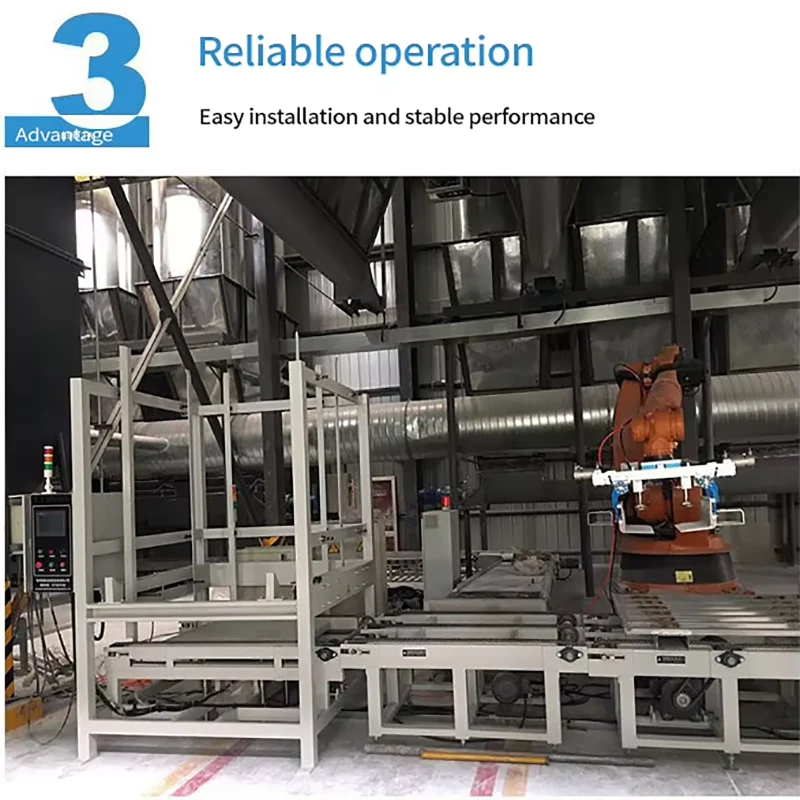

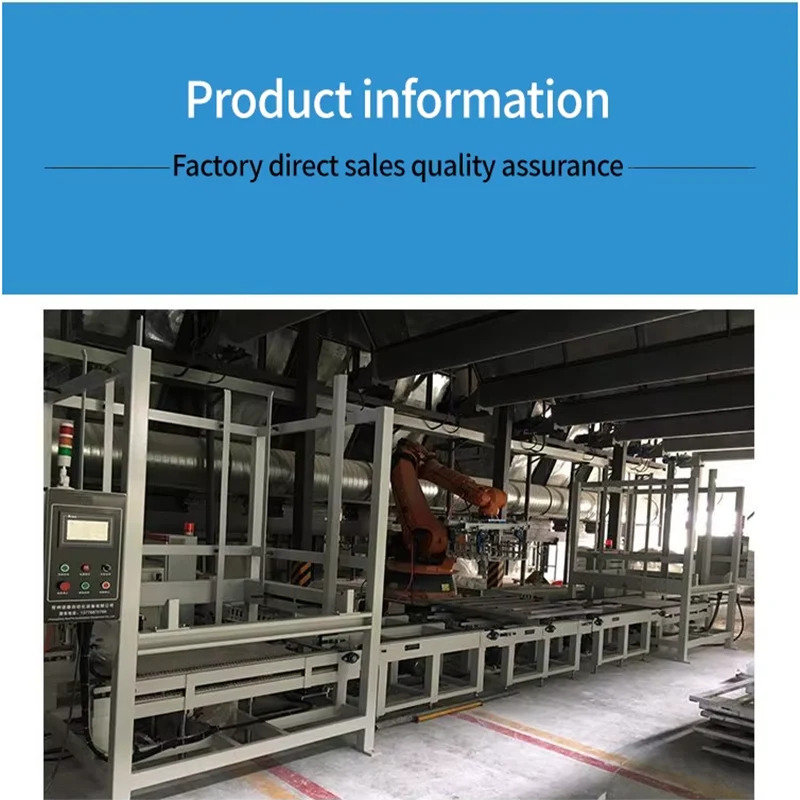

The fully automatic pallet warehouse is a highly automated storage equipment, mainly used for storing and managing pallets. It can realize the functions of automatic storage, retrieval, and transportation of pallets. It is often used in conjunction with automated logistics equipment such as palletizing robots, automatic guided vehicles (AGVs), and stackers to improve the overall automation level and operating efficiency in industrial production, logistics warehousing and other fields.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Performance analysis

Products Description

Structural composition of large-scale automated pallet warehouse

1. Storage unit: generally composed of multi-layer shelves for storing pallets. The shelf structure is sturdy and can be designed with different layers and layouts according to the site space and pallet storage requirements. Common forms include through-type shelves and shuttle shelves, which make full use of vertical space and improve storage density.

2. Conveying system: including roller conveyors, chain conveyors, belt conveyors and other types. Responsible for conveying pallets between different areas, such as from the pallet storage area to the palletizing station, or from the palletizing completion area to the temporary storage area. The conveying speed and direction can be adjusted according to the actual production rhythm.

3. Lifting device: such as vertical lifts, etc., used to realize the transfer of pallets between different height layers. The use of precise transmission mechanisms and control systems ensures that the pallets are lifted and lowered smoothly and accurately, with high lifting efficiency and precise positioning.

4. Automatic storage and retrieval equipment: Stackers are common automatic storage and retrieval equipment. They run along the track and realize automatic storage and retrieval of pallets through forks and other pick-up and placement devices. With the ability of high-speed operation and precise positioning, it can complete the storage and retrieval tasks of a large number of pallets in a short time.

5. Control system: With industrial computers and programmable logic controllers (PLC) as the core, combined with sensors, communication modules, etc. The software program can monitor and dispatch the operation of the entire pallet warehouse equipment, receive external instructions, coordinate the actions of various components, and ensure the stable and efficient operation of the system. It can also be connected with the enterprise's production management system (MES) and warehouse management system (WMS) to achieve information interaction and intelligent management.

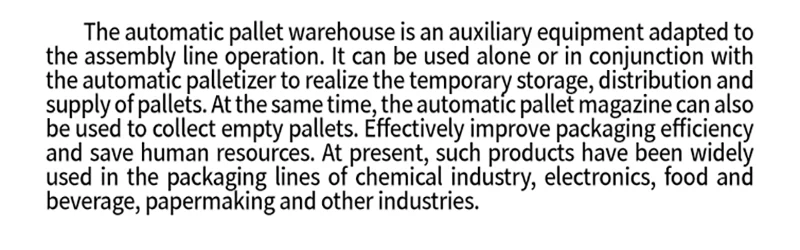

Fully automatic pallet in and out of the warehouse workflow

1. Pallet storage: Forklifts or AGVs transport pallets to the entrance of the pallet warehouse, the conveying system sends the pallets to the designated location of the storage unit, and the automatic storage and retrieval equipment (such as stackers) accurately places the pallets on the shelves.

2. Pallet storage: Pallets are stored in order in the storage unit, waiting to be called. During this period, the control system monitors the location, quantity and other information of the pallets in real time.

3. Pallet out of the warehouse: When there is a demand on the production line, the control system issues a command, the automatic storage and retrieval equipment finds the target pallet and takes it out, and transports the pallet to the designated workstation through the conveying system, such as the palletizing robot for cargo palletizing.

4. Empty pallet recovery: After the cargo palletizing is completed, the empty pallet is returned to the pallet warehouse through the conveying system for recycling.

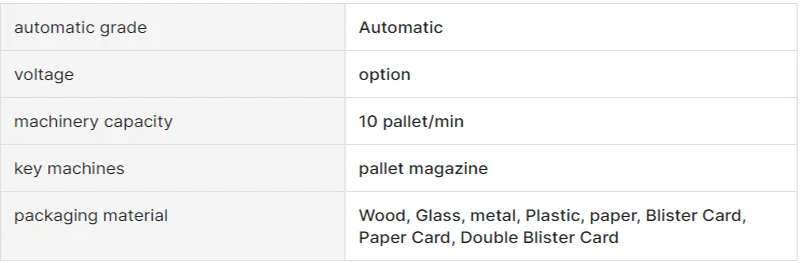

Technical parameters of fully automatic pallet in and out of the warehouse

1. Storage capacity: Determined by the number of shelf layers, the number of columns and the size of the pallet, for example, it can store dozens to hundreds of pallets.

2. Access speed: measured by the number of pallets accessed per hour, generally up to dozens to hundreds, and advanced equipment has faster access speed.

3. Carrying capacity: depends on the structural design of the pallet warehouse and the selection of components. The common range of a single pallet's carrying capacity is from hundreds of kilograms to several tons.

4. Positioning accuracy: The positioning accuracy of the automatic storage and retrieval equipment can usually reach the millimeter level to ensure accurate access to the pallet.

Advantages of fully automatic pallet in and out of the warehouse

1. Improve efficiency: realize automatic storage and rapid deployment of pallets, reduce manual operation time, seamlessly connect with automated production lines, and speed up cargo turnover.

2. Reduce costs: reduce manual handling and reduce labor costs; make rational use of space, reduce warehouse floor space, and reduce site rental costs.

3. Improve accuracy: Automated operation and precise positioning avoid errors caused by manual operation, and ensure the accuracy of pallet storage and cargo stacking.

4. Enhance safety: The equipment has complete safety protection measures, such as safety light curtains, emergency stop buttons, etc., to reduce the risk of personnel operation.

5. Data management: It can record the inventory quantity, location, in and out time of pallets in real time, which is convenient for inventory management and data analysis, and provides a basis for enterprise production decisions.

<img src="/uploads/allimg/20250430/1-250430135615Z6.webp" title="Pallet warehouse production line""alt="4.jpg"/>

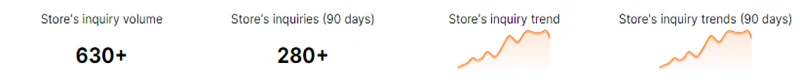

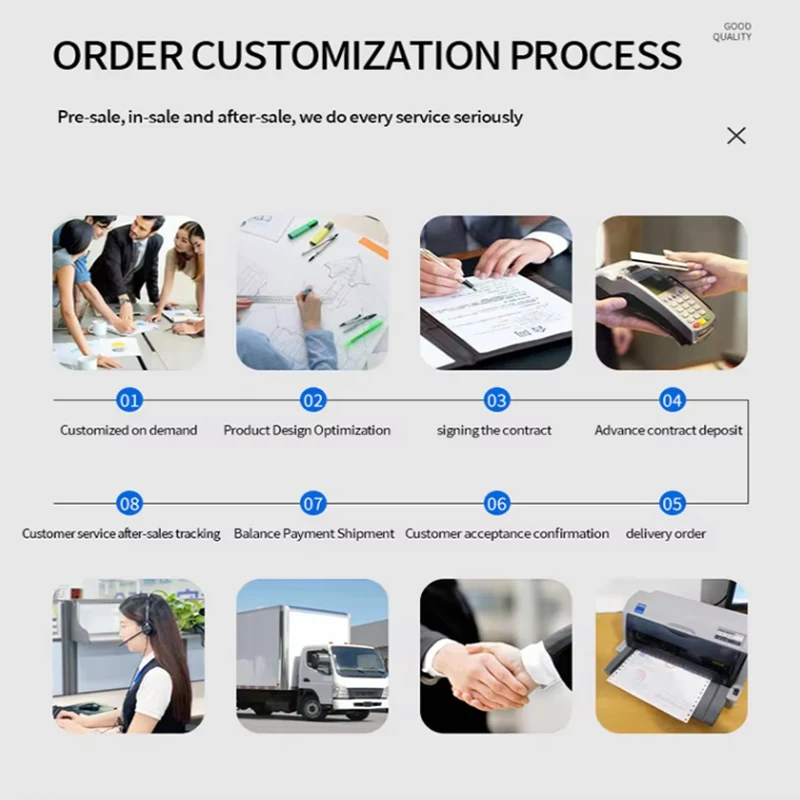

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry