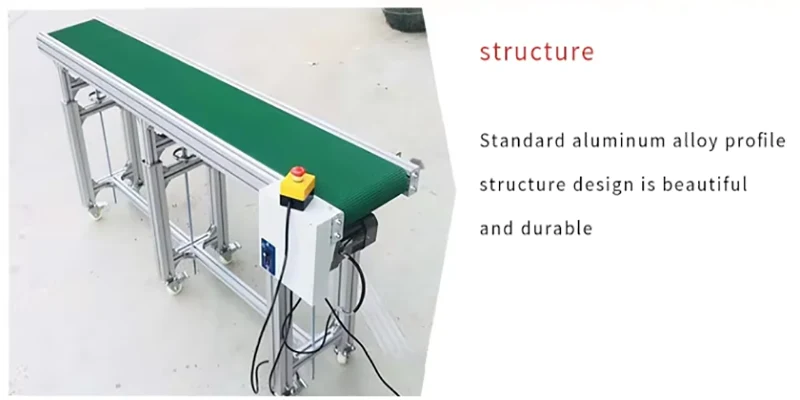

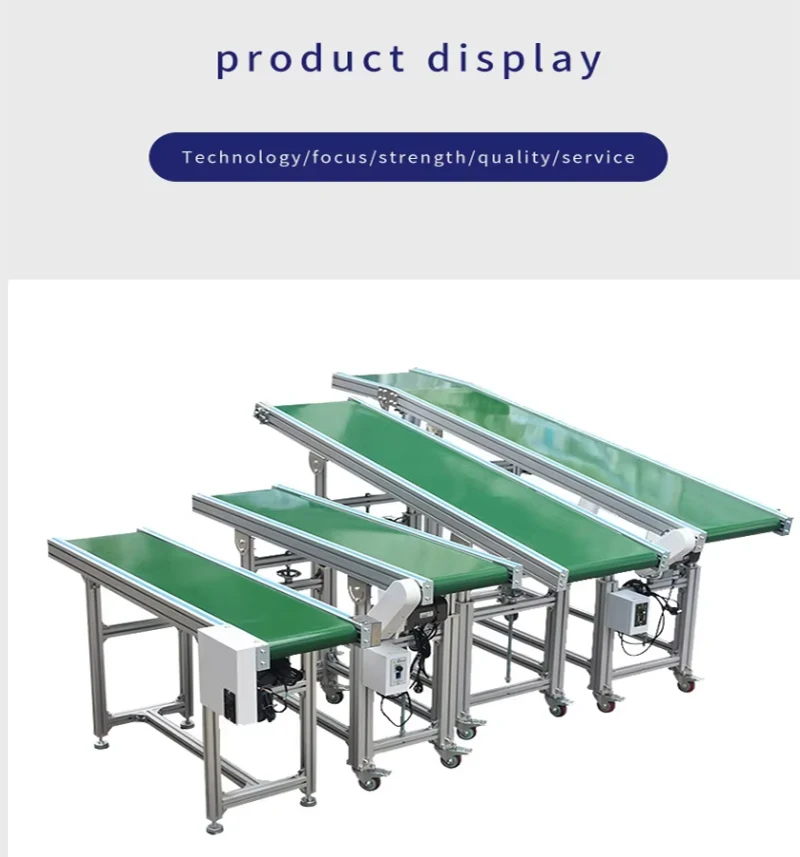

The small belt conveyor is designed for small and medium-sized enterprises. With its flexible and compact structure and excellent performance, it has become an ideal transmission equipment for light industrial production, warehousing logistics, food processing and other scenarios. Its body length can be customized according to actual needs, with a minimum of only 1 meter, which is suitable for narrow spaces and diversified operation processes, effectively saving site resources.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Product details of small belt conveyor

The equipment adopts a variety of high-quality conveyor belt materials such as food-grade PU, wear-resistant rubber, anti-static PVC, etc., to meet the special requirements of different industries for hygiene, anti-slip, corrosion resistance, etc.; equipped with low-energy frequency conversion motor, supports 0.1-1.5m/s stepless speed regulation, and accurately matches the transmission needs of sorting, assembly, packaging and other links. At the same time, the modular design enables rapid disassembly and maintenance, reducing the cost of enterprise equipment operation and maintenance; multiple safety devices such as emergency stop switches and guardrails fully guarantee the safety of operators.

Core advantages of small belt conveyors

1. Flexible customization: supports horizontal, inclined, turning, lifting and other conveying modes, suitable for production lines, warehousing, sorting and other scenes.

2. High efficiency and energy saving: low-noise motor with intelligent control system, energy consumption is 30% lower than traditional equipment.

3. Safe and durable: anti-deviation device, overload protection system, emergency brake button to ensure stable operation of equipment.

4. Easy maintenance: Modular structure design, key components support quick replacement, maintenance cost reduced by 50%.

Applicable industries of small belt conveyors

- Food and medicine: Food-grade conveyor belts meet GMP standards and are suitable for clean transmission of cakes and medicines.

- Electronic appliances: Anti-static materials prevent component damage and are suitable for assembly and sorting of precision parts.

- Logistics and express delivery: high-speed sorting and climbing transportation to improve package handling efficiency.

- Light industry: material handling and packaging connection in daily chemicals, hardware, building materials and other industries.

Service guarantee

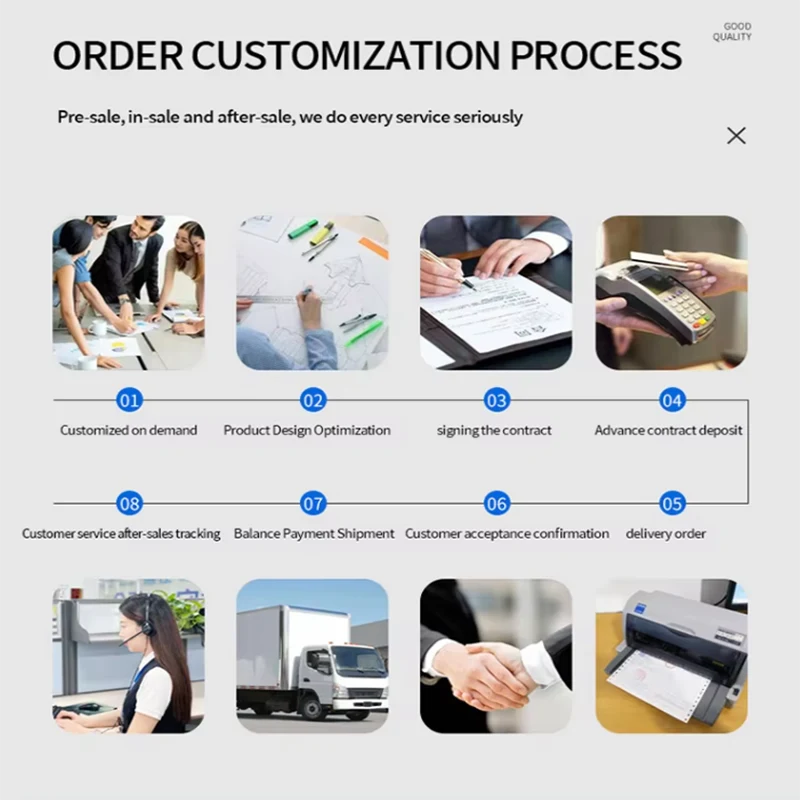

- Customized support: Provide free solution design and match the best model according to needs.

- Installation and after-sales: On-site installation and commissioning nationwide, 1-year warranty, 24-hour technical response.

- Accessories supply: Long-term supply of original conveyor belts, motors, rollers and other accessories to ensure stable operation of equipment.

Choose our small belt conveyor to achieve enterprise automation upgrade with high cost performance and open a new chapter of efficient production!

Products Description

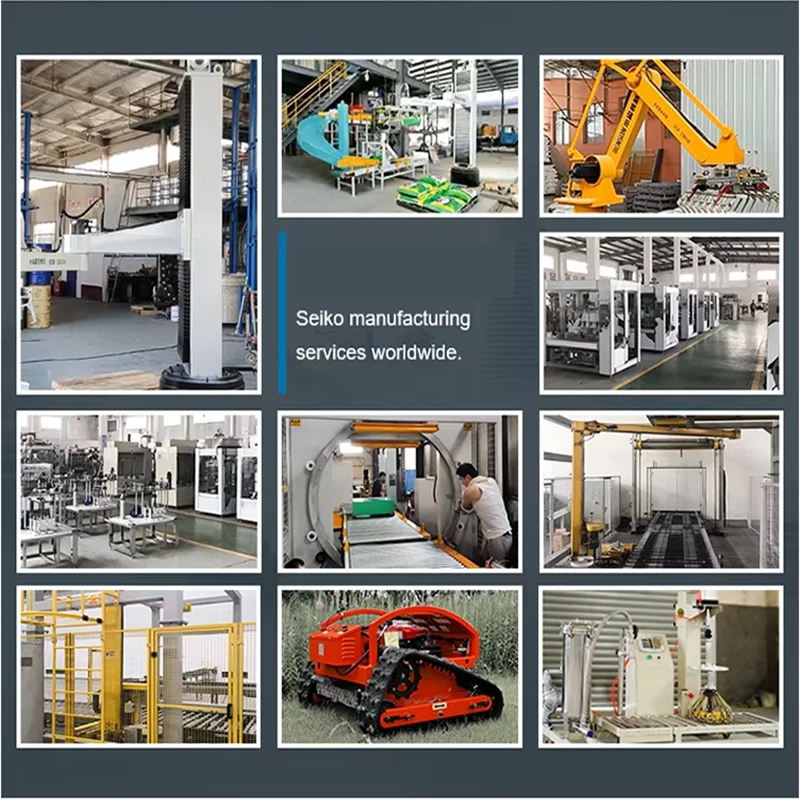

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry