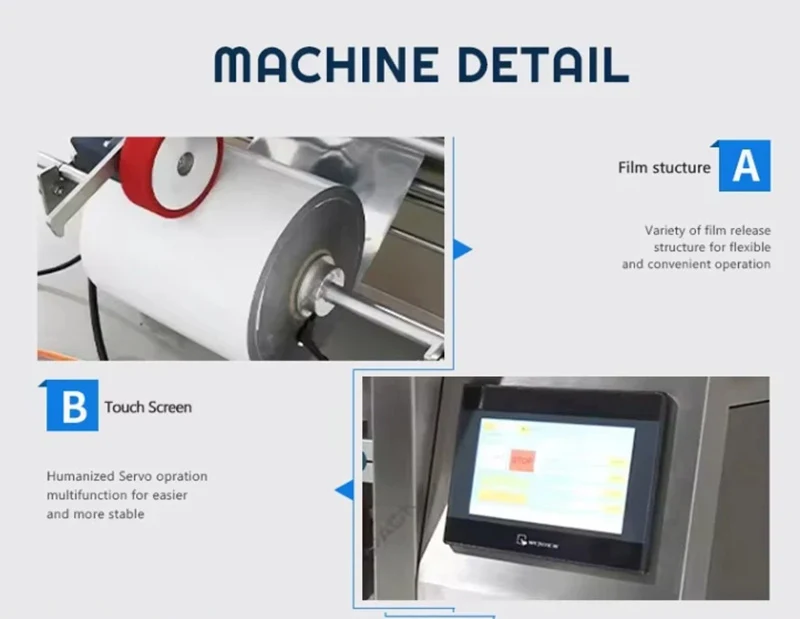

The automatic dry powder tank and bottle filling machine is a specialized piece of equipment designed for the efficient and accurate filling of dry powder into various tanks and bottles. It integrates advanced automation control systems, mechanical transmission mechanisms, and precise measurement devices. The machine can complete a series of operations such as powder feeding, metering, filling, and sealing automatically, greatly reducing manual intervention and improving production efficiency.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

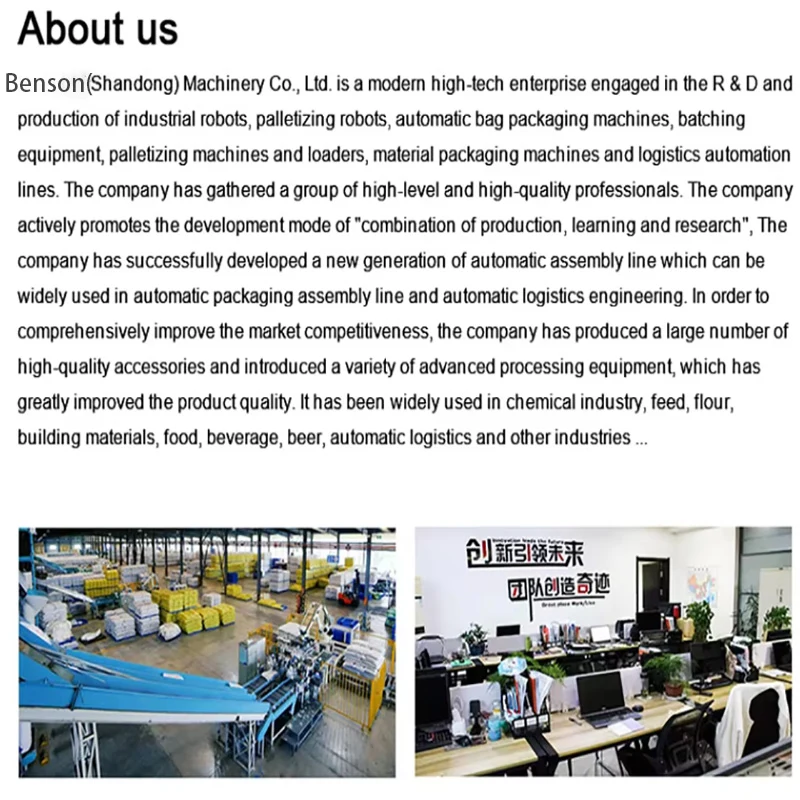

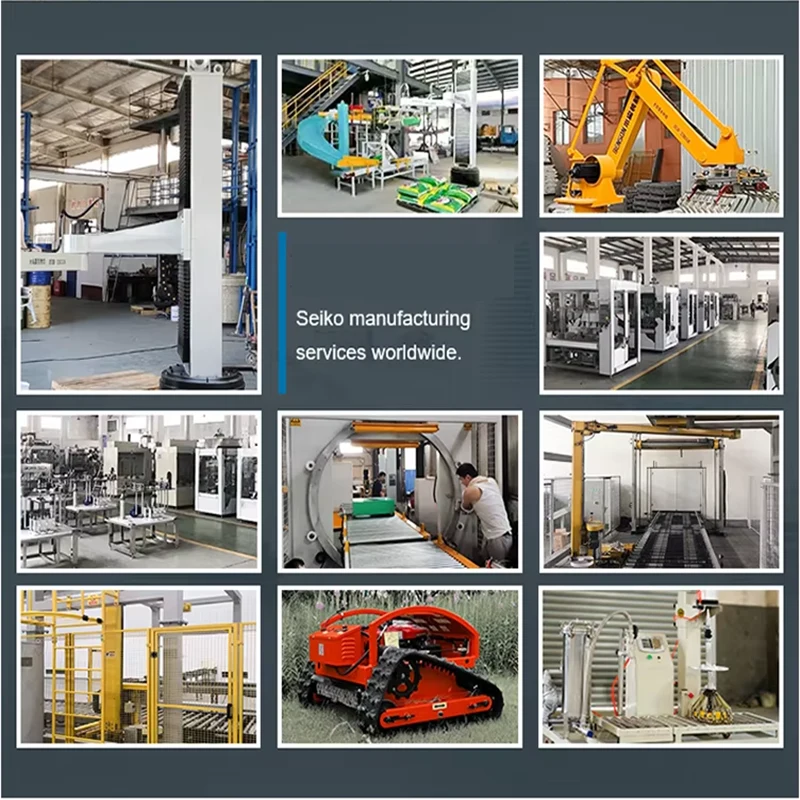

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Automatic Dry Powder Tank Filling MachineAdvantages

1. High Efficiency:With automated operation, it can continuously work for a long time, significantly increasing the production output compared to manual or semi - automatic filling methods. It can handle a large number of tanks and bottles within a short time, meeting the needs of mass production.

2. Accurate Filling:Equipped with precise metering systems, it can ensure high - precision filling of dry powder, minimizing filling errors. This helps to maintain product consistency and quality, reducing material waste caused by over - filling or under - filling.

3. Reduced Labor Costs:By replacing a large amount of manual labor, it decreases the need for a large workforce, thereby saving labor costs. Meanwhile, it also reduces the labor intensity of workers, creating a more comfortable working environment.

4. Flexibility:It can be easily adjusted to adapt to different sizes, shapes, and capacities of tanks and bottles. Additionally, it can handle various dry powder materials with different flow characteristics, making it highly versatile for different production requirements.

5. Improved Hygiene and Safety:The enclosed filling process reduces the contact between dry powder and the external environment, preventing dust pollution and ensuring the hygiene of the filled products. Moreover, the machine is equipped with multiple safety protection devices to avoid potential safety hazards during operation.

Automatic Dry Powder Tank Filling MachineApplications

1. Fire - fighting Industry:Used to fill dry powder fire extinguishing agents into fire extinguisher tanks, ensuring that fire extinguishers have the appropriate amount of effective substances to deal with fires promptly.

2. Chemical Industry:Applied for filling various chemical dry powder raw materials or products into storage tanks and packaging bottles, facilitating storage, transportation, and subsequent processing.

3. Pharmaceutical Industry:In the production of some powdered drugs, it can accurately fill drug powders into pharmaceutical bottles, meeting strict hygiene and filling accuracy requirements in the pharmaceutical field.

4. Food Industry:For filling dry food powders such as milk powder, coffee powder, and seasoning powder into packaging containers, ensuring the quality and quantity of products meet consumer expectations.

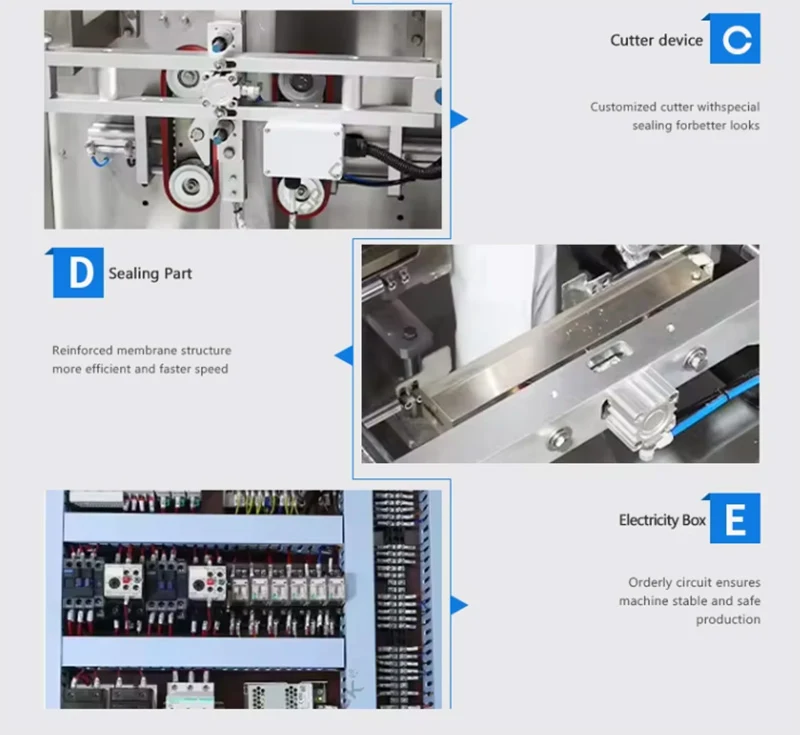

Automatic Dry Powder Tank Filling MachineFeatures

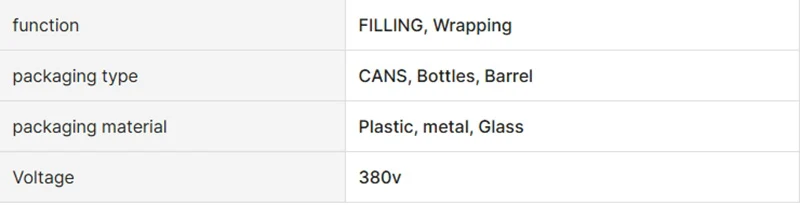

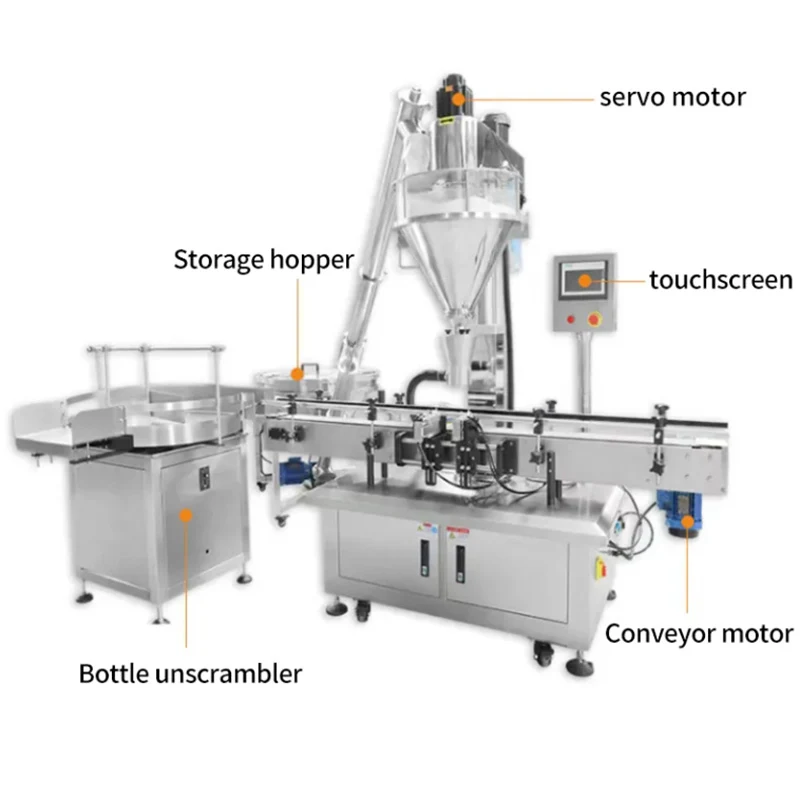

1. Intelligent Control:Adopts advanced PLC control systems and touch - screen interfaces, enabling users to easily set parameters such as filling volume, filling speed, and production quantity. The intelligent control system can also monitor the operation status of the machine in real - time and give alarms in case of malfunctions.

2. High - quality Components:Uses high - performance motors, sensors, and valves, which are durable and reliable, reducing the failure rate of the machine and extending its service life. The materials in contact with dry powder are corrosion - resistant and easy to clean, ensuring product quality and hygiene.

3. Easy Maintenance:The modular design of the machine makes it easy to disassemble and assemble components. Regular maintenance and part replacement can be carried out quickly, minimizing downtime and ensuring continuous production.

4. Low Noise Operation:Through optimized mechanical design and the use of noise - reducing components, the machine operates with relatively low noise, providing a more pleasant working environment and reducing noise pollution.

Products Description

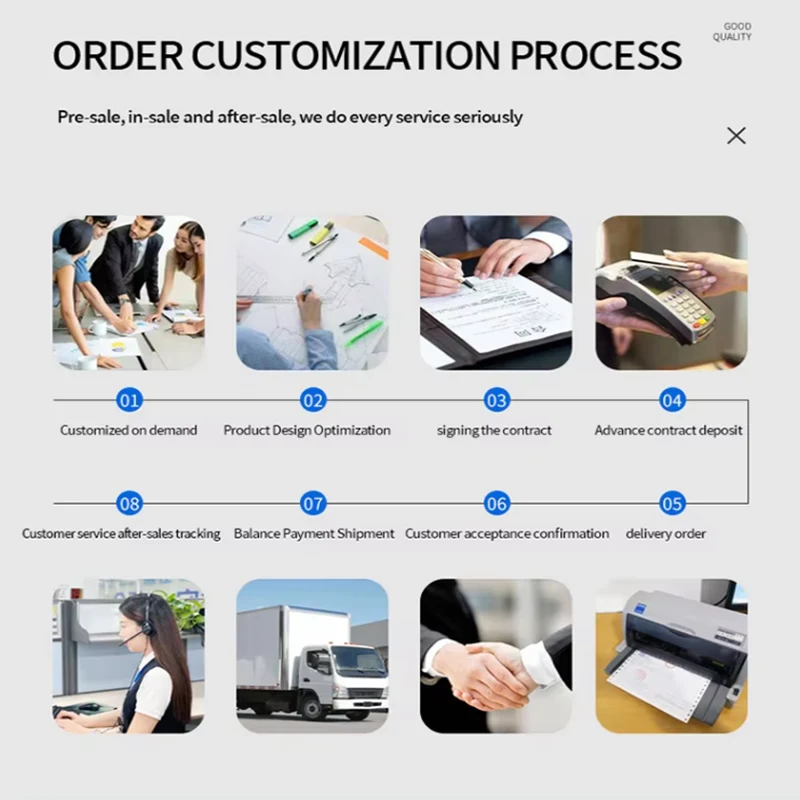

Product Inquiry