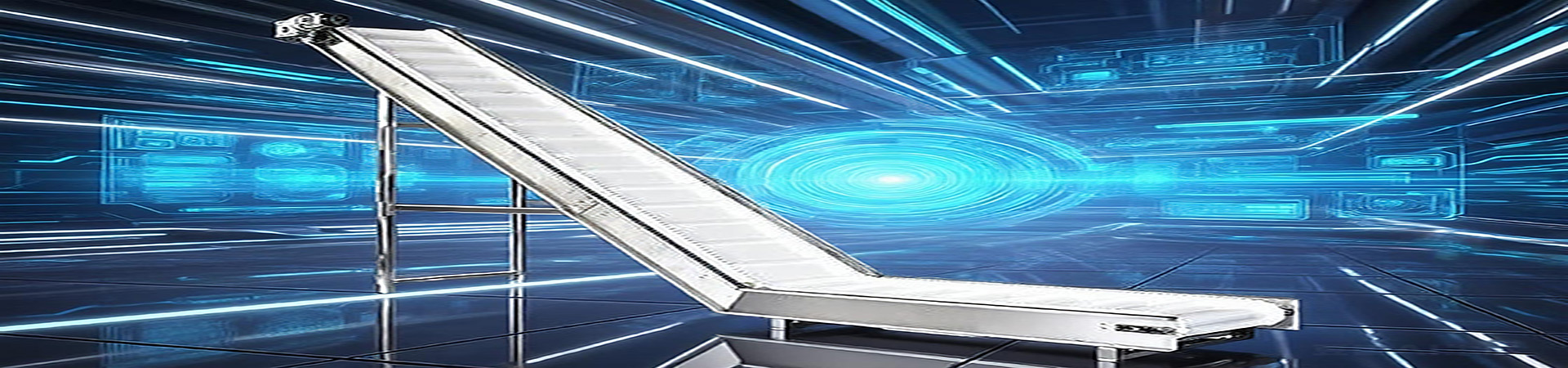

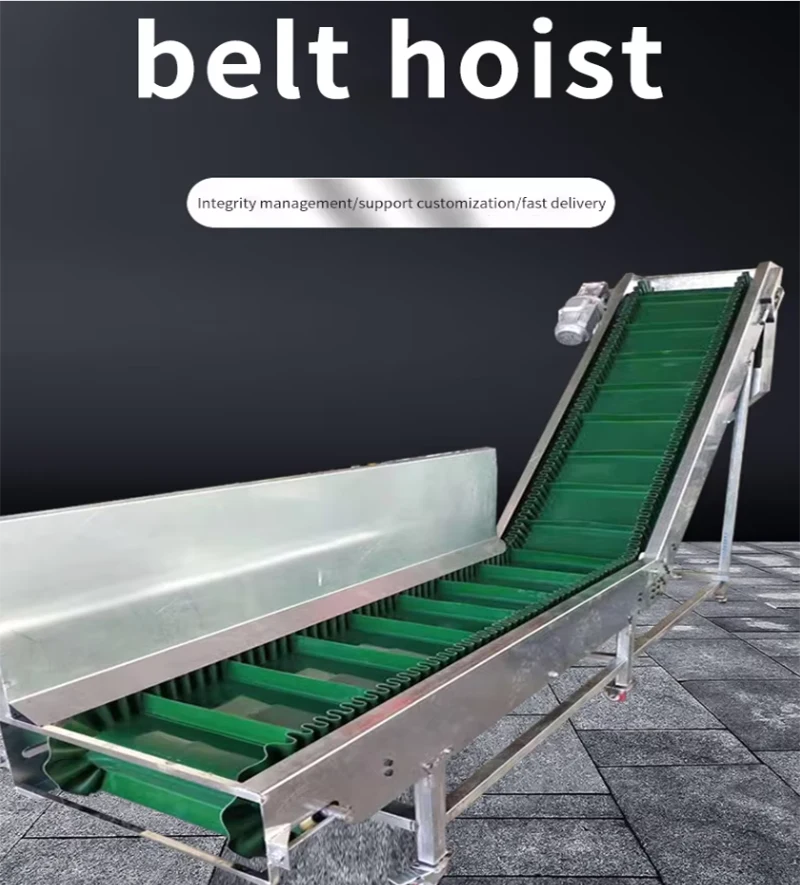

Automatic grading fruit and vegetable belt conveyor is an intelligent equipment specially developed for the production and processing of fruits and vegetables. It integrates efficient conveying and precise grading functions, effectively solves the problems of low efficiency and large errors in traditional manual sorting, and significantly improves the intelligence and standardization level of the fruit and vegetable processing industry.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Automatic grading fruit and vegetable belt conveyor - intelligent sorting, efficient empowerment of modern agricultural production

Core functions and technical advantages of automatic grading fruit and vegetable belt conveyor

1. Accurate automatic grading: Equipped with advanced visual recognition system and high-precision sensors, it can quickly identify the size, weight, color, shape and other multi-dimensional characteristics of fruits and vegetables. According to the preset parameters, it can accurately grade various fruits and vegetables such as apples, citrus, grapes, potatoes, etc., and the sorting accuracy can reach more than 98%, ensuring that the quality of fruits and vegetables of the same grade is highly consistent.

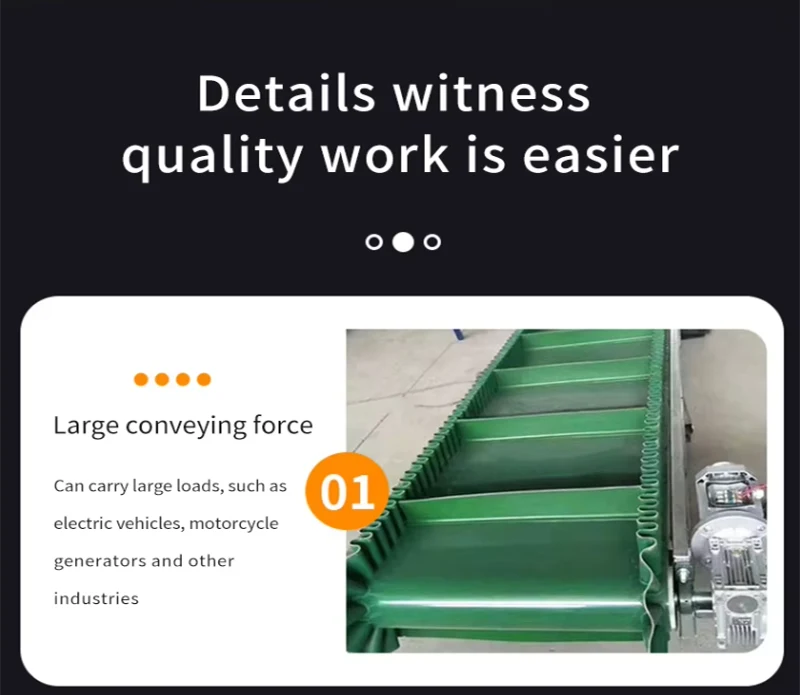

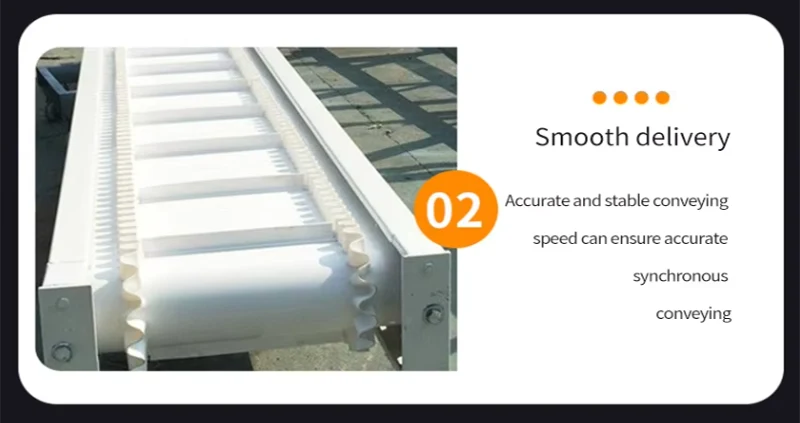

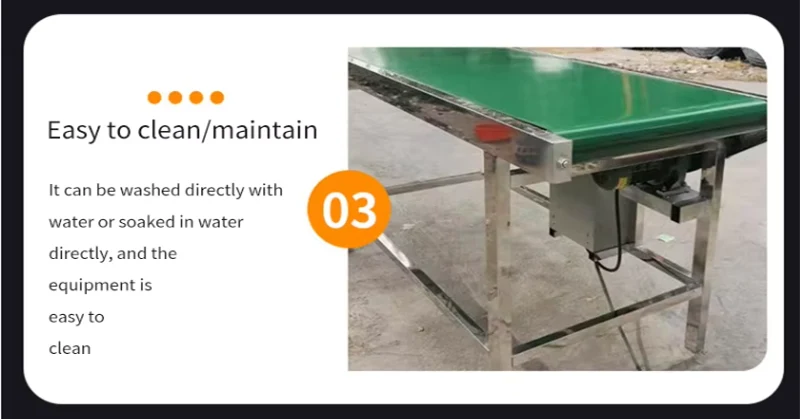

2. Efficient and stable transportation: It adopts high-strength, food-grade conveyor belts, which are wear-resistant, corrosion-resistant, and easy to clean, which can effectively prevent fruits and vegetables from being damaged during transportation. At the same time, the equipment conveying speed can be flexibly adjusted according to actual production needs to meet the requirements of production operations of different scales to the greatest extent. The processing capacity can reach several tons per hour, greatly improving production efficiency.

3. Intelligent control and convenient operation: Equipped with a humanized touch screen control system, the operation interface is simple and intuitive, and the operator can quickly complete the equipment parameter setting and operation monitoring. In addition, the equipment supports docking with the factory's intelligent management system to achieve real-time data transmission and remote control, which is convenient for production scheduling and management.

Core functional modules of automatic grading fruit and vegetable belt conveyor

1.AI visual recognition system:

Equipped with industrial-grade high-resolution cameras and deep learning algorithms, it can quickly capture the surface texture, color differences and internal defects of fruits and vegetables (need to cooperate with near-infrared detection modules), and complete the multi-dimensional data collection of single fruits in milliseconds.

2.Dynamic weighing unit:

Adopting high-precision pressure sensors and shock-absorbing structure design to ensure that fruits and vegetables can achieve ±2g weight grading accuracy in motion and avoid weight errors caused by collisions.

3. Intelligent sorting actuator:

Combination of various sorting methods such as pneumatic push rods, flip plates, and air valves, which respond quickly according to grading instructions, realize flexible sorting, and reduce the damage rate of fruits and vegetables to less than 1%.

4. PLC control system:

Support modular programming, can set grading parameters and monitor equipment status through touch screens or remote terminals, and support production data statistics and fault self-diagnosis functions.

Application scenarios

1. Fruit and vegetable planting base: Quick grading after harvesting, selling according to quality pricing, and increasing the added value of agricultural products.

2. Food processing plants: provide standardized raw material sorting for canned food, juice, preserved fruit and other processing links.

3. Cold chain logistics center: grading and packaging before storage, optimizing storage space utilization and reducing transportation losses.

4. Export trading companies: meet the strict grading standards of fruit and vegetable quality in the international market and improve customs clearance efficiency.

Quality assurance and service support

Our automatic grading fruit and vegetable belt conveyor is manufactured in strict accordance with international quality standards, and key components are made of imported high-quality materials to ensure long-term and stable operation of the equipment. At the same time, we provide customers with perfect after-sales service, including equipment installation and commissioning, operation training, and regular maintenance to make customers worry-free.

After-sales service

- Installation and commissioning: A professional team of engineers provides on-site installation, commissioning and operation training services.

- Warranty service: 1 year warranty for the whole machine, 2 years warranty for core components (motors, sensors, etc.), and lifetime cost price maintenance.

- Quick response: 7×24-hour technical support hotline, arrive at the site within 48 hours to handle sudden failures.

- Software upgrade: Free system algorithm optimization and function iteration services to ensure that the equipment performance continues to lead.

Choosing our automatic grading fruit and vegetable belt conveyor means choosing an efficient, intelligent and reliable fruit and vegetable sorting solution to help you seize the initiative in the fierce market competition!

Products Description

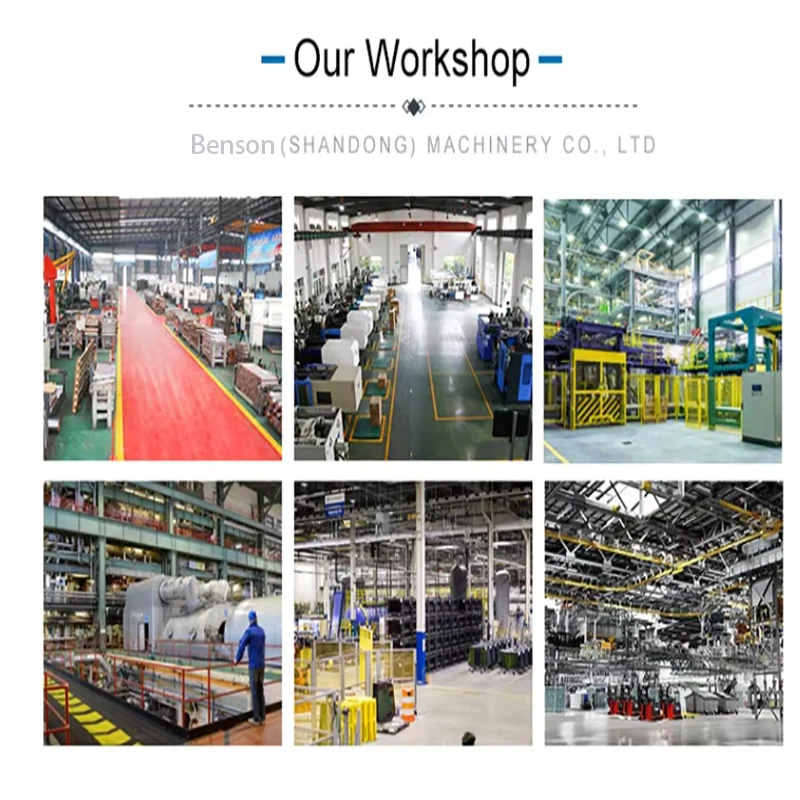

Company Profile

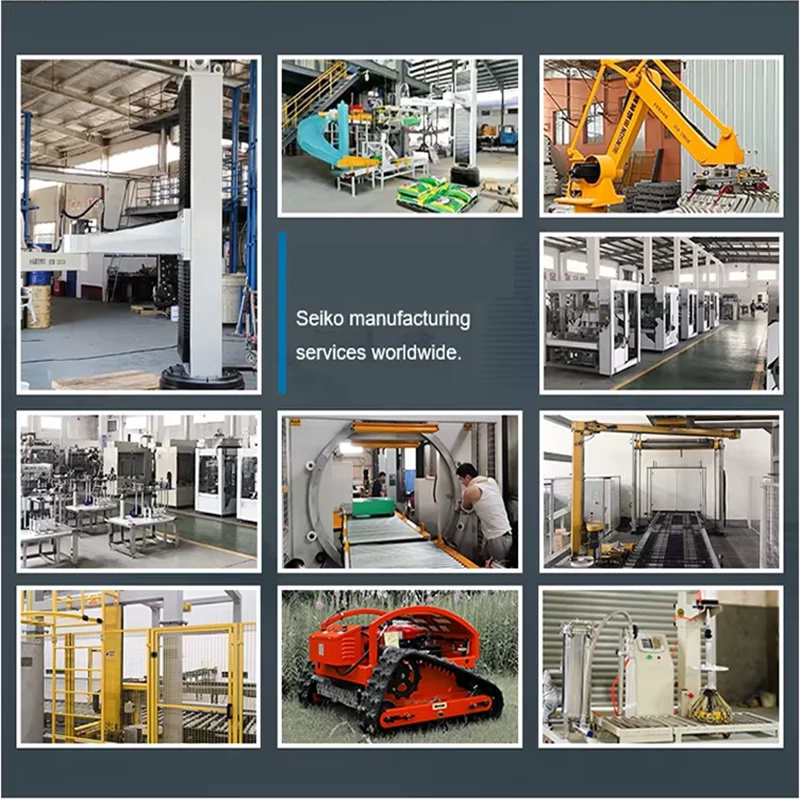

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry