The automatic dry mortar packaging machine is a highly specialized equipment designed for the efficient and accurate packaging of dry mortar products. It integrates advanced

mechanical, electrical, and pneumatic technologies to automate the entire packaging process, which includes metering, filling, sealing, and conveying. This machine is capable of handling various types of dry mortar, such as cement - based mortar, gypsum - based mortar, and special - purpose mortar, ensuring consistent packag

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

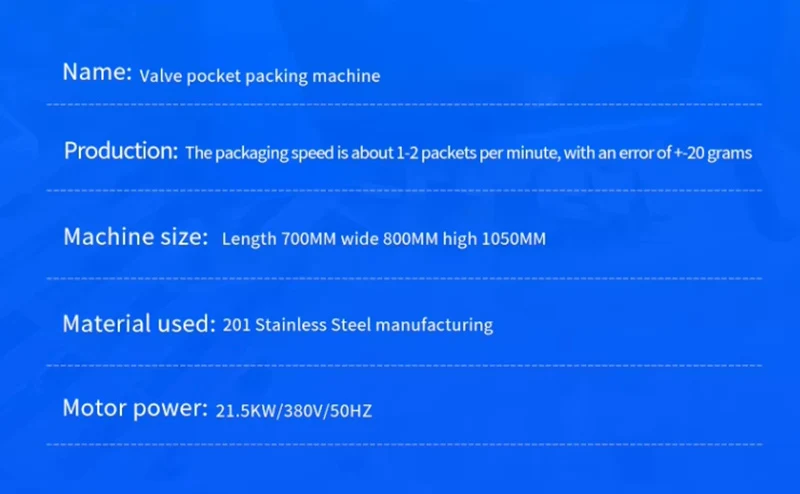

Automatic dry mortar packaging machineAdvantages

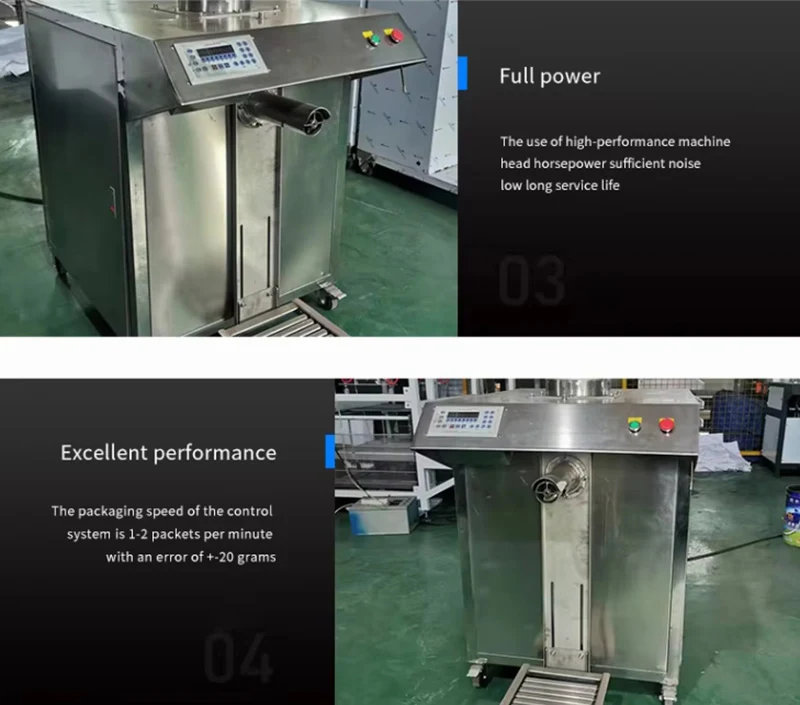

1. High Efficiency:It can significantly increase production speed compared to manual or semi - automatic packaging methods. With high - speed operation capabilities, it can handle a large volume of dry mortar packaging within a short time, meeting the demands of large - scale production.

2. Accurate Metering:Equipped with precise weighing and metering systems, the machine ensures that each package of dry mortar has a consistent weight, reducing product waste and improving customer satisfaction.

3. Labor - Saving:By automating the packaging process, it greatly reduces the need for manual labor, saving labor costs and minimizing human - error - related packaging issues.

4. Flexibility:It can be adjusted to package different weights and specifications of dry mortar products, adapting to various market requirements. Additionally, it can work with different types of packaging materials, such as paper bags, plastic bags, and woven bags.

5. Reliability and Durability:Built with high - quality components and materials, the machine has a long service life and requires relatively low maintenance. Its stable performance ensures continuous and reliable operation in industrial production environments.

6. Enhanced Product Quality:The automated sealing and packaging process protects the dry mortar from moisture, dust, and other contaminants, maintaining the product's quality during storage and transportation.

Automatic dry mortar packaging machineApplications

1. Construction Industry:It is widely used in construction material production plants to package dry mortar for various construction applications, including masonry, plastering, tiling, and insulation.

2. Building Material Stores:Helps in packaging dry mortar for retail sales, enabling easy storage and transportation for end - users such as contractors, builders, and DIY enthusiasts.

3. Infrastructure Projects:Used to package dry mortar for large - scale infrastructure construction projects, such as bridges, roads, and tunnels, ensuring a steady supply of high - quality packaged materials.

4. Precast Concrete Plants:For packaging dry mortar used in the production of precast concrete components, ensuring proper bonding and strength.

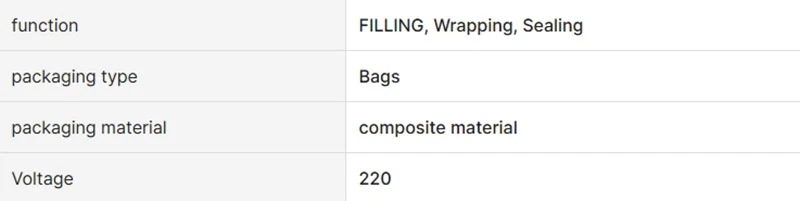

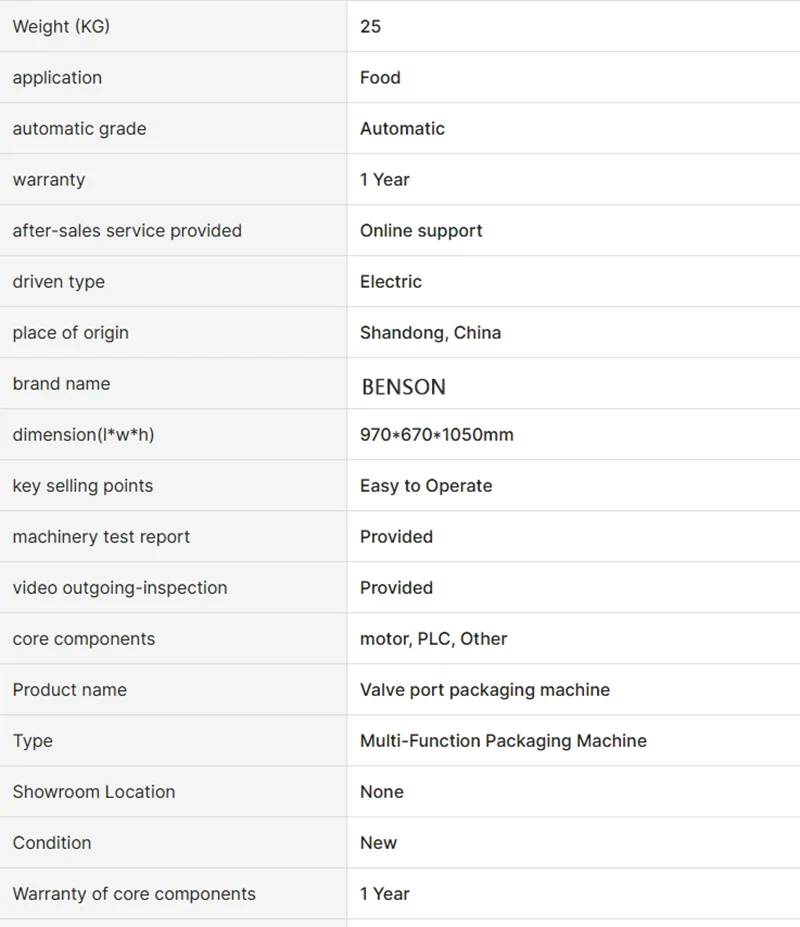

Automatic dry mortar packaging machineCharacteristics

1. Intelligent Control System:Features a user - friendly and intelligent control panel, allowing operators to easily set packaging parameters, monitor the production process, and adjust operations as needed. Some advanced models may also be equipped with remote monitoring and control functions.

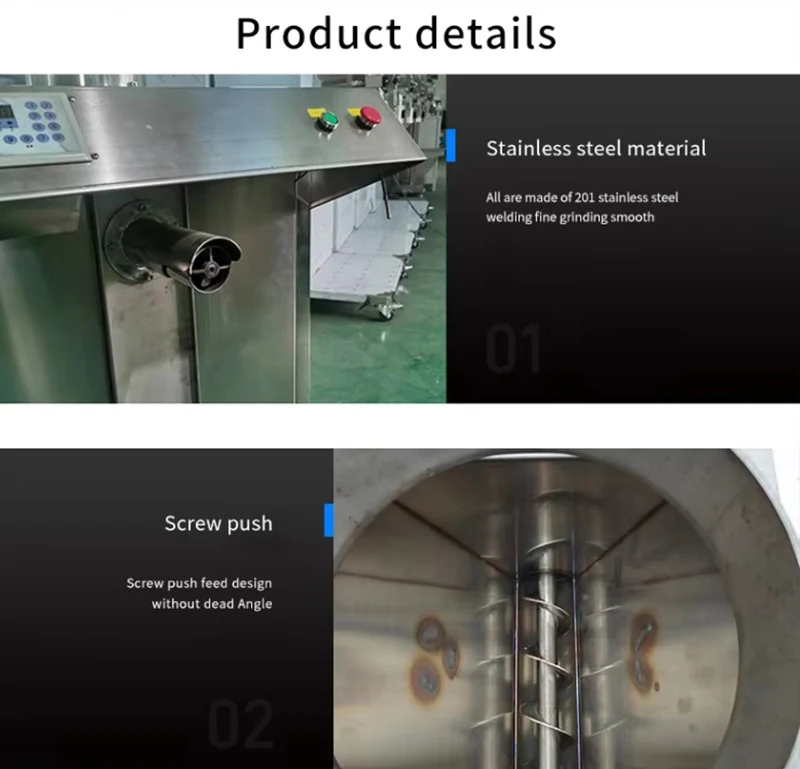

2. Dust - Proof Design:To address the issue of dust generated during the packaging of dry mortar, the machine is designed with effective dust - proof structures and dust - collection systems, creating a cleaner and safer working environment.

3. High - Precision Weighing Sensor:Utilizes high - precision weighing sensors to ensure accurate measurement of the dry mortar, with a high level of sensitivity and stability to guarantee consistent package weights.

4. Modular Structure:The modular design makes the machine easy to install, disassemble, and maintain. Different modules can be upgraded or replaced separately, reducing downtime and maintenance costs.

5. Safety Protection Devices:Equipped with various safety features, such as emergency stop buttons, protective covers, and safety interlocks, to prevent accidents and ensure the safety of operators during the machine's operation.

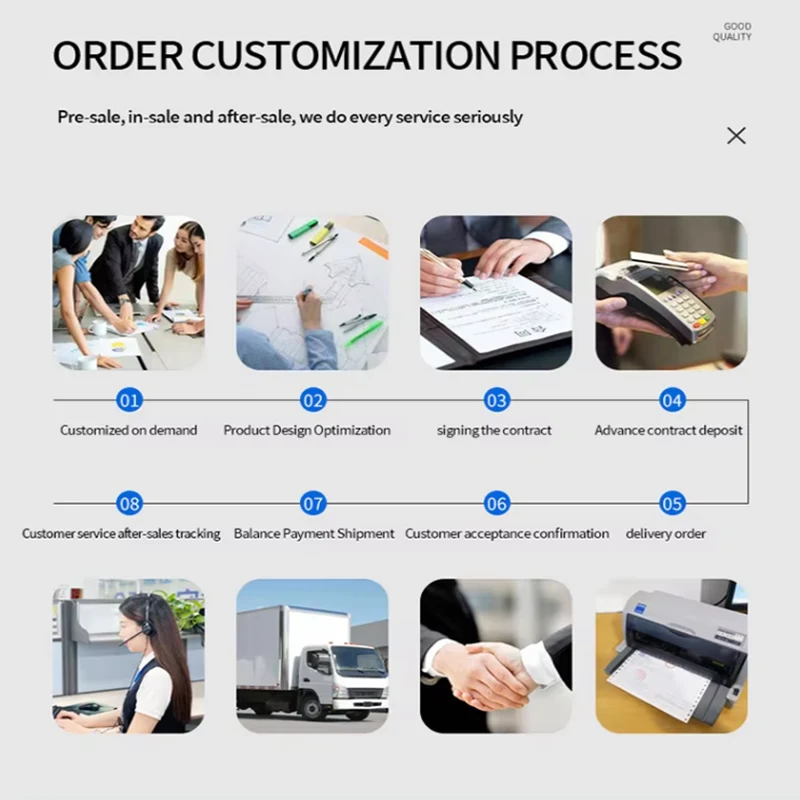

Product Inquiry