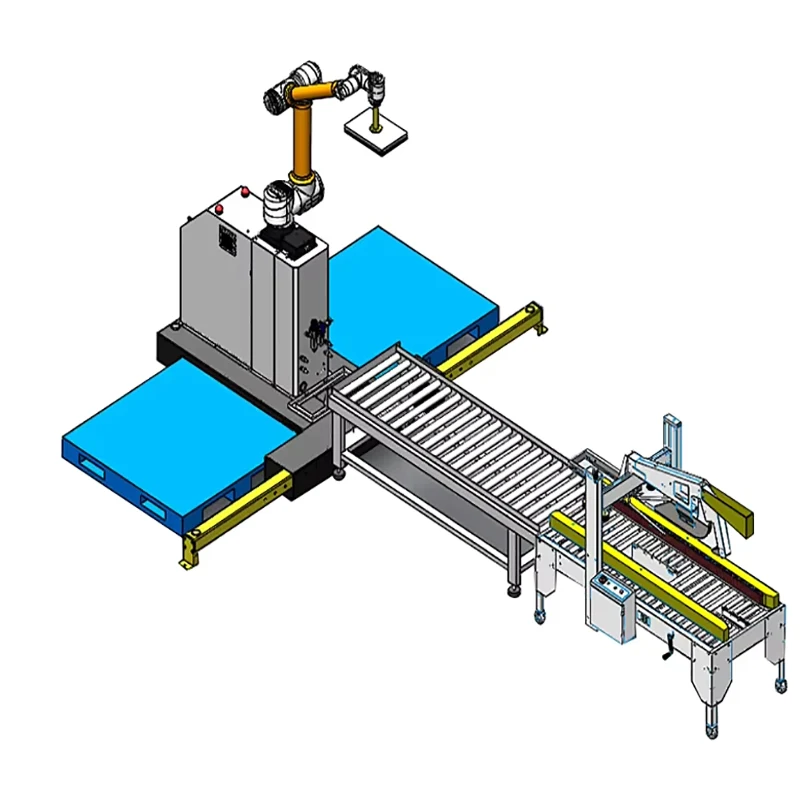

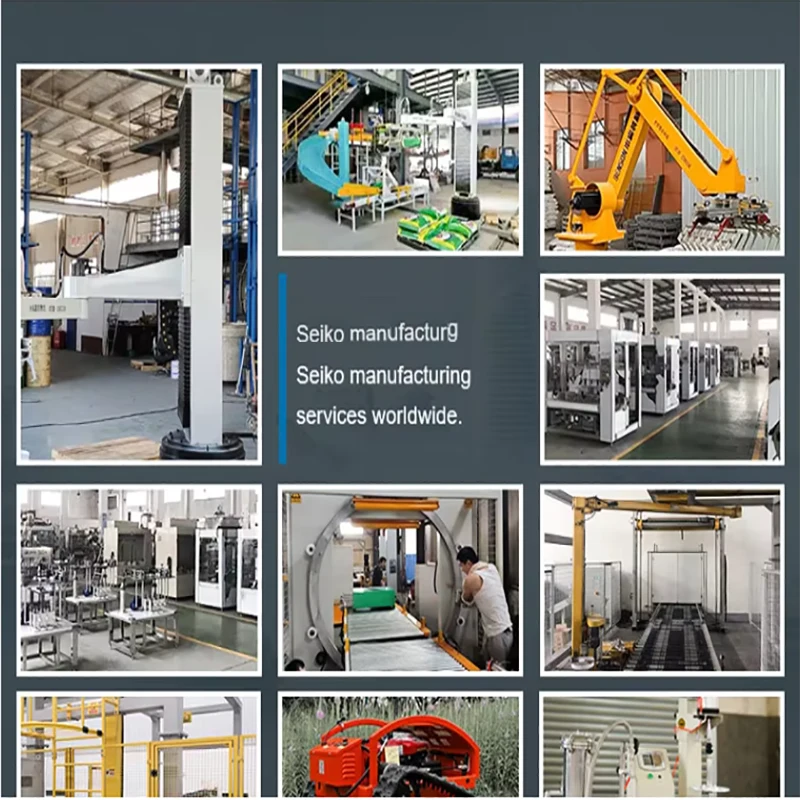

The organic fertilizer pallet loading and unloading collaborative robot is an intelligent device used in the organic fertilizer production, storage and logistics links to realize the automated loading, unloading, handling and palletizing of organic fertilizer pallets. It integrates mechanics, electronics, sensors, control technology and software algorithms, and has the ability to work autonomously and collaboratively.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Packaging and delivery

1. Wheat automated pallet loading and unloading collaborative robot safe collaboration: equipped with multiple sensors such as laser radar, visual sensors, force sensors, etc., it can sense the surrounding environment and the proximity of people in real time. When encountering obstacles or people entering the dangerous area, it will automatically slow down, stop or adjust its movements to avoid collision. It can work with workers in the same work area without setting up additional safety isolation facilities.

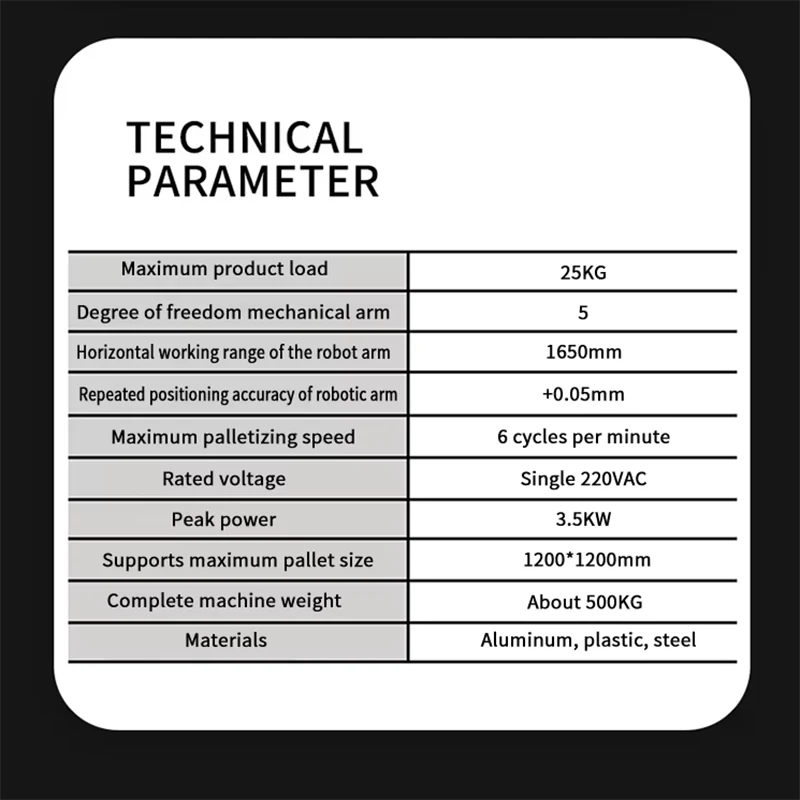

2. Efficient and accurate: It has a fast running speed and a repeat positioning accuracy of ±[X] mm. It can quickly and accurately grab, carry and place organic fertilizer pallets. It can complete more than [X] loading and unloading actions per hour, which greatly improves the efficiency compared to manual work. The palletizing is neat and standardized, the pallet shape is stable, and the risk of cargo collapse is reduced.

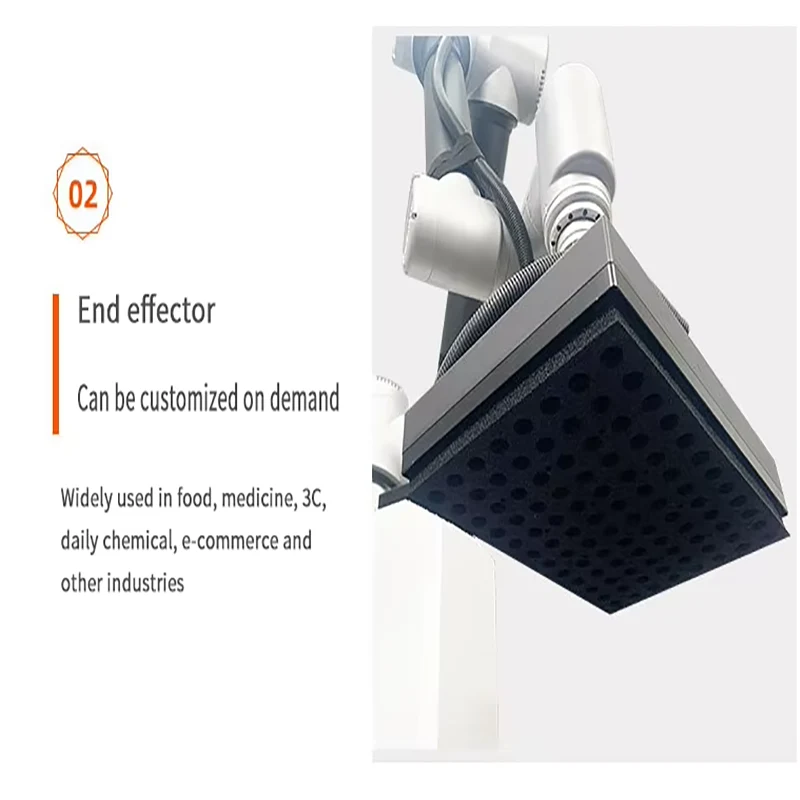

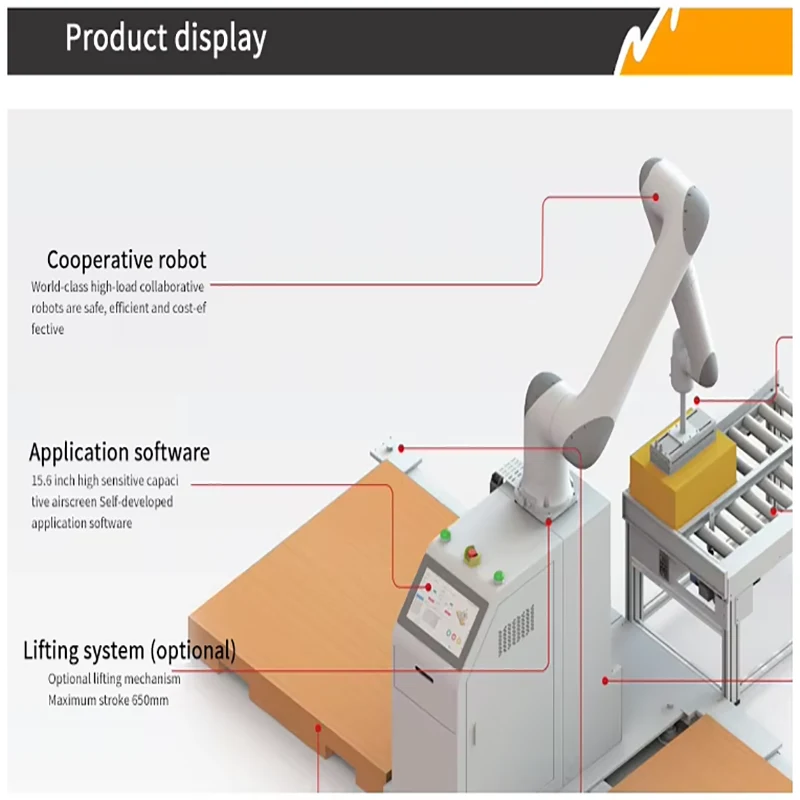

3. Flexible and versatile: The robotic arm has a high degree of freedom and flexible movements. The end effector can be quickly replaced according to different pallet types (such as wooden and plastic pallets) and organic fertilizer packaging forms (bags, barrels), and can adapt to the loading and unloading and palletizing needs of organic fertilizer pallets of various specifications and sizes. It can also flexibly adjust the operation path and method according to the warehouse layout, production line layout and operation process.

4. Intelligent and easy to use: It uses advanced visual recognition system and intelligent algorithm to automatically identify the position and posture of pallets and goods, and plan the optimal operation path. The operation interface is simple and intuitive, supporting various programming methods such as teaching programming and graphical programming. Operators do not need professional programming knowledge and can operate, debug and maintain after simple training. It has fault diagnosis and early warning functions, can detect equipment abnormalities and alarm in time, and is convenient for maintenance personnel to troubleshoot and solve problems.

5. Stable and reliable: The main structure is made of high-strength and wear-resistant materials, and key components are made of high-quality brand products. After rigorous testing and aging tests, it has good anti-interference ability and environmental adaptability. It can operate stably in complex and harsh organic fertilizer production and storage environments such as high temperature, humidity, and dust, reducing equipment failure rate and maintenance costs, and extending service life.

Collaborative robots for pallet loading and unloading

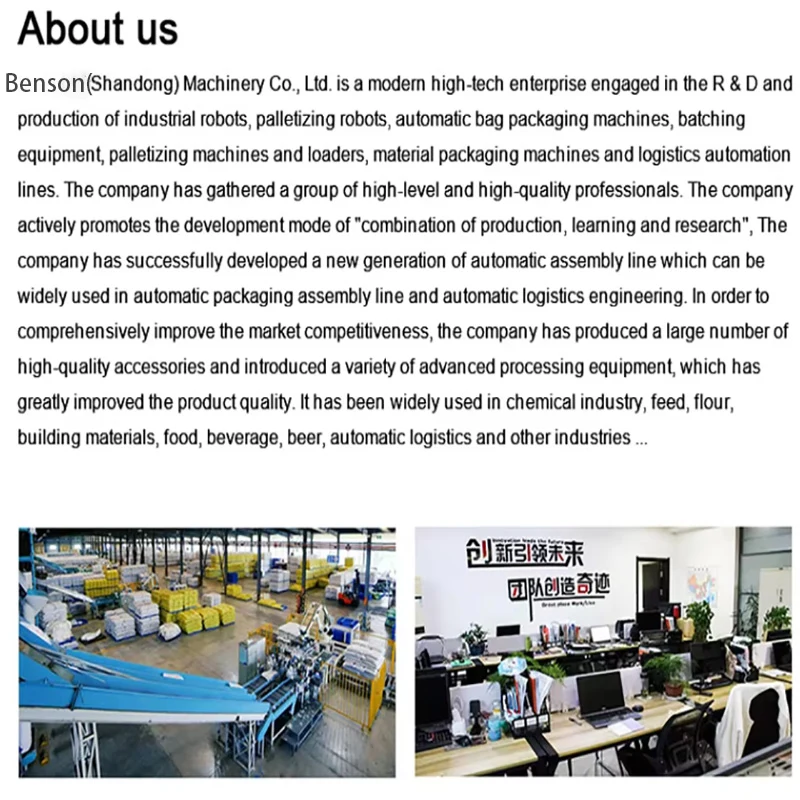

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

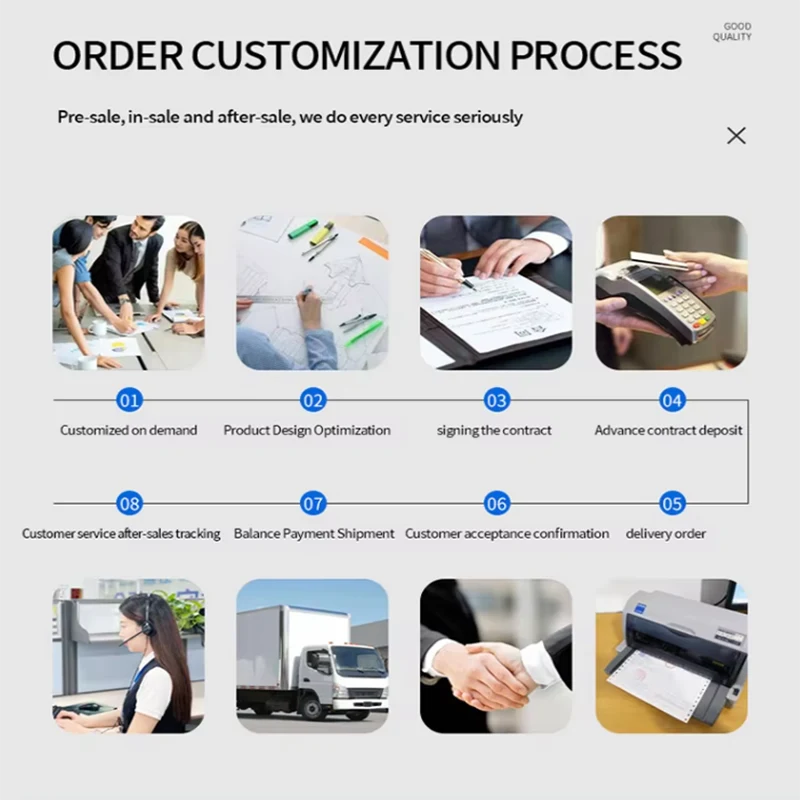

Product Inquiry