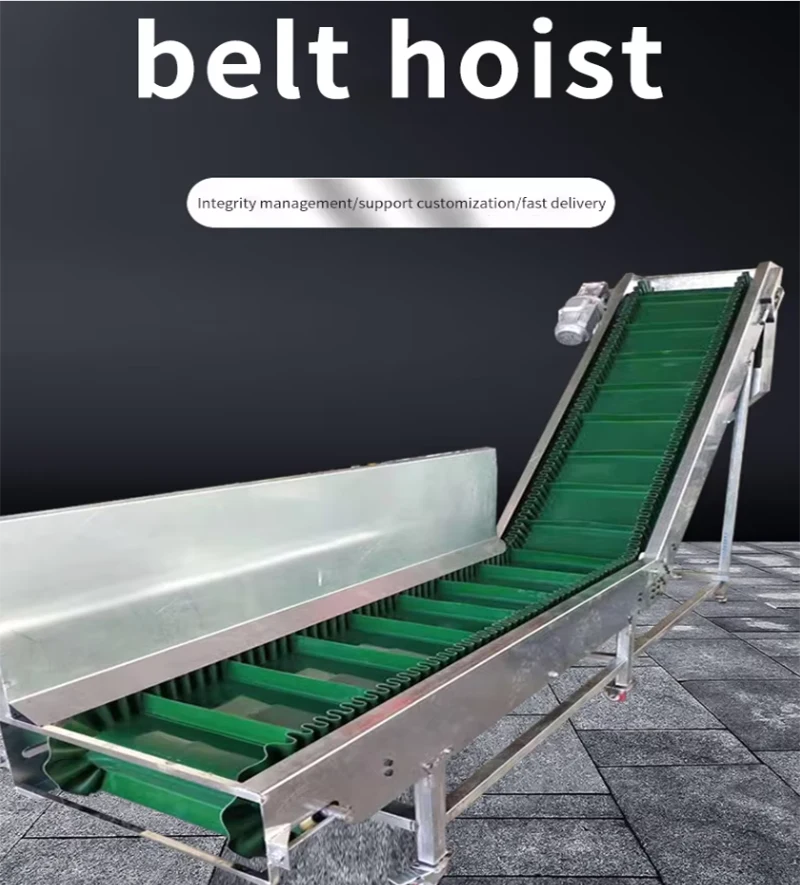

Climbing conveyor is an efficient equipment designed for complex terrain and large-angle material transportation. Through a unique structure and transmission system, it can realize vertical or large-angle climbing transportation of materials from low to high positions. It is widely used in mining, building materials, logistics, agriculture and other fields, effectively solving the problem of inclined transportation that traditional conveying equipment is difficult to cope with.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

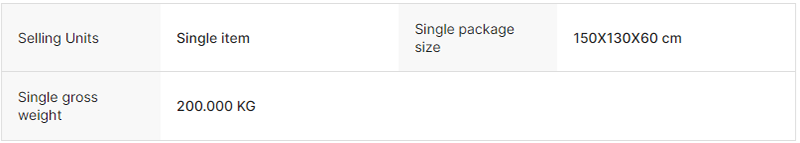

Packaging and delivery

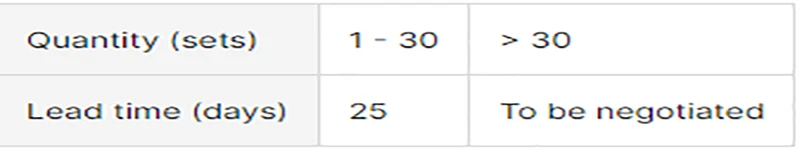

Lead time

Climbing conveyor - an efficient conveying tool that breaks through terrain restrictions

Core structure and configuration of climbing conveyor

1. High-strength frame of climbing conveyor: Made of high-quality carbon steel or stainless steel, welded or modularly assembled, it has high strength and stability and can adapt to long-term operation under heavy load and harsh environment.

2. Climbing conveyor components

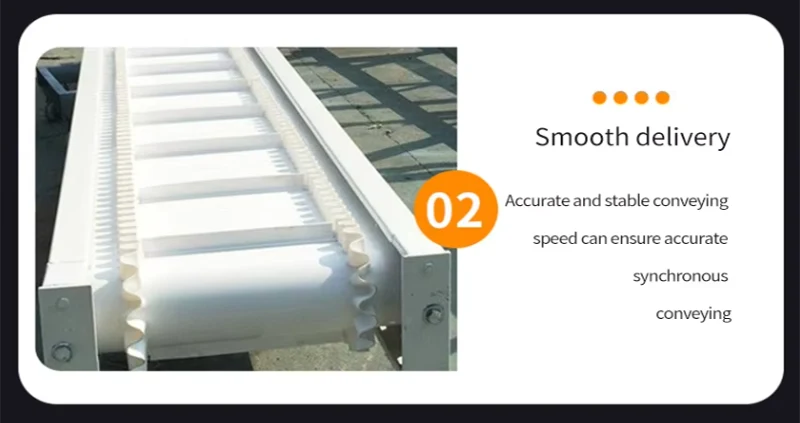

- Belt structure: Equipped with anti-slip patterned belt, skirt baffle or cross partition to prevent materials from sliding down; food-grade materials are optional, suitable for food and pharmaceutical industries.

- Chain plate structure: stainless steel chain plate or high-strength engineering plastic chain plate, with anti-slip tooth design, strong bearing capacity, suitable for conveying block and heavy materials.

3. Power and transmission system of climbing conveyor: high-power motor with planetary reducer to provide strong driving force; optional variable frequency speed regulation function to achieve flexible speed adjustment of 0-15m/min.

4. Safety protection device: including anti-reversal device, emergency stop switch, anti-deviation sensor, overload protection system to ensure safe and reliable operation of equipment.

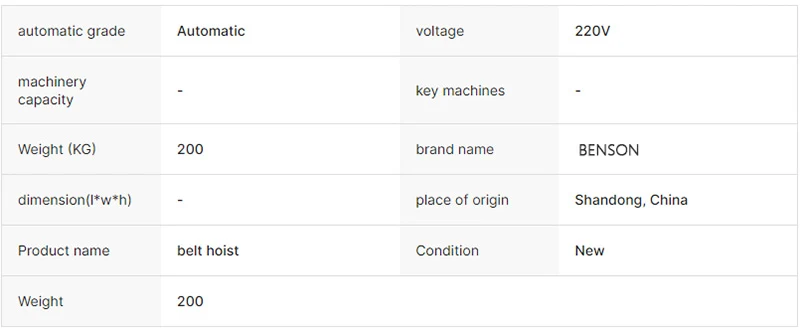

Performance parameters of climbing conveyor

Item Parameter range

Conveying angle 0°-90° (supports customized ultra-large angle)

Conveying speed 0.5-15m/min (adjustable by frequency conversion)

Conveying capacity 5-200 tons/hour (depending on the model)

Maximum climbing height Conventional ≤30 meters (customizable for special working conditions)

Working voltage 380V/50Hz (supports overseas voltage customization)

Environmental adaptability -20℃-60℃, humidity ≤90%

Powerful performance and intelligent control of climbing conveyors

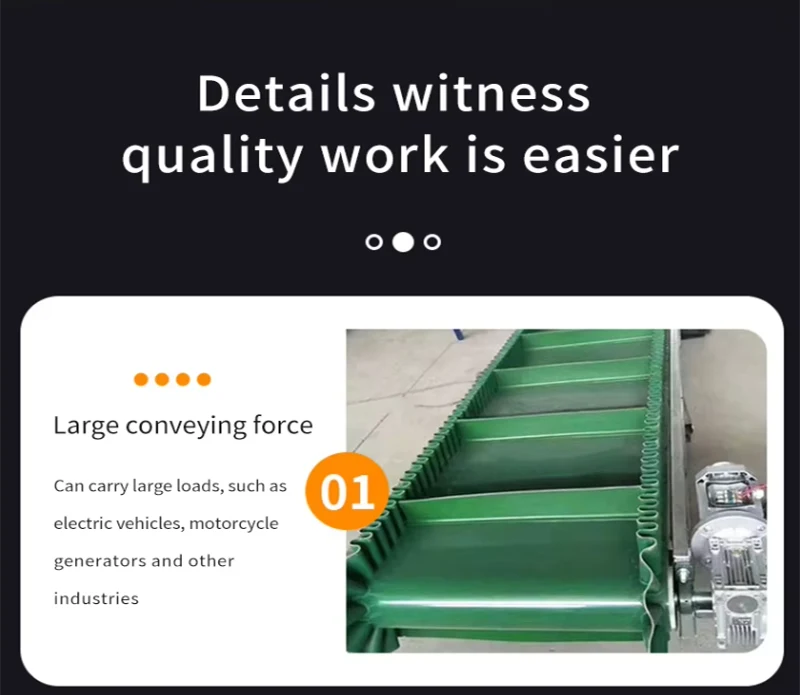

- Large-angle conveying: Supports 0°-90° ultra-large angle conveying, suitable for complex scenes such as mine tunnels and high-level storage, saves space, and optimizes production layout.

- Efficient heavy load: The conveying volume can reach 5-200 tons per hour, easily transporting heavy materials such as sand, gravel, ore, and packaged goods.

- Intelligent control: Equipped with variable frequency speed regulation and PLC control system, it can adjust the conveying speed and operating status in real time; multiple sensors automatically monitor deviation, overload and other abnormalities to ensure stable operation of the equipment.

Product advantages of climbing conveyor

1. Large-angle conveying: Breaking through the angle limitation of traditional conveyors, achieving nearly vertical climbing transportation, saving space, and optimizing production line layout.

2. High load capacity: Chain plate or special belt design can carry heavy materials such as sand, ore, packaged goods, and the hourly conveying volume can reach 200 tons.

3. Intelligent and stable: PLC control system + multiple sensors, real-time monitoring of operating status, automatic adjustment of speed and tension, to ensure continuous and stable operation.

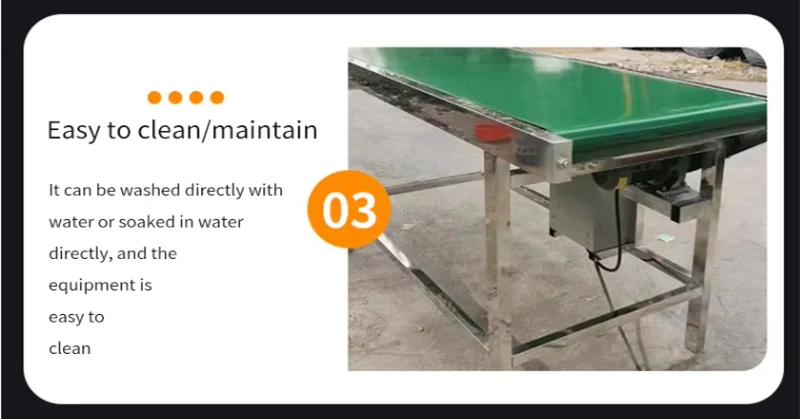

4. Easy maintenance: Modular design, wearing parts (such as belts, chains) can be quickly replaced; open structure is convenient for daily maintenance and cleaning.

5. Customized service: Support non-standard size, special material (stainless steel/corrosion-resistant coating), explosion-proof design, suitable for mines, ports, cold chains and other diversified scenarios.

Wide application areas of climbing conveyors

- Mining: Realize continuous lifting and transportation of ore and slag in inclined tunnels to improve mining efficiency.

- Logistics warehousing: Automatically complete the climbing and loading and unloading of goods on high-level shelves to accelerate the sorting and transportation process.

- Agricultural processing: After washing fruits and vegetables, they are transported to the sorting line by climbing, and food-grade materials ensure hygiene and safety.

- Environmental protection engineering: Help garbage incineration plants and sewage treatment plants complete efficient climbing and transportation of materials.

Worry-free service guarantee

- Installation and commissioning: Professional team provides on-site installation, commissioning and operation training services.

- Spare parts support: Original accessories respond 24 hours a day to ensure rapid equipment repair.

- Regular maintenance: Provide annual inspection and system upgrade services to extend the service life of equipment.

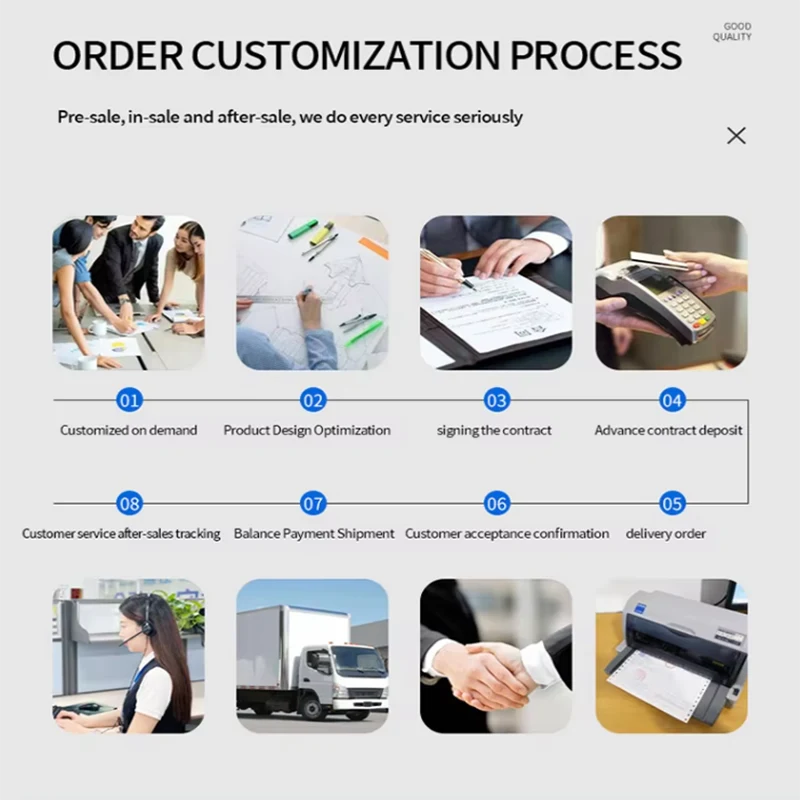

From customized solution design to professional installation and commissioning, to lifelong maintenance support, we provide one-stop service. Original spare parts respond quickly, regular inspection and upgrade to ensure that the equipment always maintains the best performance and escorts your production and transportation.

Choosing a climbing conveyor is to choose the ultimate conveying solution that breaks through terrain restrictions and improves efficiency!

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry