, in the food industry, packaged food cartons can be quickly and neatly stacked for easy storage and transportation; in the pharmaceutical industry, pharmaceutical cartons can be accurately handled to meet the strict hygiene and quality requirements of pharmaceutical production.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

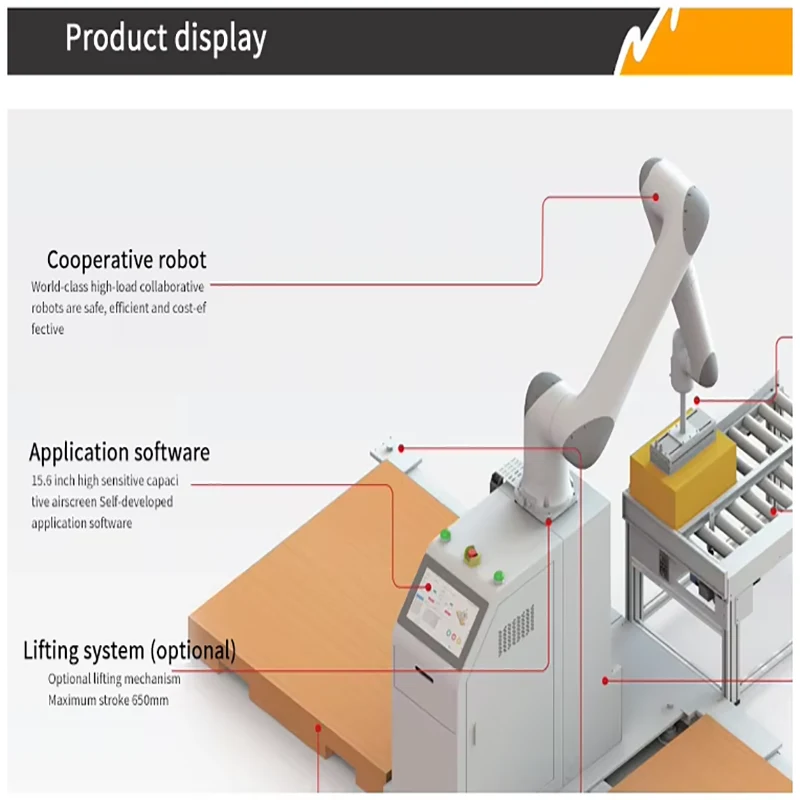

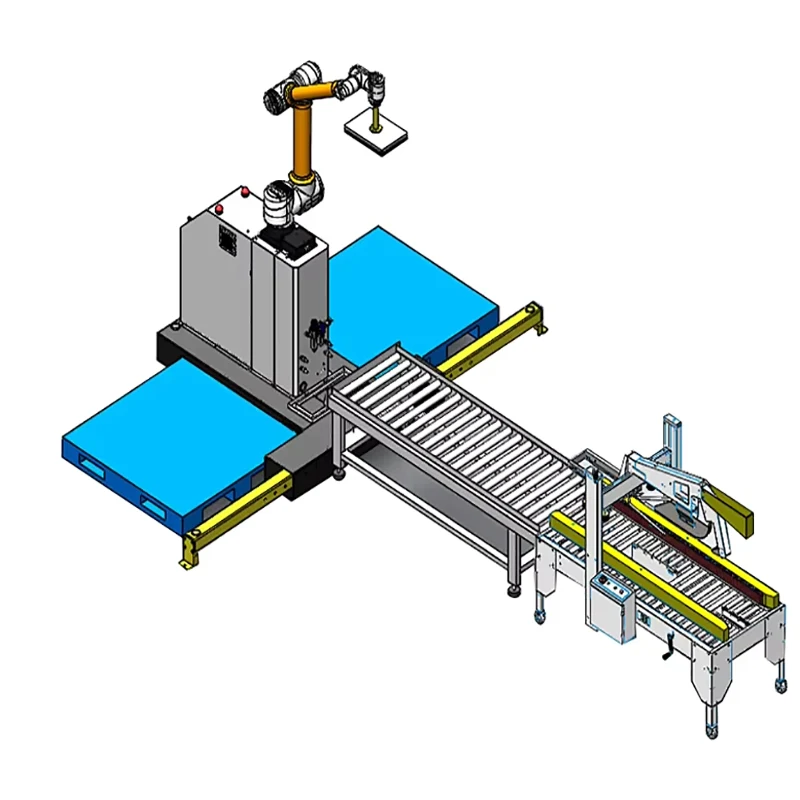

Working principle of automated collaborative robot for carton pallet machine

Visual recognition and positioning: With the help of high-precision visual recognition system, the cartons on the conveyor belt are scanned to accurately determine the position, size, shape and placement angle of the cartons.

Intelligent path planning: Based on visual recognition data and preset pallet requirements, the robot control system quickly plans the movement path of the robot arm to ensure efficient and accurate operation.

Grasping and placing: The end of the robot arm is equipped with suitable grasping tools such as suction cups or grippers to grasp the cartons according to the planned path and place them on the pallet according to the established pallet type. When the pallet is full, the robot can cooperate with forklifts and other equipment to replace the pallet and continue to work.

Performance characteristics of automated collaborative robot for carton pallet machine

High-precision operation: It can accurately grasp and place cartons to avoid collision and dislocation, and reduce product loss.

Efficient operation: It has fast running speed and response ability, and can achieve a palletizing frequency of [X] times per minute. Compared with manual palletizing, the efficiency is greatly improved and the production cycle is effectively shortened.

Flexibility and versatility: The robot arm is highly flexible and can adapt to cartons of various sizes and weights and different pallet requirements. Through simple programming or teaching, the operation tasks can be quickly switched, which is suitable for multi-variety and small-batch production modes.

Safety and reliability: Equipped with multiple safety protection devices such as collision detection, emergency stop button, safety light curtain, etc., it can stop quickly when encountering people approaching or abnormal situations to ensure the safety of operators. At the same time, the key components are of reliable quality and have been strictly tested, with a long average trouble-free operation time and a long maintenance cycle.

Intelligent interaction: With an intuitive and friendly operation interface, operators do not need complex programming knowledge and can complete task setting, parameter adjustment and other tasks through simple graphical operations. Support remote monitoring and fault diagnosis, which is convenient for managers to grasp the status of equipment in real time and deal with problems in time.

Product advantages of carton pallet automated collaborative robots

Reducing costs: reducing the use of manual labor, reducing labor costs and management costs, and having a high return on investment in the long run.

Improving quality: Standardized and standardized operations ensure the consistency of palletizing quality and improve the overall image and transportation safety of products.

Adapt to development: Help enterprises realize production automation and intelligent upgrades, enhance enterprise competitiveness, and adapt to future industrial development trends.

Products Description

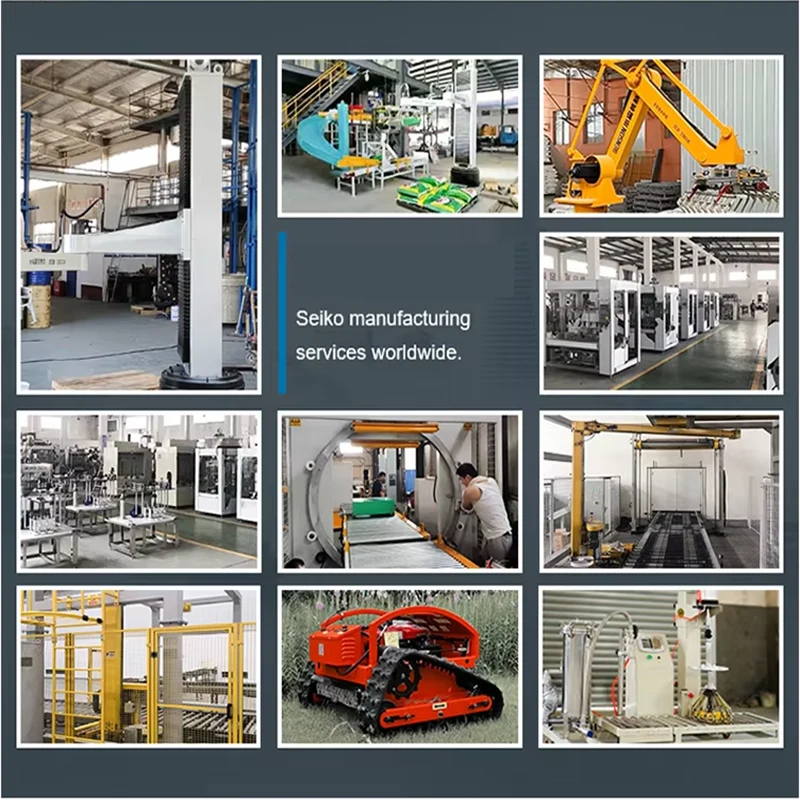

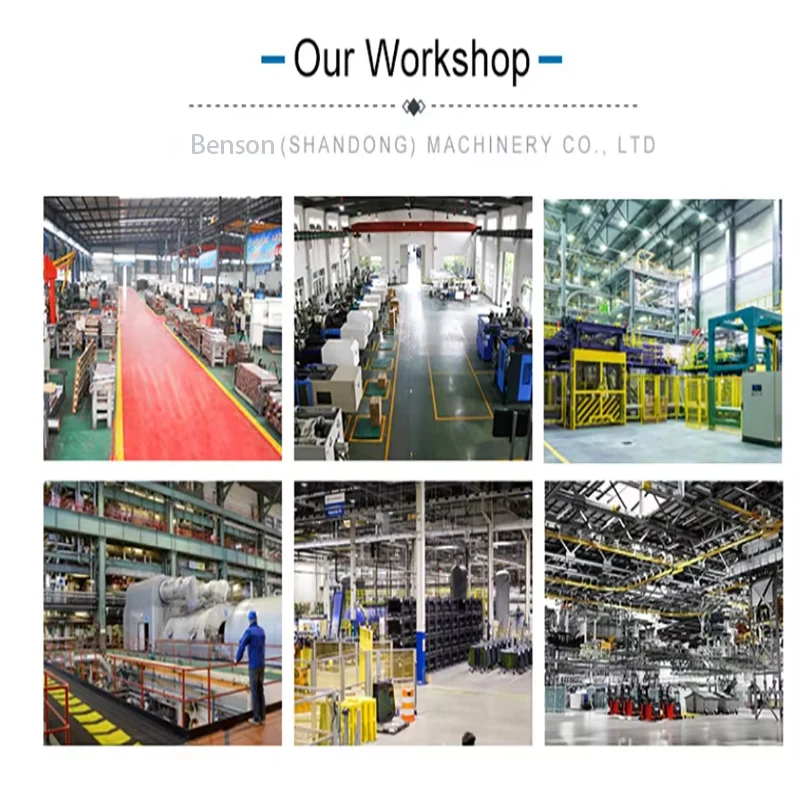

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

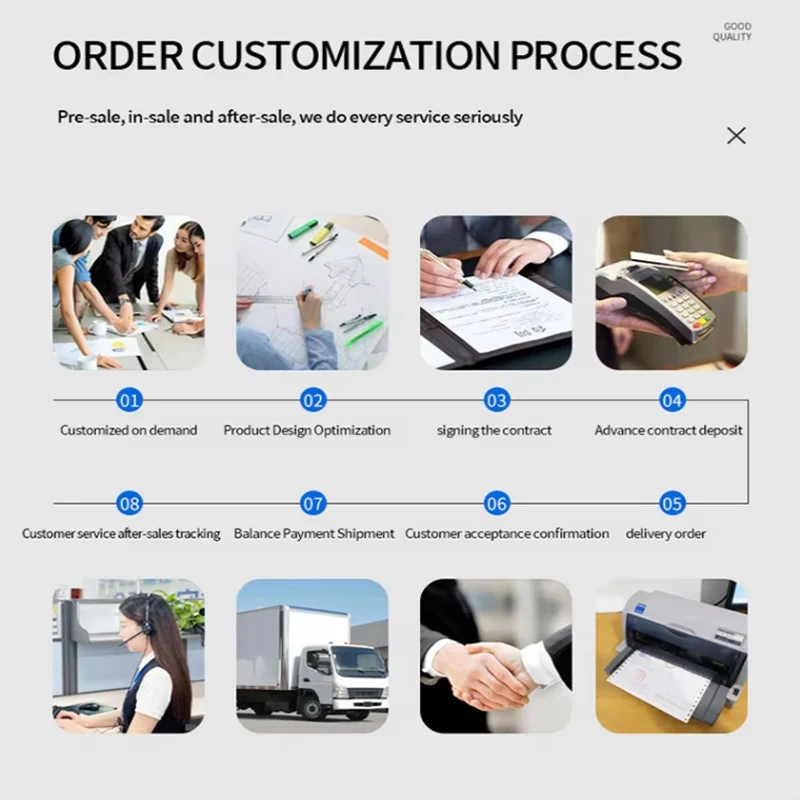

Product Inquiry