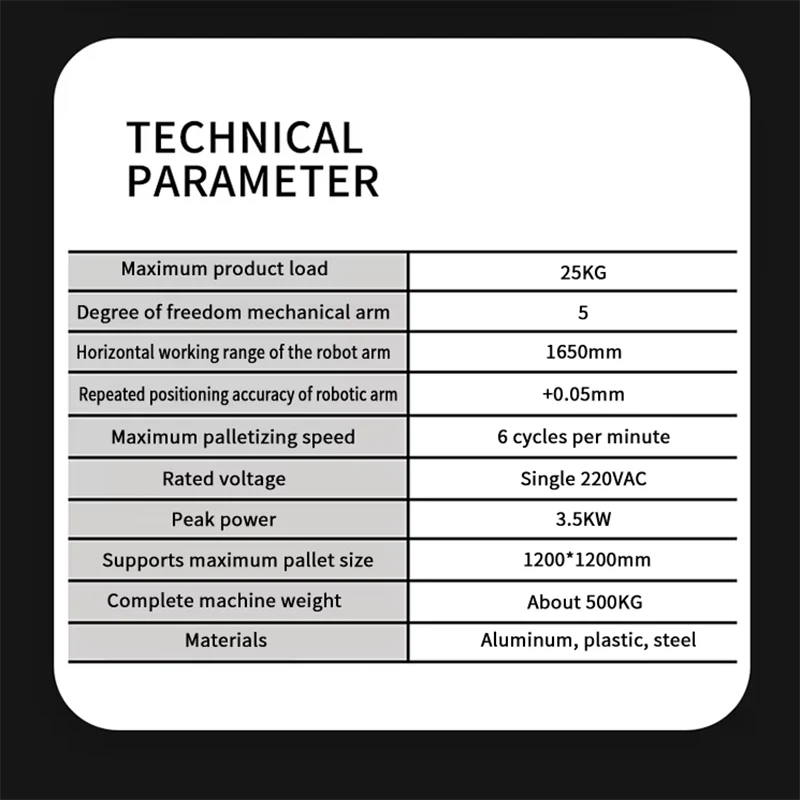

The fully automatic pallet stacking machine is a highly automated mechatronic device, which is mainly used to stack goods neatly on pallets according to specific rules to form stable cargo stacks for easy storage, transportation and subsequent logistics operations. It is widely used in many industries such as chemical, petroleum, food, beverage, medicine, building materials, logistics and warehousing, and can handle products in various packaging forms such as bags, rubber blocks, boxes, barrels,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Products Description

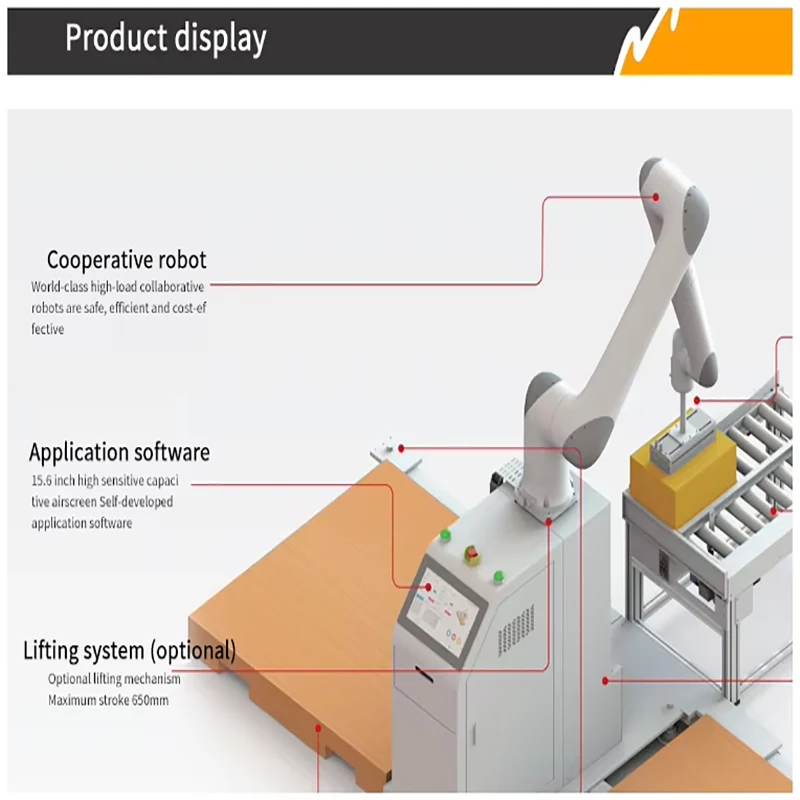

Mechanical structure of barreled fully automatic pallet stacking machine

- Frame: usually made of high-strength steel, providing stable support for the equipment, ensuring structural rigidity during operation, and reducing vibration and deformation.

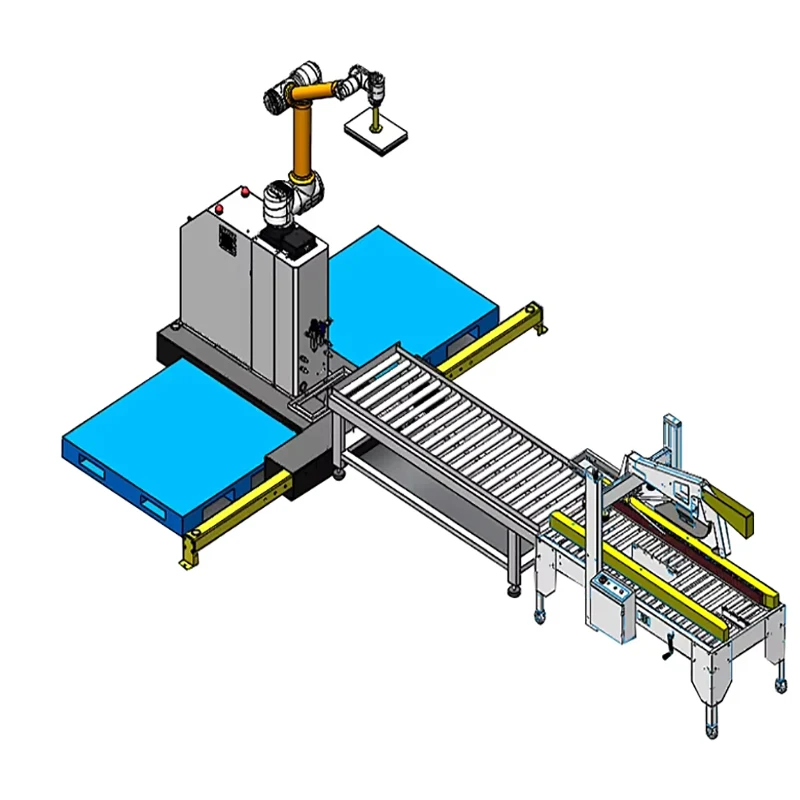

- Conveying system: including feed conveyor, discharge conveyor, etc., responsible for smoothly conveying the goods to the designated location and sending out the pallets after palletizing.

- Lifting mechanism: commonly composed of guide rails, screw rods, hydraulic cylinders or electric cylinders, etc., to achieve the lifting and lowering of goods in the vertical direction to complete the stacking operation of different layers.

- Fork or gripper: Fork is used to carry pallets, with single extension and double extension; gripper can be customized according to the shape and size of the goods, such as clamping type, suction cup type, etc., for grabbing goods.

- Positioning device: such as block, sensor, etc., to accurately position the goods and pallets to ensure neat and accurate stacking.

Electrical control system of barreled fully automatic stacking pallet machine

- Controller: Generally, a programmable logic controller (PLC) or industrial computer is used. It is the control core of the equipment and is responsible for receiving signals, processing instructions and coordinating the actions of various components.

- Driver: Such as vector variable frequency driver, it provides power to the motor and controls its speed, torque and other parameters to achieve smooth operation of the equipment.

- Sensor: Including photoelectric sensors, position sensors, weight sensors, etc., which monitor the position, quantity, weight and equipment operation status of the goods in real time to ensure the safe and accurate operation of the equipment.

- Human-machine interface: Such as touch screen, which is convenient for operators to perform parameter setting, program selection, fault diagnosis and other operations to achieve human-machine interaction.

Working principle

The goods enter the equipment through the feed conveyor. After being accurately positioned by the positioning device, the lifting mechanism and the fork or gripper cooperate to place the goods on the pallet layer by layer according to the preset stacking mode (such as the number of rows and columns, the number of layers, etc.). When one layer of stacking is completed, the lifting mechanism descends to a certain height and continues to stack the next layer until the set number of stacking layers is reached. The pallets after palletizing are sent out by the discharging conveyor and enter the subsequent storage or transportation link. During the whole process, the electrical control system adjusts the action of each component in real time according to the feedback signal of the sensor to ensure the efficient, accurate and stable stacking operation.

Product features

1. High degree of automation: a series of operations such as cargo grabbing, handling, stacking, pallet replacement and transportation can be automatically completed without human intervention, greatly reducing manpower requirements, reducing labor intensity and improving production efficiency.

2. Accurate stacking: Through high-precision positioning system and advanced control algorithm, it can accurately stack according to the preset mode, with tight and neat stacking shape, which is convenient for subsequent storage and transportation, and reduces the risk of scattered and damaged goods during handling.

3. Stable and reliable operation: It adopts high-quality mechanical parts and electrical components, and has been strictly tested and optimized. It has good stability and reliability, can operate continuously and stably for a long time, and reduce equipment failure rate and maintenance cost.

4. Strong flexibility: According to the shape, size, weight and stacking requirements of different goods, the stacking mode can be quickly adjusted through simple parameter settings or replacement of grippers to meet the stacking needs of various products.

5. Easy operation: The humanized human-machine interface is simple and easy to understand, and the operator can operate proficiently after simple training. At the same time, it has fault self-diagnosis and alarm functions, which is convenient for quick troubleshooting and troubleshooting.

6. Good safety: Equipped with a variety of safety protection devices, such as light curtains, safety fences, emergency stop buttons, limit switches, etc., to prevent personnel from accidentally entering dangerous areas, avoid equipment damage due to misoperation or abnormal conditions, and ensure the safety of personnel and equipment.

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

FAQ

Product Inquiry