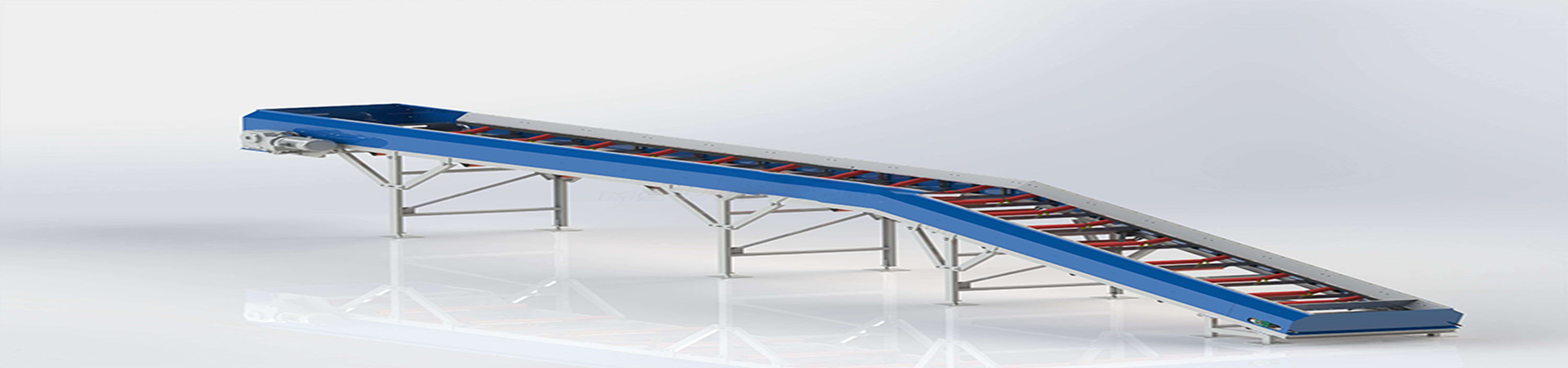

Automatic agricultural machinery screw conveyor: the core equipment for efficient transportation in modern agriculture

Automatic agricultural machinery screw conveyor is specially designed for agricultural production scenarios. With its intelligent, efficient and multifunctional characteristics, it has become a key equipment in the agricultural material transportation link. It is widely used in grain storage, agricultural product processing, animal husbandry and other fields。

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Service

Free replacement parts service

Get free replacement parts service and online technical support for 1 year after purchase. Additional shipping fees may apply. Additional shipping fees may apply.

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Innovative structural design of automatic agricultural machinery screw conveyor

- Corrosion-resistant and wear-resistant trough: The trough is made of high-strength and corrosion-resistant engineering plastics or high-quality stainless steel, which can effectively resist the erosion of acid and alkali substances in agricultural materials and humid environment, and extend the service life of the equipment; the interior of the trough is specially polished, the surface is smooth, and the material conveying resistance is reduced, the residue is reduced, and it is easy to clean and maintain.

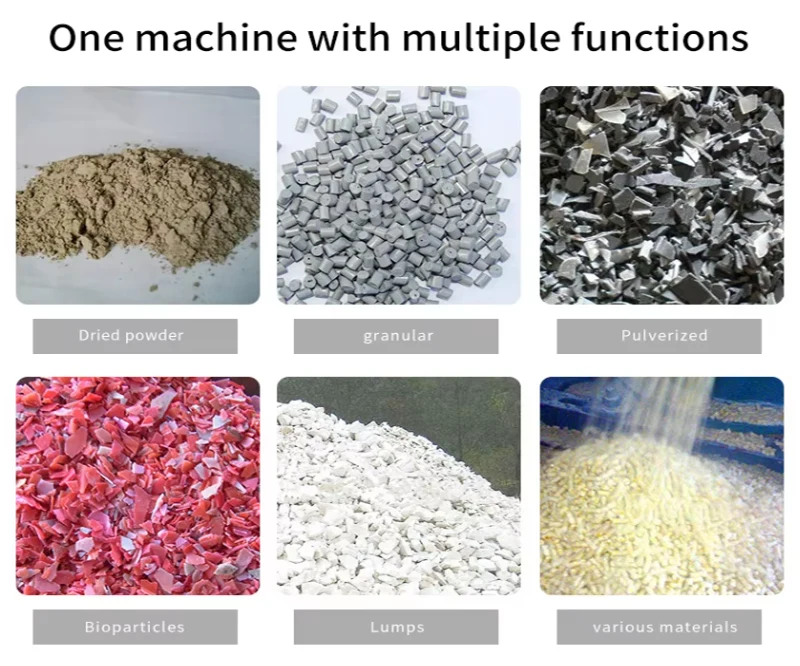

- Customized spiral blades: According to the characteristics of different agricultural materials (such as granular grains such as wheat, corn, and rice, or fibrous materials such as straw fragments and feed), spiral blades with different pitches and thicknesses are equipped. The blade design for granular materials ensures rapid conveying, while the blade for processing fibrous materials optimizes the structure to prevent winding and blockage, ensuring smooth conveying.

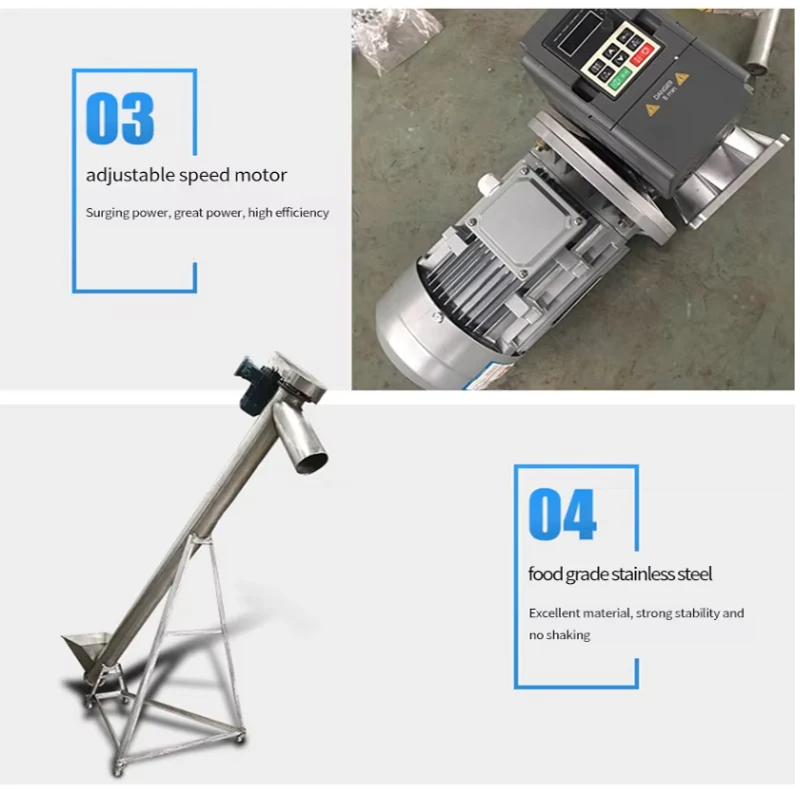

- The power system has a speed regulation function, which can flexibly adjust the conveying speed according to the conveying volume to achieve precise and efficient operation.

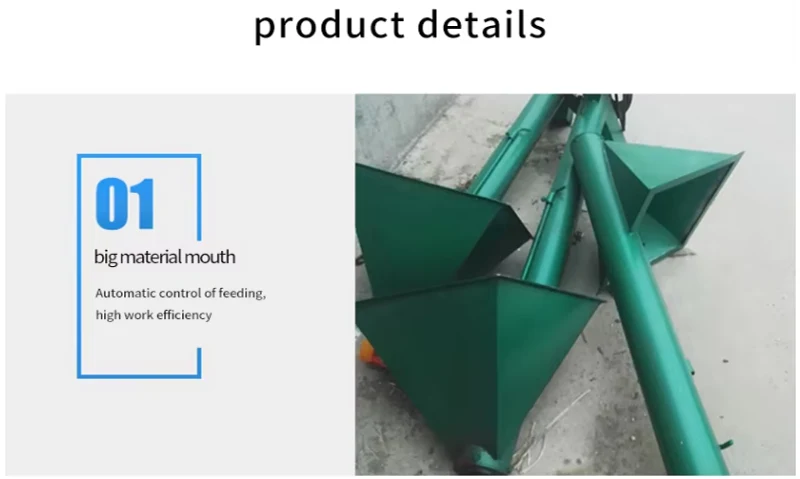

- Convenient connection components: Equipped with a quick connection interface, it can quickly connect with agricultural equipment such as granaries, threshers, dryers, and feed mixers, which is convenient for flexible combination in different operation links, greatly improving the continuity and automation of agricultural production.

Significant product advantages of automatic agricultural machinery screw conveyor

- Efficient conveying: adopting large-diameter screw shaft and reasonable screw blade design, the conveying volume is large and stable, and the efficiency is increased by more than 40% compared with traditional conveying methods. It can quickly complete the loading and unloading, transportation, and distribution and feeding of grain, effectively saving manpower and time costs.

- Intelligent control: Supports the remote control function of the Internet of Things. Through the mobile phone APP or the farm central control system, the equipment operation status can be monitored in real time and the conveying parameters can be adjusted; the built-in intelligent sensor can automatically detect abnormal conditions such as blockage and overload, and issue alarms in time to reduce the risk of equipment failure and ensure production safety.

- Energy saving and environmental protection: The optimized transmission system is matched with energy-saving motors, and the energy consumption is lower; the closed conveying structure avoids the loss of materials and dust flying during the conveying process, which not only reduces resource waste, but also improves the agricultural operation environment, which meets the requirements of green agricultural development.

- Strong adaptability: It can realize horizontal, inclined, vertical and other angles of transportation, adapting to different terrains and layouts such as granaries, farms, and breeding farms; at the same time, the equipment has been specially protected for complex agricultural environments such as humidity and high temperature to ensure stable operation under various climatic conditions.

Wide application scenarios of automatic agricultural machinery screw conveyors

- Grain storage: During the grain harvesting season, the grain harvested in the field can be quickly transported to transport vehicles, granaries or processing equipment to efficiently complete the collection and storage of grain; in the grain outbound link, the transportation volume is accurately controlled to ensure the orderly loading and processing process.

- Agricultural product processing: It is used for material transportation in the processing of agricultural products such as fruit and vegetable juice residues, tea, and medicinal materials to avoid material pollution and loss caused by manual handling, and help improve the quality and production efficiency of agricultural product processing.

- Animal Husbandry: Realize the automated transportation of feed from the storage warehouse to the breeding house, and feed accurately according to the needs of different breeding areas; at the same time, it can be used for the collection and transportation of livestock and poultry manure, reduce the cleaning burden of the breeding farm, and improve the breeding environment.

- Biomass energy: In the collection and pre-processing of biomass raw materials such as straw and rice husk, the loose materials are transported to the processing equipment in a centralized manner, providing a stable supply of raw materials for biomass power generation, biogas production, etc., and promoting the resource utilization of agricultural waste.

Products Description

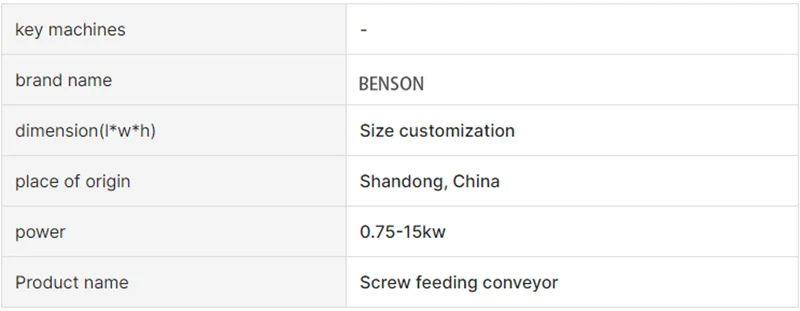

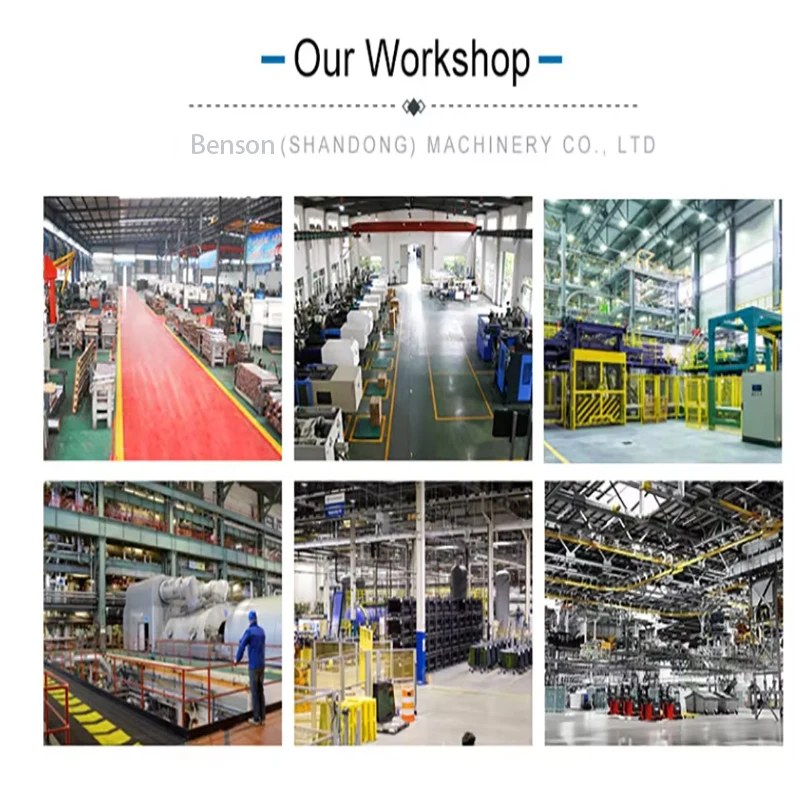

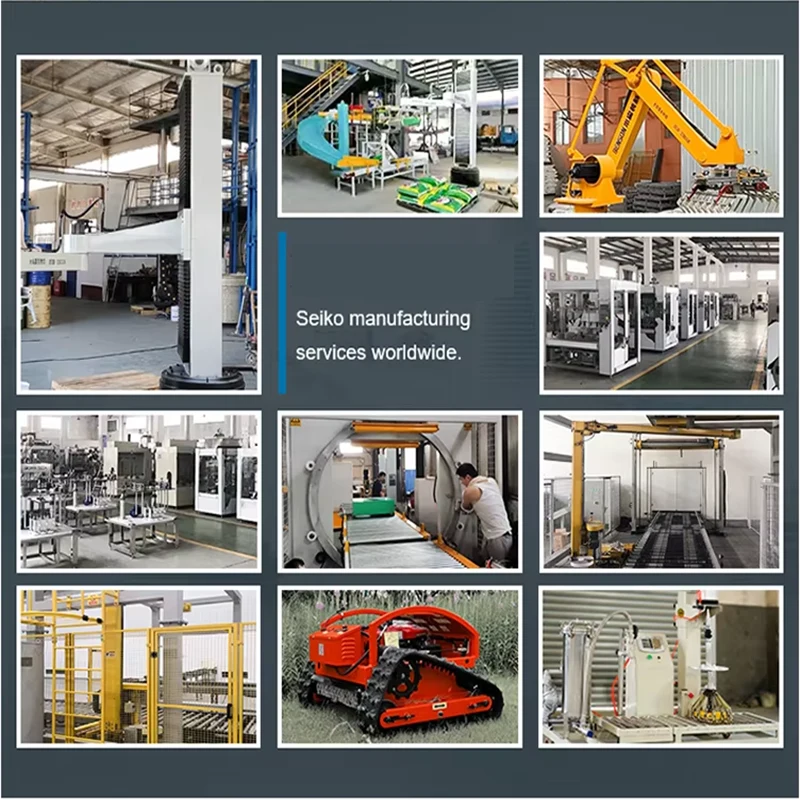

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry