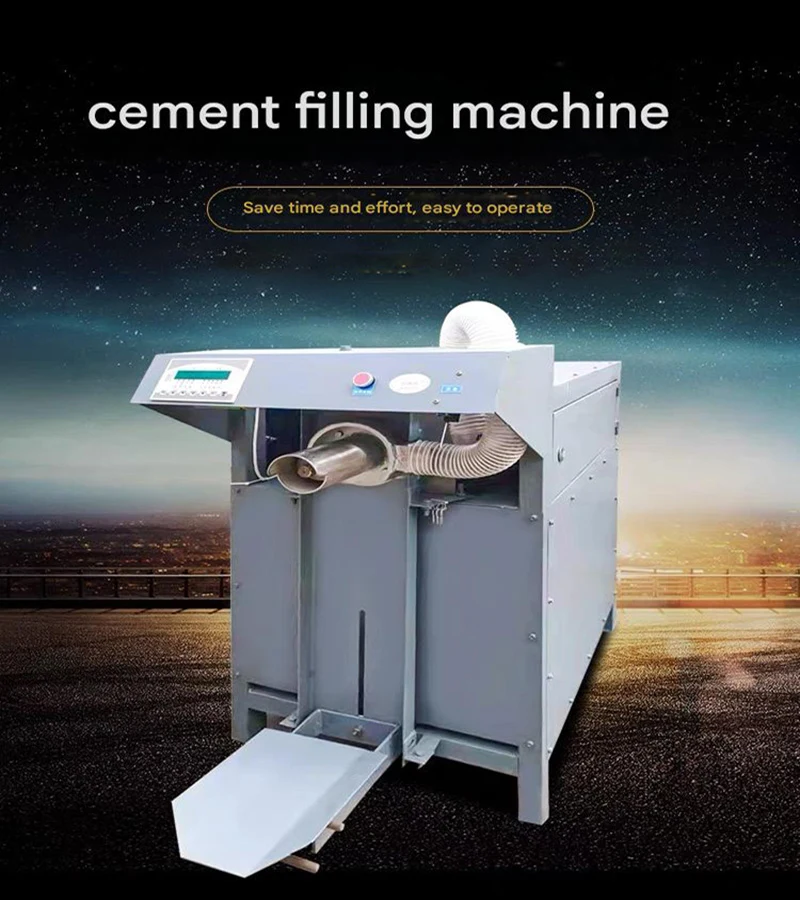

The automatic dry powder mortar impeller packaging machine is specialized equipment designed for efficient and precise packaging of dry powder mortar. It integrates advanced automation control systems, using impeller structures to accurately measure and fill dry powder mortar into various packaging containers (e.g., bags or barrels). The machine can automatically complete a series of operations, including material metering, filling, and sealing, significantly enhancing packaging effiency while

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

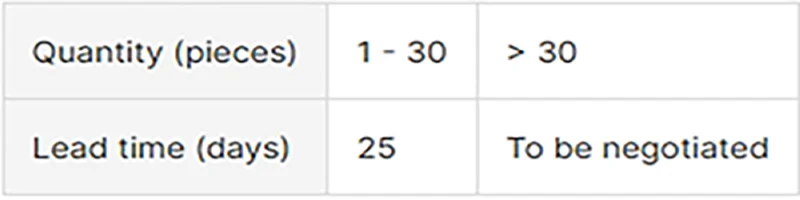

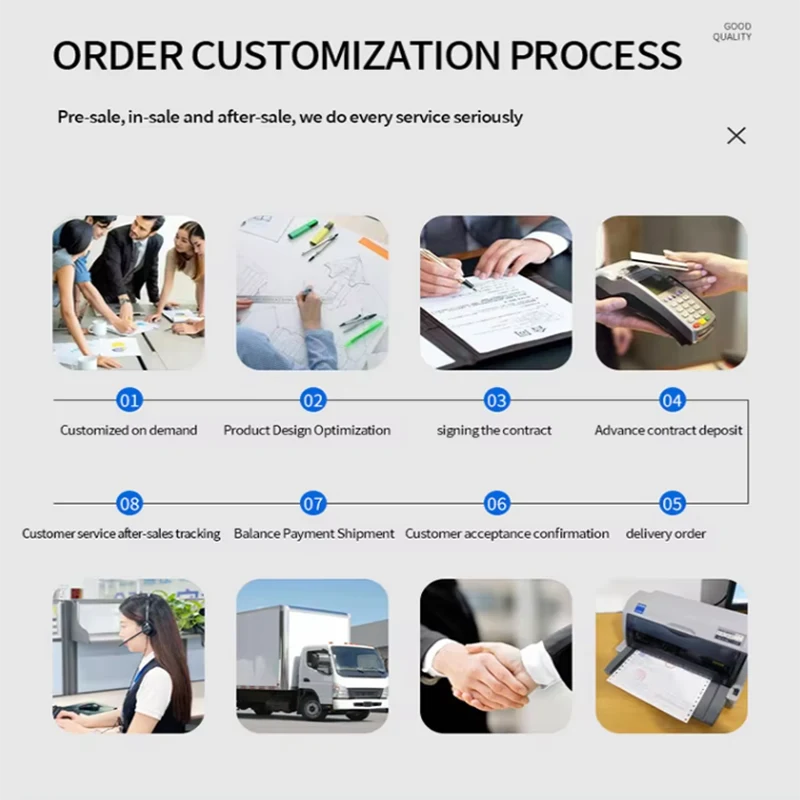

Lead time

Benson Automatic Dry Powder Mortar Impeller Packaging MachineAdvantages

1. High Efficiency: With automated operation, it enables continuous work with minimal manual intervention, drastically increasing packaging speed and output to meet large-scale production demands.

2. Accurate Measurement: The impeller metering system achieves high-precision measurement of dry powder mortar, reducing material waste and ensuring consistent product weight per package, which facilitates standardized production and market sales.

3. Cost Saving: By reducing labor costs and minimizing material spillage/waste, the machine helps enterprises save long-term production costs. Its high-speed operation also shortens the production cycle, improving resource utilization.

4. Reliability: Constructed from high-quality materials and components, the machine features strong durability, stability, and low failure rates. Regular maintenance ensures long-term stable operation, reducing downtime and maintenance costs.

BensonAutomatic Dry Powder Mortar Impeller Packaging MachineFeatures

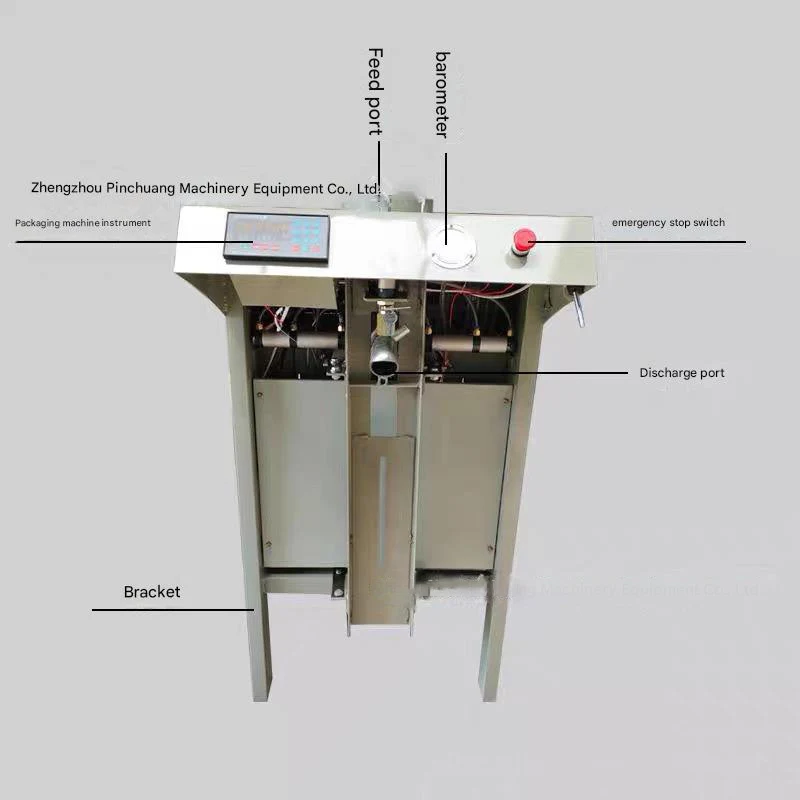

1. Automated Control: Equipped with intelligent control systems (e.g., PLC), it allows easy programming to adjust packaging parameters (filling volume, packaging speed, sealing time) according to different production needs.

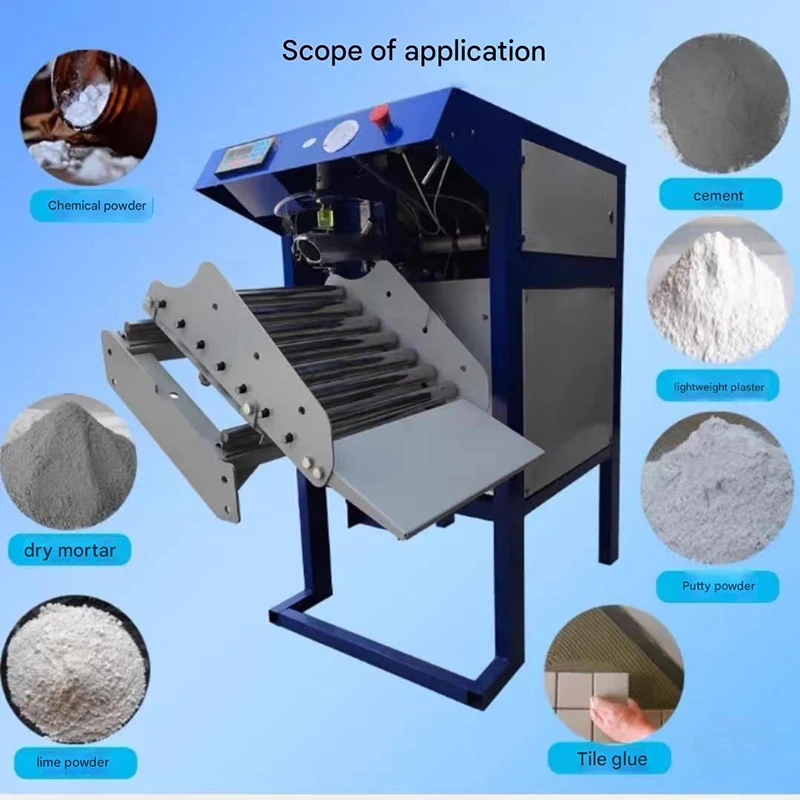

2. Versatility: Adaptable to various packaging specifications and materials, it handles both small retail packages and large construction-grade dry powder mortar, as well as different mortar types (masonry mortar, plastering mortar, tile adhesive).

3. User-Friendly Design: Features an intuitive operation interface for easy operator training and use. Safety protections (emergency stop buttons, safety fences) ensure operator safety during operation.

4. Dust-Proof Design: Designed with effective dust control measures (dust collection hoods, sealed structures) to address the dusty nature of dry powder mortar, reducing emissions, improving the work environment, and protecting operator health.

BensonAutomatic Dry Powder Mortar Impeller Packaging MachineApplications

1. Building Materials Industry: Primarily used for packaging dry powder mortar in construction material production enterprises. Dry powder mortar is widely applied in building projects (wall masonry, surface plastering, floor tiling), helping manufacturers quickly and accurately package products for delivery to construction sites or markets.

2. Decoration Industry: Meets the high demand for small-package dry powder mortar in home improvement projects. The machine enables decoration material suppliers to package products in various specifications, providing convenient and standardized solutions for decoration projects.

3. Large-Scale Construction Projects: Supports infrastructure projects (bridges, highways, large buildings) requiring massive dry powder mortar. Its high-efficiency and accurate packaging ensures timely supply of high-quality mortar, enhancing construction efficiency and quality.”

Products Description

Product Inquiry