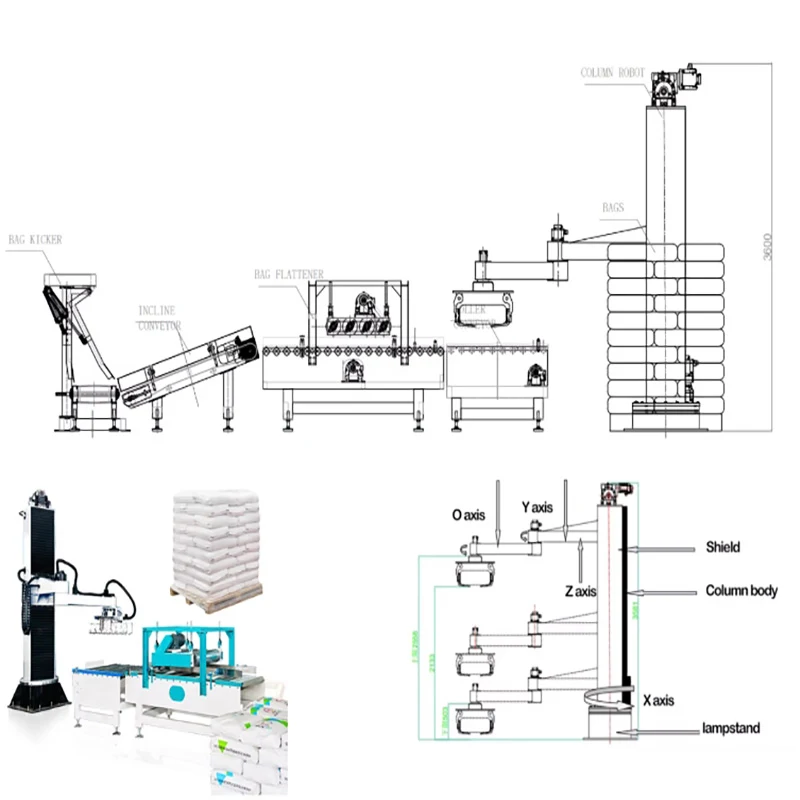

The automatic PLC - controlled column stacker is the core equipment of modern intelligent warehousing, achieving precise automated operation through a Programmable Logic Controller (PLC). In terms of hardware, the double - column structure ensures stability. The variable - frequency motor and servo system drive the stacker to move horizontally and vertically. The laser rangefinder and encoder, combined with RFID identification, achieve precise positioning at the ±5mm level.

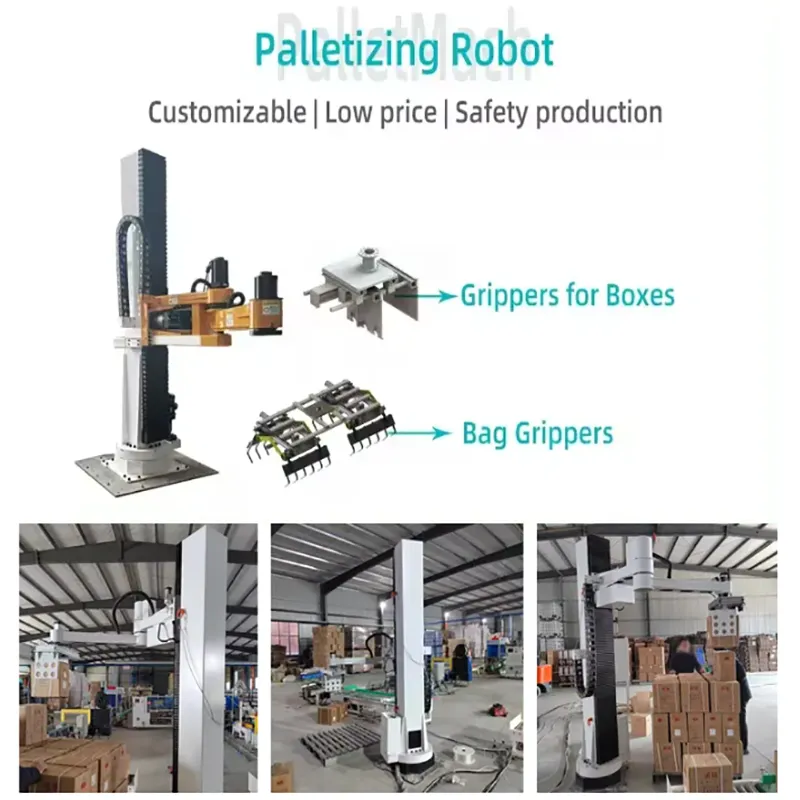

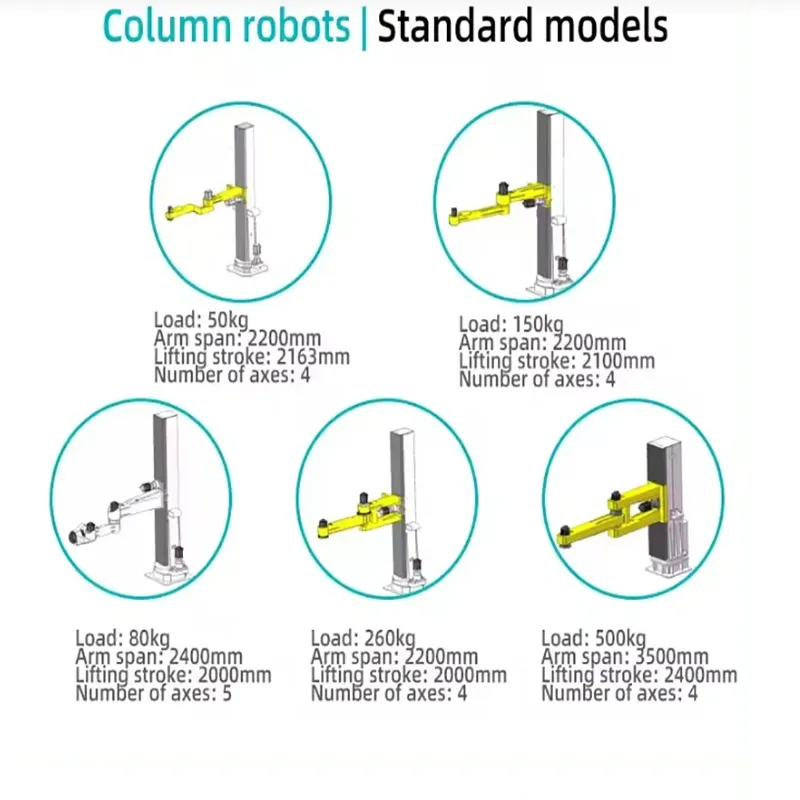

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

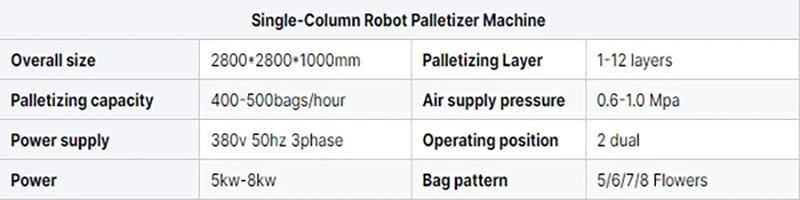

Products Description

Automatically PLC - controlled column stacker

In the steel forest of intelligent warehousing, the automatic PLC - controlled column stacker is like a nimble mechanical dancer, precisely pe

rforming the precise ballet of goods storage and retrieval. Its upright column is equipped with a multi - layer fork mechanism. Under the in

telligent command of the PLC (Programmable Logic Controller), it can perceive the environment of the roadway in real - time with the help of a sensor matrix and complete three - dimensional space positioning with millimeter - level accuracy. When receiving instructions from th

e warehouse management system, the Automatically PLC - controlled column stacker quickly analyzes the tasks, drives the servo motor to ma

ke the stacker move smoothly along the roadway track, and the vertical lifting mechanism starts simultaneously. With the dexterous pickin

g of the telescopic forks, it can accurately lift the designated goods from the stereo rack within a few seconds. Whether it is the shuttle ope

ration in the high - density storage area or the challenge of the low - temperature environment in the cold - chain warehouse, the PLC - co

ntrolled stacker can efficiently coordinate the flow of goods through preset programs and dynamic algorithms, increasing the warehousing

efficiency to more than three times that of traditional equipment and becoming the core hub of modern industrial logistics automation.

Automatic PLC control column stacker working process:

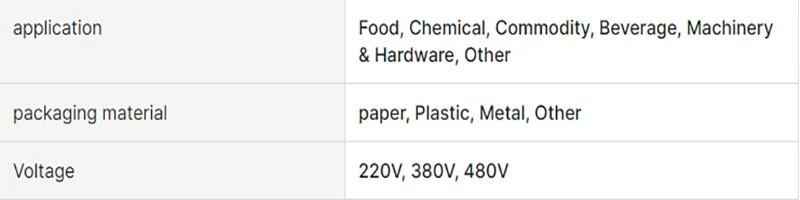

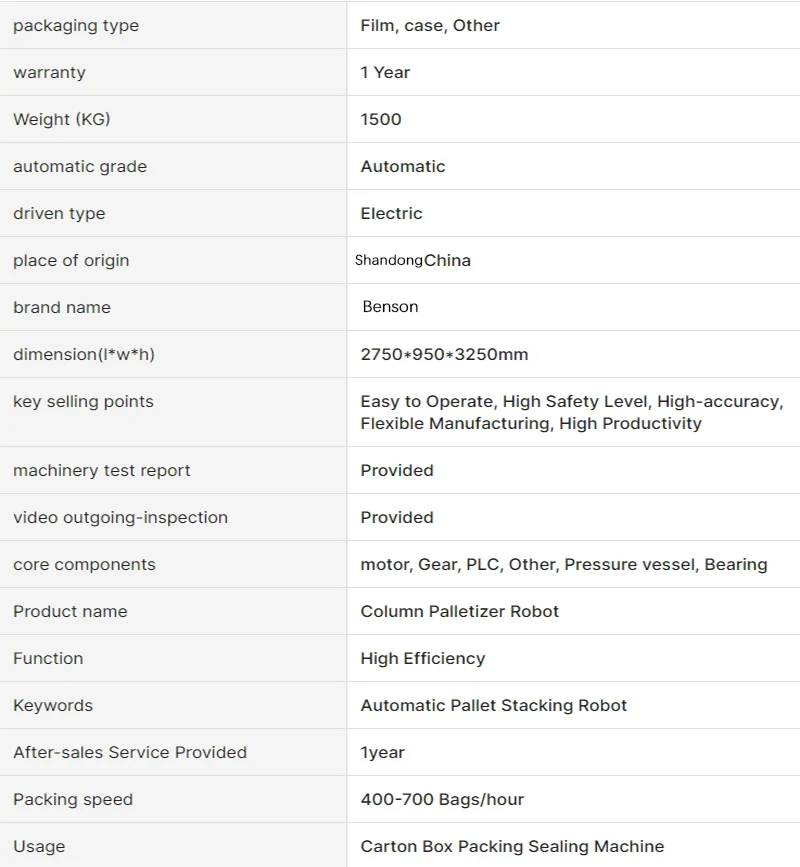

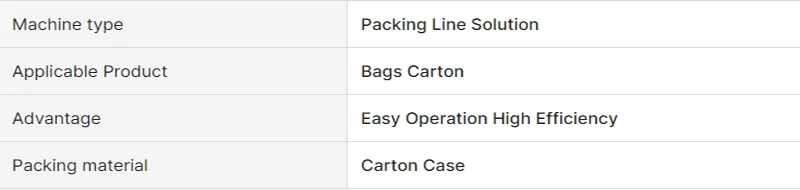

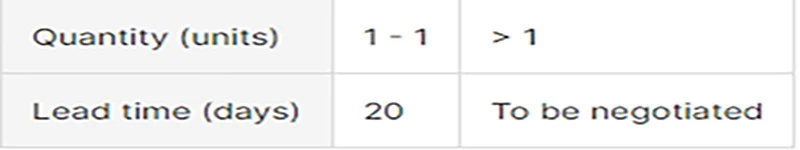

Specification

Main characteristics of the working process of the automatic PLC - controlled column stacker:

1.Full - process automation and precise control

Millimeter - level positioning ability: By driving servo motors through PLC, combining encoders (for horizontal movement) and laser rangefinders (for vertical lifting), a positioning accuracy of ±5mm in three - dimensional space is achieved, ensuring error - free cargo access.

Closed - loop feedback control: Each motion link (horizontal movement, vertical lifting, and fork extension and retraction) is equipped with real - time sensors (such as limit switches and weight sensors). The PLC dynamically adjusts the operating parameters according to the feedback data, forming a closed - loop control chain of "instruction - execution - verification".

2. Intelligent task analysis and path optimization

Multi - task priority management:automatic PLC - controlled column stacker The PLC can receive multiple sets of operation instructions simultaneously and automatically sort them according to factors such as task urgency and cargo location distribution, avoiding idle running or congestion of equipment.

Dynamic path - planning algorithm: Combining the operating status of equipment in the roadway (such as the positions of other stackers and AGVs), the shortest - path algorithm (such as the Dijkstra algorithm) is used to optimize the travel route in real - time, reducing the ineffective moving distance and increasing the operation efficiency by more than 30%.

3. Modular structure and flexible operation

Multi - layer fork collaborative operation: The multi - stage telescopic forks (such as single - deep and double - deep forks) carried by the column can be adapted to different specifications of pallets (such as 1200mm×1000mm standard pallets). The compatible handling of "light and small items" and "heavy goods" can be completed by switching the PLC program.

Multi - mode operation switching: It supports the "single - cycle mode" (single access task) and the "compound operation mode" (picking + placing in one trip), flexibly adapting to diverse needs such as warehousing, outbound, and inventory transfer

.

4. High - density storage and space utilization

Narrow - roadway operation ability: The width of the stacker is only 200 - 300mm wider than the shelf roadway and can operate in a high - density roadway with a width of ≤1.5m. Compared with the traditional forklift - shelf system, the storage space utilization is increased by 40% - 60%.

High - rise shelf adaptability: The vertical lifting speed can reach more than 120m/min, and the maximum operating height can reach 40 meters, meeting the storage needs of the stereoscopic warehouse for "upward expansion".

5. Multiple safety protection and reliability

Hardware - level safety design::automatic PLC - controlled column stacker Equipped with laser anti - collision sensors (detecting obstacles 2 - 5 meters ahead), mechanical buffers, emergency stop switches, etc. to prevent equipment collisions; the forks are equipped with anti - detection devices to ensure stable cargo grasping.

Fault self - diagnosis and fault - tolerance mechanism: The PLC monitors parameters such as motor current, temperature, and running time in real - time. If abnormalities (such as overload and overspeed) are detected, it immediately triggers a shutdown and sends an alarm to the WMS. At the same time, it saves the status data before the fault for quick troubleshooting.

6. System integration and data interconnection

Seamless connection with WMS: Through industrial protocols such as OPC UA and Modbus, inventory data, equipment status, and operation progress are synchronized in real - time, realizing digital management of the entire process of "order - warehousing - logistics".

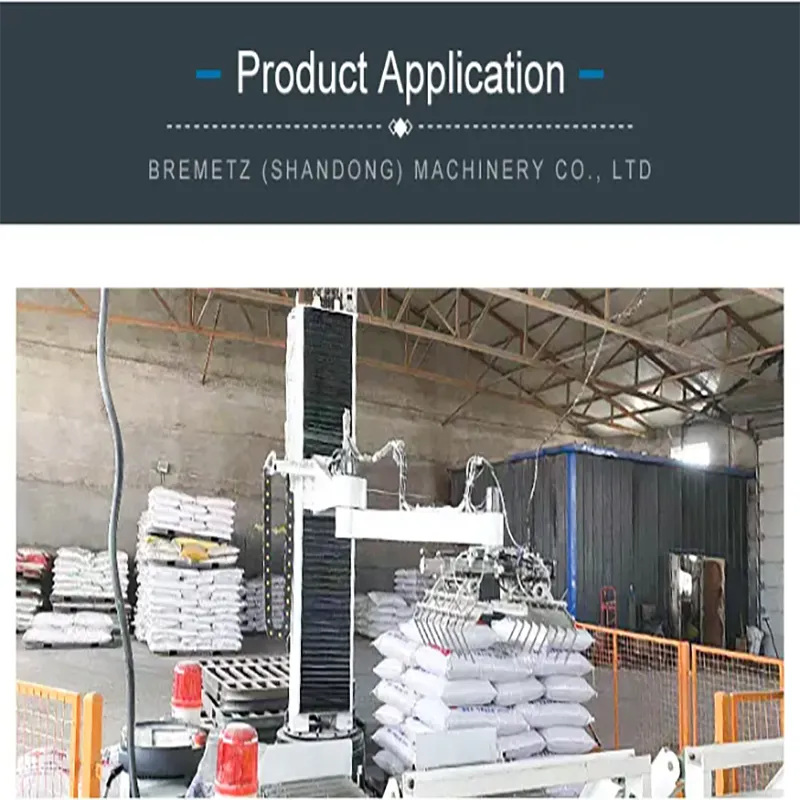

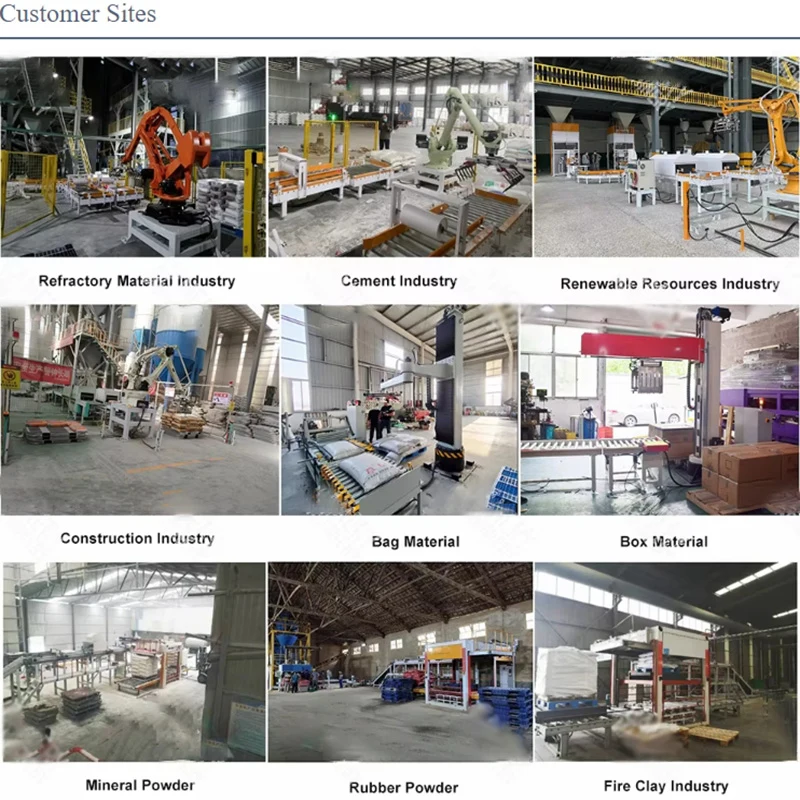

Benson Intelligent Equipment (Shandong) Co., Ltd. was founded in 2013, including self-researching and development, design, produ

ction and sales. Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizi

ng machine, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing

and other industries.Benson has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting cou

ntries including United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided prof

essional solution with efficient and intelligent products to each customer, got the high recognization and compliment from every se

rviced domestic and foreign client. Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-

win, continue to provide our customers with high-end products and quality service.

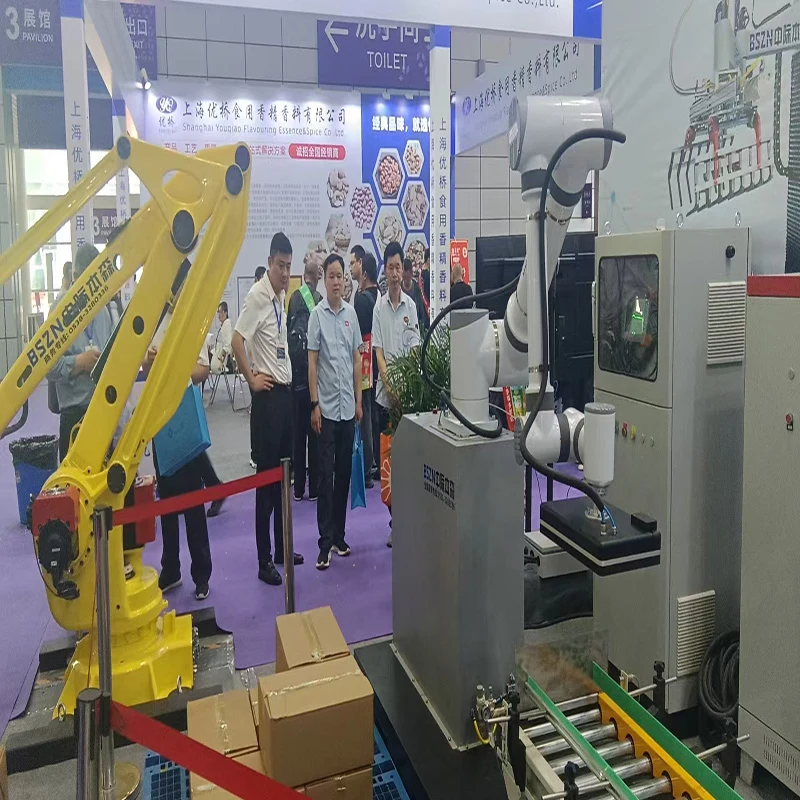

Exhibition

Product Inquiry