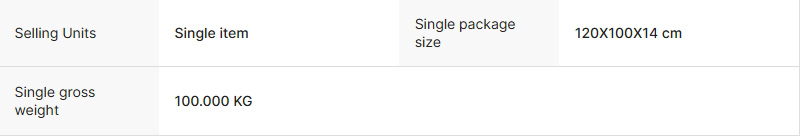

An automatic powder filling machine is an automated device designed for precise measurement and filling of powdery materials. Its core structure includes a storage hopper, a precision metering system (such as screw, volumetric, or weighing metering devices), a filling head, a conveying device, and an intelligent control system. During operation, powdery materials are accurately measured by the metering system from the storage hopper and filled into packaging containers

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

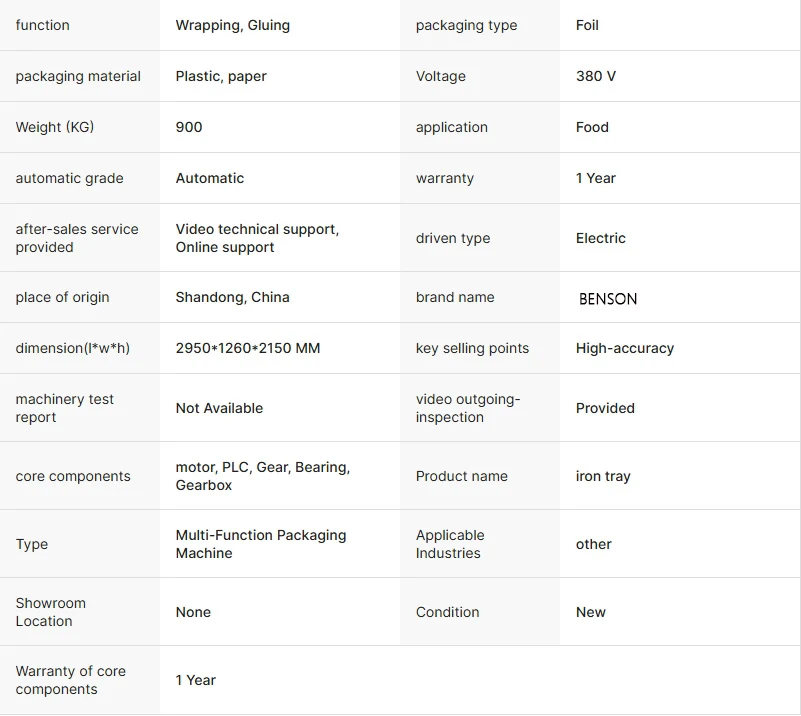

Automatic Powder Filling MachineAdvantages

1. High-precision metering: Using technologies such as screw metering and weighing feedback, the filling accuracy can reach ±0.5% to ±2%, meeting the strict quantitative requirements of industries such as pharmaceuticals and food.

2. Efficient production: It can complete 10–60 fillings per minute (depending on the model), adapting to mass production and increasing efficiency by 3–5 times compared to traditional manual filling.

3. Low dust pollution: The closed filling channel and dust removal interface design reduce powder flying, improve the working environment, and comply with hygiene standards such as GMP.

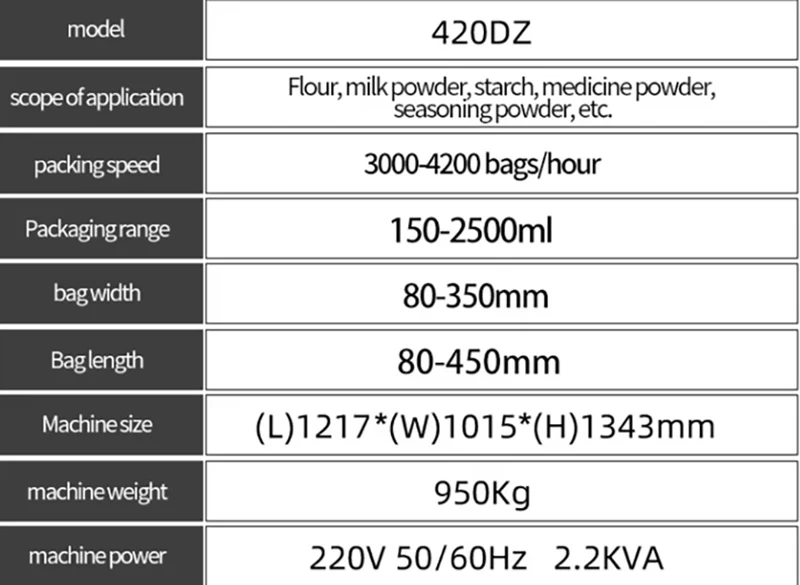

4. Flexible adaptation: By replacing metering components or adjusting parameters, it can quickly switch between different powders (such as flour, milk powder, pharmaceutical powder, and chemical powder) and packaging specifications (50g–50kg).

5. Intelligent management and control: The touchscreen operation interface supports parameter storage, production data statistics (such as output and material consumption), and is equipped with a fault self-diagnosis function to reduce operation and maintenance costs.

Automatic Powder Filling MachineCharacteristics

1. Modular design: Key components (such as metering devices and filling heads) can be quickly disassembled and cleaned, facilitating maintenance and model changeover production, suitable for multi-variety and small-batch scenarios.

2. Dust-proof and explosion-proof: For hygroscopic or flammable and explosive powders (such as metal powders and starch), nitrogen filling protection and anti-static materials can be optionally configured to enhance safety.

3. Environmental protection and energy saving: Low-energy consumption motors and optimized pneumatic systems reduce operating costs, and waste recycling devices reduce material waste.

4. Production line compatibility: It can be linked with automatic bagging machines, sealing machines, metal detectors, and other equipment to form a fully automated packaging production line.

Automatic Powder Filling MachineApplication Fields

1. Food industry: Used for quantitative filling of powders such as milk powder, coffee powder, seasonings, and starch, adapting to retail packaging (such as bags and cans) and large-scale industrial packaging.

2. Pharmaceutical industry: Meets the aseptic filling needs of pharmaceutical powders and health product powders, supports precision packaging such as西林 bottles (vials) and aluminum foil bags, and complies with GMP cleanliness standards.

3. Chemical industry: Fills pigments, coating powders, plastic additives, etc. For corrosive materials, stainless steel or corrosion-resistant material components can be optionally configured.

4. Building materials industry: Used for large-scale filling of cement, putty powder, coating powders (such as 25kg/bag), and achieves efficient operation with supporting automatic sewing machines.

5. Pesticide and fertilizer industry: Prevents leakage during the filling of pesticide powders and fertilizer granules, reduces the risk of manual contact with toxic materials, and improves safety.

<img src="/uploads/allimg/20250522/1-25052209403V26.webp" title="Automatic Powder Filling Machine alt="5.22发品31.jpg修改.jpg"/>

Product Inquiry