The fully automatic paper drum filling and packaging machine is a highly automated packaging equipment. It realizes the quantitative filling and sealed packaging of materials in paper drums through automation technology. The working process covers that the feeding system conveys materials to the storage bin. The conveyor belt, in cooperation with the automatic positioning system, accurately sends the empty paper drums under the filling head.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

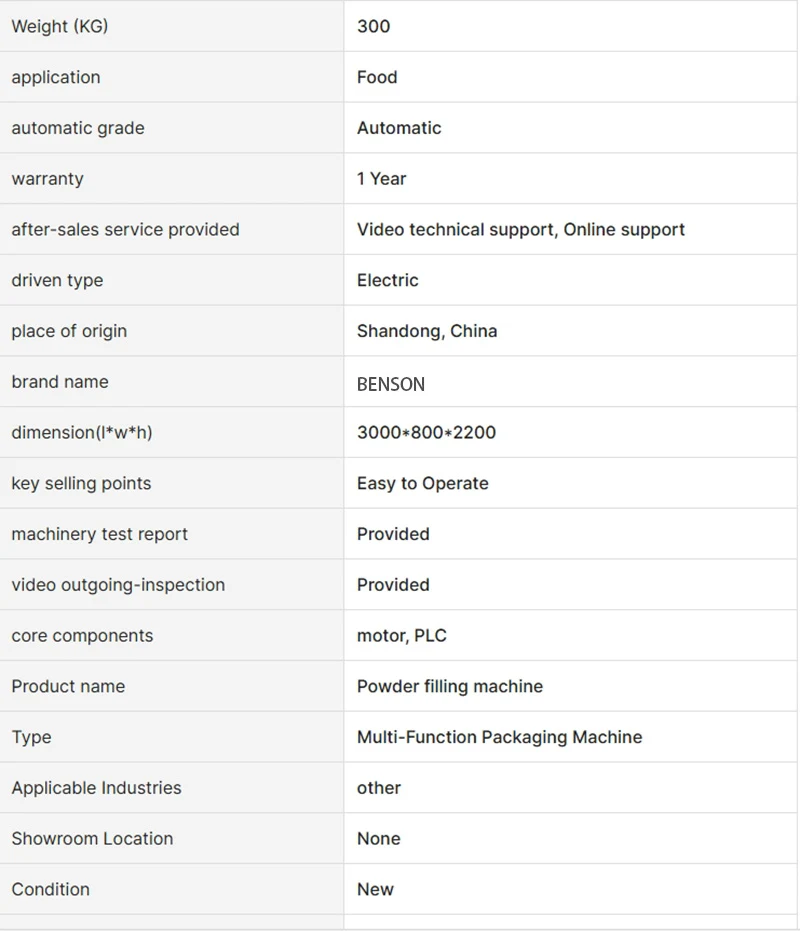

Fully Automatic Paper Drum Filling and Packaging MachineAdvantages

1. High production efficiency: With fully automated operation, it can achieve continuous and high - speed filling and packaging. It can handle a large number of paper drum packaging tasks in a short time, significantly increasing production capacity and meeting the needs of mass production.

2. High filling accuracy: Equipped with high - precision weighing sensors and advanced control systems, it can accurately control the filling quantity of materials in each drum, reducing errors, ensuring the consistency and stability of product quality, and enhancing the market competitiveness of products.

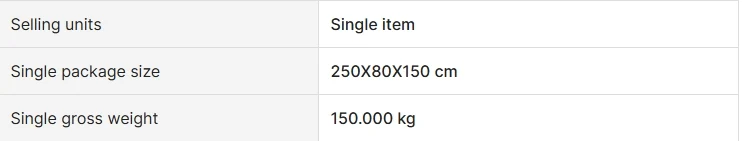

3. Intelligent operation: Integrated with an intelligent control system and a human - machine interface, it is easy to operate. Workers can get started after simple training. It can quickly adjust parameters according to different materials and packaging specifications.

4. Cost reduction: Although the initial equipment purchase cost is relatively high, in the long run, automation reduces the dependence on labor, cutting labor costs. At the same time, precise control reduces material waste, improves resource utilization, and lowers operating costs.

5. Safety and hygiene: With a fully enclosed design, it reduces the risk of external contamination of materials during the packaging process, meeting the hygiene standard requirements of industries such as food and medicine. Moreover, automated operation reduces the labor intensity of workers and the risk of exposure to harmful substances.

6. Strong flexibility: By replacing the filling head, adjusting parameters, upgrading software, etc., it can quickly adapt to the packaging requirements of different materials (liquids, semi - liquids, solids, powders, etc.) and paper drum specifications, meeting the production of diversified market orders.

Fully Automatic Paper Drum Filling and Packaging MachineApplications

1. Chemical industry: Used for filling and packaging various liquid or powdery chemical products such as chemical raw materials, coatings, inks, and adhesives.

2. Food industry: Suitable for the paper drum packaging of foods such as edible oils, sauces, honey, milk powder, and solid beverages, ensuring food hygiene safety and packaging quality.

3. Pharmaceutical industry: Can be used for the packaging of pharmaceutical raw materials, granular drugs, powdered drugs, etc., meeting the strict hygiene and metering requirements of pharmaceutical products.

4. Agricultural field: For the paper drum filling and packaging of products such as pesticides and fertilizers, effectively preventing material leakage and contamination.

5. Other industries: Products such as cosmetic raw materials, spices, and dyes can also use the fully automatic paper drum filling and packaging machine for packaging.

Fully Automatic Paper Drum Filling and Packaging MachineFeatures

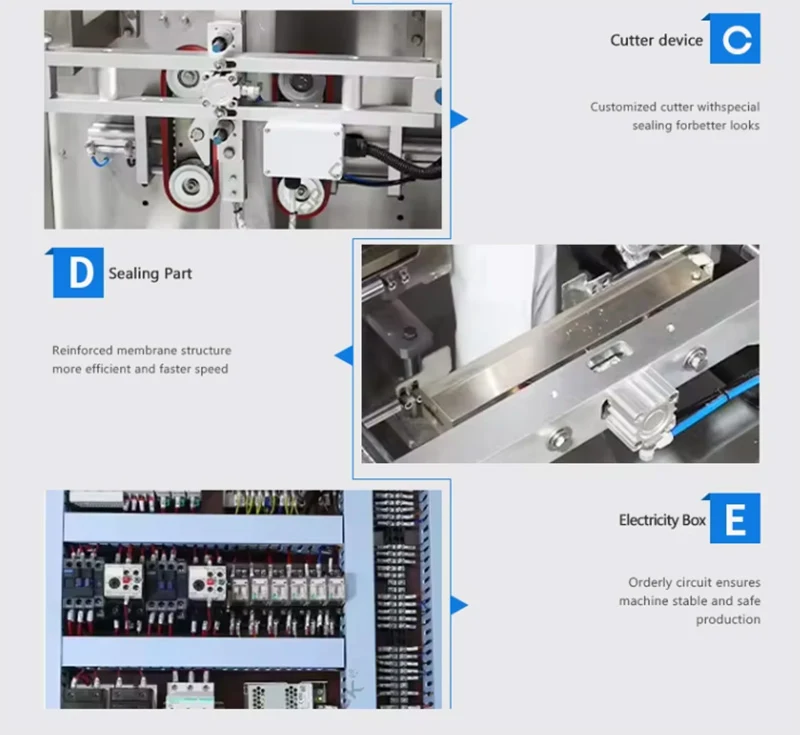

1. High degree of automation: The entire filling and packaging process requires little or no human intervention. From paper drum transportation, material filling to capping and inspection, all links are automatically completed, reducing the influence of human factors.

2. Precise measurement: Equipped with advanced measuring devices, it can achieve multiple measurement methods such as volume or mass, and can be freely converted, ensuring accurate material filling quantity and controlling errors within a very small range.

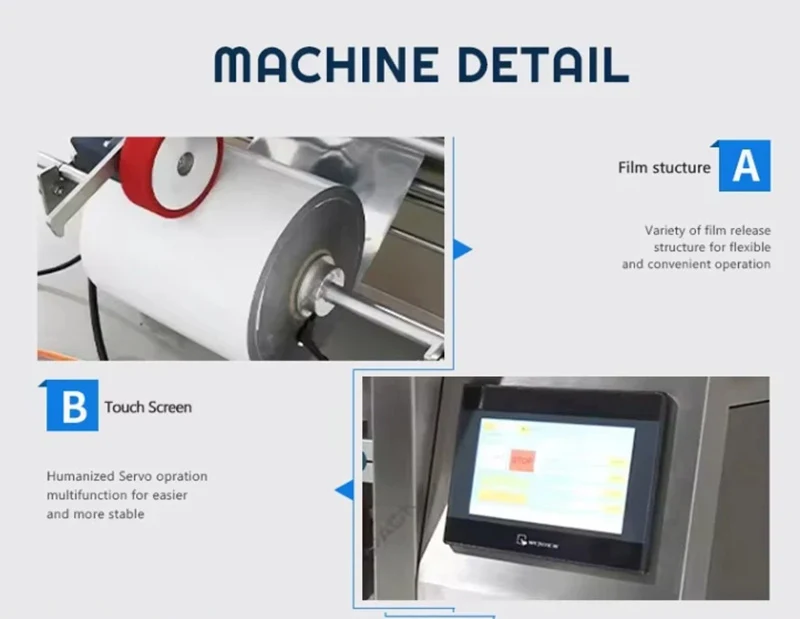

3. Multifunctional filling head: Designed for materials of different properties (such as viscosity, fluidity, etc.). Some are also equipped with a vacuum suction - back system to prevent dripping after filling. At the same time, it can achieve fast and slow dual - speed filling, ensuring both efficiency and avoiding overflowing of the drum.

4. Good stability: Adopting high - quality materials and advanced mechanical design, and using high - quality components for key electrical and pneumatic controls, it ensures the long - term stable operation of the equipment and reduces the failure rate and maintenance cost.

5. Expandability: Usually, functional expansion interfaces or spaces are reserved, which can be combined with equipment such as automatic cap sorting and placing machines, inkjet printers, labeling machines, case packers, and palletizers to form a complete automated packaging production line.

Product Inquiry