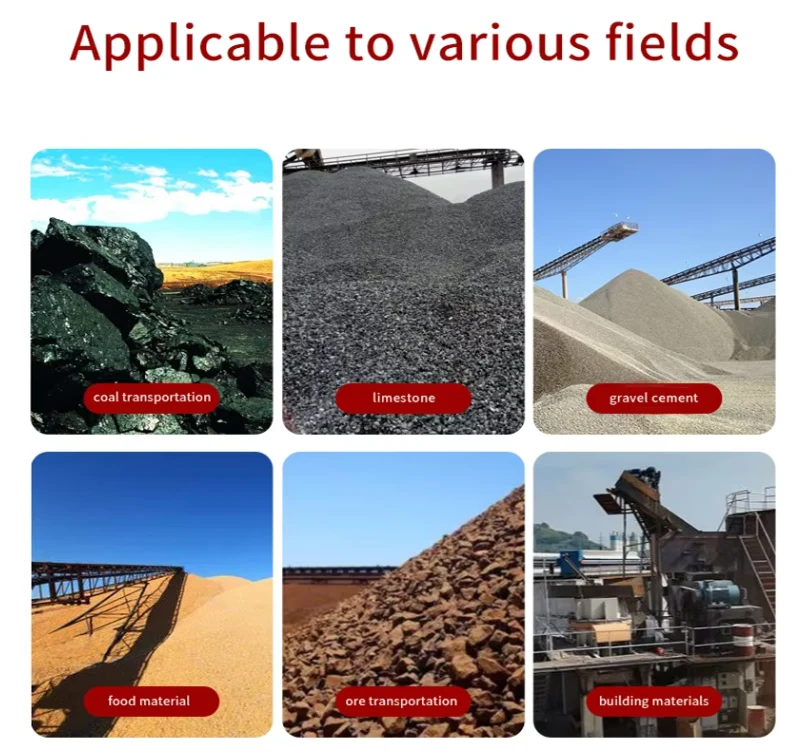

In modern industrial production, material transportation is a key link to ensure smooth production processes. With its excellent performance, the automatic NE plate chain feeder has become a powerful assistant for many companies in the field of material transportation. It is widely used in mining, metallurgy, building materials, chemicals, electricity and other industries, providing a reliable solution for the efficient transportation of various bulk materials.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Automatic NE plate chain feeder: ideal for efficient material transportation

Working principle of automatic NE plate chain feeder

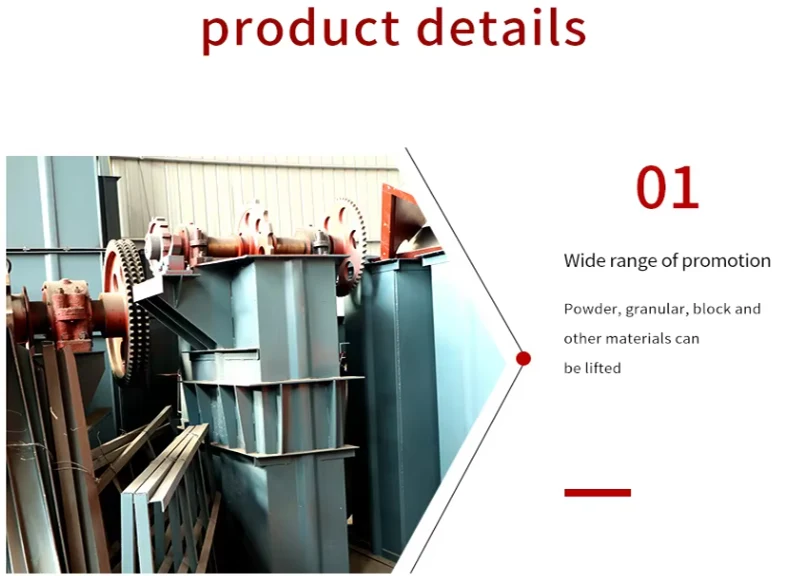

When reaching the top, the material is discharged smoothly from the discharge port under the combined action of gravity and centrifugal force, completing the entire conveying process. This unique working principle minimizes the extrusion and collision between the material and the moving parts during the conveying process, effectively reducing the breakage rate of the material, while also reducing the wear of the equipment and extending the service life of the equipment.

Product advantages of automatic NE plate chain feeder

1. Powerful conveying capacity: with a variety of specifications and models, such as NE15, NE30, NE50, NE100, NE150, NE200, NE300, NE400, NE500, NE600, NE800, etc., the lifting capacity range is wide, up to 15-800m³/h, which can fully meet the diversified needs of enterprises of different production scales, whether it is a small production line or a large industrial project, it can be easily dealt with.

2. Significant energy-saving effect: Gravity-induced unloading is adopted, and it is combined with densely arranged large-capacity hoppers for conveying. The chain speed is low, and there is almost no material return and digging during the material lifting process, which greatly reduces the consumption of invalid power. According to theoretical calculations, its shaft power is only about 45% of that of the chain hoist, which saves a lot of energy costs for the enterprise.

3. Long service life: The feeding method greatly reduces the friction and collision between the moving parts and the materials, and effectively avoids the wear of the materials on the machine body. At the same time, the plate chain type high-strength wear-resistant chain selected for the conveyor chain has excellent wear resistance and high strength, which greatly prolongs the service life of the chain and chain bucket. According to the data of similar foreign products in long-term production practice, the service life of its conveyor chain can exceed 5 years, reducing the maintenance and replacement costs of the equipment.

4. The automatic NE plate chain feeder has a high lifting height: With the characteristics of low chain speed, smooth operation, and the application of plate chain type high-strength wear-resistant chain, the automatic NE plate chain feeder can achieve a high lifting height, up to 40m, which can meet some production scenarios with special requirements for material lifting height.

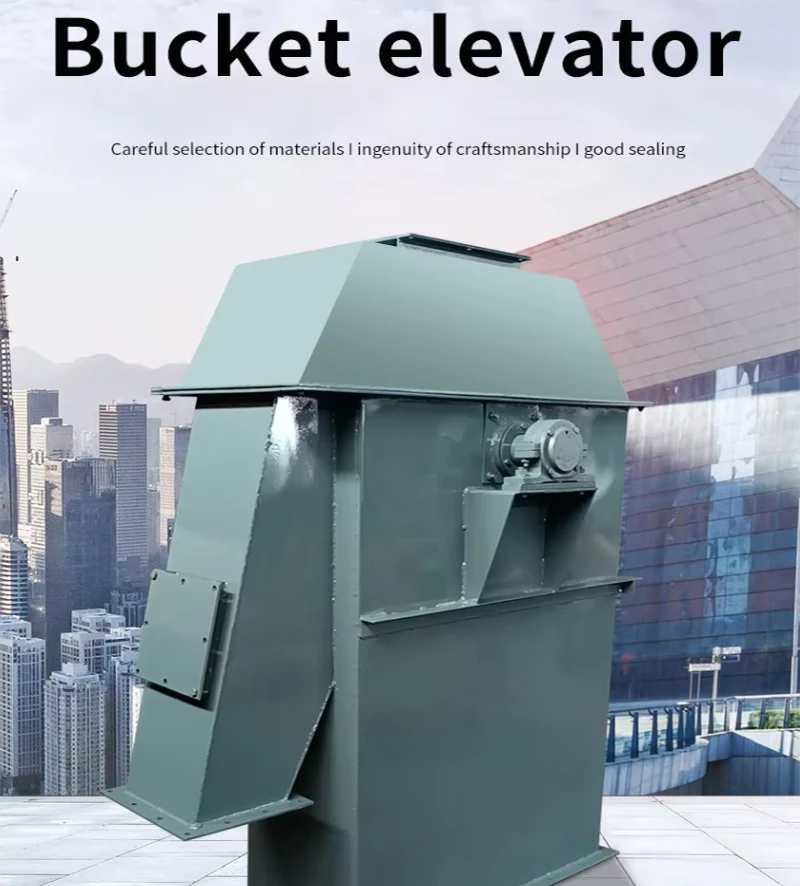

5. Good sealing: The fully enclosed casing design effectively prevents the flying and leakage of materials during transportation, reduces the pollution of dust to the environment, creates a clean production environment for the enterprise, and also avoids the waste of materials, which meets the requirements of environmental protection and safe production.

6. High operating reliability: The scientific and reasonable design principle ensures the high reliability of the whole machine operation. The equipment operates stably, has a low failure rate, can work continuously for a long time, provides stable material transportation guarantee for the production of the enterprise, reduces production interruptions caused by equipment failure, and improves production efficiency.

7. The automatic NE plate chain feeder is easy to operate and maintain: The equipment structure is compact, the operation is simple and easy to understand, and it is convenient for staff to carry out daily operation and management. At the same time, there are fewer wearing parts and it is easy to replace, which reduces the maintenance difficulty and maintenance cost of the equipment, reduces the downtime maintenance time, and improves the utilization rate of the equipment.

Structural composition of automatic NE plate chain feeder

1. Operating parts: It consists of a hopper and a special plate chain. Among them, single-row chains are used for NE30 and below specifications, and double-row chains are used for NE50-NE800 specifications. The design of the hopper fully considers the characteristics of the material, and there are various shapes and capacities to choose from to achieve efficient material loading and conveying; the special plate chain has the advantages of high strength and wear resistance, which ensures the stability and reliability of operation.

2. The driving device of the automatic NE plate chain feeder: it can be driven in a variety of driving combinations according to the actual needs of the user. The driving platform is equipped with an inspection frame and a railing to facilitate the staff to inspect and maintain the equipment. The driving device is divided into two forms: left-mounted and right-mounted, which can be flexibly selected according to the on-site installation space and process requirements.

3. Upper device: equipped with a track (double-row chain) to prevent the chain from swinging during operation and ensure the stability of the chain operation; equipped with a backstop to effectively prevent the hopper from rotating and avoid material backflow; the discharge port is equipped with an anti-return rubber plate to further prevent material return and ensure the smoothness and efficiency of unloading.

4. Middle casing: Some intermediate sections are equipped with tracks (double chains), which are also used to prevent the chain from swinging during operation and ensure the stability of equipment operation. In addition, some intermediate sections are also equipped with inspection doors to facilitate staff to inspect and repair the inside of the equipment, and to promptly discover and solve potential problems.

5. The lower device of the automatic NE plate chain feeder: a tensioning device is installed to adjust the tightness of the chain to ensure that the chain is always in a suitable working state. Among them, NE15 - NE50 adopts a spring tensioning method with a simple structure and easy adjustment; NE100 - NE800 adopts a heavy hammer box tensioning method, which can provide a more stable tensioning force and ensure the reliable operation of the equipment.

If you are looking for an efficient, energy-saving and reliable material conveying equipment, the automatic NE plate chain feeder is undoubtedly your best choice. We will provide you with a full range of technical support and high-quality after-sales service to help your company's production reach a higher level.

Products Description。

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry