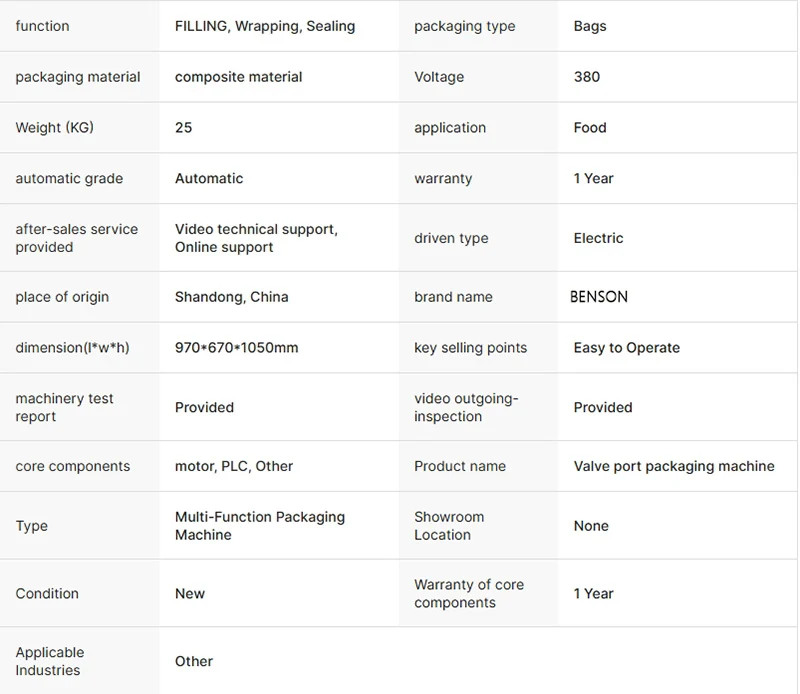

The automatic weighing gypsum powder and pigment packaging machine is an automated packaging equipment specially designed for powdery materials such as gypsum powder and pigments, integrating a high-precision weighing system, intelligent control system, and professional powder handling module. The equipment uses sensors to monitor material weight in real time and combines with a servo motor-driven feeding mechanism to achieve precise measurement and quantitative packaging of powders.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

It can automatically complete the entire process of feeding, weighing, filling, sealing, and conveying, suitable for powdery products with different particle sizes and densities, especially for industrial scenarios with high requirements for measurement accuracy.

BensonAutomatic weighing gypsum powder and pigment packaging machineAdvantages

1. High-precision measurement: Using digital weighing sensors and dynamic compensation algorithms, weighing errors can be controlled within ±0.1%–±0.5%, meeting strict quantitative packaging requirements.

2. Efficient automation: Fully automated operation can complete 10–30 bags of packaging per minute (adjusted according to material characteristics), significantly reducing manual intervention and improving production efficiency.

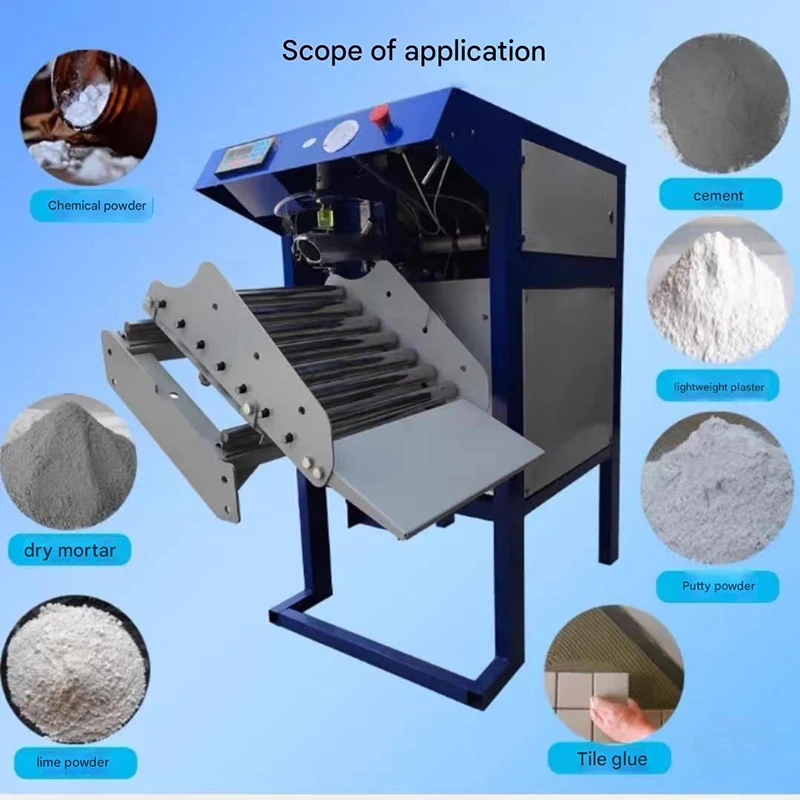

3. Multi-functional adaptability: Supports various packaging specifications (e.g., 5kg, 10kg, 25kg). Material types or packaging weights can be switched by quickly adjusting parameters, compatible with gypsum powder, pigments, coating powders, chemical raw materials, and other categories.

4. Low dust pollution: A closed weighing and filling structure with a dust removal interface effectively reduces powder spillage, improves workshop environment, and meets environmental and safety standards.

BensonAutomatic weighing gypsum powder and pigment packaging machineFeatures

1. Intelligent control system: Equipped with a touchscreen operation interface, supporting formula storage (can save 50+ groups of process parameters), fault self-diagnosis, and real-time monitoring of production data for convenient operation and high visibility.

2. Anti-sticking and anti-blocking design:

The hopper and conveying pipes are made of stainless steel with polishing treatment, combined with a vibration arch-breaking device to prevent wall adhesion and blockage caused by moisture absorption or electrostatic adsorption of powders.

3. Modular structure: Key components (e.g., weighing units, sealing devices) can be quickly disassembled for maintenance, reducing downtime and suitable for continuous production scenarios.

4. Safety protection configuration: Equipped with emergency stop switches, overload protection, leakage monitoring, and other devices to ensure operator safety and prevent equipment damage from abnormal loads.

BensonAutomatic weighing gypsum powder and pigment packaging machineApplications

1. Building materials industry: Used for quantitative packaging of gypsum powder, putty powder, cement additives, etc., meeting the large-scale shipment needs of building materials manufacturers.

2. Coatings and pigments industry: Suitable for precise packaging of various powdery pigments (e.g., titanium dioxide, iron oxide pigments) and dyes to ensure product quality consistency.

3. Chemical industry: Applicable for packaging chemical powders (e.g., resin powder, rubber additives), supporting explosion-proof customization to meet special requirements in flammable and explosive environments.

4. Food and pharmaceutical excipients: Can be used for packaging hygienic-grade powders such as starch, milk powder, and pharmaceutical intermediates (requires optional stainless steel anti-corrosion materials and sterile sealing components).

5. Scientific research and laboratories: Provides precise dispensing of small-batch powder samples, adapting to the high-precision packaging needs of experimental materials in universities and research institutions.

Products Description

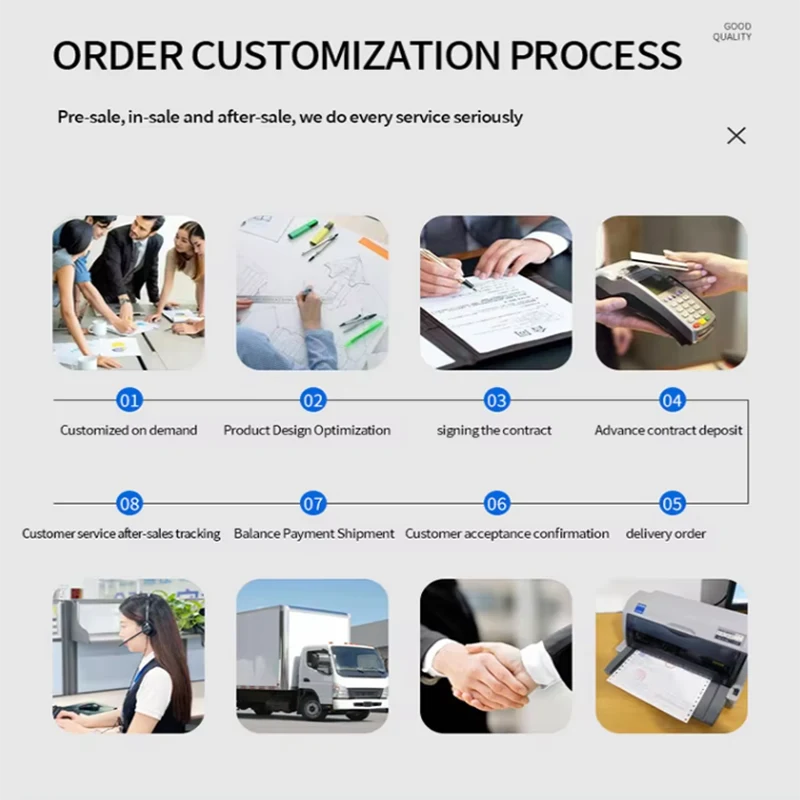

Product Inquiry