The Automatic Tile Adhesive Mortar Packaging Machine is a highly automated industrial device specially designed for the quantitative packaging of tile adhesive mortar. The equipment integrates multiple functional modules such as material conveying, precise metering, automatic filling, and sealing. Through advanced sensors and intelligent control systems, it can carry out continuous and efficient packaging operations for tile adhesive mortar. Its design conforms to the characteristics

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Automatic Tile Adhesive Mortar Packaging MachineAdvantages

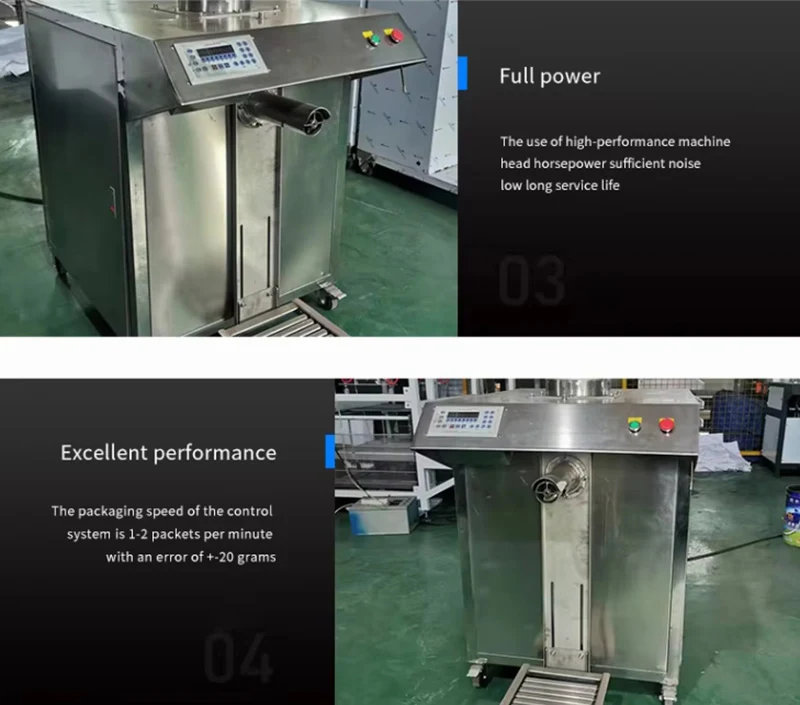

1. High Efficiency and Energy Saving: Using an automated production line, it can significantly improve packaging speed compared with traditional manual packaging, reducing production time costs. At the same time, the optimized power system of the equipment reduces energy consumption, achieving green production.

2. High-Precision Metering: Equipped with high-precision weighing sensors and intelligent control systems, it can control the packaging weight error within a极小 (very small) range, ensuring that the weight of each bag of tile adhesive mortar is consistent and enhancing product quality and brand reputation.

3. Reduced Labor Costs: Automated operation reduces reliance on a large amount of labor, not only reducing the labor cost expenditure of enterprises but also avoiding the problem of unstable packaging quality caused by manual operation.

4. Strong Flexibility: It can quickly adjust packaging parameters according to different specifications of packaging bags and packaging weight requirements, meeting diversified production needs and being suitable for production scenarios of different scales and requirements.

Automatic Tile Adhesive Mortar Packaging MachineApplications

1. Building Material Production Enterprises: Used for the finished product packaging link after tile adhesive mortar production, meeting market demand for standardized packaged products and helping enterprises improve production efficiency and market competitiveness.

2. Building Material Wholesale Markets: Providing on-site packaging services for small building material distributors, flexibly adjusting packaging specifications according to customer order requirements to achieve rapid delivery.

3. Renovation Project Sites: In large-scale renovation projects, tile adhesive mortar can be directly packaged at the construction site, reducing losses during transportation and facilitating construction management and material use.

Automatic Tile Adhesive Mortar Packaging MachineFeatures

1. Intelligent Control: Equipped with a PLC intelligent control system and an intuitive and user-friendly operation interface, operators can easily set packaging parameters through a touch screen, monitor equipment operation status, and achieve fault self-diagnosis and alarm functions, facilitating quick repair and maintenance.

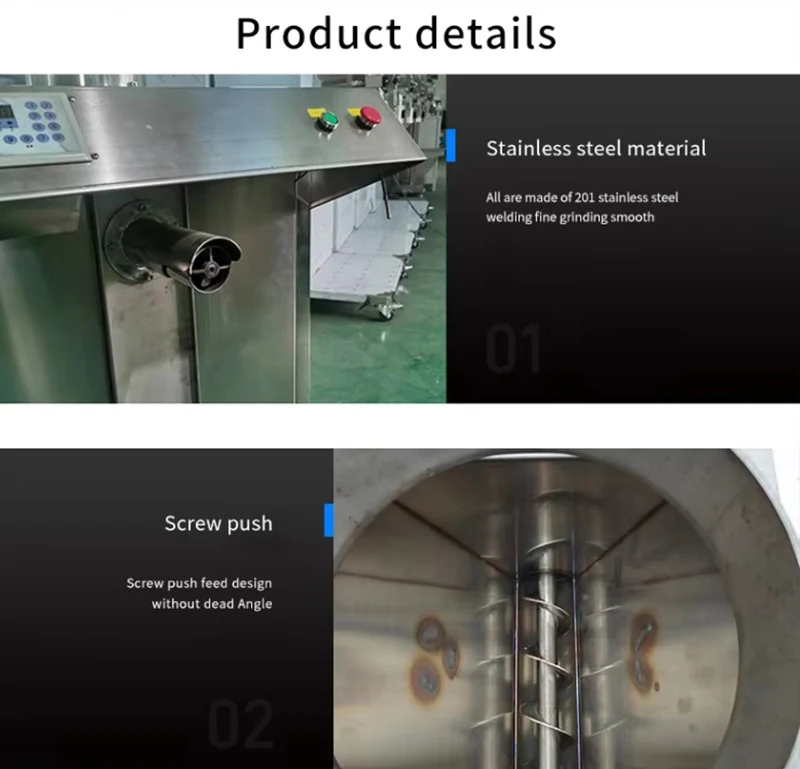

2. High-Quality Materials and Structure: The machine body is made of corrosion-resistant and high-strength stainless steel and alloy materials, with good wear resistance and impact resistance, adapting to the characteristics of high dust and strong corrosion in the tile adhesive mortar production environment and extending equipment service life.

3. Environmental Design: Equipped with an efficient dust removal device, it can effectively collect dust generated during the packaging process, reduce dust pollution in the workshop, improve the working environment, and comply with environmental protection production standards.

4. Modular Design: Each functional module is independent and can be quickly disassembled and assembled, facilitating equipment installation and debugging, daily maintenance, and later upgrading and transformation, reducing equipment maintenance difficulties and costs.

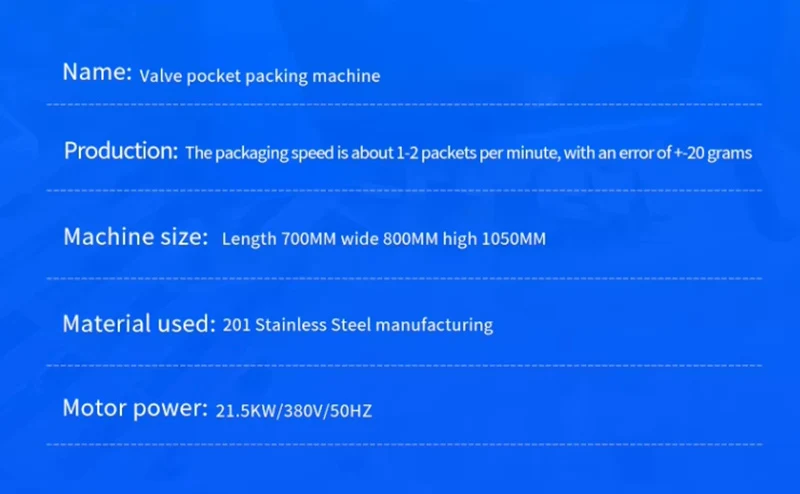

Products Description

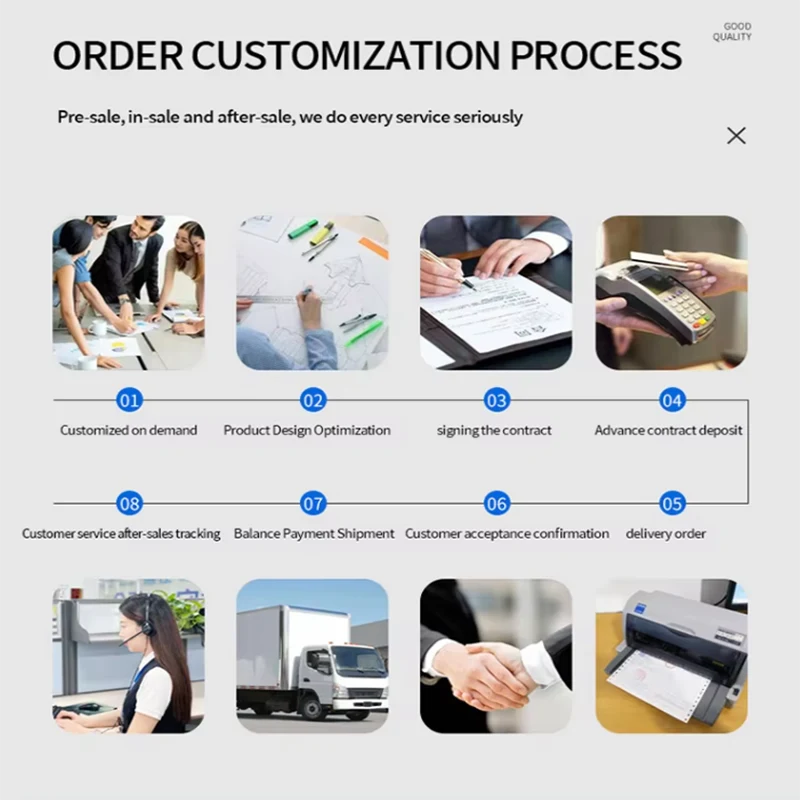

Product Inquiry