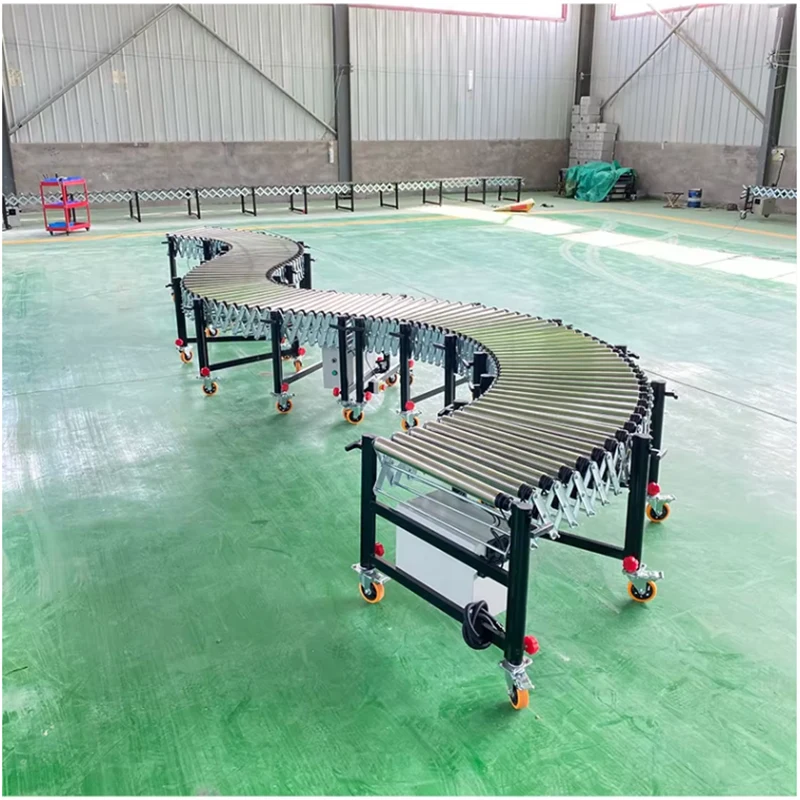

High-strength gravity conveyor roller is a kind of equipment that relies on the object's own gravity to realize material conveying. It is widely used in various industrial production and logistics scenarios. With its unique high-strength design, it can stably and efficiently complete the material conveying task in harsh working environment and high-load working conditions, providing strong support for the production and logistics links of enterprises.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

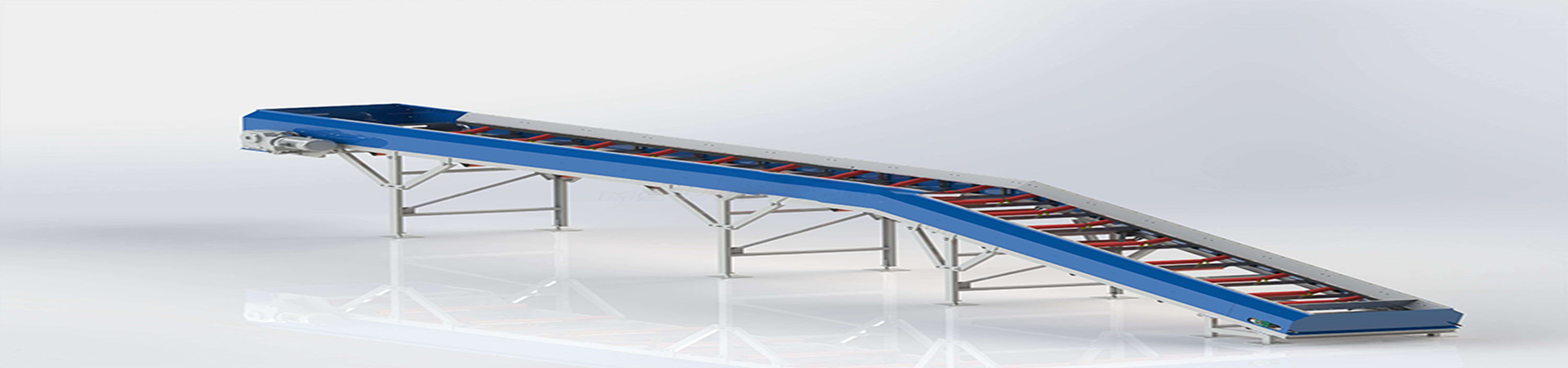

High-Quality Automated Conveyor: Designed for efficient and reliable operation, this powered roller conveyor ensures seamless line management for a wide range of industrial applications.

Customizable Sizes: Product sizes can be customized to meet specific user needs, allowing for flexible integration into existing production lines or assembly lines.

Energy Efficient: 220V electric design minimizes energy consumption, reducing operating costs and environmental impact.

Durable Construction: Made of high-quality materials, this conveyor system can withstand heavy use and ensure a long service life.

Brand New Condition, Benson Brand Guarantee: Purchase this product with a brand new condition guarantee and backed by the reputable Benson brand, giving users peace of mind.

Free replacement parts

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Product Features

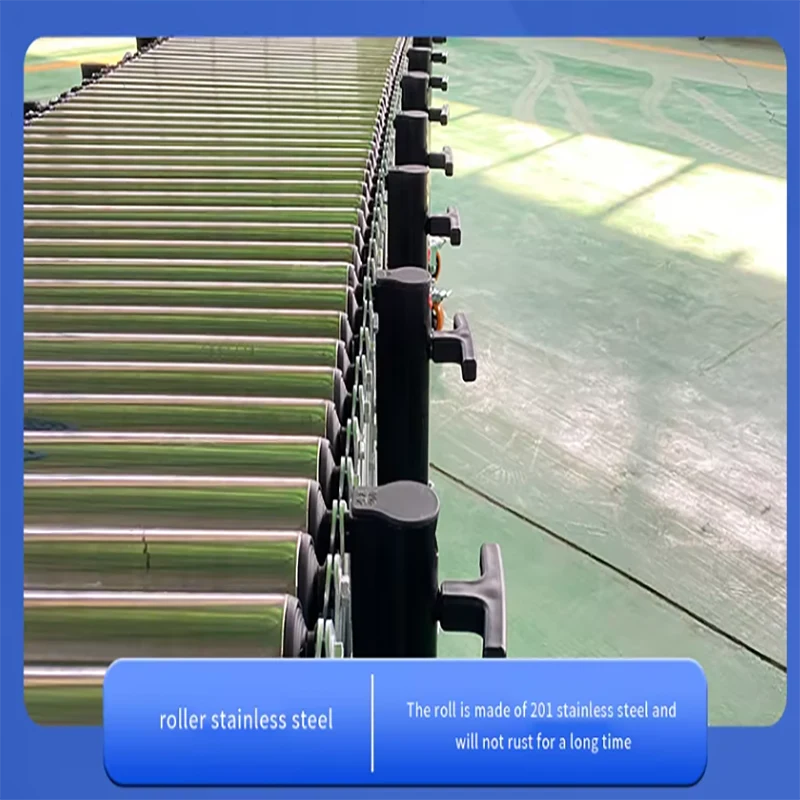

Roller material: High-quality alloy steel or high-strength carbon steel is used as the main material of the roller. These materials have excellent tensile strength and hardness and can withstand greater pressure and impact. After a special heat treatment process, the wear resistance and toughness of the roller are further improved to ensure that it is not easy to deform and damage during long-term use.

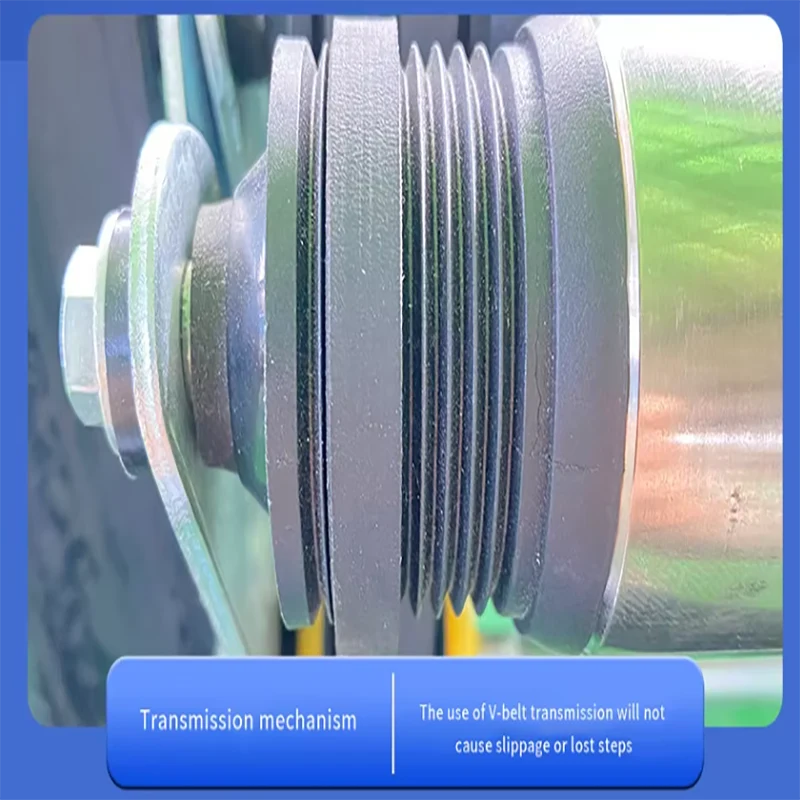

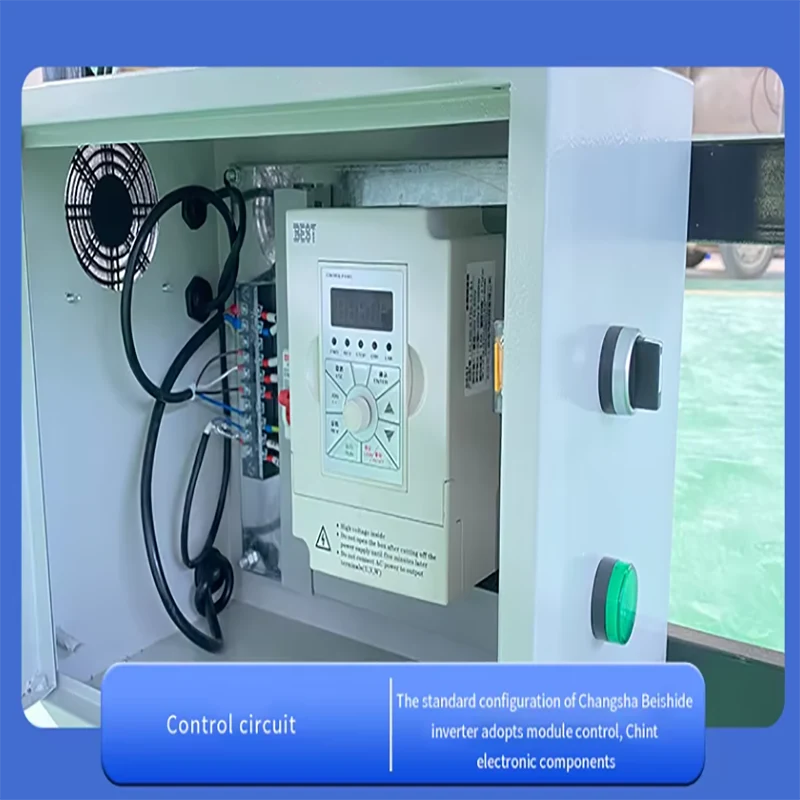

Wear-resistant gravity conveyor roller bearing configuration: equipped with high-precision, high-strength bearings, effectively reducing friction when the roller rotates and improving transmission efficiency. At the same time, the bearings have good load-bearing capacity and fatigue resistance, and can adapt to the working requirements of frequent start-stop and heavy-load operation.

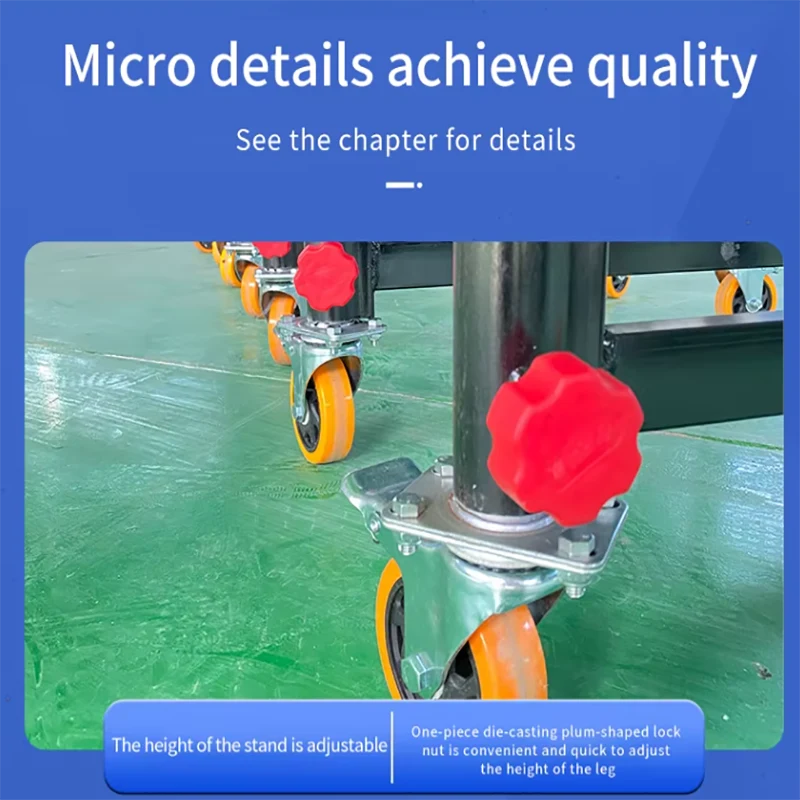

Frame design: The frame adopts a sturdy structural design and has been optimized for mechanical calculations to ensure that it will not deform when subjected to a large load. The surface of the frame is treated with anti-corrosion treatment, such as galvanizing, spraying, etc., which can effectively prevent rust and corrosion and extend the service life of the equipment.

Efficient conveying capacity

Gravity drive: The material is conveyed by using the gravity of the object itself, without the need for additional power equipment, reducing energy consumption and operating costs. At a certain inclination angle, the material can roll quickly and smoothly on the roller, which improves the conveying efficiency.

Conveying speed: According to different application scenarios and material characteristics, the conveying speed of the material can be controlled by adjusting the spacing, inclination angle and other parameters of the roller. Generally speaking, the conveying speed can be flexibly adjusted within a certain range to meet the needs of different production rhythms.

High-strength gravity conveyor roller conveying accuracy: The roller is manufactured with high precision and has a good surface finish, which can ensure the stability and accuracy of the material during the conveying process. At the same time, through the reasonable layout of the roller and the setting of the guide device, it can effectively avoid the deviation and slipping of the material and ensure the conveying accuracy.

Product Advantages

Stainless steel gravity conveyor rollers reduce costs

Due to the use of gravity drive, no additional power equipment is required, which greatly reduces energy consumption and operating costs.

The high-strength structural design makes the equipment have a long service life and reduces the cost of equipment replacement and maintenance.

Improve efficiency

The efficient conveying capacity can quickly and accurately complete the material conveying task, improving production and logistics efficiency.

Enhance reliability

High-quality materials and exquisite manufacturing technology ensure the reliability and stability of the equipment and reduce the probability of failure.

The perfect after-sales service system can respond to customer needs in a timely manner and ensure that the equipment can be quickly repaired when problems occur.

After-sales service

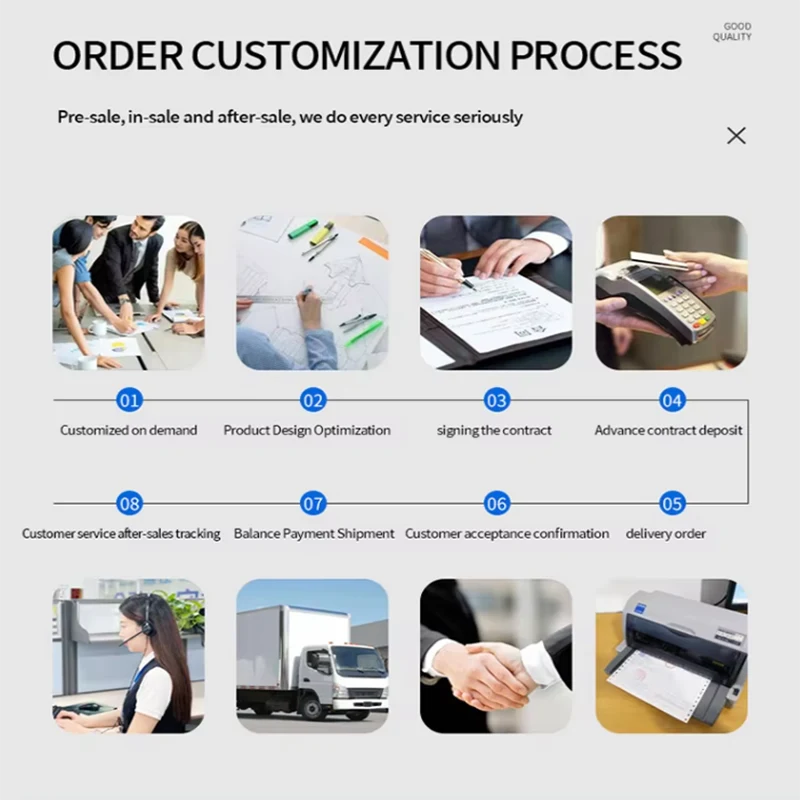

Installation and commissioning: We provide professional installation and commissioning services to ensure that the equipment can be correctly installed and operate normally. The installation and commissioning personnel have rich experience and professional knowledge, and can perform reasonable installation and commissioning according to the actual needs of customers and on-site conditions.

Training guidance: Provide customers with comprehensive operation training and technical guidance, so that customers' operators can master the operation methods and maintenance points of the equipment. The training content includes the working principle, operation process, daily maintenance, troubleshooting and other aspects of the equipment.

Repair and maintenance: We have established a complete after-sales service network to respond to customers' repair needs in a timely manner. We have a professional maintenance team and sufficient spare parts to quickly solve equipment failures. At the same time, we also provide regular equipment maintenance services to extend the service life of the equipment.

Technical support: Provide customers with long-term technical support and promptly answer technical problems encountered by customers during use. Our technicians will continuously improve and optimize the products based on customer feedback and needs to ensure that the products always maintain a leading technical level.

Products Description

<img src="/uploads/allimg/20250503/1-250503113QL15.webp" title="Gravity Conveyor Rollers alt="025.png"/>

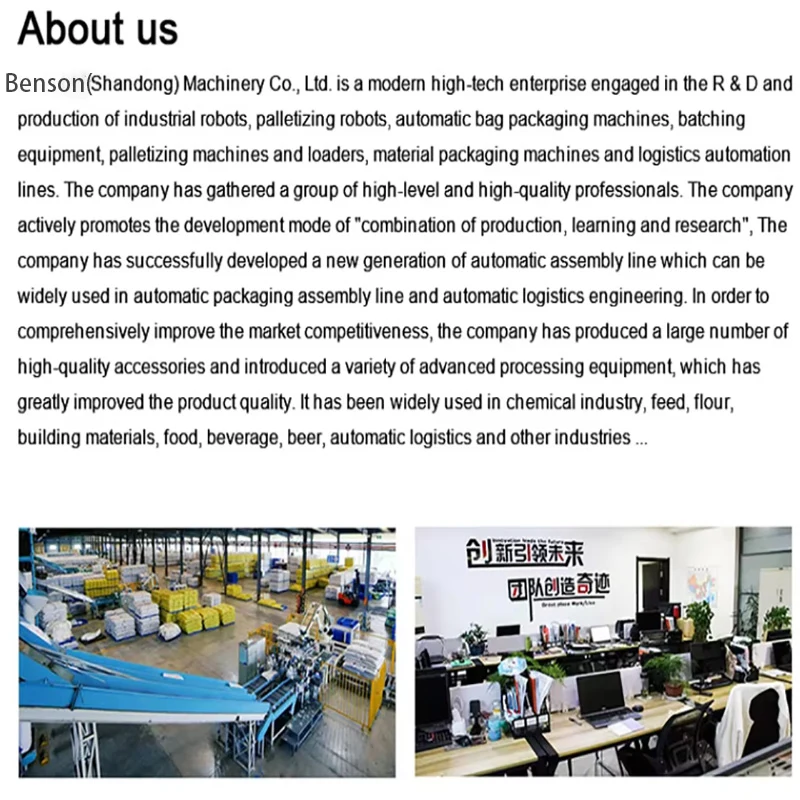

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry