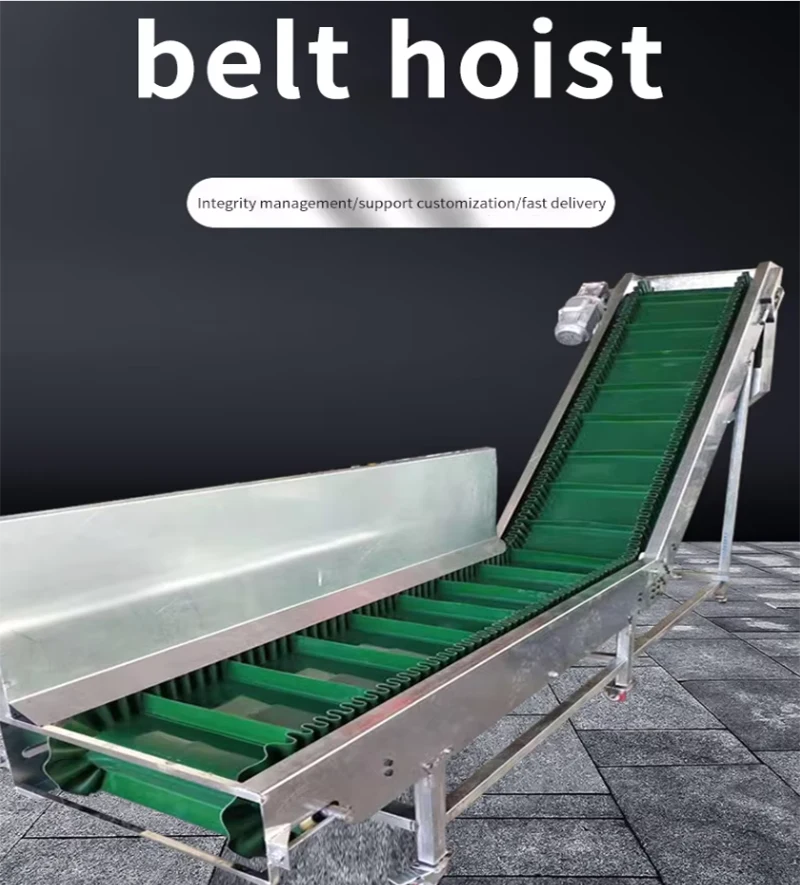

Stainless steel slope conveyor has become an indispensable material conveying equipment in modern industrial production due to its excellent performance and wide applicability. It uses high-quality stainless steel as the main material, and through a unique inclined conveying design, it effectively realizes the continuous transmission of materials from low to high positions, greatly improving production efficiency.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

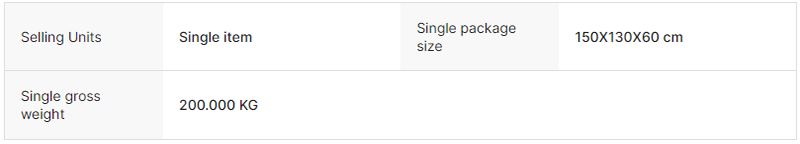

Packaging and delivery

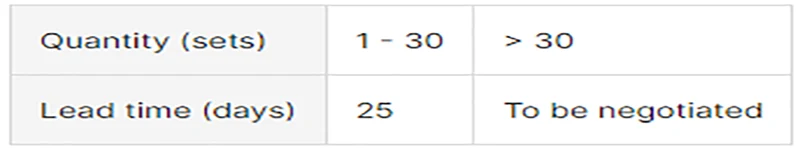

Lead time

Stainless steel slope conveyor - efficient vertical conveying solution

Structure of stainless steel slope conveyor

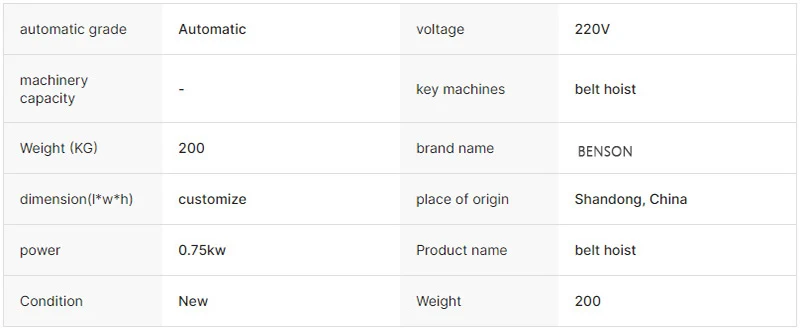

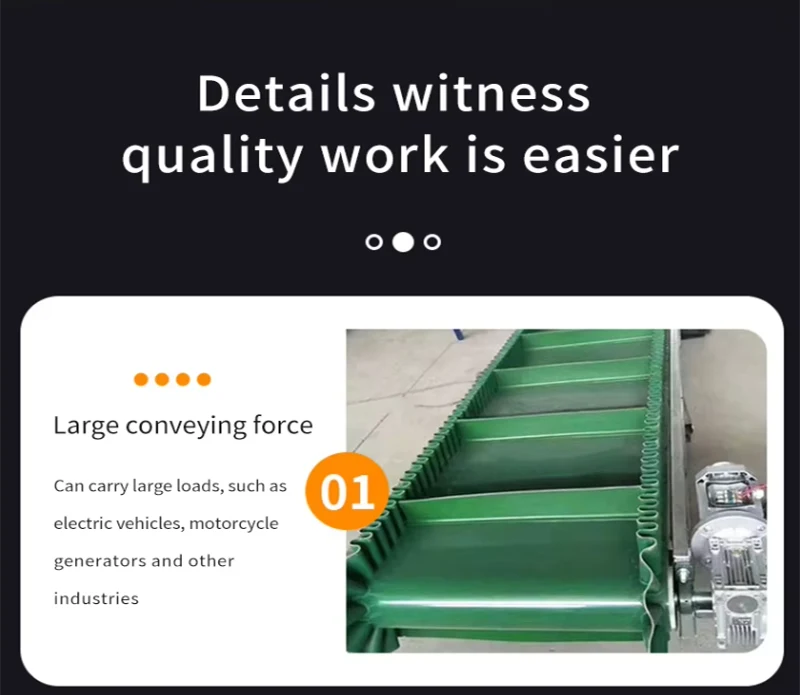

1. Frame: Made of high-quality 304 or 316 stainless steel, it has excellent strength and stability, can withstand large loads, and has good corrosion resistance and oxidation resistance, and is suitable for harsh environments such as humidity, acid and alkali.

2. Conveying components of stainless steel slope conveyor

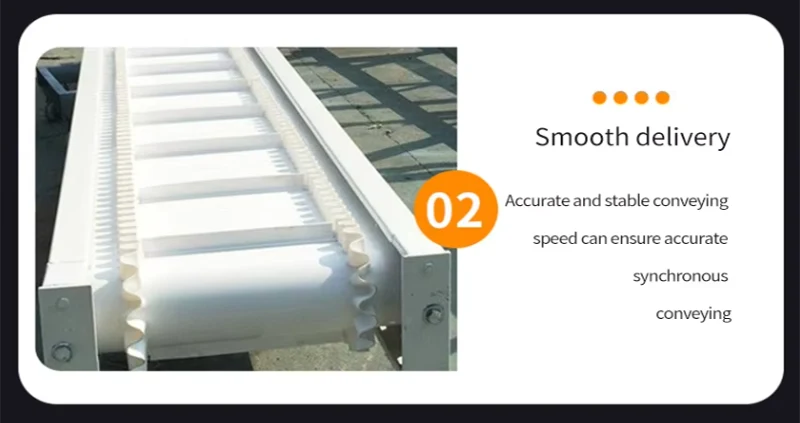

- Belt type: Conveyor belts made of food-grade or industrial-grade rubber, PVC, PU and other materials are selected, which have the characteristics of wear resistance, oil resistance and aging resistance. The surface of the conveyor belt can be designed as a smooth surface, a patterned surface or a skirt or baffle according to the needs to prevent the material from slipping and meet the conveying requirements of different materials.

- Chain plate type: The chain plate is made of stainless steel and has various styles such as flat plate type and lifting plate type. The chain plates are connected by high-strength pins, which run smoothly and have strong load-bearing capacity. They are suitable for conveying heavier and larger materials, such as glass bottles and metal parts.

3. Drive device: Equipped with an energy-efficient motor and a reducer, it can provide stable power output. The motor has functions such as overload protection and overheat protection to ensure the safe operation of the equipment. There are various speed adjustment methods, and frequency conversion speed regulation or stepless speed reduction motor can be selected to meet the requirements of conveying speed for different production processes.

4. Stainless steel slope conveyor tensioning device: The screw or heavy hammer tensioning structure can be used to easily and quickly adjust the tension of the conveyor belt or chain plate to ensure that the conveying components maintain appropriate tension during operation and prevent problems such as slipping and deviation.

5. Support and guide components: Multiple rollers or rollers are installed to support the conveyor belt or chain plate to reduce running resistance; at the same time, a guide device is set to guide the material along the predetermined conveying route to ensure the stability of the conveying process.

Advantages of stainless steel slope conveyor products

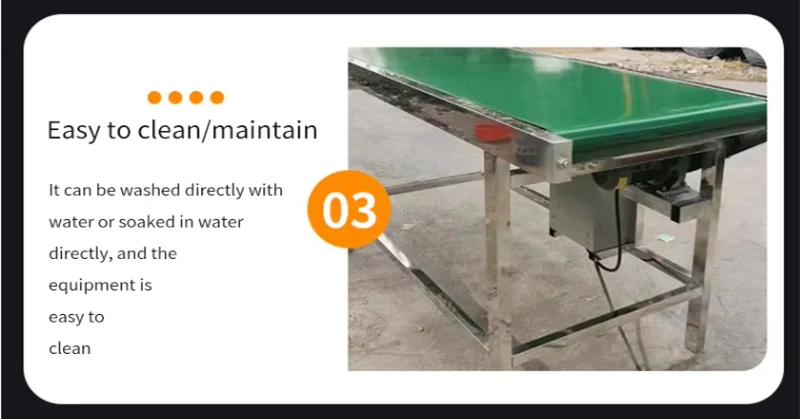

1. Hygiene and environmental protection: Stainless steel material meets the hygiene standards of food, medicine and other industries, with a smooth surface, not easy to breed bacteria, easy to clean and disinfect, and effectively prevent materials from being contaminated during transportation.

2. Sturdy and durable: The high-quality stainless steel material and exquisite manufacturing process make the equipment have strong resistance to wear and corrosion, and can operate stably for a long time under harsh working conditions, reducing equipment maintenance costs and replacement frequency.

3. Stainless steel slope conveyor is efficient and energy-saving: The optimized drive system and reasonable structural design make the equipment consume less energy during operation, effectively reducing production costs while ensuring efficient transportation.

4. Flexible customization: The size, conveying components, drive mode, speed control, etc. of the conveyor can be customized according to the special needs of different industries, perfectly adapting to various complex production processes.

5. Safe and reliable: Equipped with complete safety protection devices, such as emergency brake buttons, anti-skid devices, anti-deviation devices, etc., effectively prevent accidents and ensure the safety of operators and equipment.

Application scenarios of stainless steel slope conveyors

1. Food industry: used for the lifting and transportation of raw materials or finished products such as fruits, vegetables, meat, and baked goods to meet the needs of food processing, sorting, packaging and other links.

2. Pharmaceutical industry: suitable for conveying pharmaceutical granules, capsules, tablets, medicine bottles and other materials, in line with the strict hygiene and quality standards of pharmaceutical production.

3. Chemical industry: capable of conveying all kinds of powdered, granular and block chemical raw materials, playing an important role in the production, storage and transportation of chemical products.

4. Electronic industry: commonly used for conveying electronic product parts and finished products, the equipment runs smoothly, does not damage precision electronic products, and meets the high-precision requirements of electronic production workshops.

Maintenance and service

The stainless steel slope conveyor has a simple structure and convenient daily maintenance. You only need to regularly check the belt/chain tension, bearing lubrication, etc. to ensure the long-term stable operation of the equipment. We provide comprehensive after-sales service, including equipment installation and commissioning, operation training, regular maintenance and 24-hour fault response, so that you can use it without worry.

Choosing our stainless steel slope conveyor is to choose an efficient, safe and durable material conveying solution to help enterprises upgrade their production processes and enhance their market competitiveness!

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry