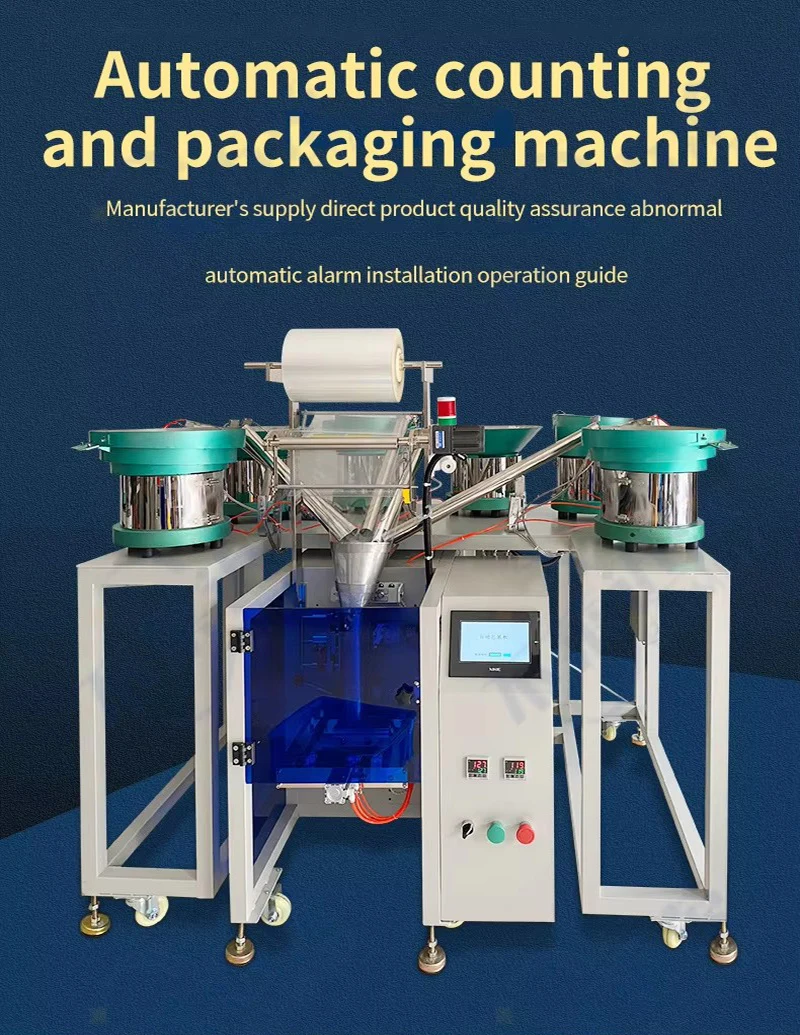

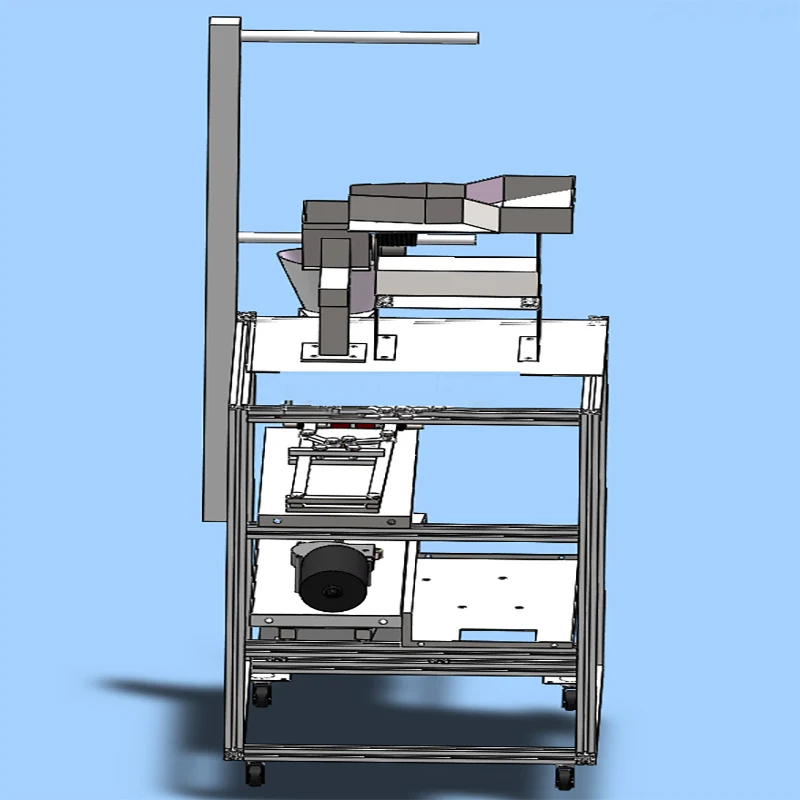

The automatic multi - functional counting and packaging machine is an automated device that integrates multiple functions such as counting and packaging. It is mainly used for accurately counting various regular or irregular products and packaging them according to set specifications. It can be widely applied in industries such as food, pharmaceuticals, daily necessities, and hardware parts, and is used for packaging items like candies, tablets, screws, and small ornaments.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Automatic Multi - functional Counting and Packaging MachineWorking Principles

1. Counting System: It uses photoelectric sensors, weighing sensors, or mechanical counting devices to count products moving on the conveyor belt one by one. For example, photoelectric sensors record the number of products by using the signal changes when the light beam is blocked by the products; weighing sensors calculate the quantity based on the relationship between the product weight and the average weight of a single product.

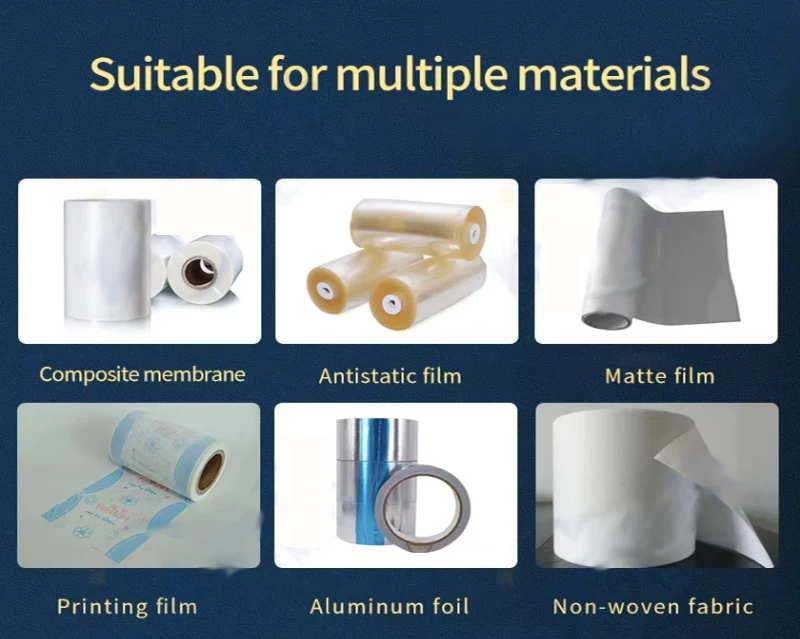

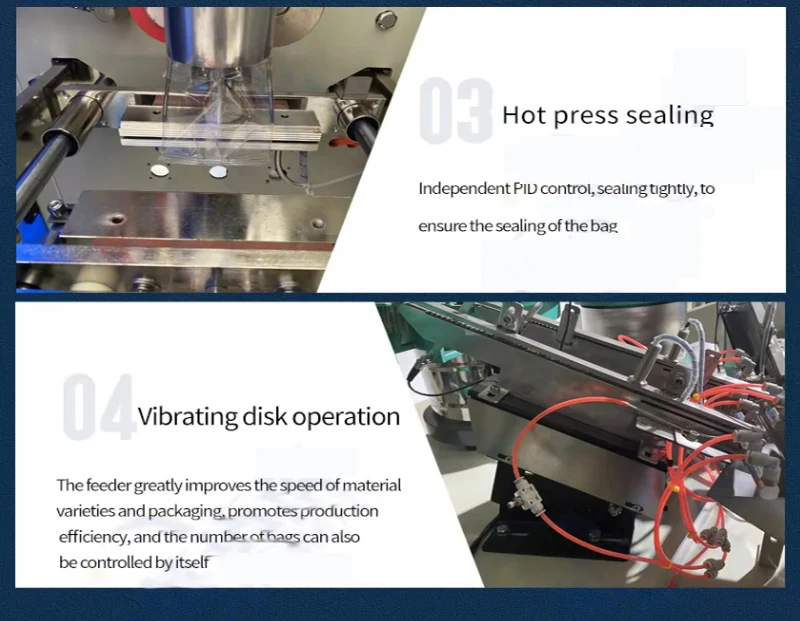

2. Packaging System: When the count reaches the set number, the products are transferred to the packaging area. The packaging system selects appropriate packaging materials (such as plastic bags, paper boxes, aluminum foils, etc.) according to the product characteristics and packaging requirements, and completes the packaging process through a series of actions including bag making, filling, sealing, and cutting. Heat - sealing technology is often used for plastic bag packaging, which bonds and seals the plastic film by heating; while paper box packaging may involve processes like folding and pasting.

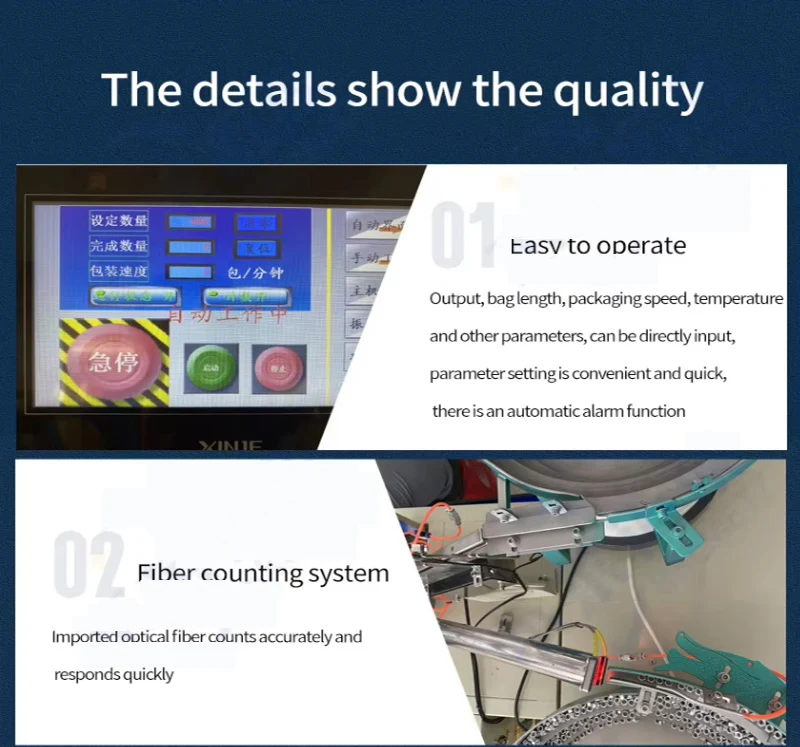

3. Control System: The operation of the entire device is controlled by a microprocessor or PLC (Programmable Logic Controller). Operators can set parameters such as the counting number, packaging specifications, and operating speed through the human - machine interface (touch screen or operation panel), and monitor the operating status of the device to achieve automated and intelligent operation.

Automatic Multi - functional Counting and Packaging MachineFunctional Features

- Multi - function Integration: It can simultaneously complete multiple processes such as counting, filling, packaging, and sealing, replacing traditional manual counting and hand - made packaging, improving production efficiency and reducing labor costs.

- High - precision Counting: Advanced counting technology ensures the accuracy of counting with a low error rate, meeting the counting needs of different products.

- Diverse Packaging Forms: It can adapt to various packaging materials and forms, such as three - side sealing, four - side sealing, and back - sealing, and can also provide customized packaging according to product requirements.

- Easy to Operate: With a user - friendly operation interface, it is easy for operators to get started. Moreover, the device has functions of automatic fault diagnosis and alarm, which facilitates maintenance and repair.

- Adjustable Production Speed: The operating speed can be adjusted according to actual production needs, which can meet the flexibility of small - batch production as well as the high efficiency of large - batch production.

Automatic Multi - functional Counting and Packaging MachineTechnical Advantages

- High Degree of Automation: The entire packaging process requ ements.

- Easy to Operate: With a user - friendly operation interface, it is easy for operators to get started. Moreover, the device has functions of automatic fault diagnosis and alarm, which facilitates maintenance and repair.

- Adjustable Production Speed: The operating speed can be adjusted according to actual production needs, which can meet the flexibility of small - batch production as well as the high efficiency of large - batch production.

ires little human intervention, reducing the impact of human factors on product quality and packaging effects.

- Hygiene and Safety: When applied in industries with high hygiene requirements such as food and pharmaceuticals, the device uses materials and designs that meet hygiene standards, effectively avoiding product contamination and ensuring product quality and safety.

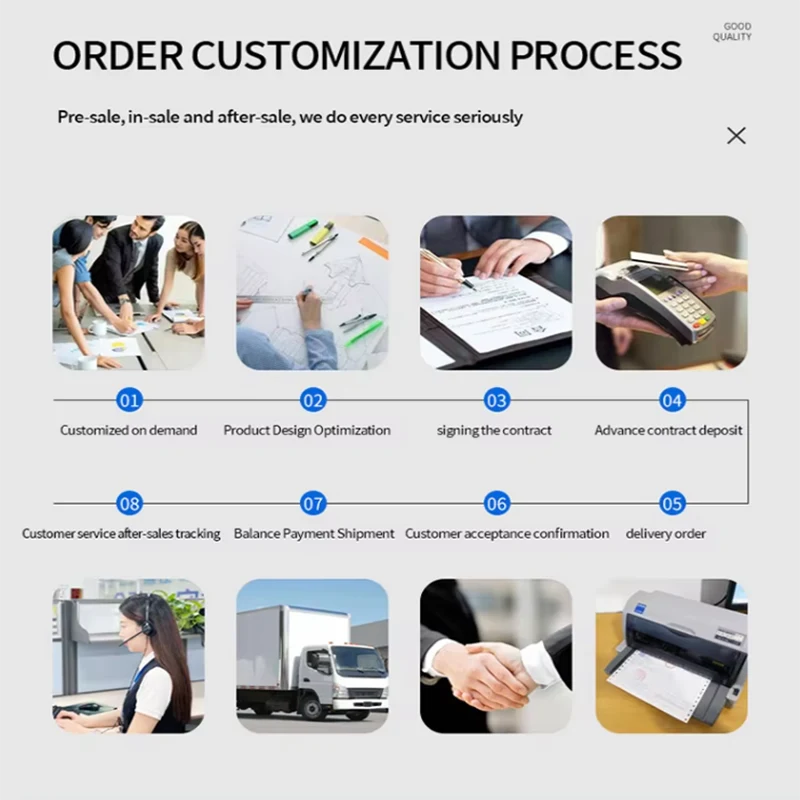

BENSON (Shandong) Machinery Co., Ltd. is a company engaged in winding machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bag feeding, large production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation A modern company that develops and produces production lines. high-tech enterprises. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "combination of production, education and research". The success of this research and development can be widely used in automated packaging routes, automated logistics engineering and other fields. A new generation of automated assembly line, the company has introduced various advanced processing equipment to comprehensively enhance market competitiveness, a large number of high-quality accessories, and product quality has been greatly improved. And other industries have been widely used, from product import to output, from electrical control to mechanical structure design, BENSON (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and equipment precision manufacturing, we have a complete after-sales service system. , To provide customers with high-quality technical support and after-sales service.

Product Inquiry