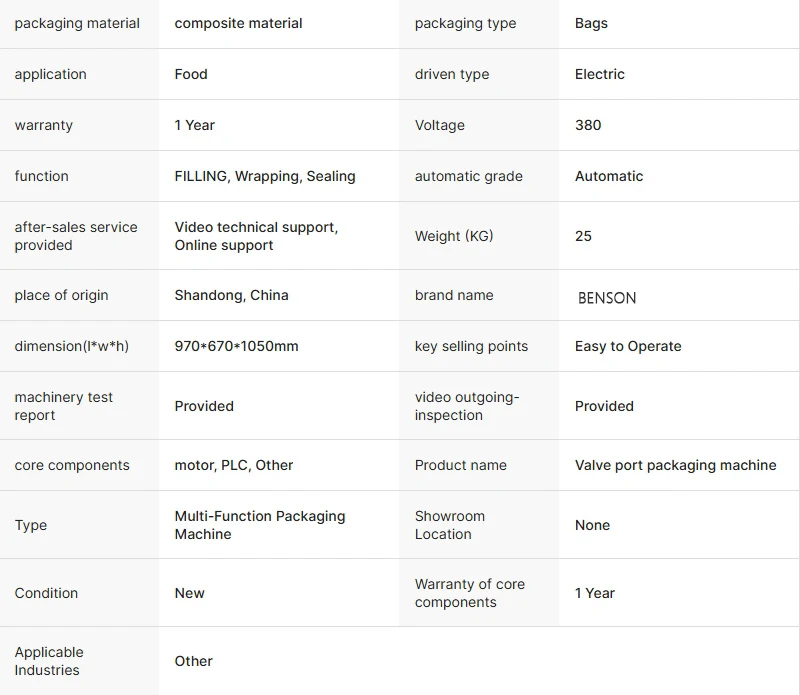

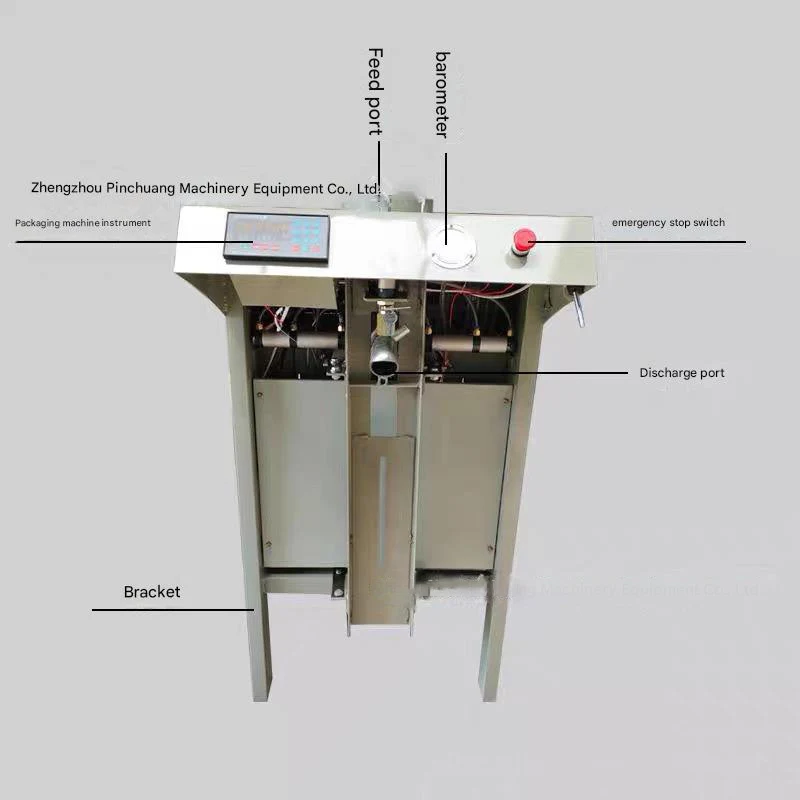

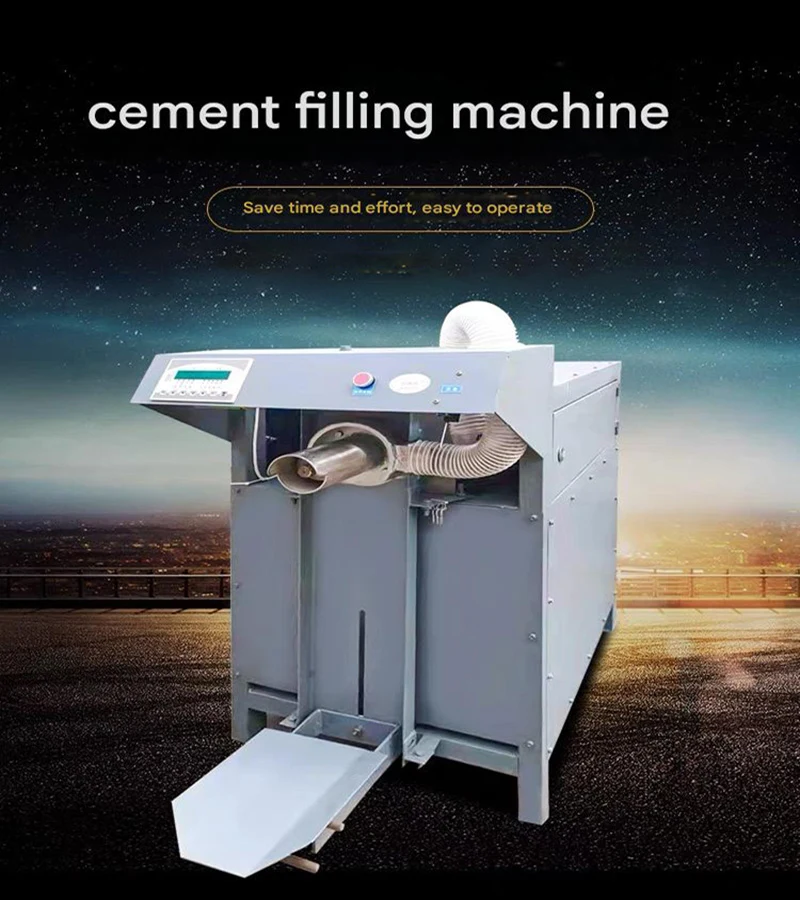

The automatic bag - in - valve packaging machine is a highly automated packaging equipment mainly used to package products in bags with a valve structure. This equipment integrates multiple technologies such as mechanical, electronic, and pneumatic technologies.Its working process is usually as follows: First, pre - fabricated bags with valves are conveyed to the designated workstations. Then, through precise metering devices, according to the product characteristics

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Lead time

After filling is completed, the bags are sealed using heat - sealing or other sealing techniques to ensure the integrity and airtightness of the packaging. The entire process is controlled by an advanced PLC (Programmable Logic Controller) system, enabling real - time monitoring of the equipment's operating status and parameter adjustment.

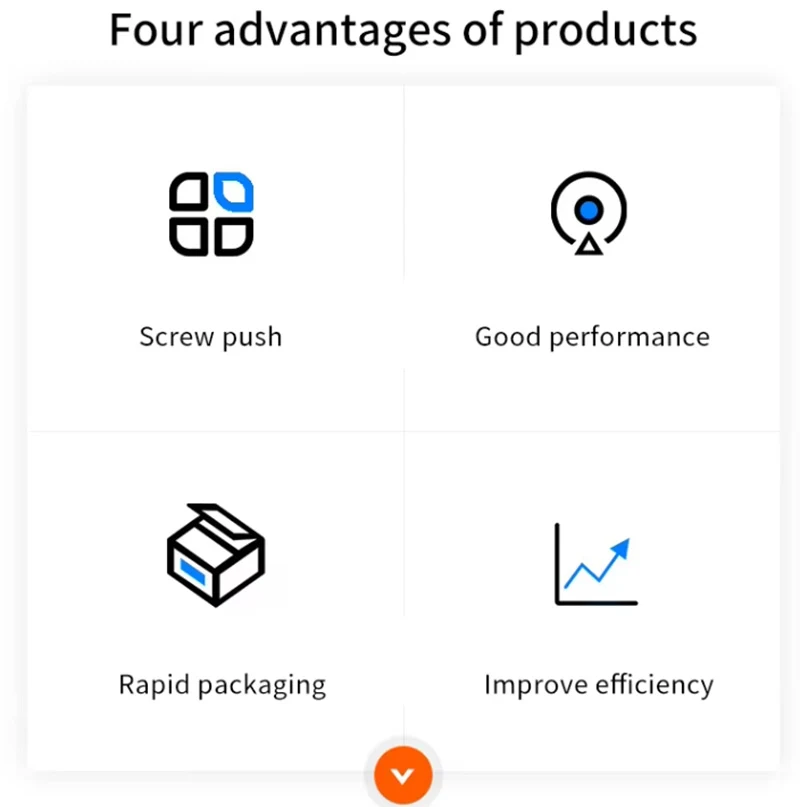

Benson Advantages of Automatic Bag - in - Valve Packaging Machine

1. High Sealing Performance: The bag - in - valve structure can effectively prevent the products inside the package from coming into contact with external air, moisture, etc. For products sensitive to the environment (such as oxidizable foods, pharmaceuticals, fine chemical products, etc.), it can greatly extend their shelf life and stability.

2. Precise Metering: Equipped with a high - precision metering system, whether it is volume metering for liquids or weight metering for powders and granules, it can achieve a high level of accuracy. The error can usually be controlled within a very small range, such as ±1%, ensuring the consistency of the specifications of each bag of products.

3. High Degree of Automation: From bag conveying, product filling to sealing, the entire packaging process requires little manual intervention, which greatly reduces labor costs and human errors. At the same time, it improves production efficiency. The packaging speed can reach dozens of bags per minute or even more, depending on the product and packaging specifications.

4. Flexible Adaptability: By adjusting the equipment parameters, it can adapt to bag - in - valve packaging of different specifications and sizes, as well as the packaging of various types of products. Whether it is small - dose sample packaging or large - scale industrial packaging requirements, it can be well - met.

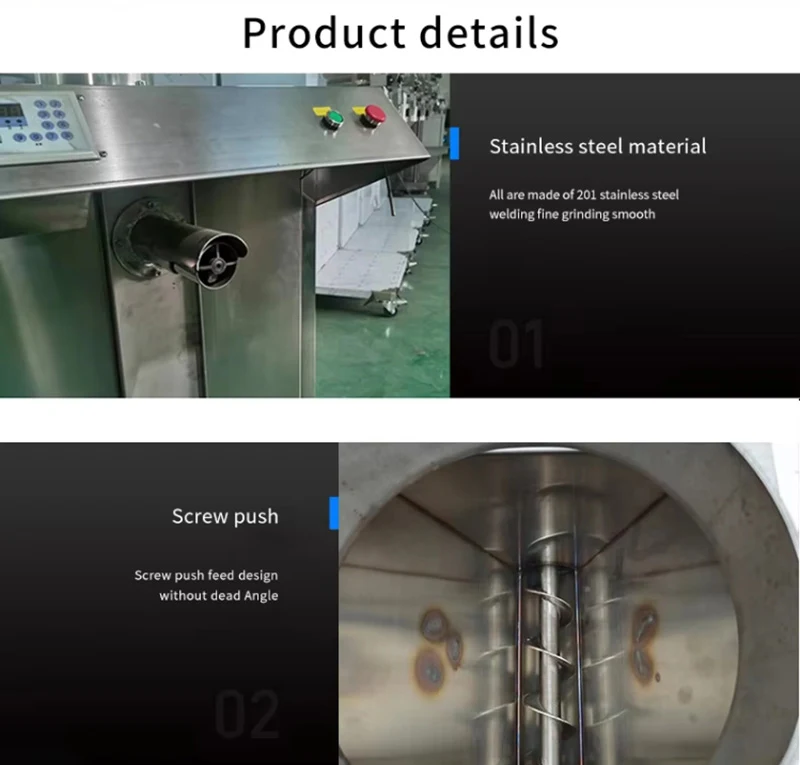

5. Hygienic and Environment - Friendly: The equipment is made of materials that meet food and pharmaceutical hygiene standards, and its internal structure is easy to clean and disinfect. During the packaging process, it can effectively prevent products from being contaminated, and at the same time, reduce material waste and dust emissions, meeting the environmental protection requirements of modern production.

Benson Features of Automatic Bag - in - Valve Packaging Machine

1. Intelligent Control: Using an advanced touch - screen human - machine interface, operators can intuitively and conveniently set packaging parameters such as packaging weight/volume, sealing temperature, speed, etc. At the same time, the equipment has a fault self - diagnosis and alarm function, which can quickly locate and prompt the fault point, facilitating maintenance personnel to handle it in a timely manner and reducing downtime.

2. Modular Design: The main components of the equipment adopt a modular design, such as the metering module, conveying module, sealing module, etc., which is convenient for maintenance and replacement. When a certain component fails or needs to be upgraded, it can be quickly replaced or upgraded without affecting the normal operation of other modules.

3. Safety Protection: Multiple safety protection devices are set, such as emergency stop buttons, photoelectric sensing devices, protective fences, etc., which can effectively prevent operators from being accidentally injured during the operation of the equipment and ensure production safety.

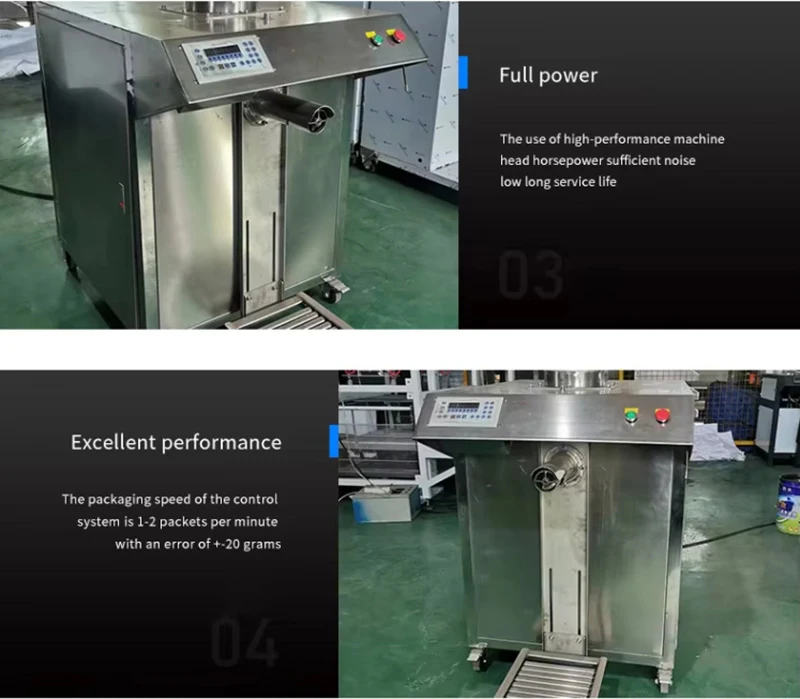

4. High Efficiency and Stability: The optimized mechanical transmission system and electrical control system make the equipment operate stably and reliably. Under the condition of long - term continuous operation, it can still maintain high packaging efficiency and stable packaging quality.

Applications of Automatic Bag - in - Valve Packaging Machine

1. Food Industry: Suitable for packaging various foods with high requirements for airtightness, such as coffee, tea, nuts, edible oil, sauces, etc. Bag - in - valve packaging can effectively prevent foods from getting damp and oxidizing, and maintain the flavor and quality of foods.

2. Pharmaceutical Industry: Used for packaging pharmaceutical powders, granulas, capsules, etc. Its high airtightness can prevent pharmaceuticals from being contaminated and deteriorating by the outside world, ensuring the safety and effectiveness of pharmaceuticals.

3. Chemical Industry: Widely used for packaging various chemical raw materials, such as coatings, inks, adhesives, pesticides, fertilizers, etc. It can meet the special packaging requirements of chemical products for moisture - proof, anti - leakage, anti - volatilization, etc.

4. Daily Necessities Industry: For the packaging of products such as cosmetics (such as loose powder, lotion) and cleaners (such as laundry liquid, detergent), the automatic bag - in - valve packaging machine can provide a beautiful, practical, and well - sealed packaging solution.

5. Automotive Care and Lubricant Industry: Used for packaging automotive lubricants, cleaners, protectants, etc., which is convenient for storage and use, and can effectively prevent product leakage and deterioration.

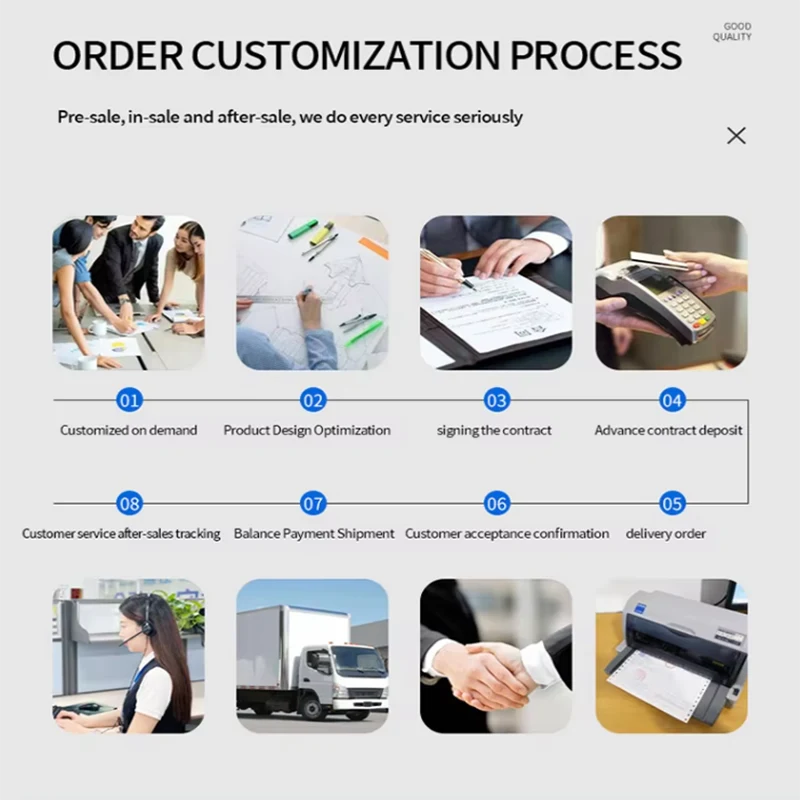

Products Description

Product Inquiry