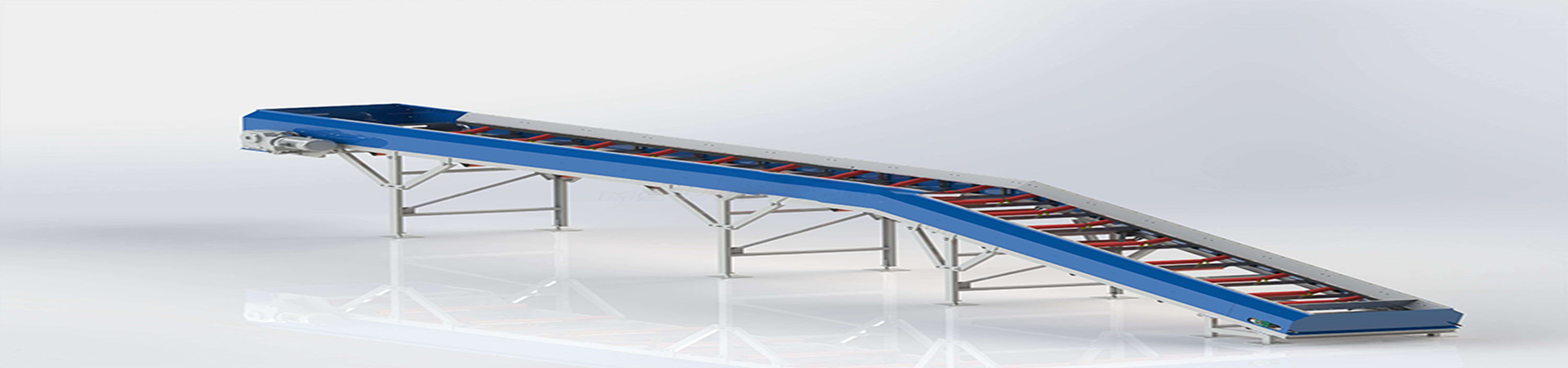

Automatic telescopic roller conveyor for boxed goods: intelligent and efficient conveying solution

In the fields of modern logistics, e-commerce warehousing and intelligent manufacturing, the rapid and accurate conveying of boxed goods is the key to improving operational efficiency. The automatic telescopic roller conveyor for boxed goods, with intelligent automation and flexible adaptability as the core, is designed for efficient transfer of boxed goods.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

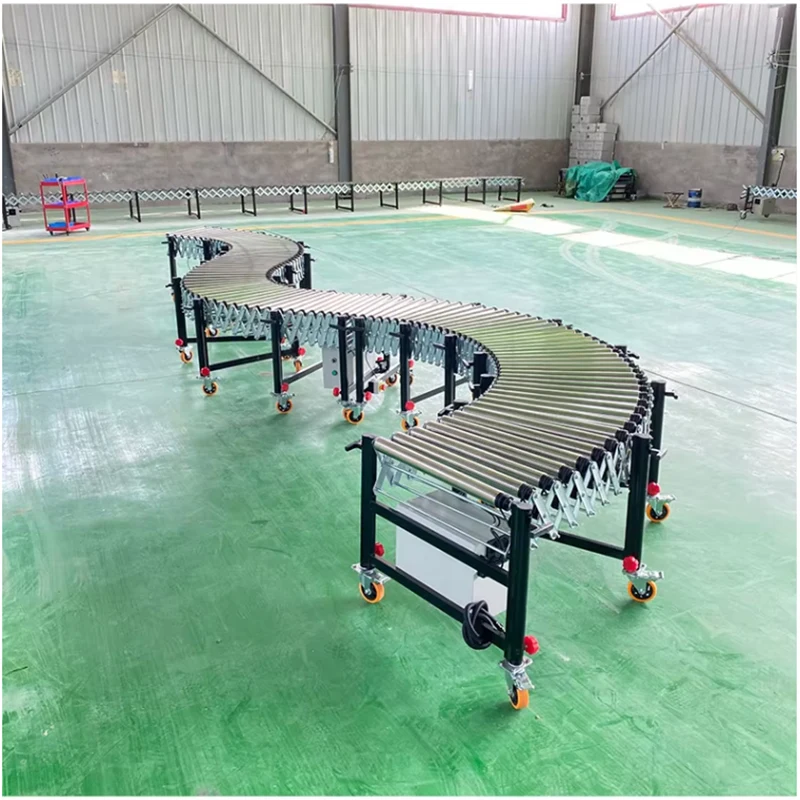

Core advantages of automatic telescopic roller conveyor: intelligent telescopic, efficient and worry-free

Fully automatic intelligent telescopic:

Equipped with an electric drive system, the conveyor length can be quickly and automatically adjusted through PLC intelligent control or remote operation panel, without manual operation, and can accurately match truck compartments of different lengths, sorting line spacing or warehouse platforms, greatly shortening the waiting time for cargo loading and unloading.

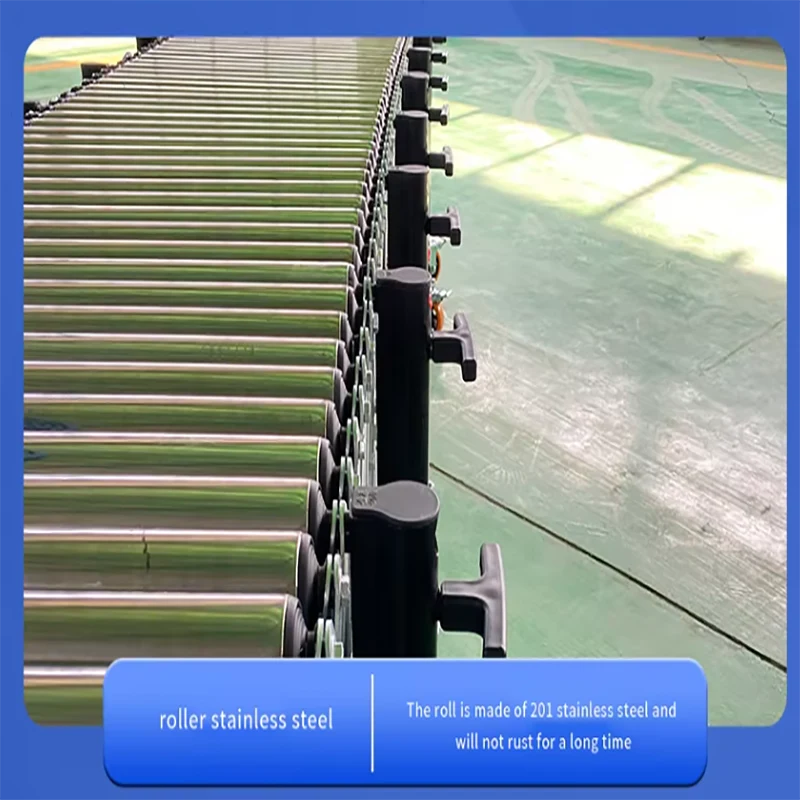

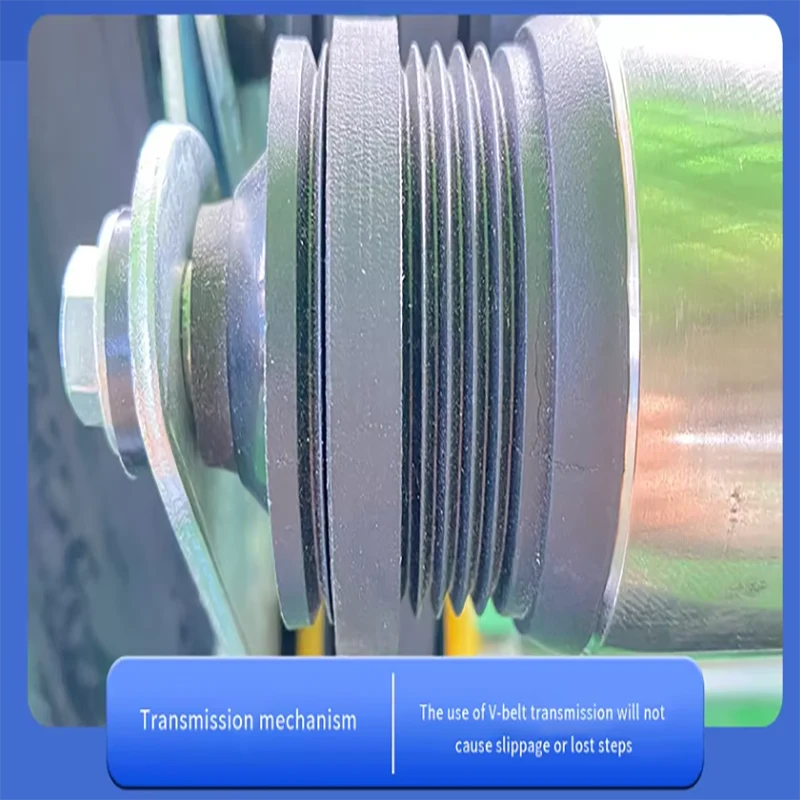

Stable and efficient transportation:

Adopt high-strength galvanized/stainless steel rollers, anti-slip surface treatment, precise spacing design, suitable for all kinds of standard boxes, cartons, turnover boxes and other packaged goods; the power drive system supports variable frequency speed regulation to ensure continuous and smooth transportation of heavy-loaded goods to avoid slipping or jamming.

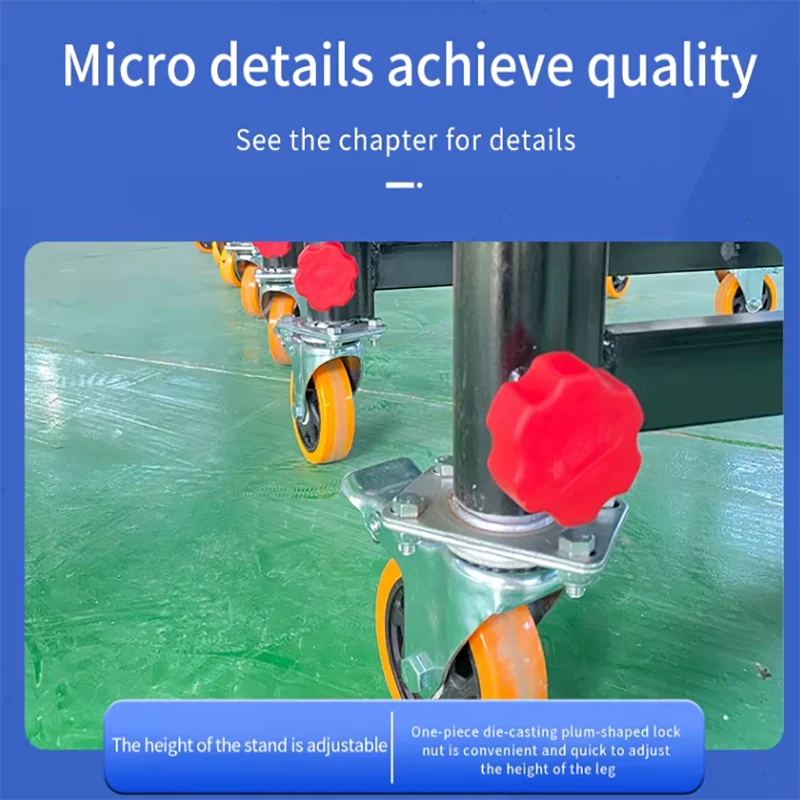

Flexible height adjustment:

Equipped with hydraulic or electric lifting devices, supporting one-button lifting, can quickly adapt to trucks, loading and unloading platforms and production lines of different heights, reduce the drop of cargo handling, reduce the labor intensity and the risk of cargo damage.

Technical highlights of automatic telescopic roller conveyor: precision quality, safe and reliable

- High-strength structural design: The whole machine adopts high-quality carbon steel/aluminum alloy frame, which is reinforced and rust-proofed by welding process to adapt to 24-hour high-intensity working environment;

- Intelligent safety protection: integrated anti-collision sensor, emergency brake button, anti-deviation device and guardrail design, automatic shutdown when encountering obstacles, all-round protection of operators and goods safety;

- Modular design: supports rapid disassembly and assembly, can flexibly expand or adjust the layout according to actual needs, convenient maintenance, and reduce long-term use costs.

Application scenarios: Covering the entire industry, customized adaptation

E-commerce warehousing and express sorting: quickly connect trucks and sorting lines to realize automated loading and unloading and sorting of packages, and improve peak operation efficiency;

Manufacturing production line: seamlessly connect production, packaging and warehousing links, ensure fast transfer of finished products, and optimize production line logistics processes;

Logistics distribution center: compatible with various specifications of cargo boxes, support the parallel use of multiple devices, and build an efficient and automated transportation network;

Retail distribution center: meet the needs of fast order sorting and delivery, and shorten the turnover time of goods.

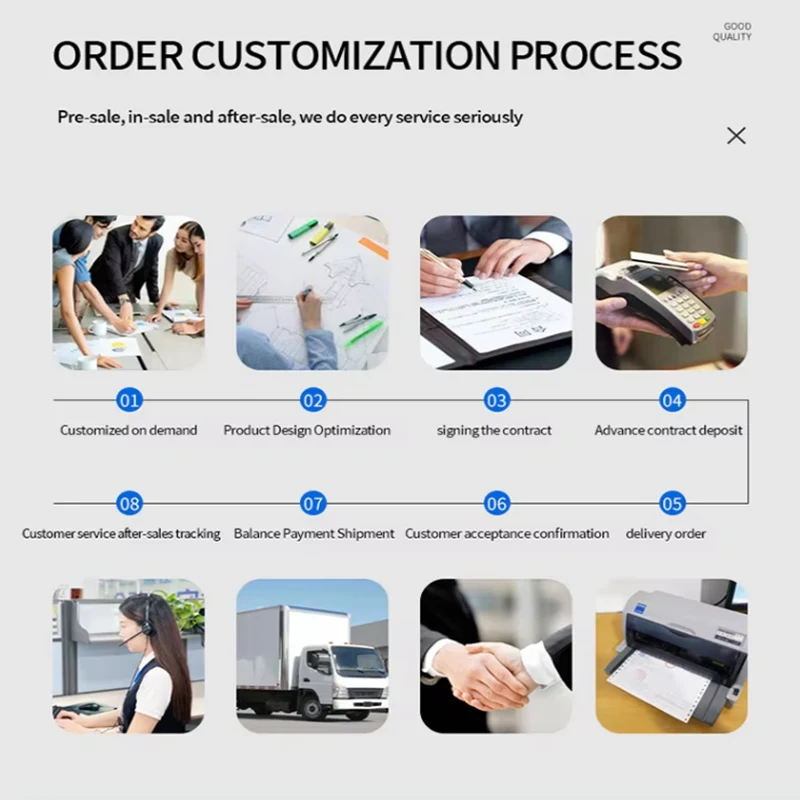

Customized service: meet personalized needs

Provide a full-process customization solution, including:

- Size customization: conveying length, width, and height are designed on demand;

- Function upgrade: add intelligent components such as scanning system, weighing module, and sorting baffle;

- Material selection: carbon steel, stainless steel, and food-grade materials are adapted to different industry standards;

- Control optimization: integrated Internet of Things (IoT) module to support remote monitoring and data management.

Products Description

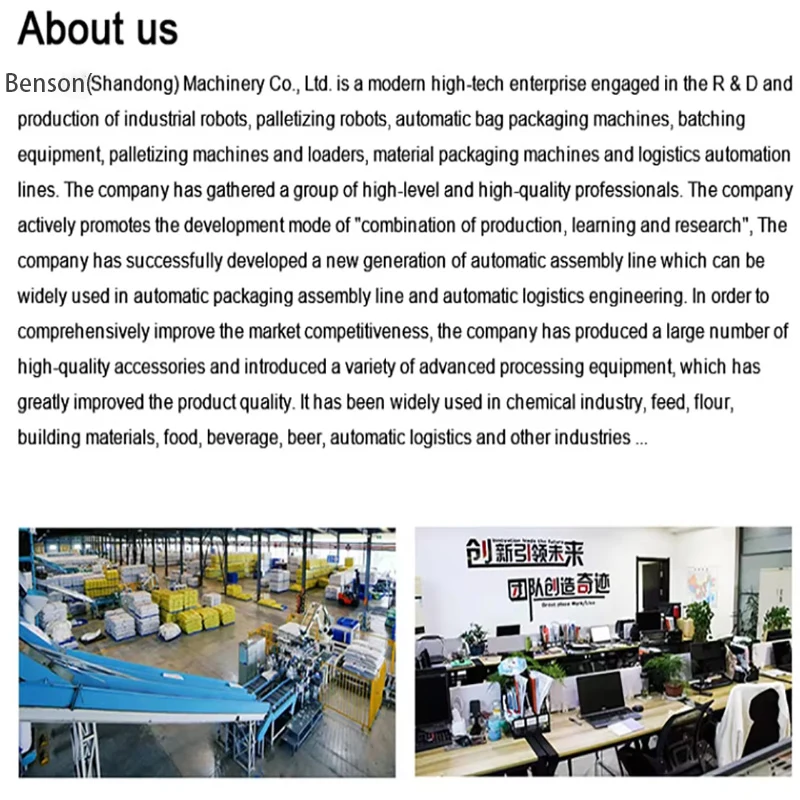

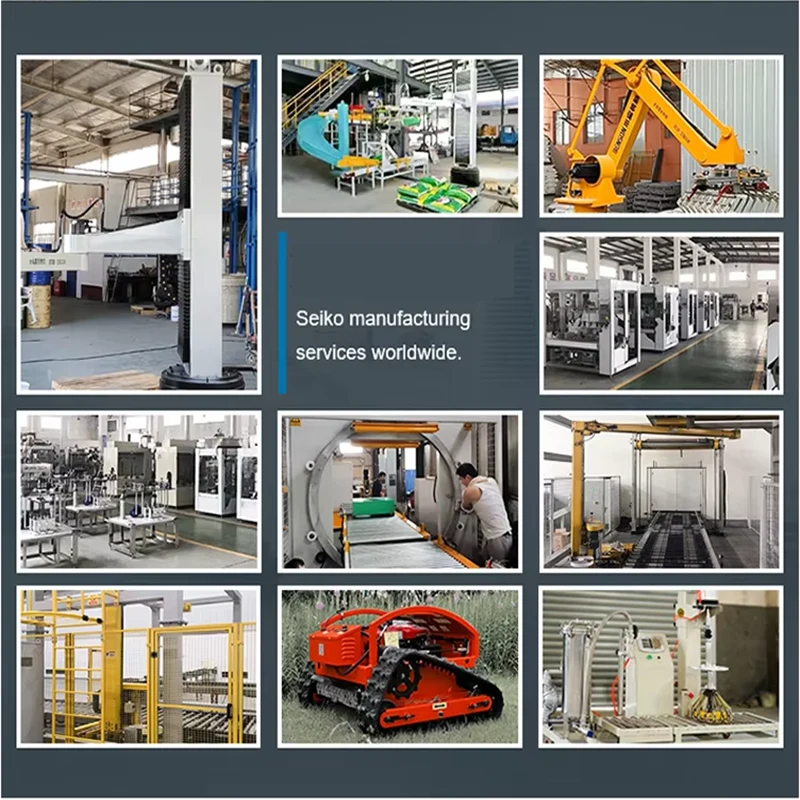

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry