Description

The Automatic Rotary Zipper Packaging Machine for Prefabricated Plastics and Glass is a packaging device specifically designed for products made of prefabricated plastic and glass materials. This device adopts advanced automatic control technology and a rotary working mode, enabling it to efficiently complete the packaging process of zipper bags. Its working process covers multiple links such as the precise transportation of materials, accurate filling into zipper bags,

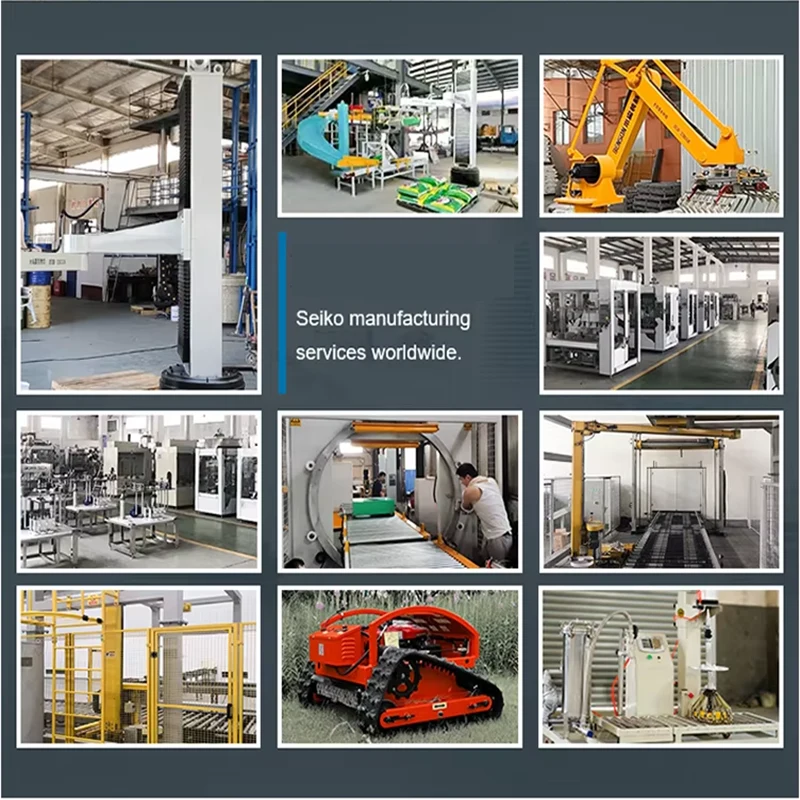

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Its working process covers multiple links such as the precise transportation of materials, accurate filling into zipper bags, and the sealing of zippers. The rotary structure of the device allows it to carry out production continuously and rapidly, meeting the production needs of large-scale and standardized production, and it can be flexibly adjusted according to the dimensions and shapes of different products.

Automatic Rotary Zipper Bag Packaging MachineAdvantages

1. High-efficiency Production: The automatic rotary working mode greatly improves production efficiency, enabling rapid product packaging, meeting the needs of large-scale production, and reducing manual operation time and costs.

2. Precise Packaging: Through precise control and metering systems, it ensures that products can be accurately filled into zipper bags, guarantees the consistency of packaging and the stability of quality, and reduces material waste.3. Good Material Compatibility: It is specially designed for products made of prefabricated plastic and glass materials and can adapt to products with different characteristics, such as fragile glass products and prefabricated plastic products with different hardness levels.

4. Strong Flexibility: It can flexibly adjust packaging parameters, such as the sealing degree of zippers and the size of bag openings, according to the different specifications and packaging requirements of products, meeting diverse production needs.

5. High Stability: By using high-quality components and advanced manufacturing processes, the device operates stably and reliably, has a low failure rate, low maintenance costs, and can run continuously for a long time.

Automatic Rotary Zipper Bag Packaging MachineApplication Areas

1. Food Industry: It is used for the zipper packaging of foods in prefabricated plastic packaging, such as candies, nuts, snacks, etc., and foods in glass packaging, such as canned goods, sauce bottles, etc.

2. Cosmetics Industry: It is suitable for the zipper bag packaging of cosmetics in containers like prefabricated plastic bottles and glass bottles, such as skin care products, perfumes, etc., protecting the safety of products during transportation and storage.

3. Pharmaceutical Industry: It can be used for the packaging of prefabricated plastic medicine boxes, pharmaceuticals in glass bottles, etc., meeting the hygiene and safety requirements of pharmaceutical packaging and ensuring the quality and effectiveness of medicines.

4. Daily Necessities Industry: It is suitable for the zipper bag packaging of daily necessities made of prefabricated plastic and glass materials, such as detergents, disinfectants, glassware, etc., making it convenient for users to use and store.

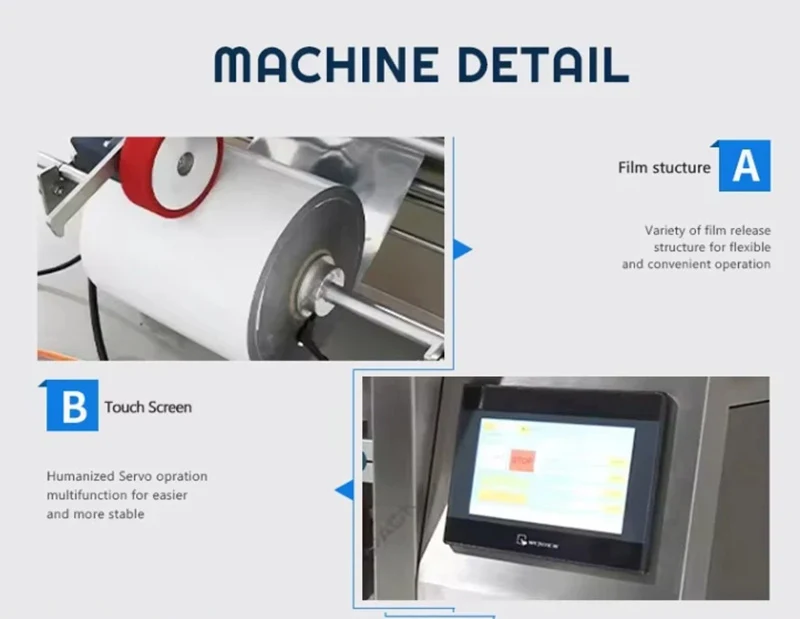

Automatic Rotary Zipper Bag Packaging MachineFeatures

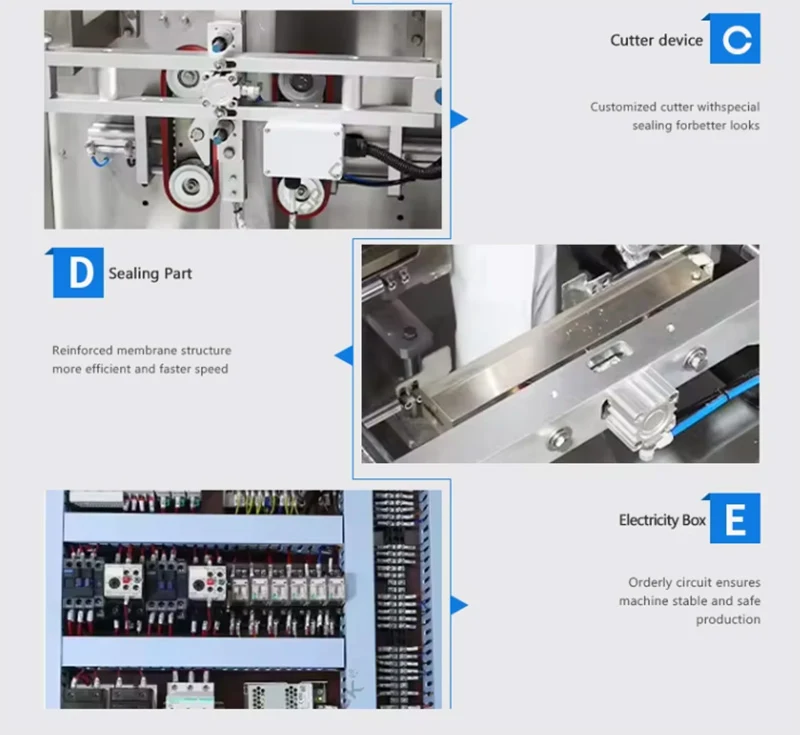

1. Automatic Control: Equipped with an advanced automatic control system, it realizes fully automated operation from material transportation, filling to zipper sealing, reducing manual intervention and improving production efficiency and packaging quality.

2. Rotary Structure: With a unique rotary design, the device can operate continuously and efficiently, improving production capacity while saving space.

3. Multifunctionality: It has multiple functions, such as the installation and sealing of zippers, the heat sealing of bag openings, and the metering and filling of products, achieving one-stop packaging.

4. Safety Protection: It is equipped with a complete set of safety protection devices, such as emergency stop buttons, safety light curtains, etc., to ensure the safety of operators.

5. Easy Maintenance: The device has a reasonable structural design, facilitating daily maintenance and reducing the difficulty and cost of repairs.

Products Description

Product Inquiry