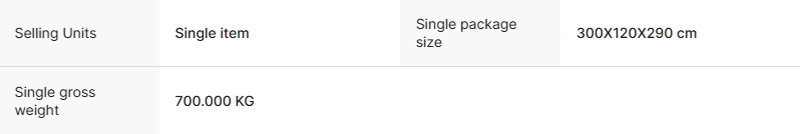

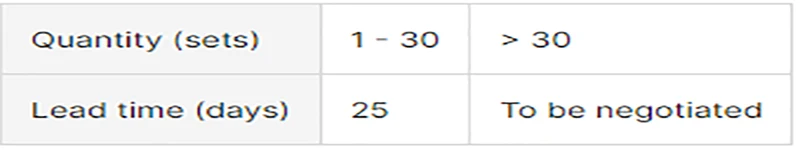

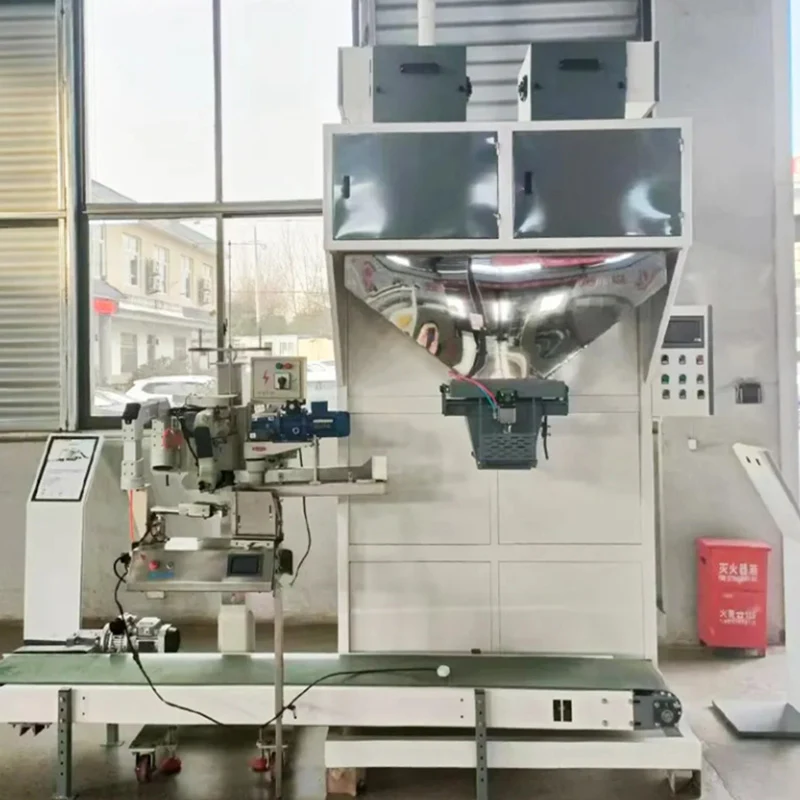

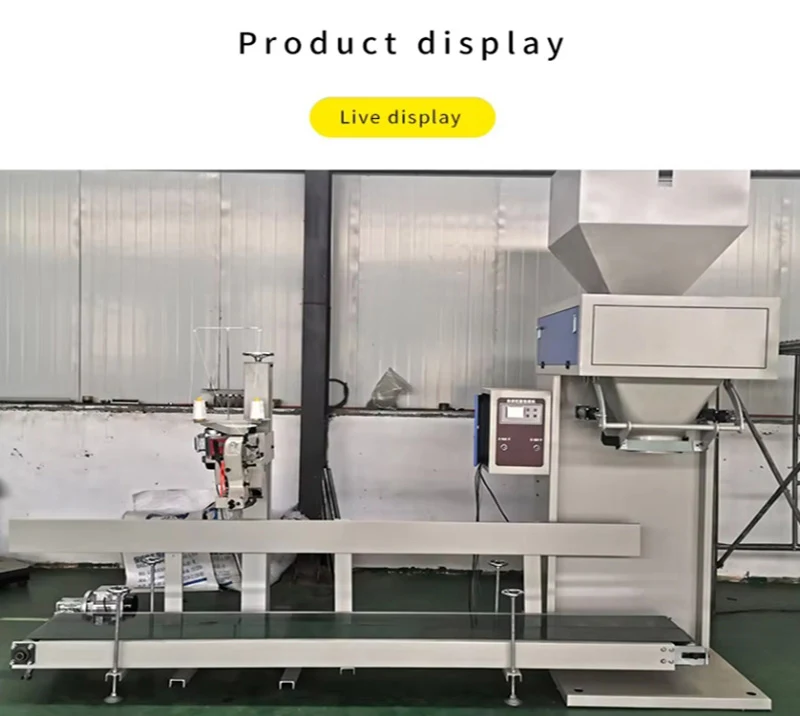

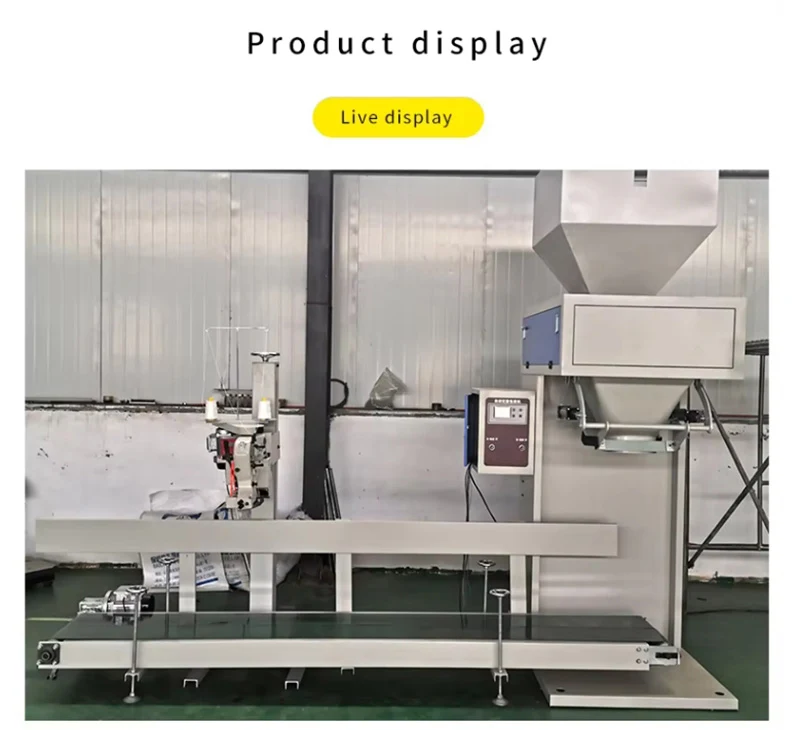

The fully automatic biomass plastic granule packaging machine is an intelligent packaging device specifically designed for biomass plastic granules (such as renewable material granules like PLA and PHA), achieving full-process automation from weighing, filling, sealing to conveying. The core of the equipment consists of an intelligent control system (integrated with PLC and touchscreen), a high-precision weighing module (error ≤±0.1%), an anti-stick feeding mechanism (vibrating/screw type),

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Beson Fully Automatic Biomass Plastic Granule Packaging Machine Core Advantages

1. Full-process Automation, High Efficiency and Low Consumption

- Driven by a servo motor, it can reach 60-120 bags/minute in high-speed mode, increasing efficiency by 50% compared to traditional equipment.

- The intelligent energy-saving control system reduces energy consumption by 30%, meeting green production requirements.

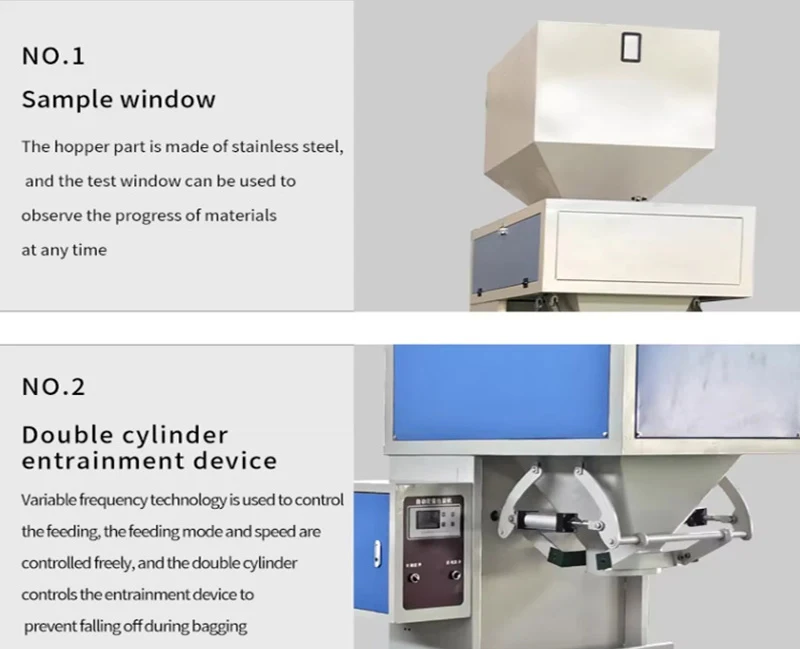

2. High-precision Measurement and Anti-stick Design

- Digital load cells ensure a measurement error ≤±0.1%, reducing material waste.

- The anti-stick feeding mechanism is optimized for the hygroscopic and sticky characteristics of biomass granules to avoid blockages and downtime.

3. Environmental Compatibility and Sealing Reliability

- Supports degradable packaging materials (such as starch-based plastic bags). The heat/cold sealing device adapts to sealing needs of different materials, with a sealing pass rate ≥99.5%.

- Optional nitrogen-filling sealing function effectively prevents moisture and oxidation, extending the granule storage period.

4. Intelligent Operation and Maintenance, Reduced Labor Costs

- The touchscreen interface is easy to operate, supporting one-click switching of packaging specifications (5kg-50kg) with a model change time ≤10 minutes.

- Built-in intelligent fault diagnosis system real-time monitors issues like blockages and sealing abnormalities, automatically alarms and displays fault codes, improving maintenance efficiency by 60%.

Benson Fully Automatic Biomass Plastic Granule Packaging MachineEquipment Features

1. Flexible Production Adaptability

- Supports multi-variety and small-batch production, quickly switching between different granule types (such as PLA and straw-based granules) and packaging specifications to meet personalized order needs.

2. Clean Production Design

- Fully enclosed body with a negative pressure dust removal system reduces workshop dust pollution, complying with ISO 14001 environmental standards, especially suitable for food-grade biomass granule packaging scenarios.

3. High Stability and Durability

- Key components are made of stainless steel (such as 304 stainless steel hoppers), corrosion-resistant and wear-resistant, suitable for 24-hour continuous operation with an annual failure rate <5%.

4. Data-driven Management Integration

- Can connect to the factory MES system to real-time record data such as production volume, energy consumption, and faults, assisting in production process optimization and traceability management.

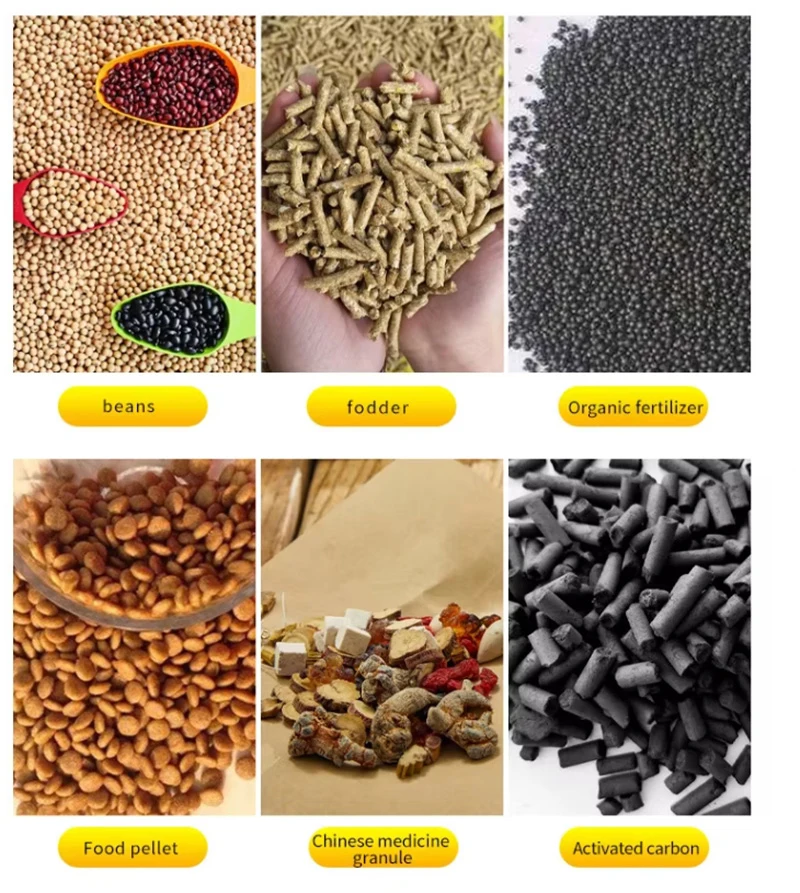

BensonFully Automatic Biomass Plastic Granule Packaging Machine ApplicationScenarios

1. Biomass Plastic Production Enterprises

- Used for finished packaging of bio-based granules such as PLA and PHA, adapting to large-scale production lines and meeting standardized packaging requirements for export and domestic markets.

2. Environmental Product Industry Chain

- Provides front-end granule packaging support for production enterprises of degradable tableware, environmental films, agricultural mulch films, etc., connecting the "raw material production-product processing" links.

3. Circular Economy and Recycling Fields

- Suitable for packaging recycled granules of plastic recycling and reuse enterprises, helping build a "waste-recycled raw material" closed-loop system.

4. Food and Pharmaceutical Industries

- Complies with food contact safety standards and can be directly used for packaging food-grade biomass granules (such as starch-based degradable materials), meeting compliance requirements like FDA and GB 4806.

BensonFully Automatic Biomass Plastic Granule Packaging Machine Typical Cases

- A PLA Production Enterprise: After introducing this equipment, the packaging efficiency increased from 30 bags/hour by manual operation to 80 bags/minute, saving over 500,000 yuan in annual labor costs. Meanwhile, the anti-stick design reduced downtime maintenance by 200 hours/year.

- Environmental Film Production Line: Through the nitrogen-filling sealing function, the moisture content of biomass granules was controlled below 0.5%, significantly reducing raw material loss in subsequent processing.

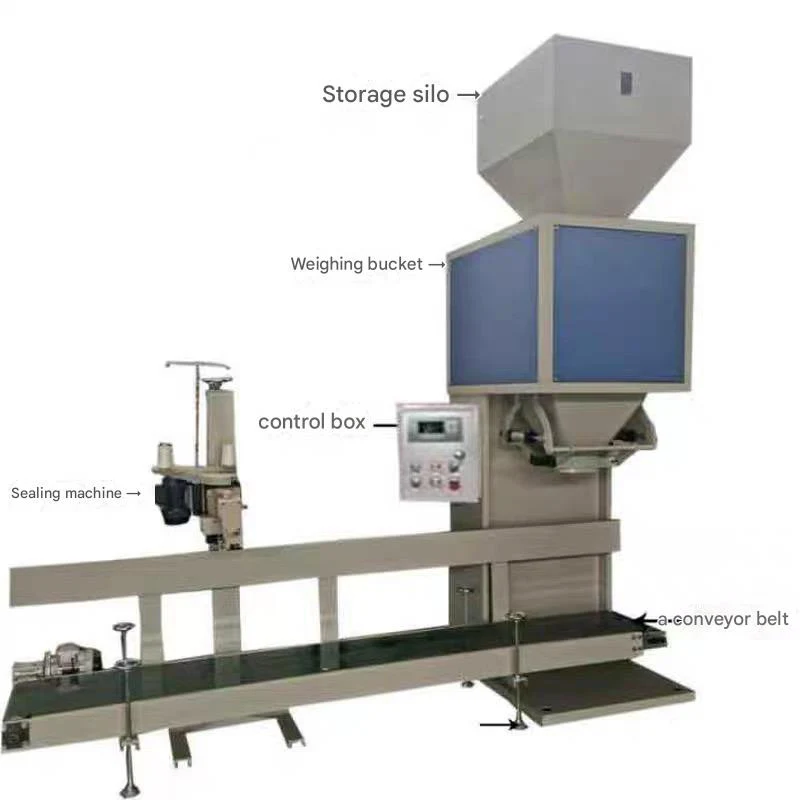

Products Description

Product Inquiry