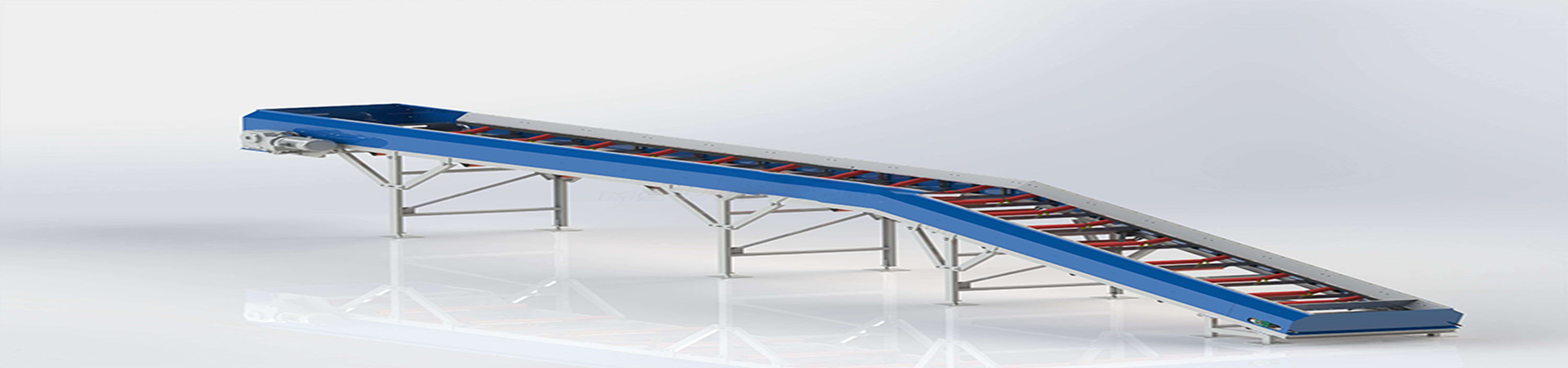

Fully automatic Hopper screw conveyor is an efficient and intelligent material conveying equipment designed to meet the diverse conveying needs in modern industrial production. It combines advanced automation technology with mature screw conveying principles, and can stably and reliably convey various types of powdered, granular and small block materials from one place to another. It is widely used in many industries such as chemical industry, building materials, food, metallurgy, and grain.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Working principle of fully automatic Hopper screw conveyor

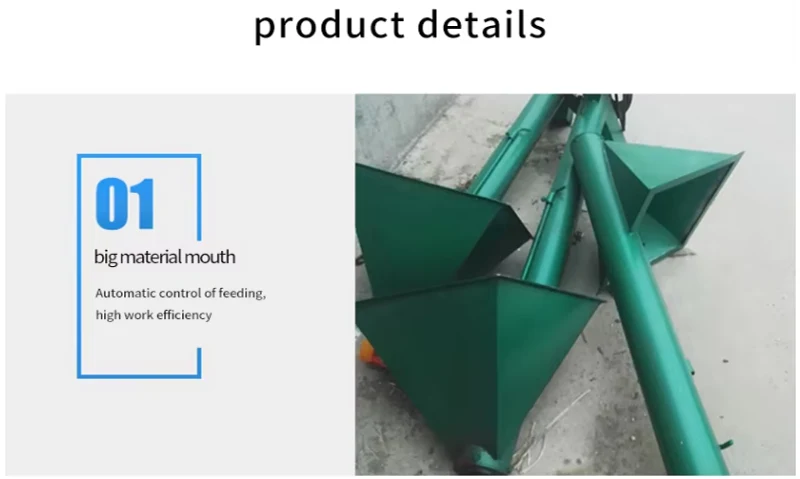

The equipment is mainly composed of a drive device, a screw shaft, a spiral blade, a trough, a feed hopper (Hopper) and a discharge port. When the drive device is started, the motor transmits power to the screw shaft through the reducer to make it rotate at high speed. The spiral blade installed on the screw shaft rotates accordingly. After the material enters the trough from the feed hopper (Hopper), under the push of the spiral blade, due to the gravity of the material itself and the friction between the material and the trough wall, the material slides linearly along the axial direction of the trough, thereby realizing a continuous conveying process from the feed port to the discharge port.

Product features of fully automatic Hopper screw conveyor

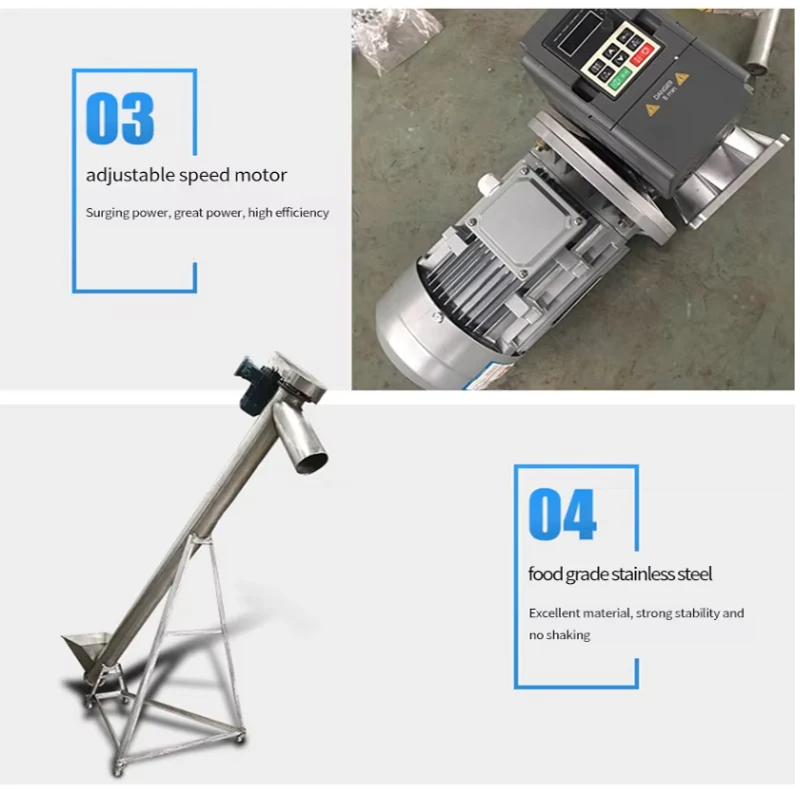

Highly automated: equipped with an advanced intelligent control system, it can realize remote control, automatic start and stop, speed regulation, fault diagnosis and alarm and other functions. The operator only needs to set the conveying parameters at the control terminal, and the equipment can automatically run according to the preset program, greatly reducing manual intervention, improving production efficiency and reducing labor intensity.

Efficient and stable transportation: The optimized spiral blades and reasonable rotation speed can ensure that the material maintains a uniform and stable flow state during the transportation process, avoiding material blockage, accumulation or leakage. The equipment has strong transportation capacity and can provide a variety of specifications and models according to different production needs. The transportation range is wide and meets the requirements of various scales of production.

Compact and reasonable structure: The overall structure design is compact and occupies a small area, which is especially suitable for installation and use in factories or production lines with limited space. At the same time, the layout of the equipment is flexible, and it can realize a combination of various transportation methods such as horizontal, inclined or vertical according to the actual situation on site, adapting to different process flows and site conditions.

Excellent sealing performance: The material trough adopts a fully enclosed design, combined with high-quality sealing materials, which effectively prevents the material from generating dust during the transportation process, avoids pollution to the environment, and also ensures the purity of the material. It is especially suitable for conveying volatile, flammable, explosive and environmentally strict materials.

Easy maintenance: The key components of the equipment are made of high-quality materials, with high wear resistance and corrosion resistance, and long service life. In addition, the design of each component fully considers the convenience of maintenance, such as the use of modular structure, quick-release connection method, etc., which facilitates daily inspection, cleaning, maintenance and replacement of parts, and reduces the maintenance cost and downtime of the equipment.

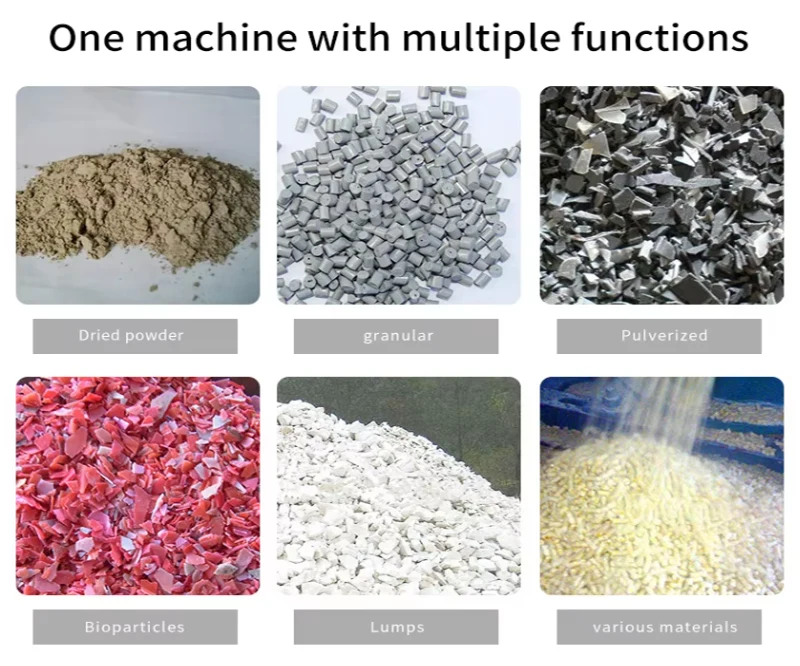

Applicable materials for fully automatic Hopper screw conveyor

Powdered materials: such as chemical raw materials, food additives, pharmaceutical powder, cement, lime powder, flour, etc.

Granular materials: such as grain (wheat, corn, soybeans, etc.), feed, plastic particles, resin particles, fertilizer particles, etc.

Small block materials: such as coal, ore, salt blocks, sugar blocks, etc., but the size of the material must meet the transportation requirements of the equipment to avoid damage to the equipment caused by oversized or hard materials.

Application industries of fully automatic Hopper screw conveyor

Chemical industry: used to transport various chemical raw materials, additives, catalysts, etc. to meet the material transportation needs in the chemical production process.

Building materials industry: widely used in the transportation of building materials such as cement, lime, gypsum, sand and gravel, providing efficient material transportation support for the production and processing of building materials.

Food industry: suitable for the transportation of food raw materials (such as flour, sugar, salt, grains, etc.) and food additives to ensure the hygiene and safety of the food production process.

Metallurgical industry: plays an important role in the transportation of materials such as ore, coal powder, coke, etc., and helps the smooth progress of metallurgical production.

Grain industry: can be used for the storage, processing and transportation of grain, to achieve efficient loading and unloading and transportation of grain, and ensure the quality and safety of grain.

If you are interested in our fully automatic Hopper screw conveyor, or have any questions and needs, please feel free to contact us. We will serve you wholeheartedly and look forward to working with you to create a better future!

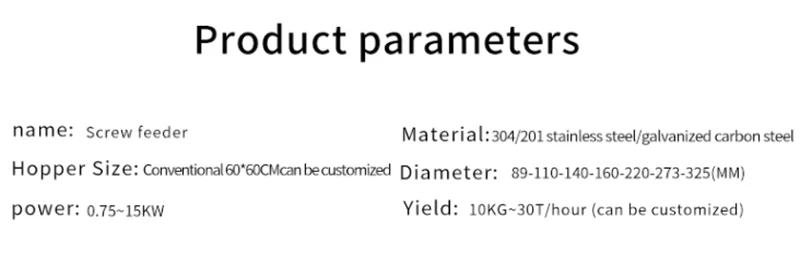

Products Description

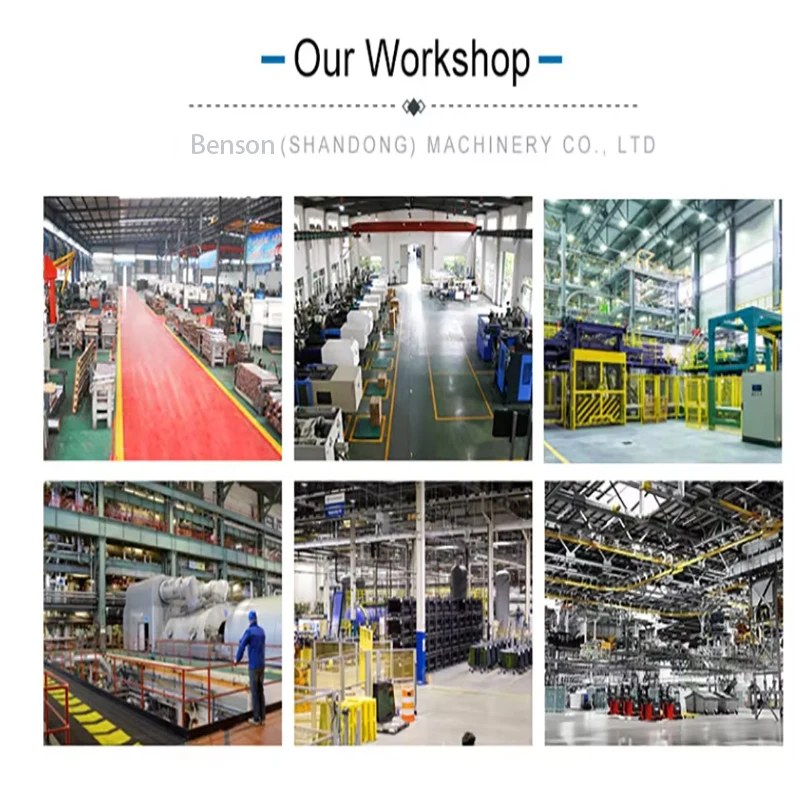

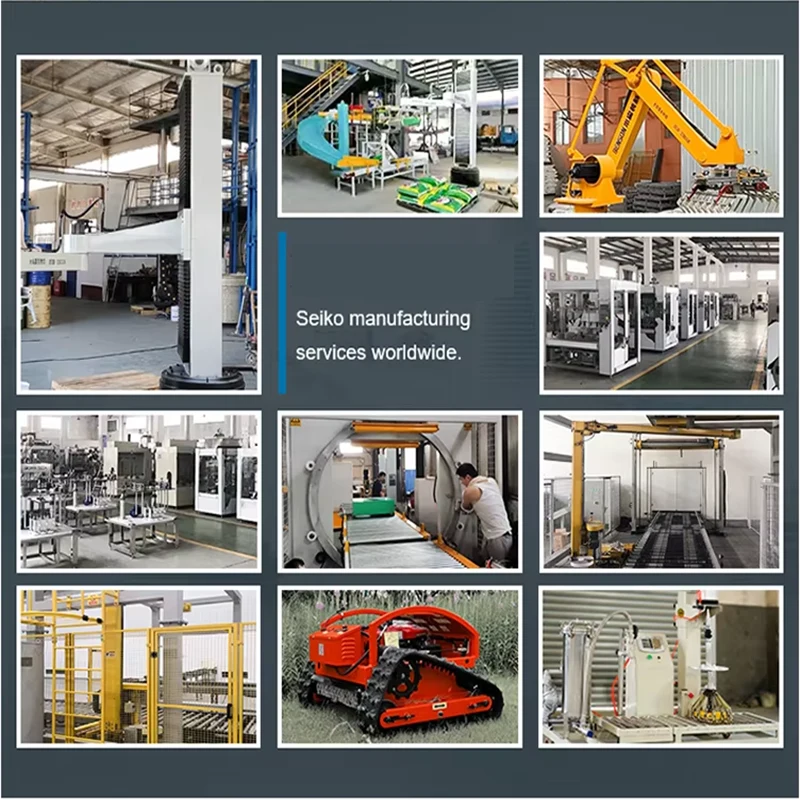

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry