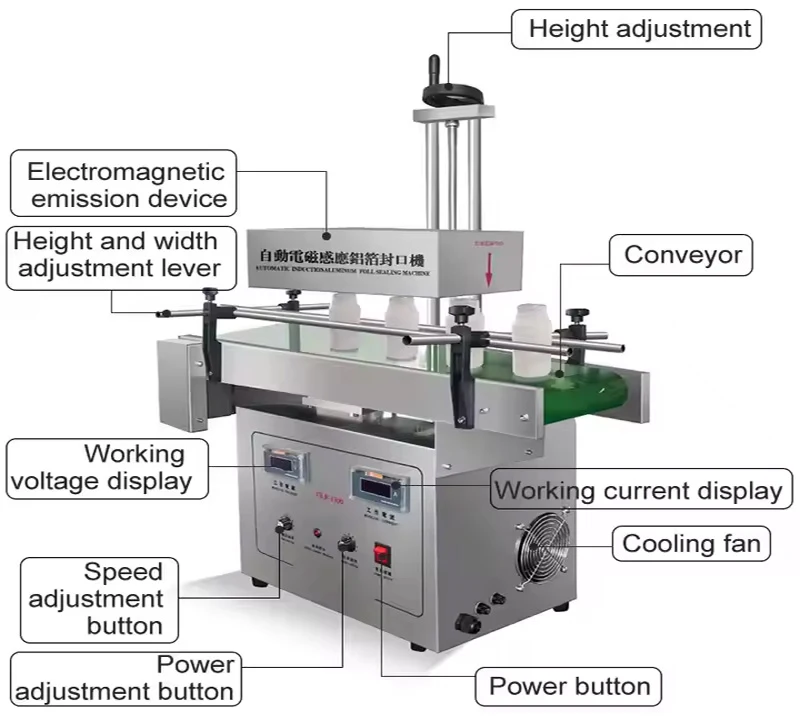

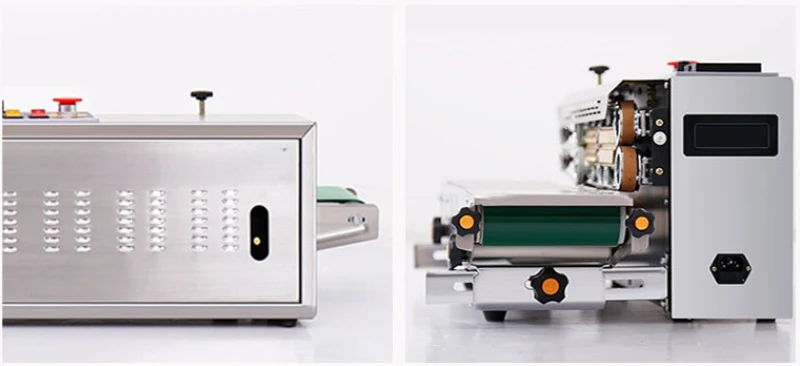

The automatic electromagnetic induction aluminum foil sealing machine is an advanced packaging device, mainly used for sealing aluminum foil on containers filled with various products such as liquids, pastes, and solids. Based on the principle of electromagnetic induction, when the machine is in operation, the alternating magnetic field generated will induce an electric current in the metal of the aluminum foil. The heat generated by the current will melt the hot-melt adhesive layer on the alumi

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Automatic Electromagnetic Induction Aluminum Foil Sealing MachineAdvantages:

when the machine is in operation, the alternating magnetic field generated will induce an electric current in the metal of the aluminum foil. The heat generated by the current will melt the hot-melt adhesive layer on the aluminum foil, so that it can closely adhere to the mouth of the container, achieving a seal. This equipment has a high degree of automation and can automatically complete a series of operations such as feeding the foil and induction sealing. It is easy to operate and can adapt to containers of different specifications and shapes.

1. High efficiency and speed: It can achieve continuous automated operation, greatly improving production efficiency and reducing manual operation time and costs. For example, on large-scale food and pharmaceutical production lines, it can quickly complete the sealing work of a large number of products.

2. Good sealing effect: The seal is tight and firm, which can effectively prevent product leakage, volatilization, moisture absorption, and contamination, extend the product's shelf life, and ensure product quality. For instance, for some volatile liquid medicines, it can well maintain their medicinal effects.

3. Strong adaptability: It can be applied to containers made of various materials, such as plastic bottles and glass bottles. It can also adapt to aluminum foils of different thicknesses and shapes, meeting the packaging needs of different industries and products. Whether it is a round, square, or irregularly shaped container, it can achieve an effective seal.

4. Pollution-free: It uses electromagnetic induction heating without an open flame. The working process is clean and environmentally friendly, and it will not cause pollution to the products and the environment, meeting the requirements of modern green production.

5. Simple operation: The operation interface of the equipment is simple and easy to understand. Operators can skillfully operate it after simple training. Moreover, the equipment runs stably and is easy to maintain, reducing the usage threshold and maintenance costs.

6. Precise control: By setting parameters, it can precisely control the sealing time and temperature, ensuring the consistency of the sealing quality each time and improving the packaging grade of the products.

Products Description

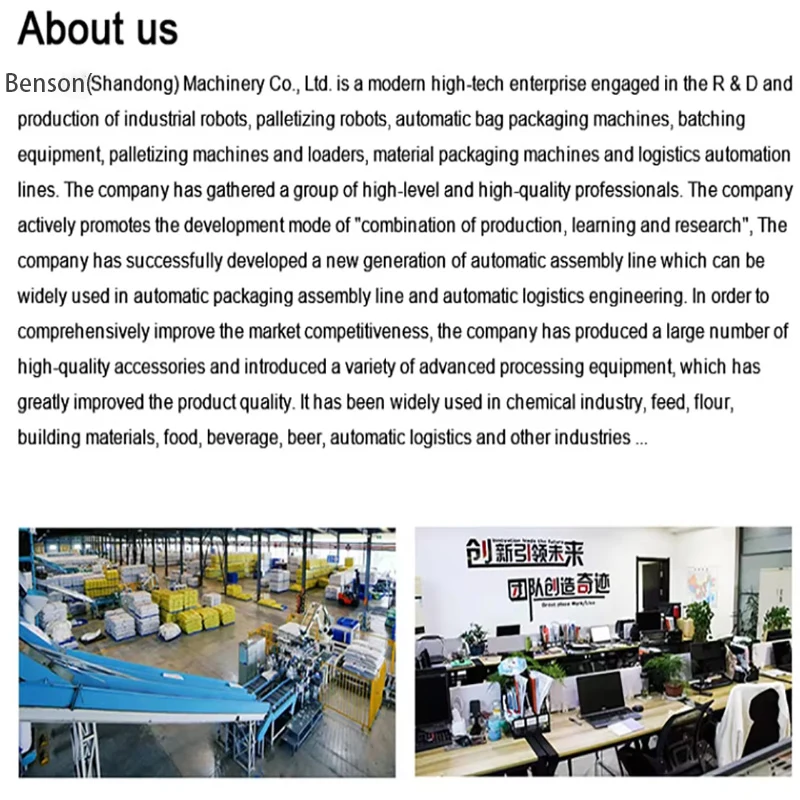

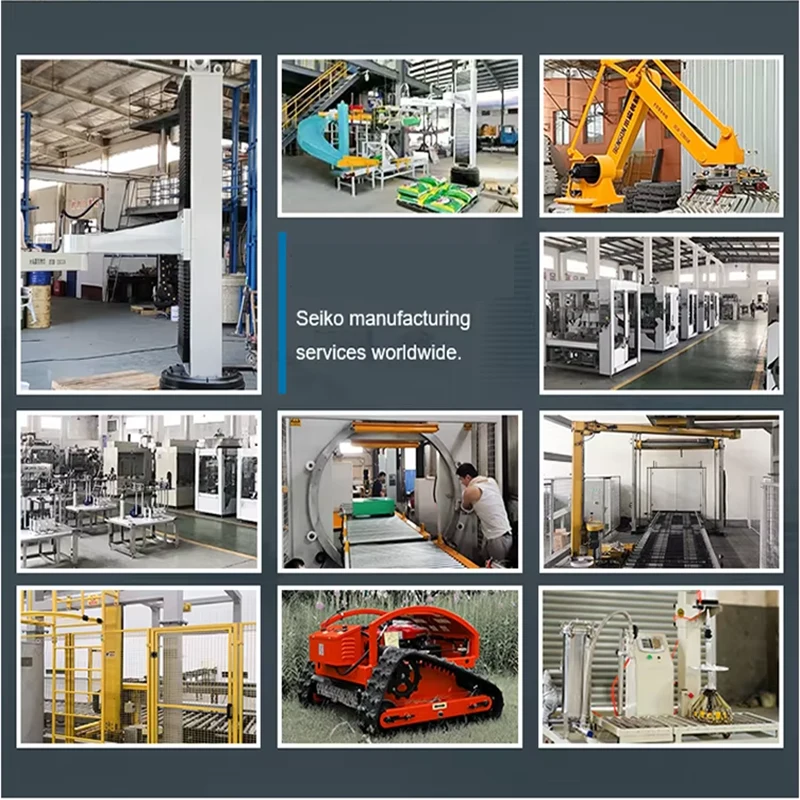

BENSON (Shandong) Machinery Co., Ltd. is a company engaged in winding machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bag feeding, large production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation A modern company that develops and produces production lines. high-tech enterprises. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "combination of production, education and research". The success of this research and development can be widely used in automated packaging routes, automated logistics engineering and other fields. A new generation of automated assembly line, the company has introduced various advanced processing equipment to comprehensively enhance market competitiveness, a large number of high-quality accessories, and product quality has been greatly improved. And other industries have been widely used, from product import to output, from electrical control to mechanical structure design, BENSON (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and equipment precision manufacturing, we have a complete after-sales service system. , To provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry