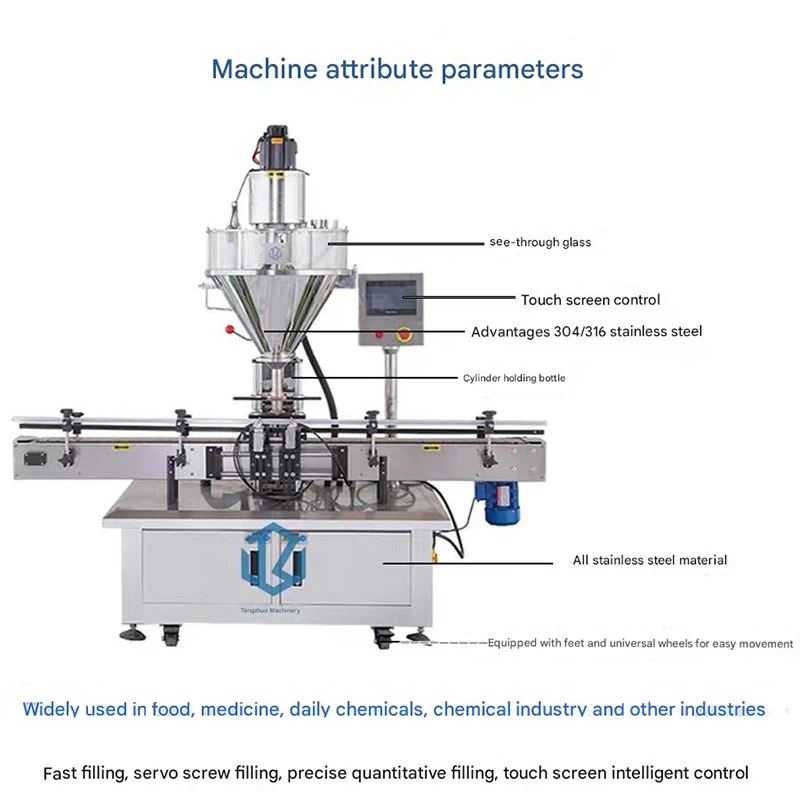

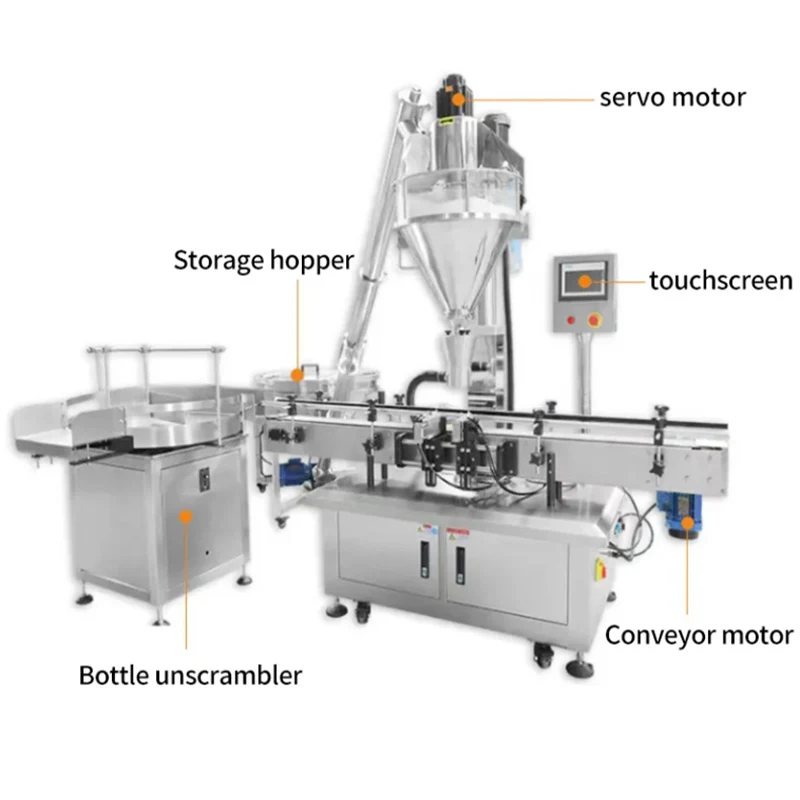

The automatic powder packaging machine is an automated equipment designed for precise measurement, filling and packaging of powdery materials. It integrates functions such as powder metering, bag feeding, filling, sealing, coding and conveying. Through an intelligent control system (such as PLC), the machine can automatically complete the whole process from material measurement to finished product output. It is suitable for various packaging materials (e.g., plastic bags, paper bags, aluminum

The column palletizer is a compact, space-saving automated palletizing machine....

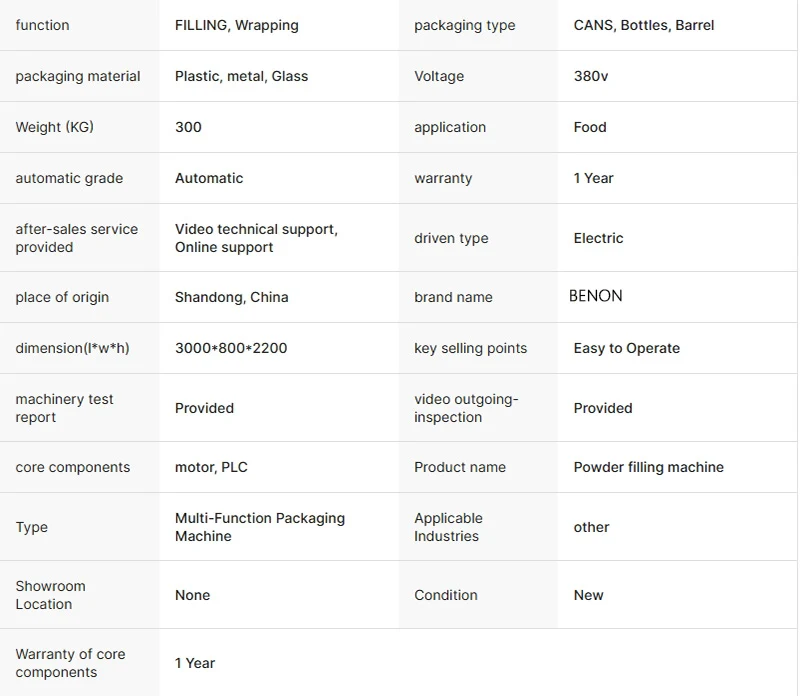

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Automatic Powder Packaging MachineAdvantages

1. High Efficiency:Fully automated operation significantly reduces manual intervention, with a packaging speed much higher than traditional manual or semi-automatic equipment, meeting mass production needs.

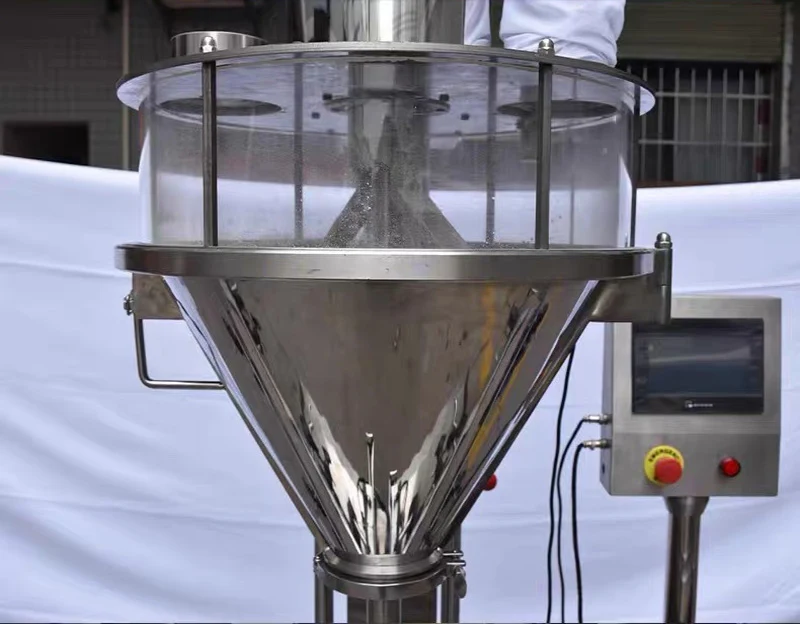

2. Precision Measurement:Equipped with advanced metering devices (e.g., screw feeders, auger fillers), it achieves high-precision dosing, with weight error typically controlled within ±0.5%-1%, ensuring product consistency.

3. Cost Saving:Reduces labor costs through automation and minimizes material waste via precise filling and reliable sealing, lowering long-term production costs.

4. Flexibility:Adjustable parameters (e.g., packaging weight, bag size, sealing mode) enable quick switching between different products and packaging specifications, adapting to diverse market demands.

5. Hygiene & Safety:Closed filling structure and food-grade material contact parts meet hygiene standards for food and pharmaceutical industries; safety alarms and emergency stop functions protect operators.

Automatic Powder Packaging MachineApplications

- Food Industry:Suitable for packaging milk powder, coffee, seasonings, flour, instant drinks, etc., ensuring hygiene and freshness.

- Pharmaceutical Industry:Used for medical powders, nutritional supplements, herbal powders, etc., meeting GMP standards for precision and cleanliness.

- Chemical Industry:Applies to industrial powders like pigments, dyes, fertilizers, and pesticides, with anti-corrosion and dust-proof designs for safe handling.

- Cosmetics Industry:Fills face powder, bath salts, cosmetic powders, etc., ensuring accurate dosing and elegant packaging.

Automatic Powder Packaging MachineFeatures

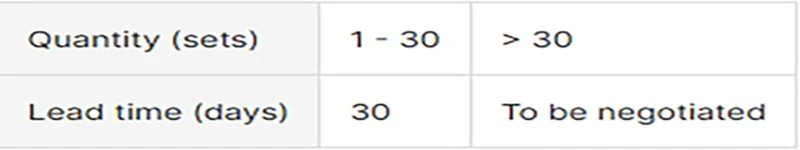

1. Intelligent Control:Touch screen interface and PLC system enable easy parameter setting, production monitoring and fault diagnosis, with high operational intuitiveness.

2. Modular Design:Detachable components (e.g., filling heads, sealing units) facilitate quick cleaning and maintenance, improving production efficiency.

3. High-Speed Sealing:Adopts heat-sealing, impulse-sealing or ultrasonic sealing technologies for firm, leak-proof seals and high-speed operation (e.g., 20-60 bags/minute).

4. Multi-Sensor Monitoring:In-built sensors detect material shortages, bag misalignment, sealing failures, etc., triggering real-time alarms to reduce downtime.

5. Energy Saving:Frequency conversion speed regulation and energy-efficient motors optimize power consumption, suitable for long-term continuous operation.

Lead time

Products Description

<img src="/uploads/allimg/20250520/1-2505201031223c.webpAutomatic Powder Packaging Machine alt="微信图片_20250429163152.jpg"/>

Product Inquiry