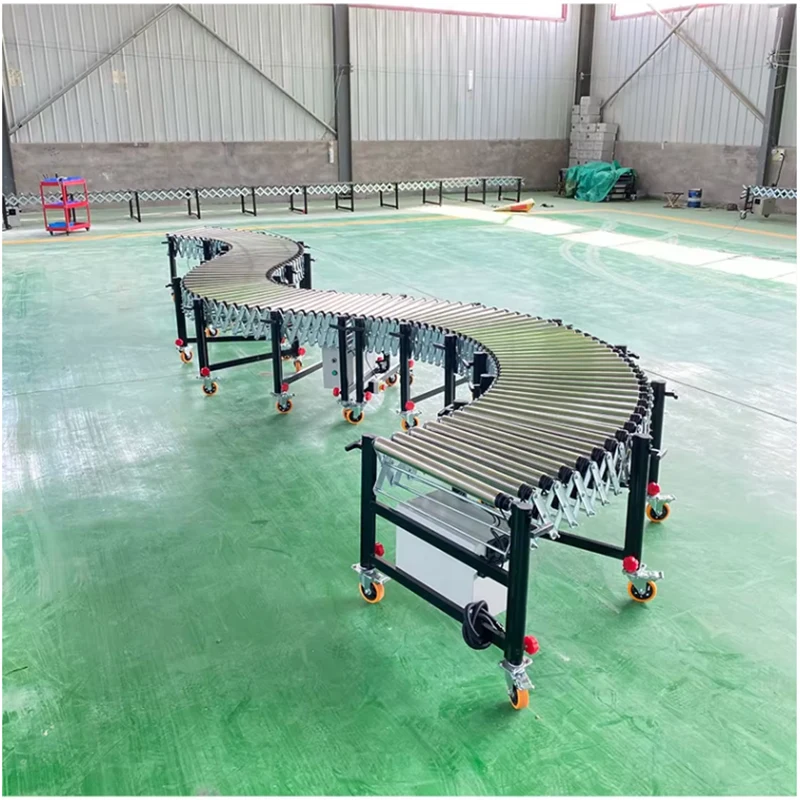

The automatic mobile power roller conveyor is an efficient material transmission equipment suitable for various industrial production scenarios and logistics warehousing and other fields. It realizes continuous and stable material transportation through electric-driven rollers, which can effectively improve the automation and work efficiency of production and logistics links.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

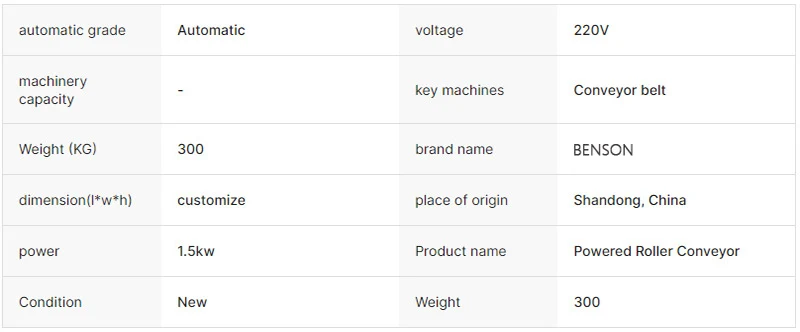

Key attributes

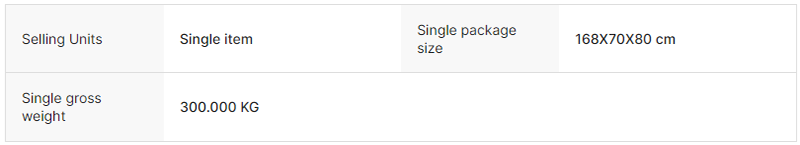

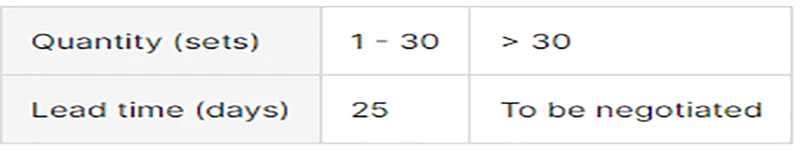

Packaging and delivery

Lead time

Automatic mobile power roller conveyor: efficient material transmission expert

Main parameters of automatic mobile power roller conveyor

- Automatic level: fully automatic operation, without too much manual intervention, can realize the automatic material conveying process.

- Voltage: 220V, suitable for common industrial and commercial power environments.

- Mechanical capacity: can be customized according to actual needs to meet the conveying requirements of materials of different weights and sizes.

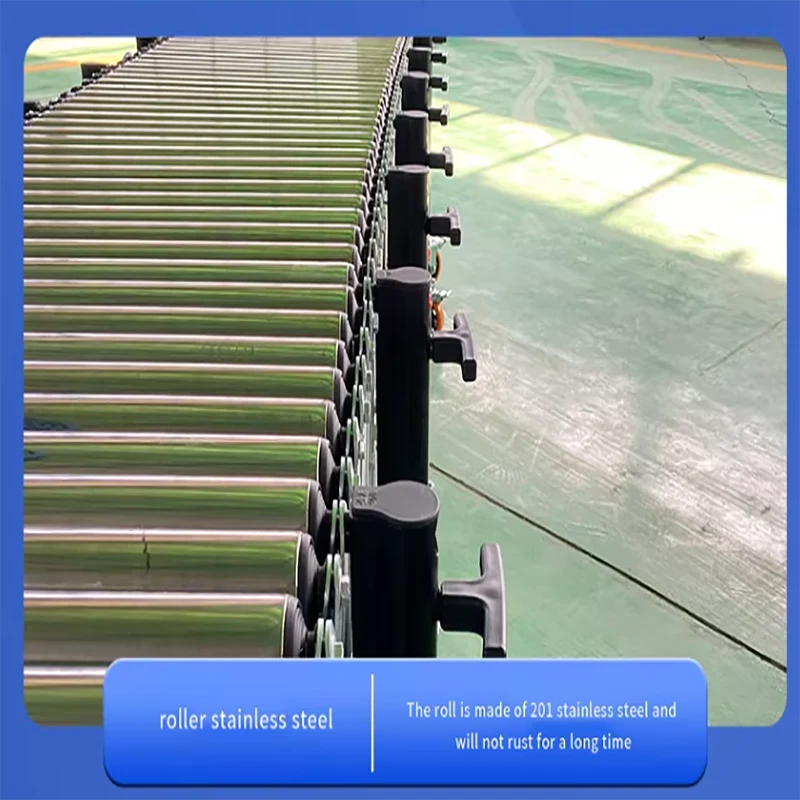

- Key machine parts: high-quality conveyor belts are used, with wear resistance, tensile resistance and other characteristics to ensure long-term stable operation.

- Weight: 300KG, the overall structure is compact and sturdy.

- Brand: with good market reputation and quality assurance.

- Size: customizable, can flexibly adapt to different site spaces and production layouts.

- Power: 1.5kw, while ensuring efficient transportation, it has good energy-saving effects.

- Product status: brand new, ensuring that users get the best performance equipment.

Product features of automatic mobile power roller conveyor

1. High degree of automation: It can be seamlessly connected with other automated equipment on the production line to realize automatic material handling, sorting and other operations, reducing labor costs and human errors.

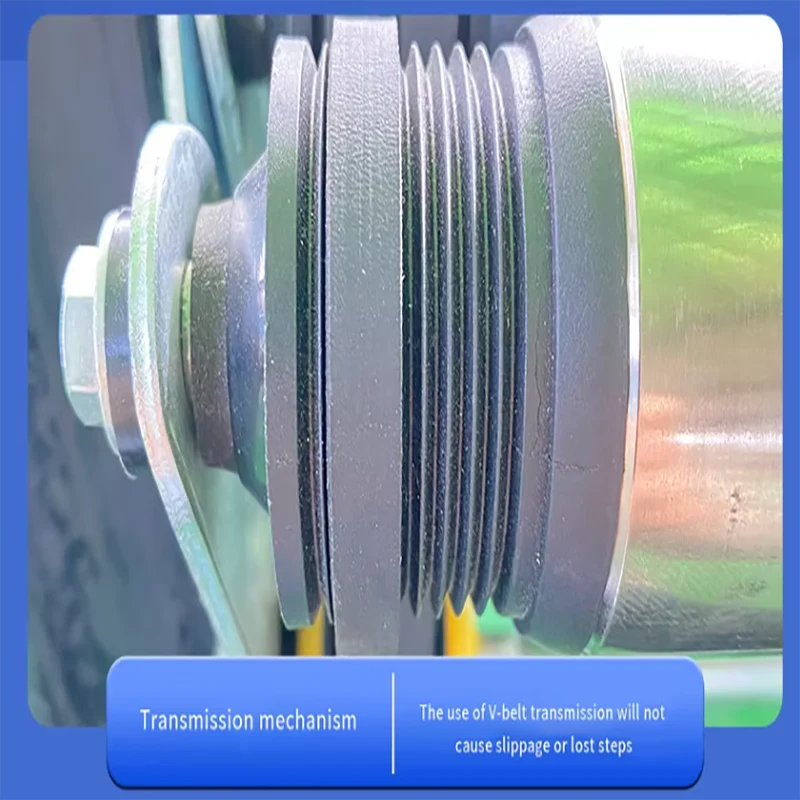

2. High conveying efficiency: The power drive of the roller enables materials to be transmitted quickly and continuously, improving the flow speed of production and logistics.

3. Strong flexibility: Customized size design can be laid out and installed according to the actual situation on site to adapt to different conveying paths and working environments.

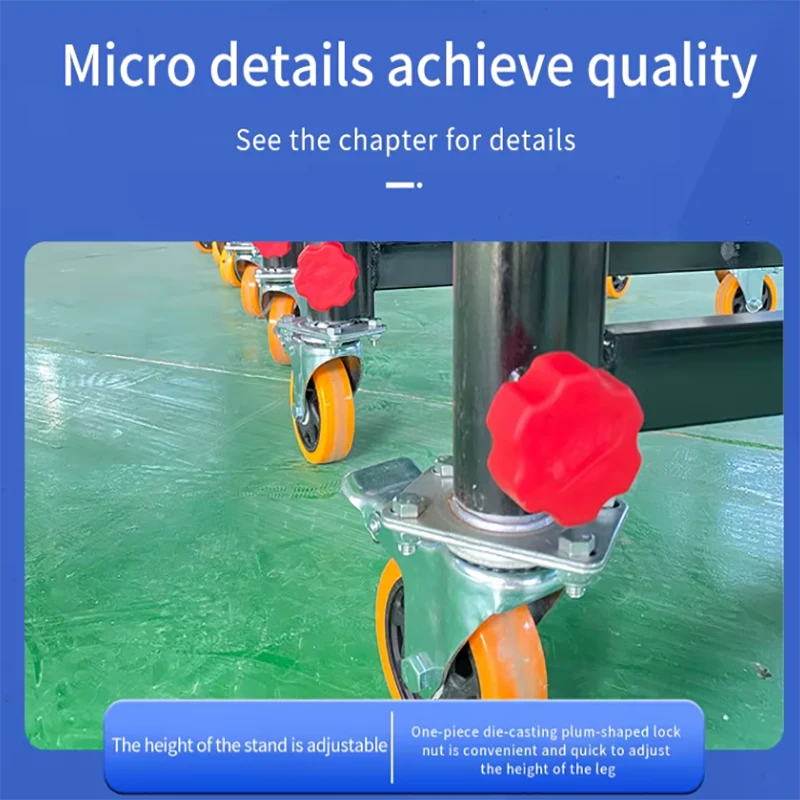

4. Good stability: High-quality component selection and precise manufacturing process ensure the stability and reliability of the equipment during long-term operation and reduce the occurrence rate of failures.

5. Easy maintenance: The structural design is reasonable, key components are easy to disassemble and replace, and daily maintenance and maintenance operations are simple, which can effectively reduce maintenance costs.

The quality of our company's automatic mobile power roller conveyor is reliable

-High quality of key components: High-quality conveyor belts are used as key machine components, with excellent wear resistance and tensile resistance, which effectively extends the service life of the equipment and ensures the stability and reliability of the equipment during long-term continuous operation.

- Sturdy and durable: The whole machine weighs 300KG, with a compact and sturdy structure. It is produced by the well-known brand bremetz, which strictly controls the production process and quality standards to ensure product quality.

Application scenarios

1. Manufacturing industry: such as automobile manufacturing, electronic and electrical manufacturing industries, used for assembly line transportation of parts and components, offline transportation of finished products, etc.

2. Logistics warehousing: In the processes of goods warehousing, storage, sorting and outbound, it realizes the rapid and accurate transmission of goods and improves the operation efficiency of warehousing logistics.

3. Food industry: It meets the material transportation needs in the food production process, meets the food hygiene and safety standards, and can be used for the production and transportation of foods such as bread and candy.

4. Pharmaceutical industry: It provides reliable material transportation solutions for the production, packaging and warehousing of drugs to ensure the cleanliness and safety of drug production.

After-sales service

We provide users with comprehensive after-sales service guarantees:

1. Installation and commissioning: Professional technical teams provide on-site installation and commissioning services to ensure that the equipment can be put into use normally.

2. Training support: Provide systematic operation training and maintenance guidance for user operators to enable them to master the use and daily maintenance methods of the equipment.

3. Maintenance response: Set up a 24-hour after-sales maintenance hotline. After receiving the fault repair report, respond quickly and arrange technicians to solve the problem in time.

4. Accessories supply: Adequate original accessories reserve to ensure timely supply when the equipment needs to replace parts, reducing downtime.

Choosing our automatic mobile power roller conveyor means choosing an efficient, stable and flexible material transmission solution to add strong impetus to your business development.

Products Description

Company Profile

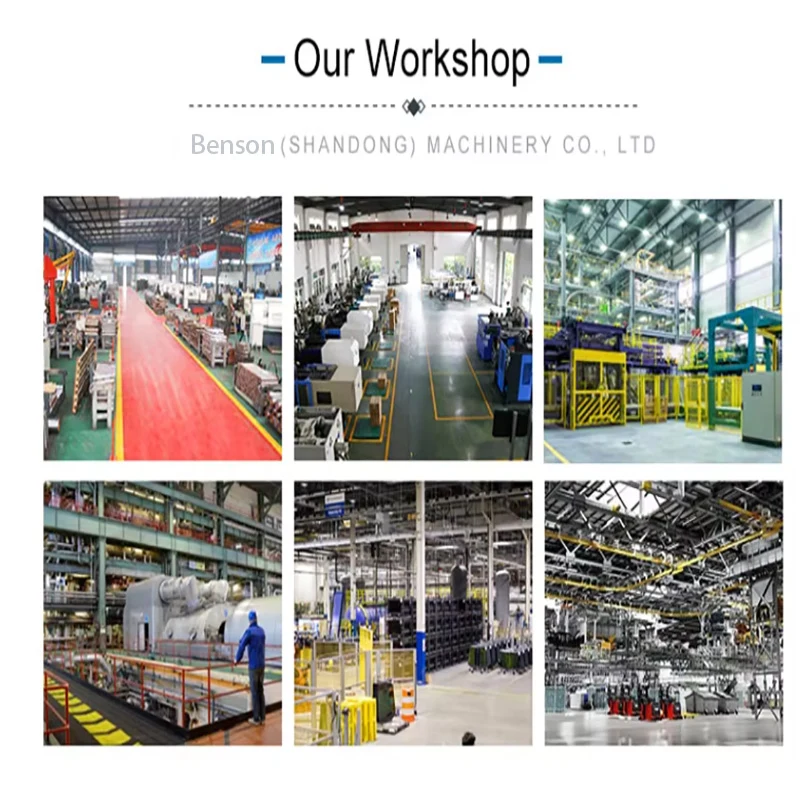

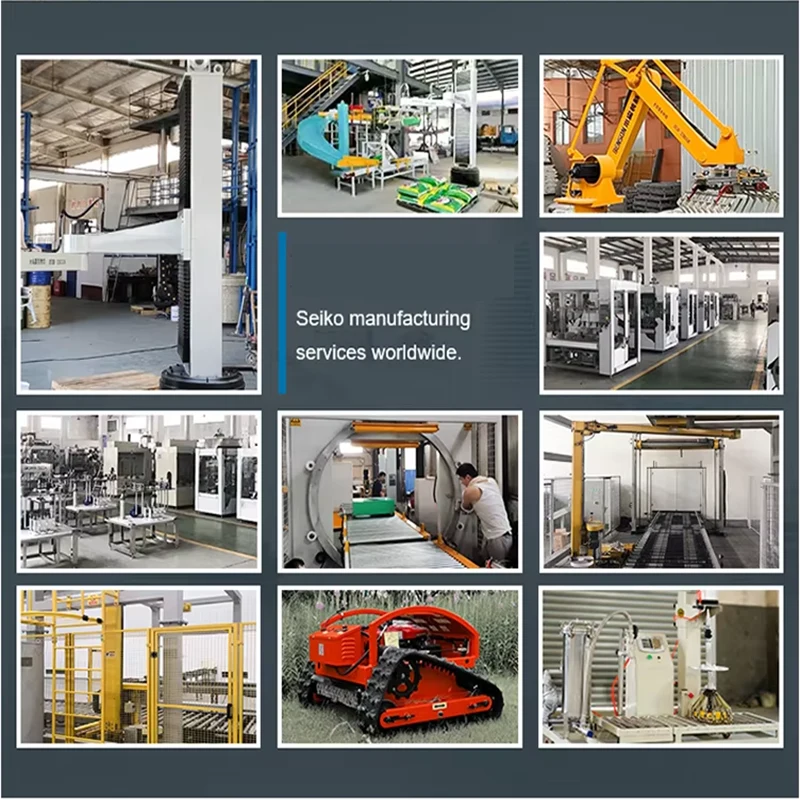

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry