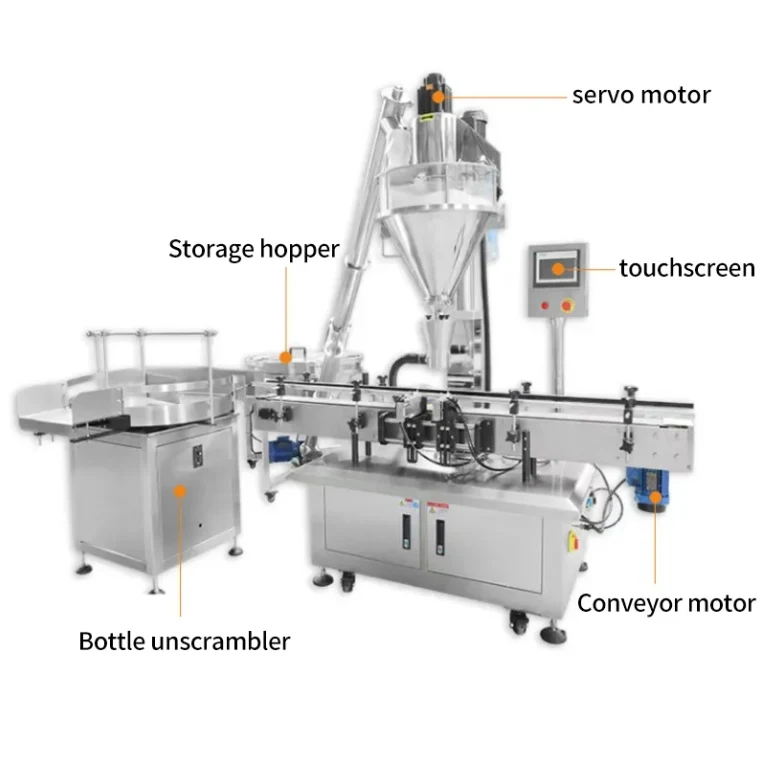

The automatic detergent powder filling and packaging machine is an advanced industrial equipment designed for high - speed and accurate filling and packaging of detergent powder. It integrates multiple functions, including powder metering, filling, bagging, sealing, and labeling. The machine is equipped with a precise powder feeding system that can accurately control the filling volume according to preset parameters. It usually works in conjunction with an automatic bag - feeding device,

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

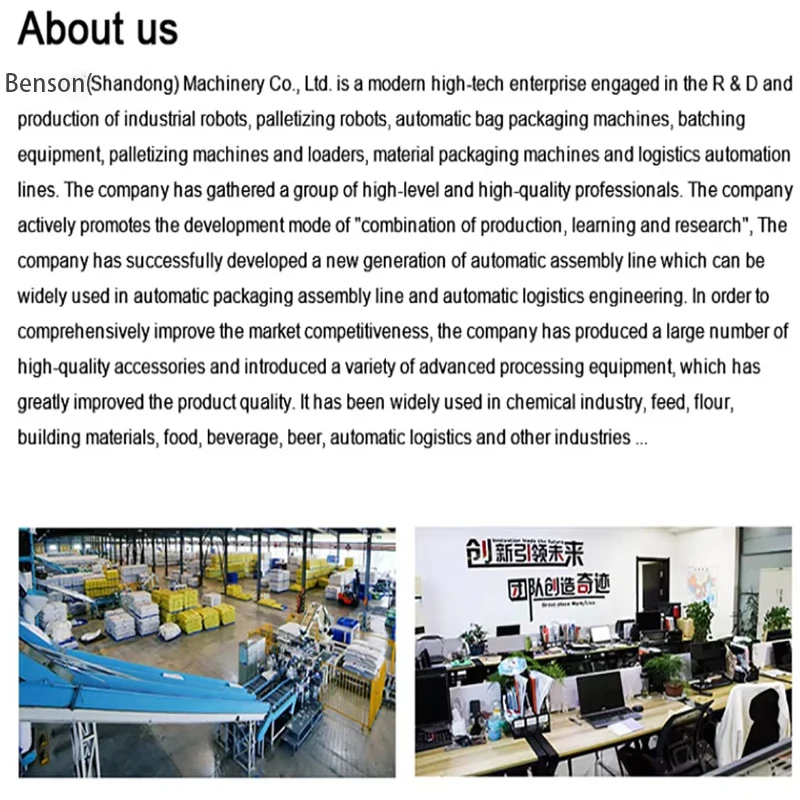

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

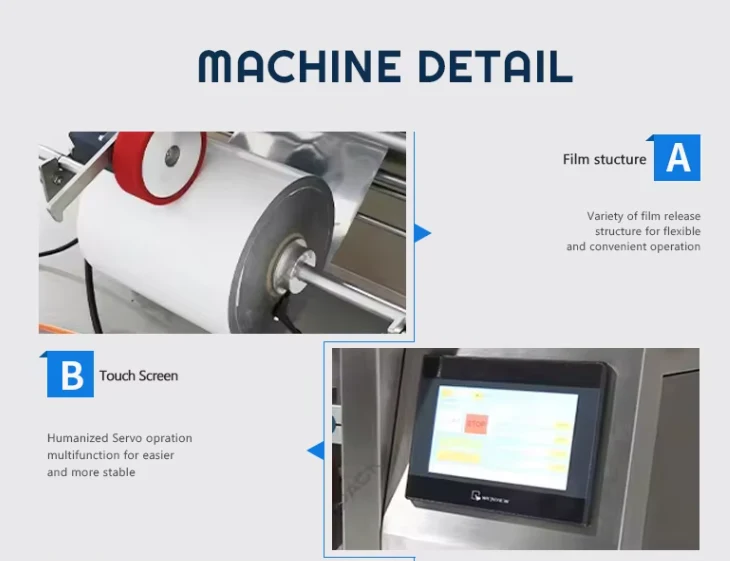

DescriptionAutomatic Detergent Powder Filling and Packaging Machine

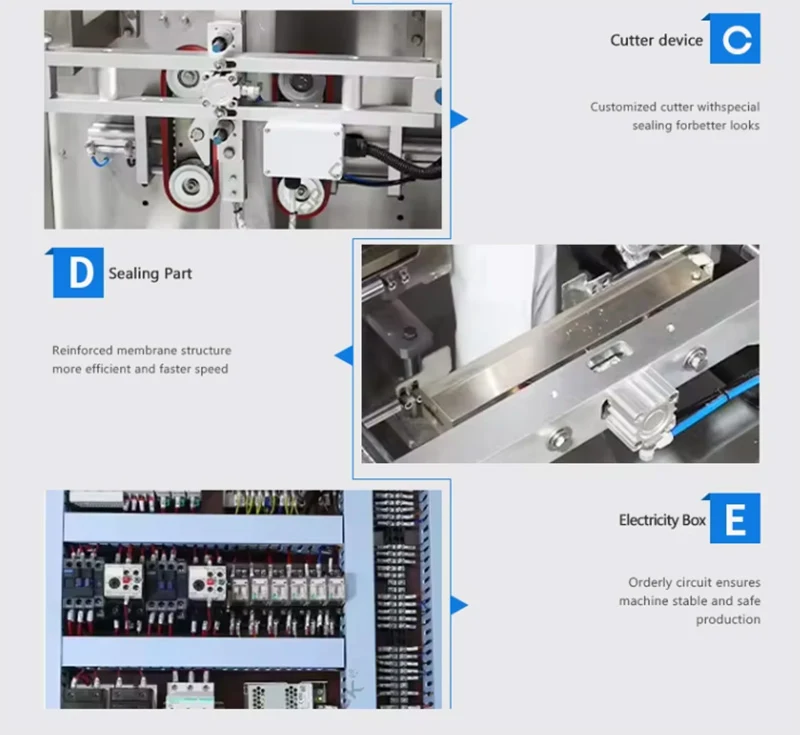

It usually works in conjunction with an automatic bag - feeding device, which can continuously feed packaging bags, improving production efficiency. The sealing part uses advanced heat - sealing or ultrasonic sealing technology to ensure the tightness of the package, preventing powder leakage.

1. High Efficiency: It can complete a large number of filling and packaging tasks in a short time, significantly increasing production output compared to manual operations. For example, it can process hundreds of packages per hour, meeting the mass production needs of large - scale detergent manufacturers.

2. Precision: The advanced metering system enables highly accurate powder filling, reducing product weight errors. This ensures product consistency and helps manufacturers comply with strict quality standards.

3. Cost - Saving: By reducing labor requirements, the machine cuts down on labor costs in the long run. Additionally, its precise filling minimizes powder waste, saving raw material costs.

4. Flexibility: It can be adjusted to handle different packaging specifications, such as various bag sizes and filling weights, making it suitable for a wide range of product lines.

5. Enhanced Product Quality: The tight sealing and clean filling process prevent product contamination, maintaining the quality and performance of the detergent powder during storage and transportation.

Automatic Detergent Powder Filling and Packaging Machine Applications

1. Detergent Manufacturing Industry: It is mainly used in large - and medium - sized detergent production plants to package various types of detergent powders, such as laundry powder, dishwashing powder, and multi - purpose cleaning powders.

2. Household Chemicals: Applicable for packaging other powdered household chemicals like fabric softener powder or deodorizing powders.

3. Small - scale Enterprises and Start - ups: Some models with adjustable production capacity can also meet the needs of small - scale producers, helping them enter the market with efficient and cost - effective packaging solutions.

4. Contract Packaging: Packaging service providers can use this machine to handle powder filling and packaging orders for different clients in the detergent and related industries

1. High automation level: It can automatically complete a series of processes such as powder metering, filling, bag feeding, sealing, and labeling with minimal human intervention, reducing labor intensity and improving production efficiency.

2. Precise filling: Equipped with an accurate powder metering device, it can control the filling volume precisely to ensure that each package has a consistent weight and meets the product quality standards.

3. High production efficiency: It has a high working speed and can process a large number of products within a short time, meeting the mass production needs of enterprises and helping them increase production output.

4. Flexible operation: It can adapt to different specifications of packaging bags and filling weights, and can be adjusted according to the actual production needs, which has strong versatility and can meet the requirements of different product lines.

5. Good sealing performance: Adopting advanced sealing technology, such as heat sealing or ultrasonic sealing, it can ensure that the packaging is tightly sealed, preventing the detergent powder from leaking and being contaminated, and extending the shelf life of the product.

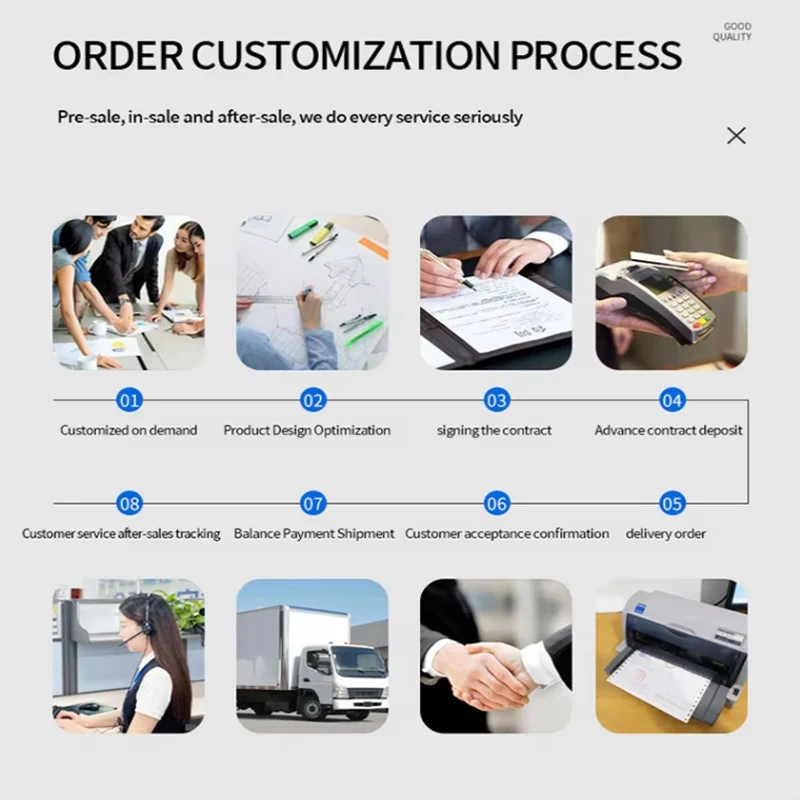

Product descriptions from the supplier

Product Inquiry