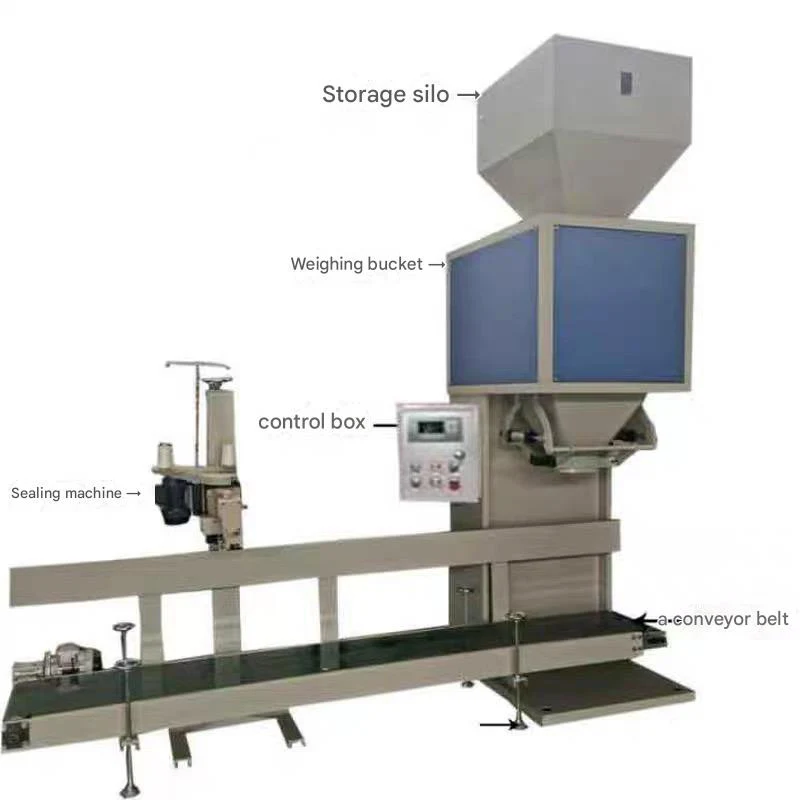

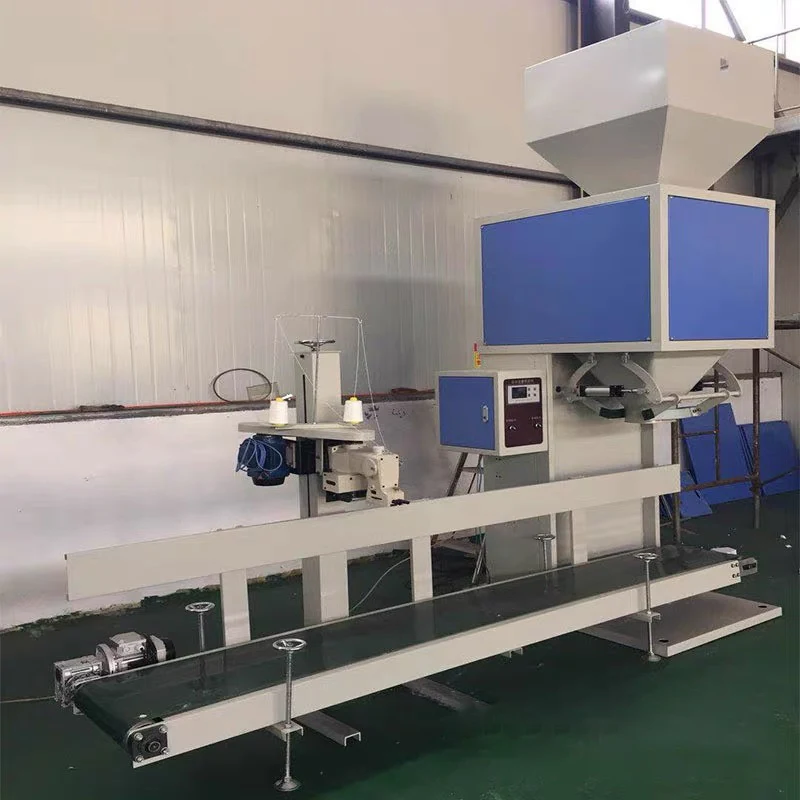

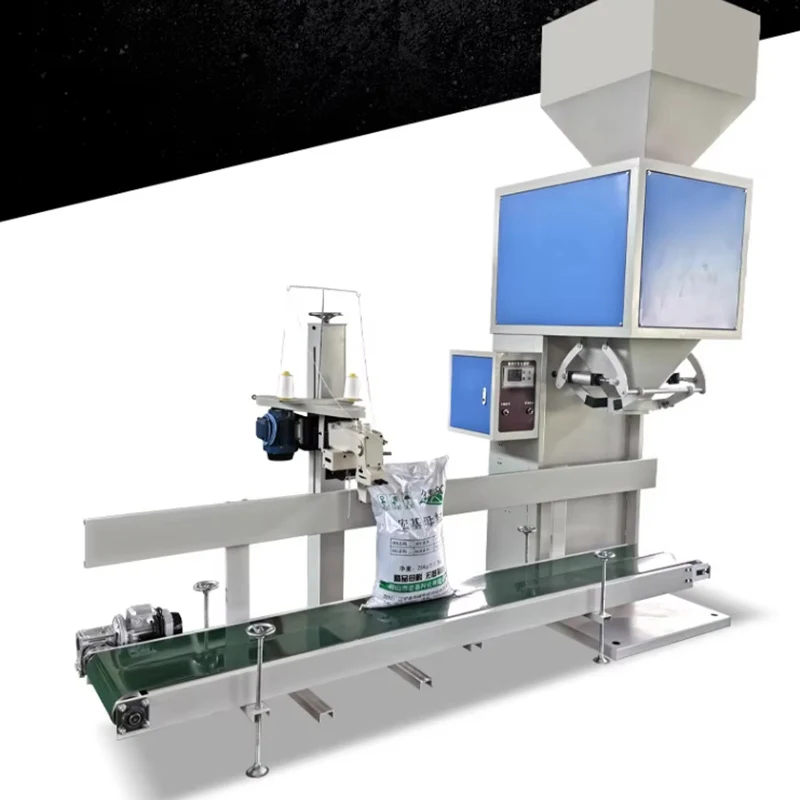

The automatic quantitative packaging machine is a highly automated packaging equipment, mainly used for accurately packaging various materials according to preset weights or volumes. It integrates advanced weighing technology, an automated control system, and a mechanical transmission system.In terms of structure, it is usually composed of components such as a feeding mechanism, weighing unit, filling device, sealing mechanism, and conveying system. The feeding mechanism is responsible

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed servic

Benson Advantages of Automatic Quantitative Packaging Machine

1. High - precision measurement: By using high - precision load cells and advanced weighing algorithms, it can achieve accurate measurement within a very small error range, ensuring that the weight or volume of each package of products meets the standard. This greatly reduces material waste and improves the stability of product quality. For example, when packaging candies in the food industry, it can precisely control the weight of each bag of candies, avoiding customer complaints due to inaccurate weights.

2. Efficient production: It has the ability to operate at high speed and can complete the packaging of a large amount of materials in a short time. Compared with manual packaging, it greatly improves production efficiency. Taking fertilizer packaging as an example, an automatic quantitative packaging machine can package hundreds of bags of fertilizer per hour, meeting the rapid supply demand for fertilizers during the peak agricultural production season.

3. Labor cost reduction: The automated packaging process reduces the dependence on manual labor, reducing the intensity of manual operation and labor costs. Enterprises do not need to hire a large number of packaging workers, and at the same time, it also reduces product quality problems caused by non - standard manual operations.

4. Simple operation: It is equipped with a user - friendly operation interface, such as a touch - screen operation terminal. Operators can start operating after simple training. Packaging parameters such as packaging weight and packaging speed can be easily set, and the operating status of the equipment is displayed in real - time, facilitating monitoring and management.

Benson Features of Automatic Quantitative Packaging Machine

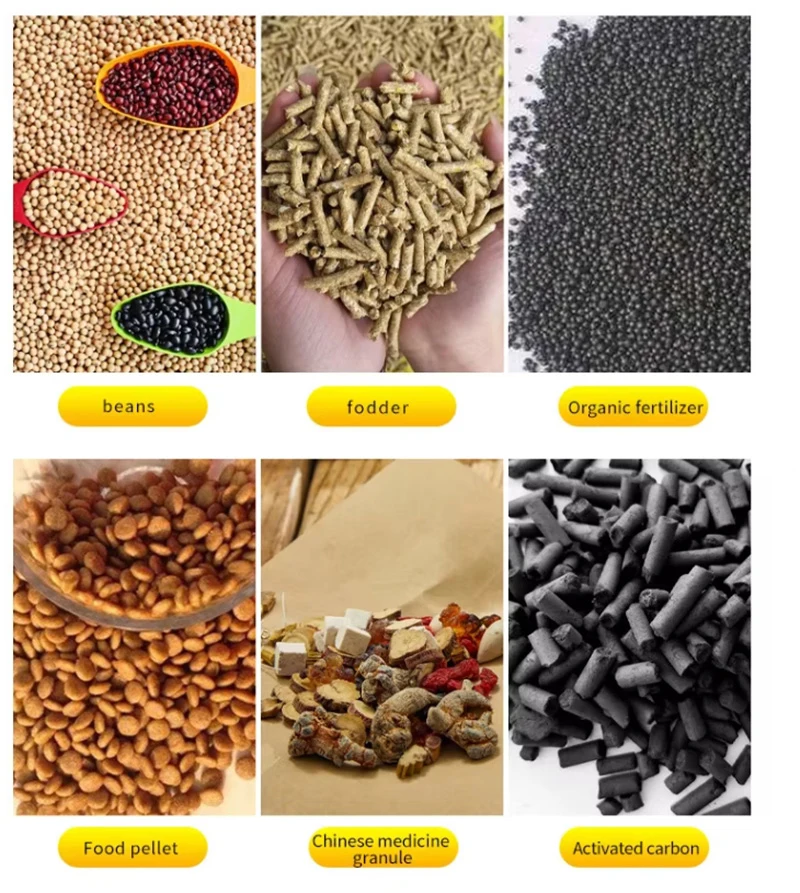

1. Strong adaptability: It can adapt to various materials in different forms, such as granular (e.g., rice, plastic granules), powdered (e.g., flour, cement), and liquid (e.g., cooking oil, beverages). At the same time, it can also be adapted to different specifications of packaging materials, such as packaging bags and boxes of different materials and sizes, meeting diverse packaging requirements.

2. High stability: It uses high - quality mechanical components and electrical elements. The equipment has a reasonable and sturdy structure design. After strict testing and debugging, it has good anti - interference ability and stability, and can operate stably for a long time continuously, reducing downtime due to failures and improving the utilization rate of the equipment.

3. Flexibility and scalability: It can be flexibly configured and functionally extended according to production needs. For example, functions such as automatic labeling, coding, and metal detection can be added to meet the personalized packaging requirements of different customers.

4. Convenient cleaning and maintenance: The structure design of the equipment takes into account the convenience of cleaning and maintenance. Some components can be disassembled for cleaning, reducing the risk of material residue and contamination. At the same time, the fault diagnosis system can quickly locate the fault points, facilitating maintenance personnel to carry out maintenance and repairs in a timely manner.

Benson Applications of Automatic Quantitative Packaging Machine

1. Food industry: Widely used in the packaging of various foods such as rice, flour, sugar, salt, nuts, milk powder, and seasonings. It ensures the accurate weight of food packaging, complies with food safety standards, and at the same time improves the packaging efficiency and product image of food production enterprises.

2. Agricultural field: Used for the packaging of agricultural production materials such as seeds, fertilizers, and feeds. For example, it conducts quantitative packaging of seeds of different specifications, facilitating farmers' purchase and use; it also conducts large - scale and rapid packaging of fertilizers and feeds to meet the needs of agricultural production.

3. Pharmaceutical industry: Plays an important role in the packaging of pharmaceutical products such as powder drugs, granular agents, and capsules. It ensures the accuracy and consistency of drug packaging dosage, complying with the strict quality standards of pharmaceutical production.

4. Daily chemical industry: Applicable to the packaging of daily chemical products such as washing powder, body wash, shampoo, and toothpaste. It realizes the automated quantitative packaging of daily chemical products, improving production efficiency and reducing production costs.

5. Industrial field: Used for the packaging of industrial materials such as building material additives (e.g., cement additives, concrete admixtures), plastic granules, metal powders, and chemical raw materials. It meets the requirements for the accuracy and efficiency of material packaging in industrial production.

Products Description

Product Inquiry