Equipment Definition and Principle

The automatic vacuum iron plate suction cup glass crane is a kind of lifting equipment that uses vacuum adsorption technology and is specially designed for handling plates such as iron plates and glass. It forms a negative pressure between the suction cup and the surface of the plate through a vacuum system, enabling the suction cup to firmly adsorb the plate. Then, it uses the lifting machinery structure to achieve operationssuch

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Automatic Vacuum Iron Plate Suction Glass Crane High Efficiency Suction Technology

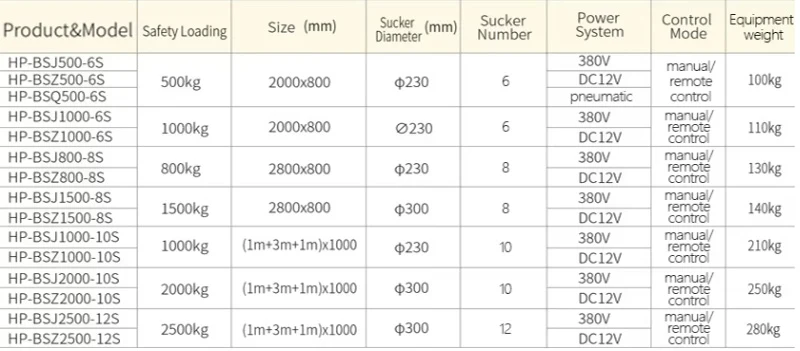

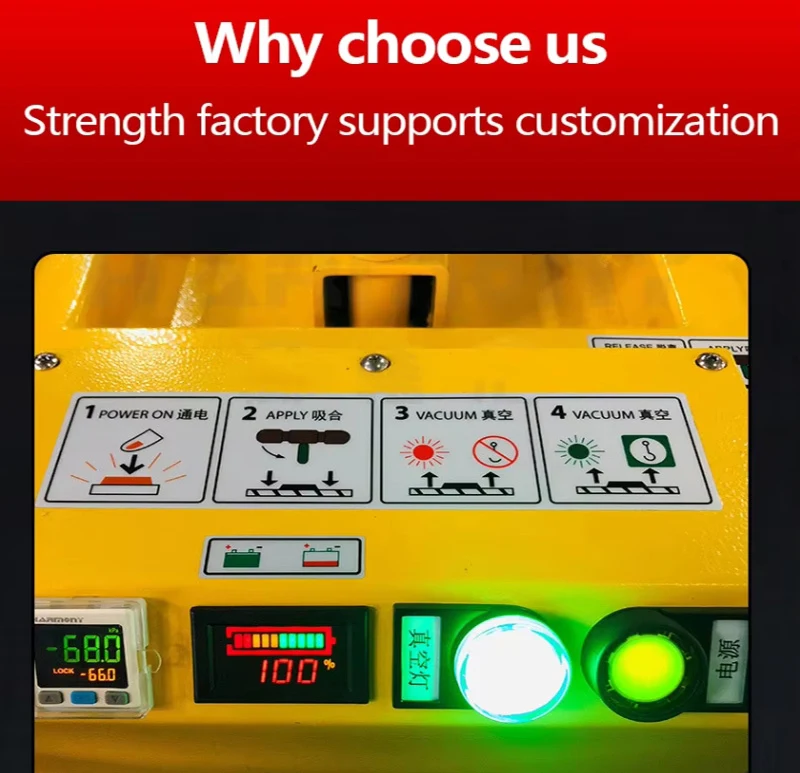

1. Vacuum System: It consists of a vacuum pump, vacuum pipelines, vacuum suction cups, and a vacuum monitoring device. The vacuum pump is responsible for evacuating the air inside the suction cup to form a vacuum; the vacuum pipelines are used for gas transmission; the vacuum suction cups directly contact the plate for adsorption; and the vacuum monitoring device monitors the vacuum degree in real - time to ensure adsorption safety.

2. Lifting Mechanism: It usually includes an electric hoist, steel wire ropes, and pulley blocks. The electric hoist provides power, and through the cooperation of steel wire ropes and pulley blocks, it realizes the vertical lifting of the plate.

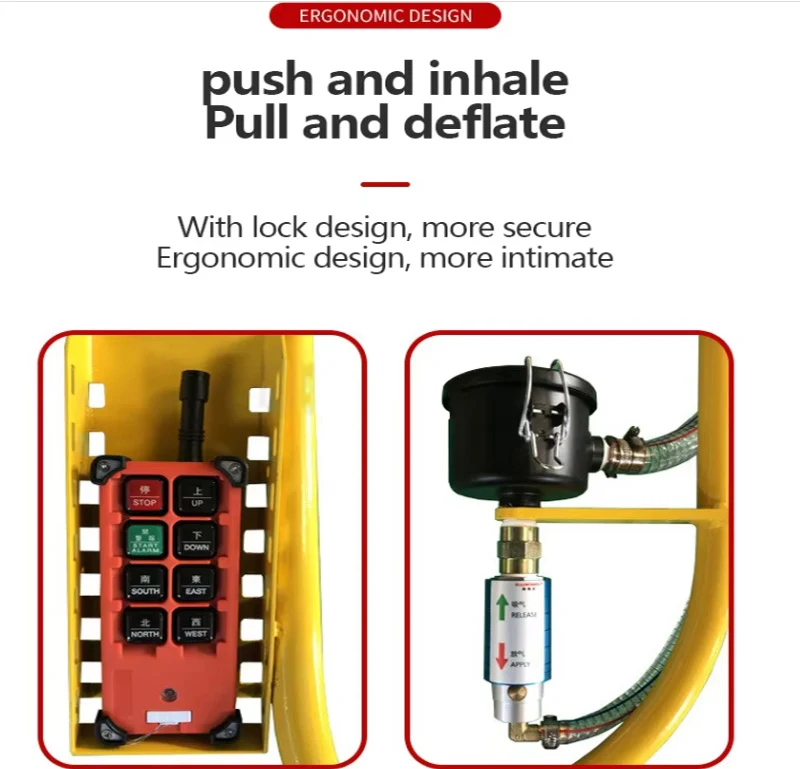

3. Travel and Control System: The travel part enables the crane to move horizontally on tracks or the ground. The control system includes an operating handle, a control panel, etc. Operators can use these to remotely or closely control various actions of the crane, such as adsorption, lifting, lowering, and translation.

Automatic Vacuum Iron Plate Suction Glass Crane High Efficiency Suction TechnologyHigh Degree of Automation: It has functions such as automatic adsorption, automatic lifting, and automatic travel, which can reduce manual intervention, improve work efficiency, and reduce labor intensity.

- Safe and Reliable Adsorption: Multiple vacuum monitoring and protection mechanisms, such as low - vacuum - pressure alarms and automatic activation of backup vacuum sources, prevent the plate from accidentally falling off and ensure operational safety.

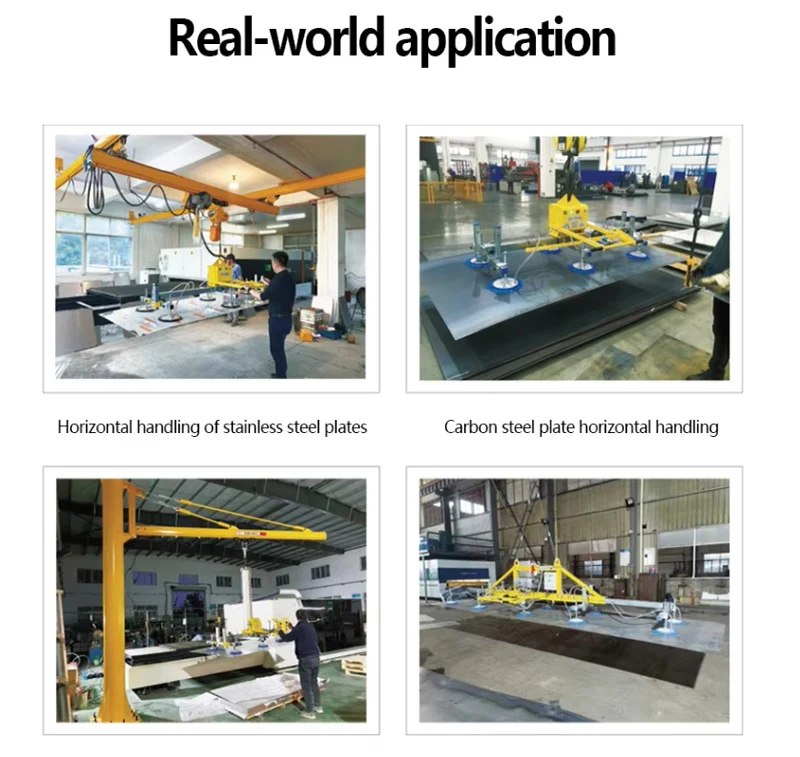

- Wide Range of Applications: It is suitable not only for iron plates and glass but also for handling relatively flat - surfaced plates such as marble and aluminum plates, and can adapt to plates of different sizes and weights.

Application Scenarios

It is widely used in places such as steel processing workshops, glass manufacturing plants, building curtain wall installation sites, and stone processing enterprises, and is used in links such as plate warehousing and transportation, loading and unloading on production lines, and installation in place.

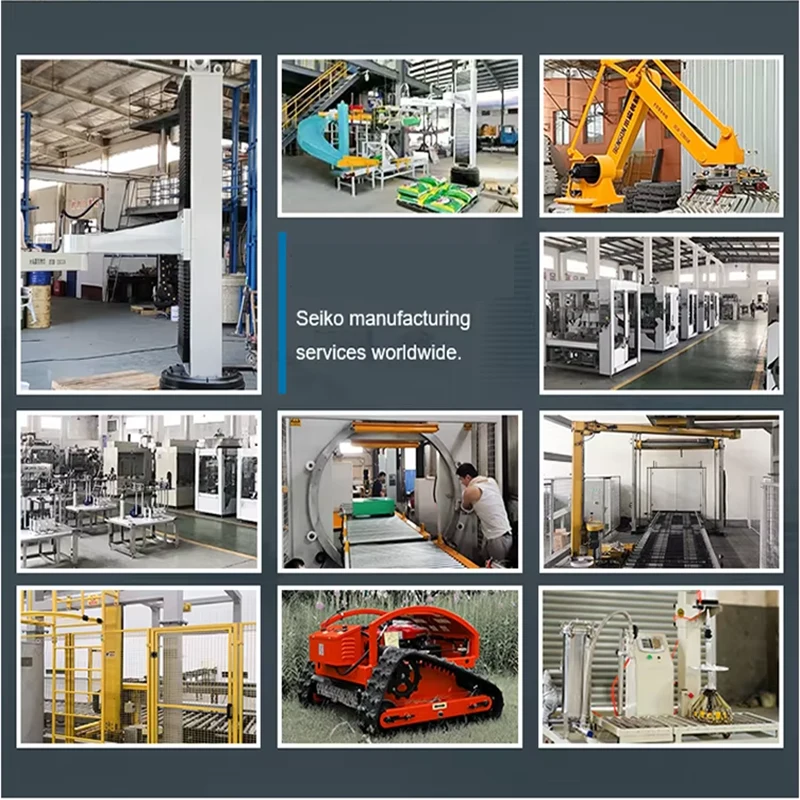

BENSON(Shandong) Machinery Co., Ltd. is a company engaged in winding machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bag feeding, large production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation A modern company that develops and produces production lines. high-tech enterprises. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "combination of production, education and research". The success of this research and development can be widely used in automated packaging routes, automated logistics engineering and other fields. A new generation of automated assembly line, the company has introduced various advanced processing equipment to comprehensively enhance market competitiveness, a large number of high-quality accessories, and product quality has been greatly improved. And other industries have been widely used, from product import to output, from electrical control to mechanical structure design, BENSON(Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and equipment precision manufacturing, we have a complete after-sales service system. , To provide customers with high-quality technical support and after-sales service

Exhibition

Product Inquiry