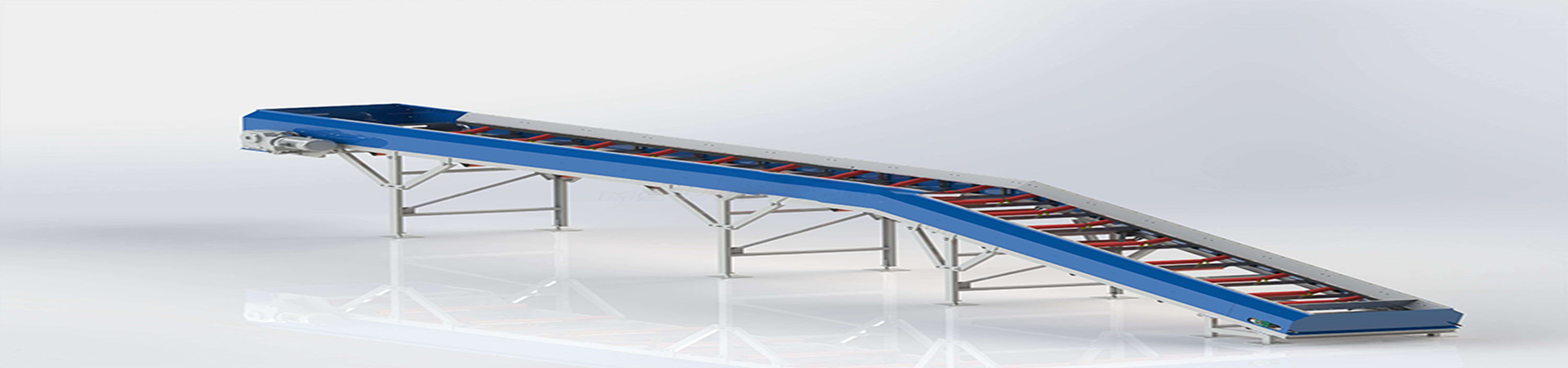

Automatic U-shaped groove tube screw conveyor: a new choice for efficient transportation

Automatic U-shaped groove tube screw conveyor is a material conveying equipment that integrates high efficiency, intelligence and stability. It is widely used in chemical, food, building materials, metallurgy and other industries. With its unique design and excellent performance, it has become an indispensable material transmission tool in modern industrial production.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

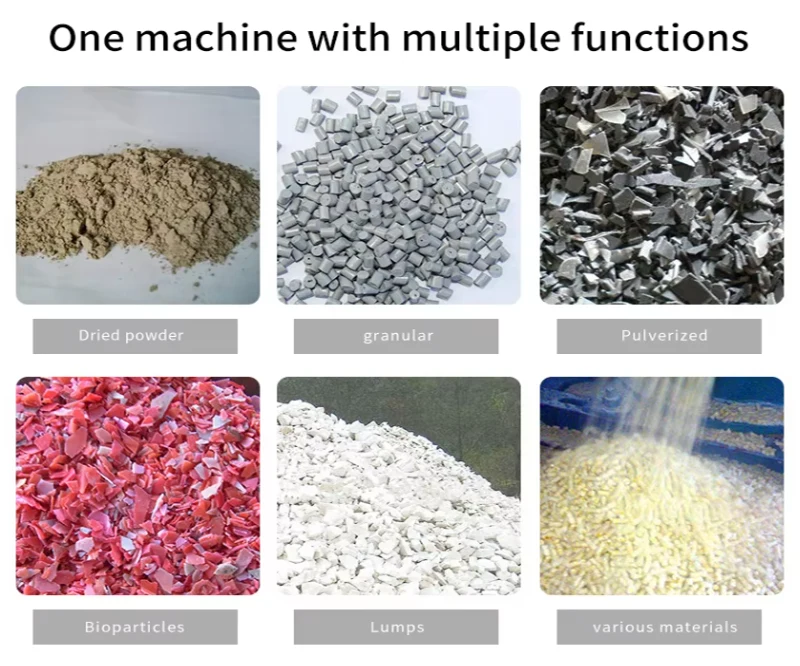

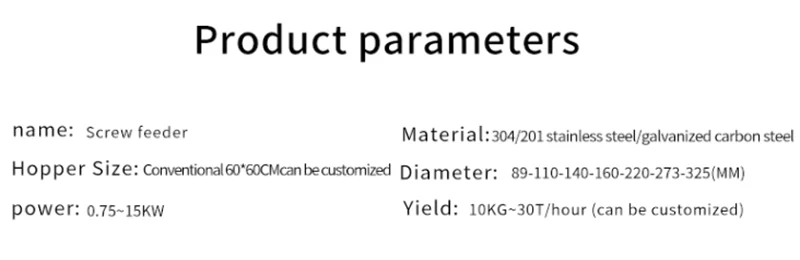

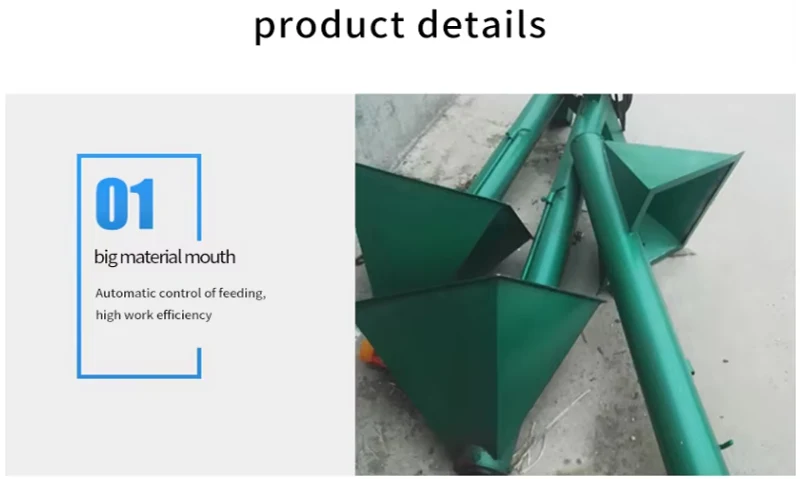

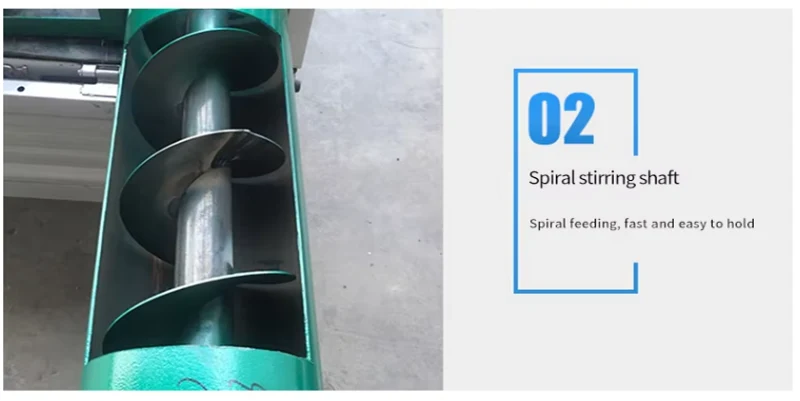

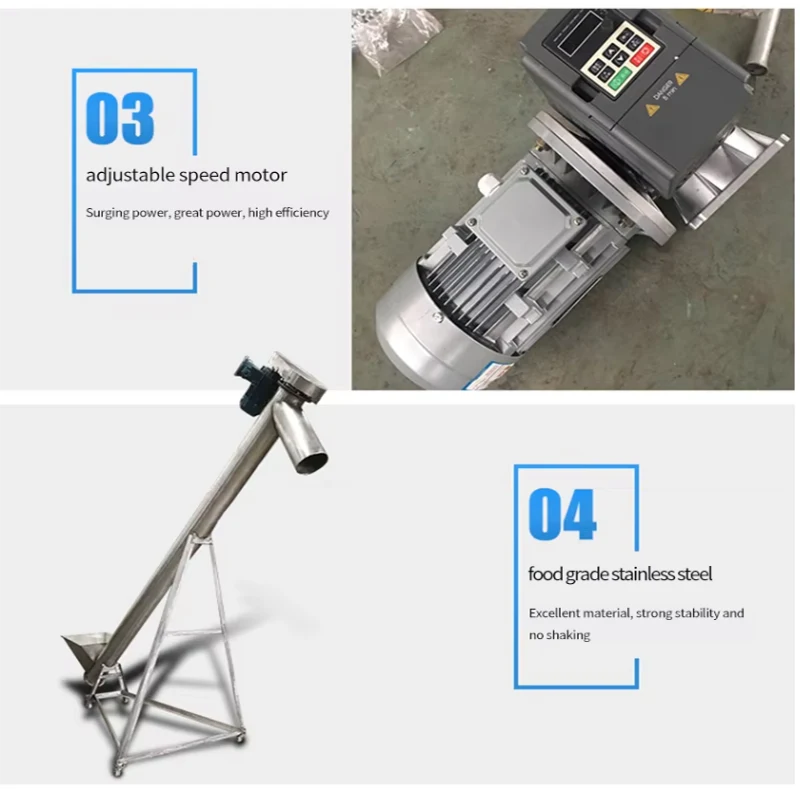

Structural design of automatic U-shaped trough tube screw conveyor

- U-shaped trough: Made of high-quality stainless steel or carbon steel, it has good wear resistance and corrosion resistance and can adapt to a variety of complex working conditions. The U-shaped design makes the material more concentrated during the conveying process, reduces material spillage, improves the conveying efficiency and facilitates cleaning and maintenance.

- Spiral blades: According to the characteristics of the conveyed material (such as particle size, humidity, fluidity, etc.), spiral blades with different pitches, diameters and thicknesses can be customized. The blades are made of high-strength materials and processed by special processes, with a smooth surface to ensure smooth material conveying and avoid adhesion and blockage.

- Drive system: Equipped with high-efficiency and energy-saving motors and high-precision reducers, it has strong power and stable operation. Through the intelligent control system, the conveying speed can be accurately adjusted to meet the needs of different production links. At the same time, the drive device has an overload protection function, which effectively extends the service life of the equipment.

- Sealing structure: The multi-layer sealing technology is used to ensure that the conveyor will not leak dust when conveying powdery, granular and other materials, which not only ensures the cleanliness of the working environment, but also avoids material waste, and meets environmental protection production requirements.

Core advantages of automatic U-groove tube screw conveyor

- Intelligent control: supports PLC intelligent control system, can realize linkage control with other equipment on the production line, and has functions such as remote monitoring and fault warning. Operators can grasp the operating status of the equipment in real time through the control panel or remote terminal, adjust the conveying parameters in time, and realize intelligent production management.

- Flexible adaptation: Equipment of different specifications, lengths and conveying angles can be customized according to the actual needs of users. Whether it is horizontal conveying, inclined conveying, or vertical conveying, it can be easily handled. At the same time, it can also be seamlessly connected with other equipment (such as silos, mixers, packaging machines, etc.) to build a complete production conveying system.

- Convenient maintenance: The equipment has a simple structure and modular design, which facilitates the disassembly and replacement of parts. Daily maintenance only requires regular inspection of the wear of the spiral blades, lubrication of the bearings, and cleaning of residual materials in the tank body. The maintenance cost is low, the downtime is short, and the continuity of production is guaranteed.

Application areas

- Chemical industry: used to transport powdered and granular chemical raw materials, such as fertilizers, pigments, resins, etc., to ensure the stable transmission of materials during the production process and avoid environmental pollution and safety hazards caused by material leakage.

- Grain industry: suitable for the transportation and loading and unloading of grain crops such as wheat, corn, and rice. It can be widely used in granaries, flour mills, feed mills and other places, effectively improving the degree of automation of grain processing.

- Building materials industry: commonly used for the transportation of building materials such as cement, sand and gravel, and coal powder. It can operate stably in harsh environments such as high temperature and high dust, providing reliable material transportation guarantees for building materials production.

- Environmental protection industry: in sewage treatment plants, garbage treatment stations and other places, it can be used to transport sludge, garbage and other materials to help the smooth implementation of environmental protection projects.

Products Description

Company Profile

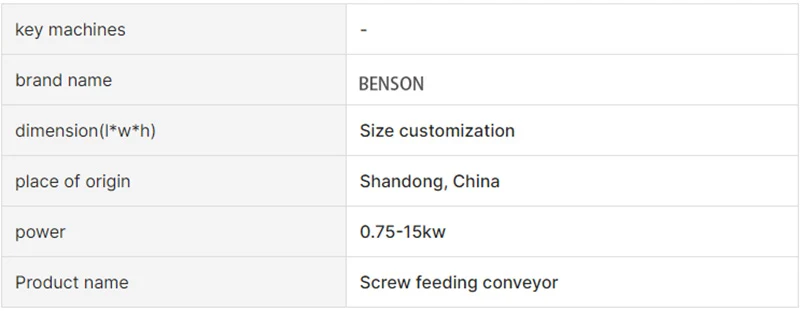

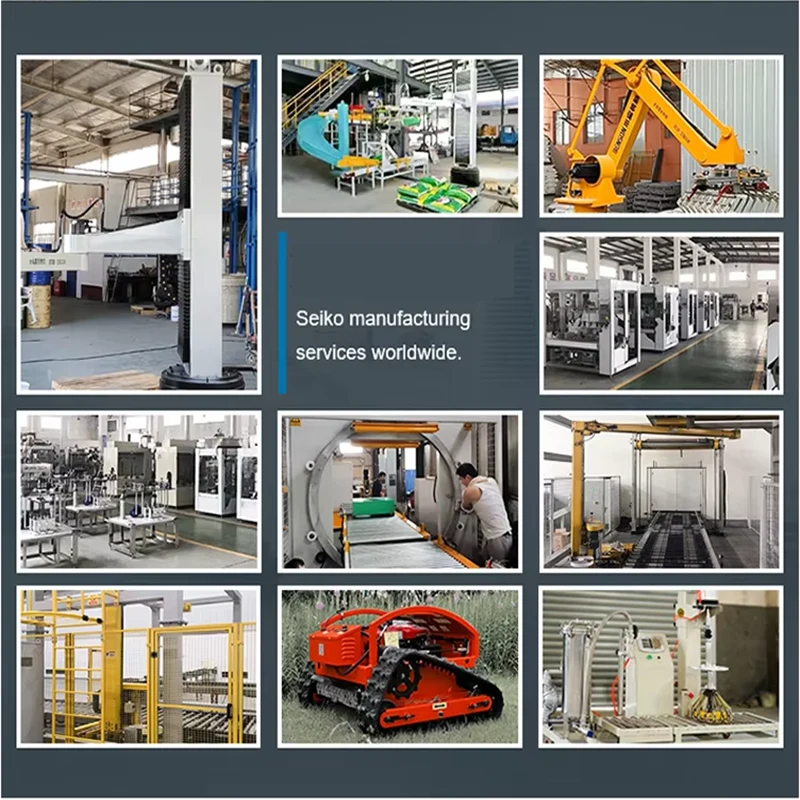

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research", and the success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been used, and the product quality has been greatly improved. The products of Bensen (Shandong) Machinery Co., Ltd. have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry