Food grade conveyor belt: adopt conveyor belt materials that meet food hygiene standards, such as PU (polyurethane), silicone, etc. Among them, PU conveyor belt has passed the US FDA hygiene standard certification, is non-toxic and odorless, can be in direct contact with food, and is made of selected food grade raw materials, adding nano anti-sticking factors to avoid food adhesion, good oil resistance, and convenient cleaning and maintenance;

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

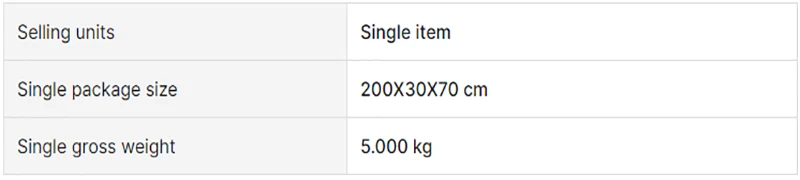

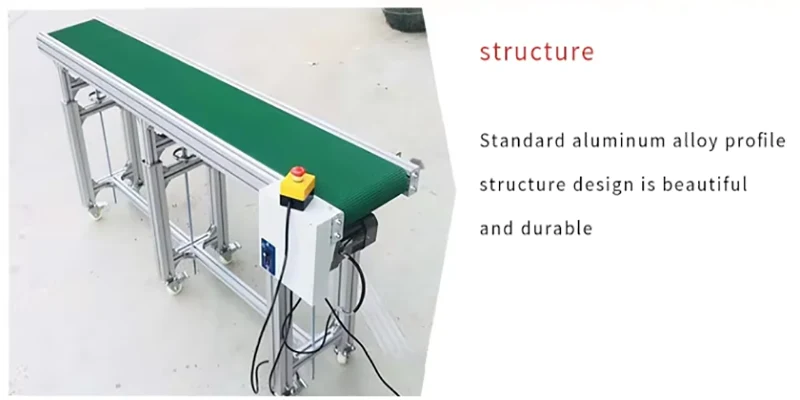

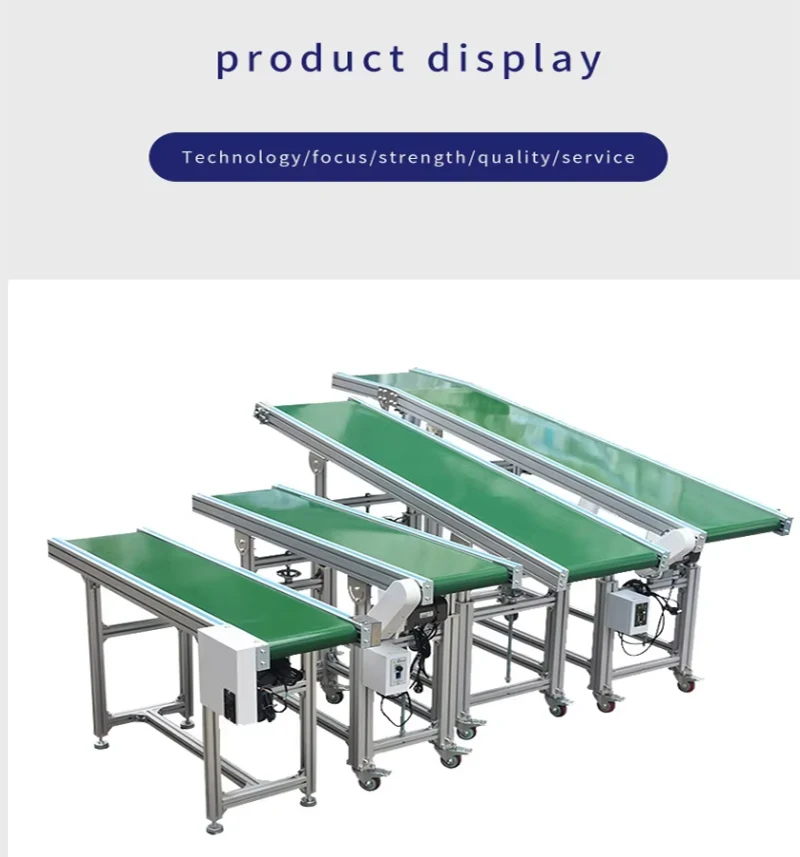

Customizable Capacity: Its compact design (200x30x70cm) and lightweight (30kg) make it an ideal choice for small to medium-sized production facilities, allowing for easy relocation and flexible production capacity adjustments based on user input.

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Product introduction of belt conveyor for food industry

In the production process of food industry, efficient and safe transportation of materials is very important, and belt conveyor for food industry is a powerful assistant for this purpose, providing stable and reliable transportation solutions for food production enterprises.

Hygiene and safety of belt conveyor for food industry

Material and structural design: The conveyor frame is mostly made of 304 stainless steel, which is corrosion-resistant and rust-proof, and meets the strict requirements of food production environment. At the same time, the structural design avoids sanitary dead corners, the surface is smooth, and the adhesion and breeding of dirt and bacteria are reduced, which is convenient for daily cleaning and regular disinfection, and comprehensively guarantees the hygienic safety of food during transportation.

Conveying performance of special belt conveyor for food industry

Stable and efficient: strong conveying capacity, and can flexibly adjust the conveying speed and conveying volume according to the weight, volume and production output requirements of different foods. Whether it is a small food workshop or a large food processing plant, it can meet the production rhythm. It runs smoothly, and there is no relative movement between the material and the conveyor belt, which effectively avoids collision, scratching and other damage to the food, ensuring the integrity and quality of the food. For example, in the transportation of baked food, it can gently hold the freshly baked bread and convey it along a fixed route without displacement and deformation.

Wide adaptability: It is suitable for the transportation of various food forms, such as bulk grains, granular candies, canned beverages, and packaged food. At the same time, it can meet the transportation needs in different food production processes, from the transportation of raw materials, the circulation during the processing, to the packaging of finished products, and can play an important role in the slaughtering, cutting, and packaging of meat processing, as well as the cleaning, sorting, and packaging of fruit and vegetable processing.

The belt conveyor for the food industry has various functions

1. Diversified transportation forms: It has various forms such as horizontal transportation, climbing transportation, and turning transportation. The climbing belt conveyor is suitable for continuous transportation of goods between floors or height differences. When the inclination angle is small (≤30°), the objects can be lifted and transported at a larger angle by adding strips, fixtures, skirts, etc. to the belt; the standard turning inner radius of the turning belt conveyor has a variety of specifications (such as R600, R900, R1200mm, etc.), and special specifications can also be customized according to customer needs to achieve smooth transportation of food in complex production layouts.

2. Customizable configuration: The conveyor can be customized according to the special requirements of the food production process. For example, add push plates, side baffles, skirts and other accessories to the conveyor belt to achieve directional transportation of food and prevent materials from falling; configure electronic speed regulation, frequency conversion speed regulation, stepless speed regulation and other speed regulation devices to meet the different requirements of conveying speed in different production links; it can also be equipped with guidance bookshelves, power sockets, pneumatic quick connectors, hanging rails, exhaust system engineering and other workstation facilities to improve overall production efficiency and convenience.

Easy maintenance

1. Simple structure: The overall structural design is concise and clear, and each component is highly standardized, which is easy to install, disassemble and maintain. Daily maintenance work is easy, such as flushing the surface of the conveyor belt with water and wiping it with a rag, and it can continue to be put into use; when the components are damaged and need to be replaced, the operation can be completed quickly, reducing equipment downtime and ensuring the continuity of food production.

2. Low energy consumption: The use of advanced drive technology and energy-saving design reduces energy consumption and production costs of enterprises while ensuring efficient transportation, which is in line with the production concept of sustainable development and provides strong support for the long-term and stable operation of food enterprises.

Products Description

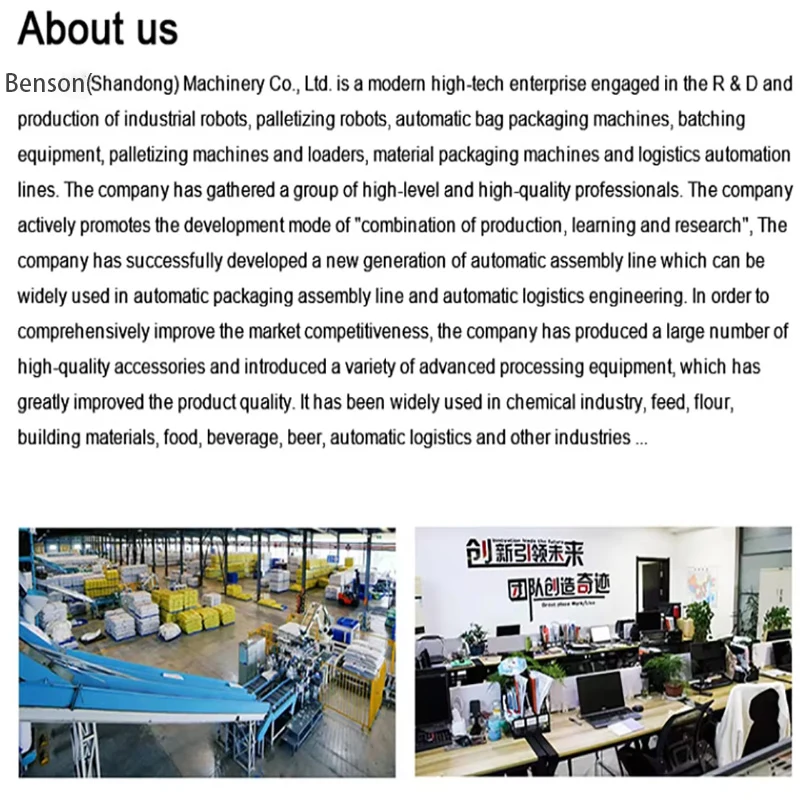

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry