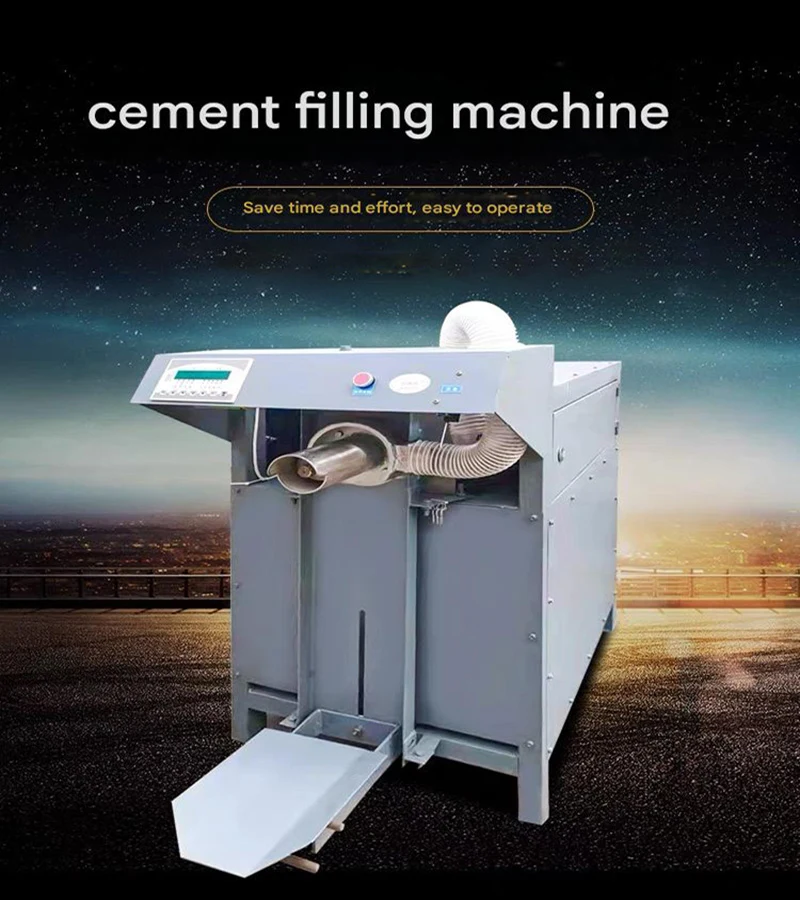

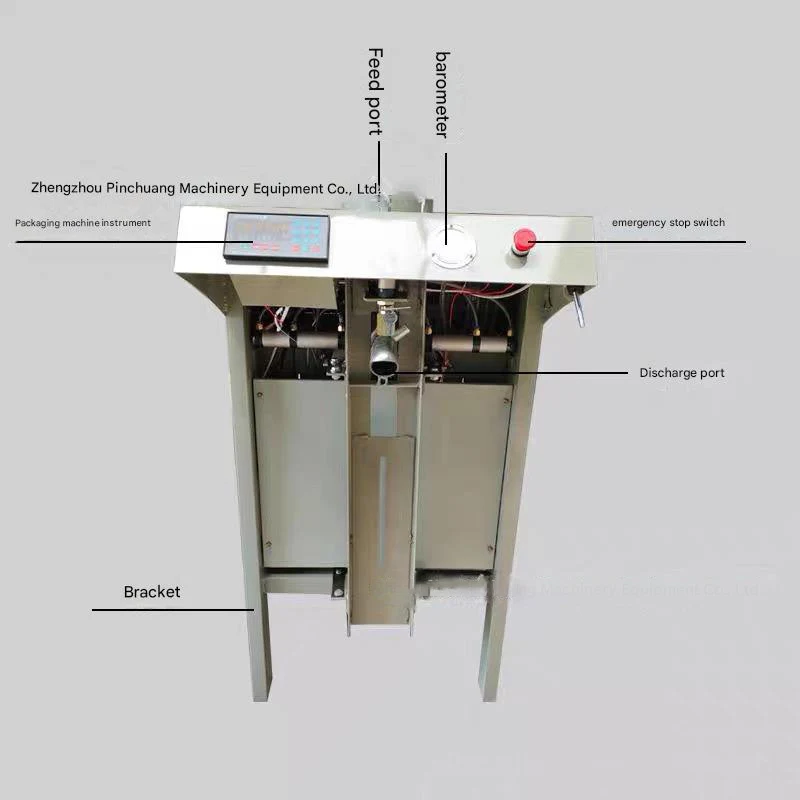

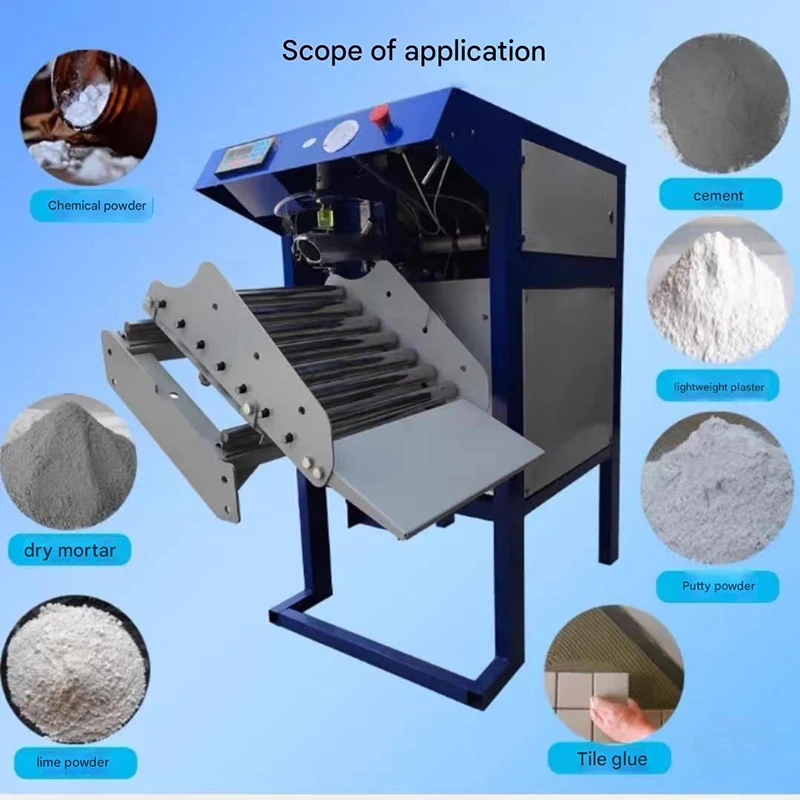

The automatic gypsum cement filling and packaging machine is an advanced industrial equipment designed for the efficient and precise filling and packaging of gypsum cement. Integrated with automated control systems, conveyor mechanisms, and weighing sensors, it can accurately measure, fill, and seal bags or containers with gypsum cement. This machine replaces traditional manual operations, streamlining the production process and enhancing the overall packaging efficiency and quality.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

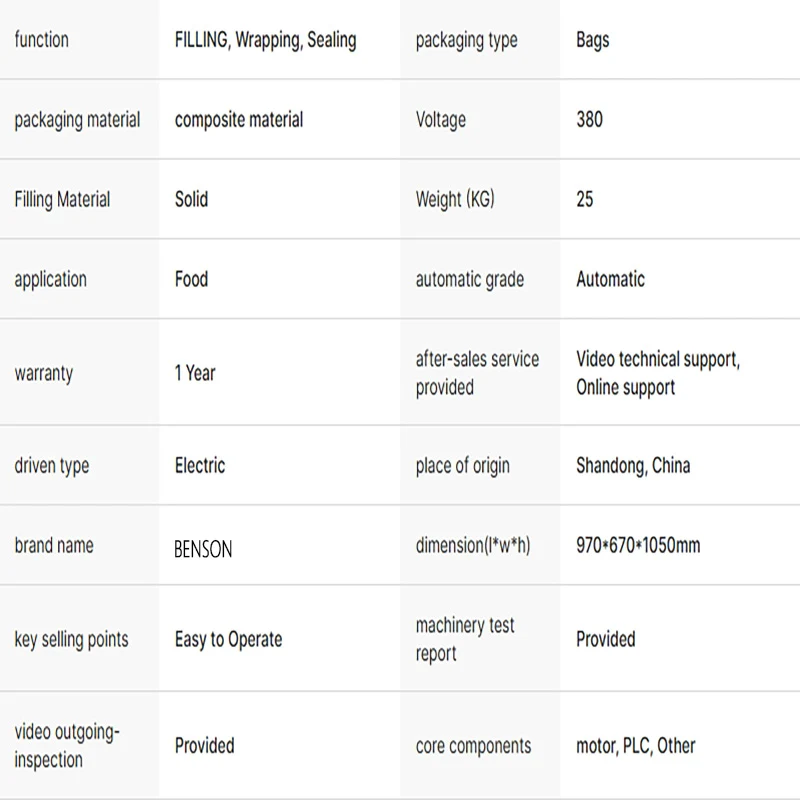

Automatic Gypsum Cement Filling and Packaging MachineAdvantages

1. High Efficiency:It can continuously operate at a high speed, significantly increasing production output compared to manual or semi - automatic packaging methods, meeting large - scale production demands.

2. Cost - effective:By reducing labor requirements, minimizing material waste, and optimizing energy consumption, the machine helps to cut down on production costs in the long run.

3. Consistent Quality:The precise weighing and filling system ensures that each package of gypsum cement has a consistent weight, reducing the occurrence of under - or over - filling, which is crucial for maintaining product quality and customer satisfaction.

Automatic Gypsum Cement Filling and Packaging MachineFeatures

1. Automated Operation:With PLC (Programmable Logic Controller) control, the machine can automatically complete the entire process of feeding, weighing, filling, and sealing, minimizing human intervention and reducing the risk of human - error.

2. Adjustable Parameters:It allows for easy adjustment of filling volume, packaging speed, and other parameters, making it adaptable to different production requirements and packaging specifications.

3. Reliable and Durable:Constructed with high - quality materials and components, the machine has excellent wear - resistance and stability, ensuring long - term reliable operation even in harsh industrial environments.

4. Safety Features:Equipped with safety devices such as emergency stop buttons, protective covers, and leakage detection systems, it provides a safe working environment for operators.

Automatic Gypsum Cement Filling and Packaging MachineApplications

1. Building Materials Industry: Widely used in cement plants and building materials manufacturing enterprises for packaging various types of gypsum cement products, which are essential for construction projects such as wall building, floor tiling, and plastering.

2. Construction Sites:Some on - site construction projects with high - volume gypsum cement usage can also benefit from this machine to quickly and accurately package materials for immediate use, improving construction efficiency.

3. Trading and Distribution:In the trading and distribution of gypsum cement, the machine can help distributors standardize product packaging, making it more convenient for transportation, storage, and sales.

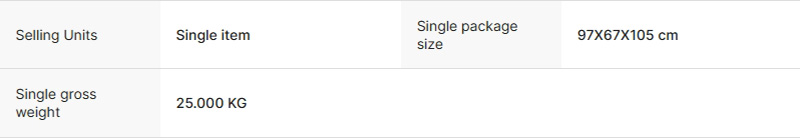

Products Description

Product Inquiry