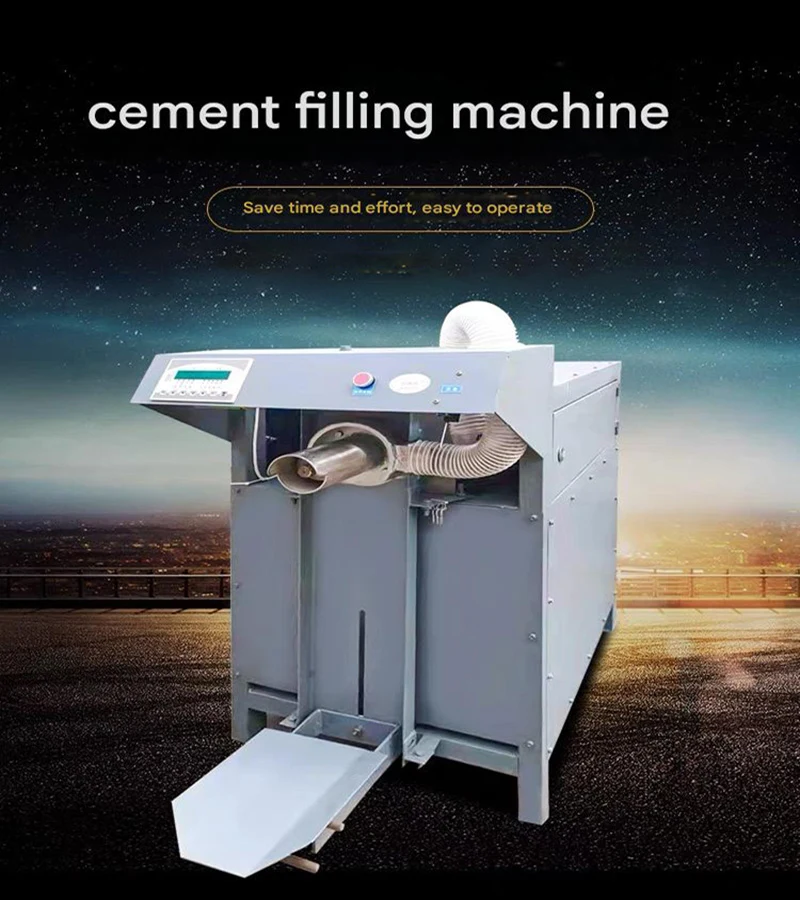

Food port valve machine packaging and canning equipment is specialized machinery designed for efficient and hygienic packaging of various food products into cans, bottles, or pouches. Equipped with precision control valves and automated conveying systems, it enables accurate metering, filling, and sealing of liquids, semi-liquids, or granular foods (e.g., beverages, sauces, canned goods). The "port valve" design ensures minimal leakage and contamination during the filling process, meeting strict

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

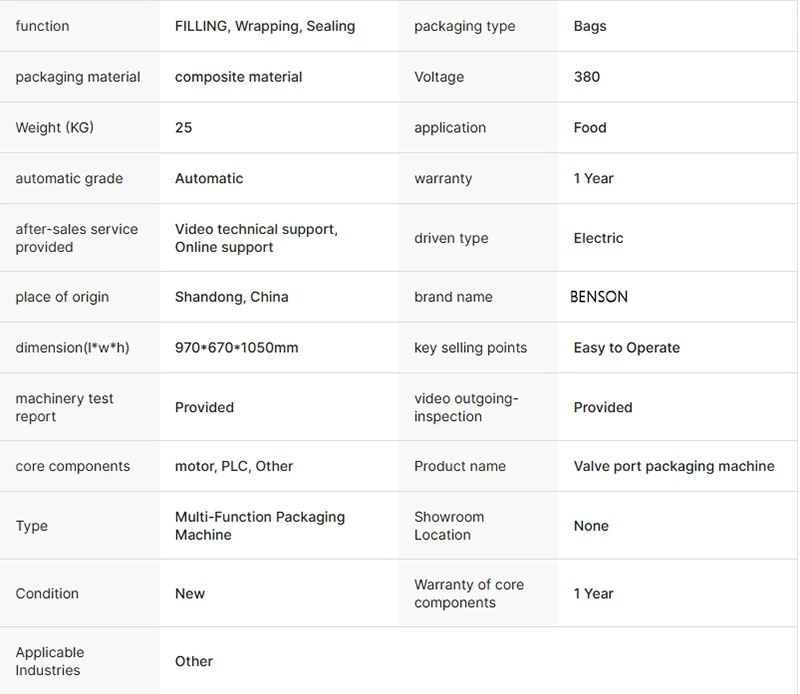

Food Port Valve Machine Packaging and CanningAdvantages

1. High Hygiene Standards:Stainless steel construction and closed-filling systems prevent microbial contamination, suitable for sensitive food products like dairy and infant formula.

2. Precision Filling:Valve-controlled technology ensures consistent filling volumes, reducing waste and improving product uniformity.

3. Multi-Package Compatibility:Adapts to various container types (cans, glass bottles, flexible pouches) and sizes, enhancing production flexibility.

4. Energy Efficiency:Low-power operation and optimized material usage reduce long-term production costs.

Food Port Valve Machine Packaging and CanningFeatures

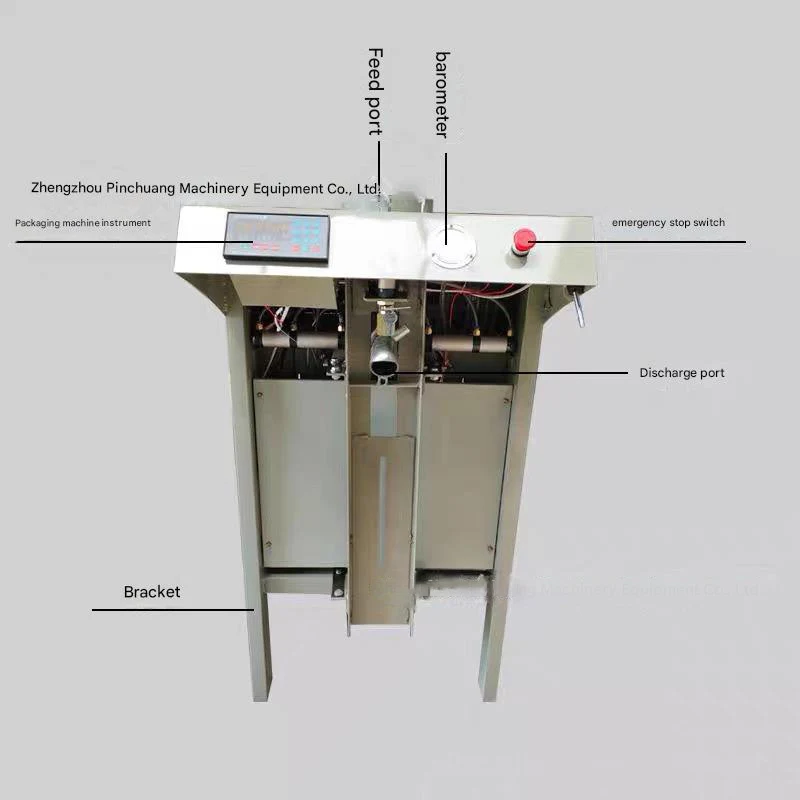

1. Automated Operation:Integrated PLC control and touchscreen interfaces enable fully automated processes (filling, capping, labeling) with minimal manual intervention.

2. Quick Changeover:Modular design allows fast adjustment of components for different products or packaging formats, minimizing downtime.

3. Safety Features:Emergency stop mechanisms, leak detection, and overload protection ensure operator safety and equipment longevity.

4. Easy Maintenance:Detachable parts and self-cleaning functions simplify sanitization and routine maintenance, complying with FDA/CE standards.

Food Port Valve Machine Packaging and CanningApplications

1. Beverage Industry:Filling carbonated drinks, juices, and energy drinks into cans or PET bottles.

2. Canned Foods:Packaging soups, vegetables, meats, and seafood in metal or glass cans for long-term storage.

3. Condiments & Sauces:Metered filling of ketchup, mayonnaise, and cooking sauces into squeeze bottles or pouches.

4. Dairy & Confectionery:Packaging yogurt, custards, and syrups into single-serve containers or bulk cans.

5. Industrial Food Production:Large-scale canning lines for food processing plants and export-oriented manufacturers.

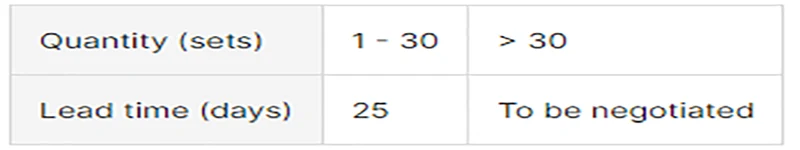

Lead time

Products Description

Product Inquiry