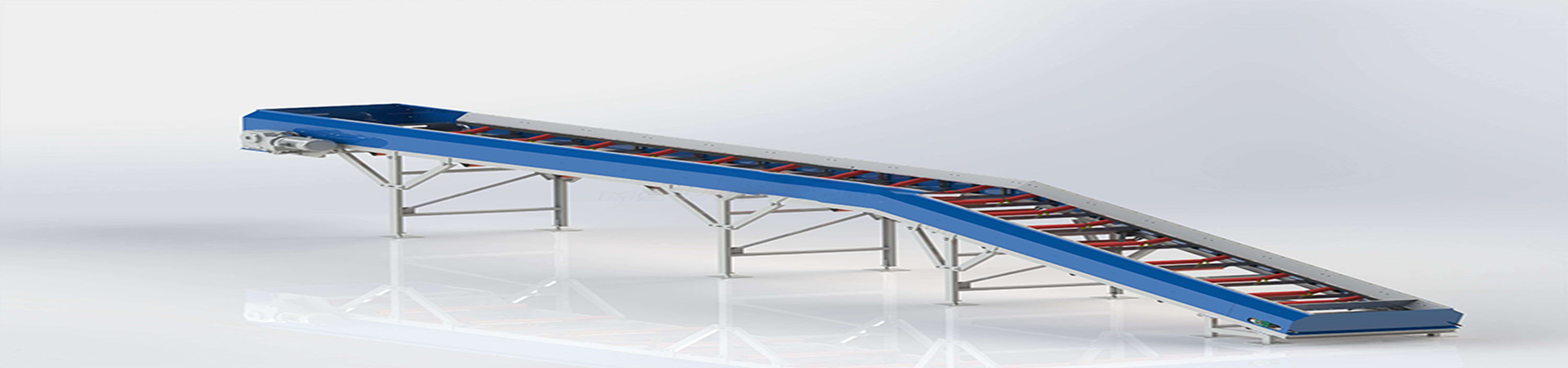

The inclined screw conveyor, also called the inclined screw conveyor, is an industrial conveying equipment. Its working principle is that the motor drives the spiral shaft to rotate, and the spiral blade pushes the powder, granular or small block materials, and moves along the fixed trough or pipeline in an inclined direction, thereby completing the material conveying task.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Free replacement parts service

You can claim platform compensation (2% of the product amount, up to US $500) for failed service.

Structural composition of stainless steel inclined screw conveyor

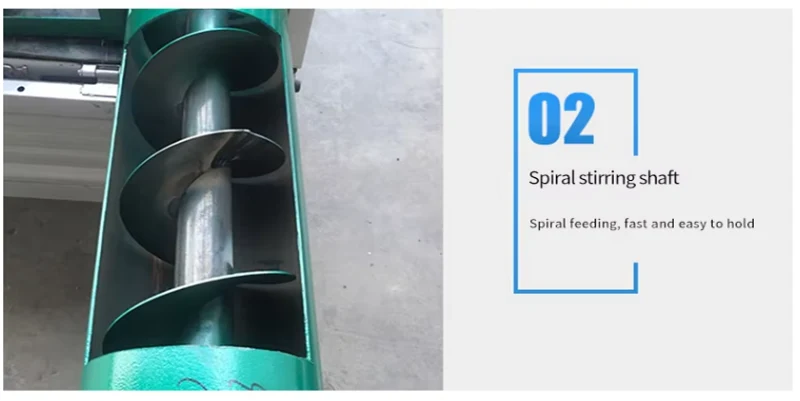

Spiral component: The spiral blade is the core component, which is divided into left-handed and right-handed, with various shapes, such as solid, belt-type, blade-type, and molding. Different shapes are suitable for different materials and working conditions. The spiral blade is installed on the hollow shaft, which has high strength and light weight. The shaft connection method includes sleeve plus screw fixation, or direct screw fixation.

Bearing: The head bearing is a thrust bearing used to bear axial force; the intermediate bearing is mostly a split sliding bearing, which plays the role of supporting the spiral shaft.

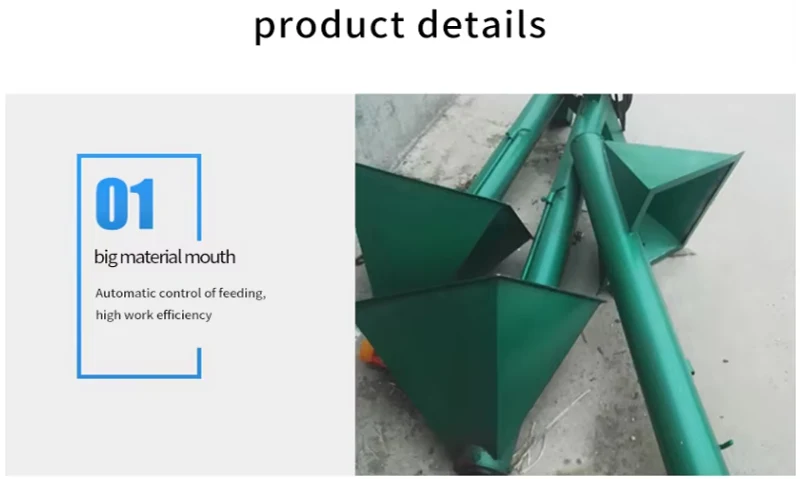

Material trough: Common types are U-shaped and cylindrical. The U-shaped type is suitable for situations with intermediate suspension bearings; the cylindrical type is suitable for situations without intermediate suspension bearings.

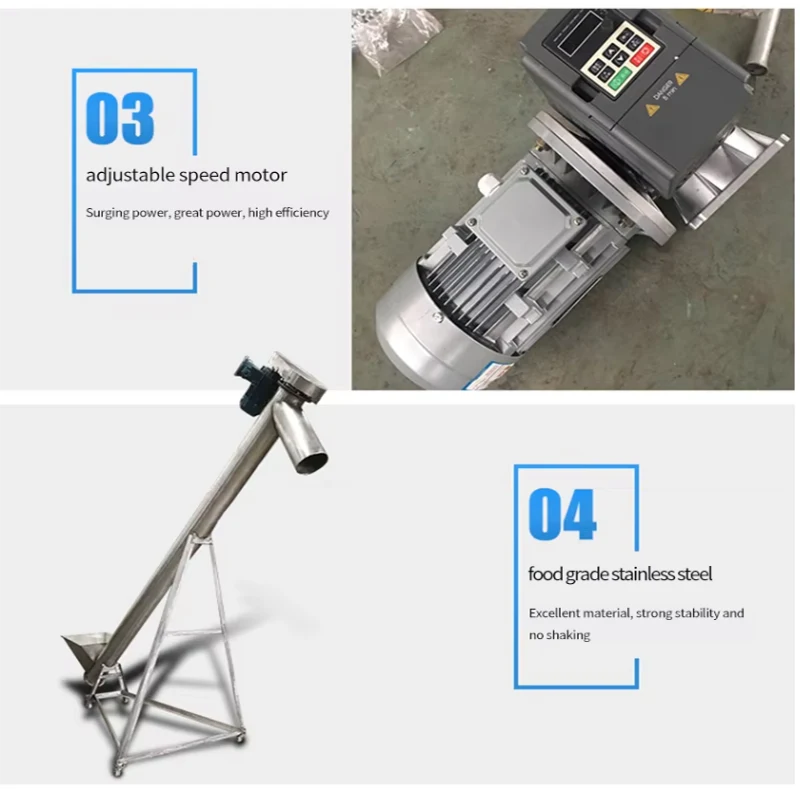

Drive device: It includes an electric motor and a reducer to provide rotational power for the conveyor to ensure stable operation.

Characteristics and advantages of stainless steel inclined screw conveyor

Flexible conveying: It can realize upward inclined conveying and multi-angle conveying, and the conveying direction can be flexibly adjusted according to site and process requirements.

Efficient conveying: It can realize vertical or inclined conveying in a limited space, efficiently complete material transfer, and ensure the rapid operation of the production process.

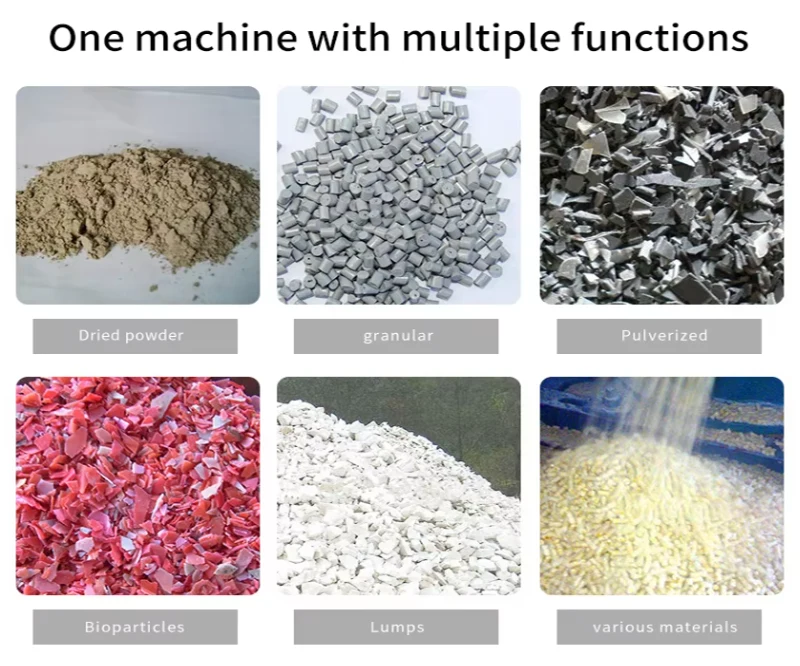

Strong adaptability: It can handle a variety of materials, such as powders, granules, etc., and is widely used in material conveying in different industries.

Compact structure: It has small dimensions and occupies less space, and can be smoothly installed and used in space-constrained environments.

Good sealing: It can effectively prevent dust leakage, meet environmental protection requirements, and protect the safety of the working environment.

Easy maintenance: The mechanical structure is simple, easy to clean and maintain, and can reduce maintenance costs and downtime.

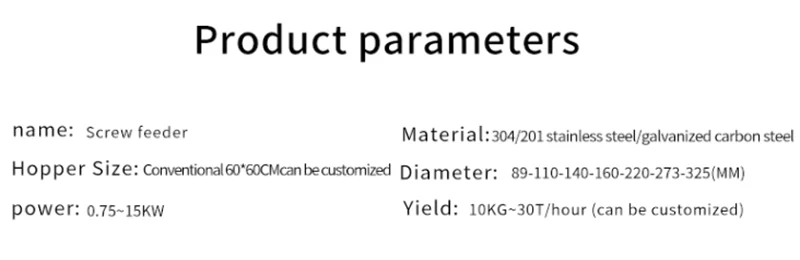

Technical parameters of stainless steel inclined screw conveyor

Incline angle: Generally not more than 60°, and the inclination angle of the shaftless design is usually not more than 15°. The larger the angle, the smaller the conveying capacity of the same type and speed conveyor.

Conveying capacity: Affected by the inclination angle, material characteristics, etc., the common range is several cubic meters to hundreds of cubic meters per hour.

Screw speed: generally tens to hundreds of revolutions per minute.

Motor power: determined by conveying volume, conveying distance, inclination angle and material characteristics, ranging from zero kilowatts to several kilowatts.

Products Description

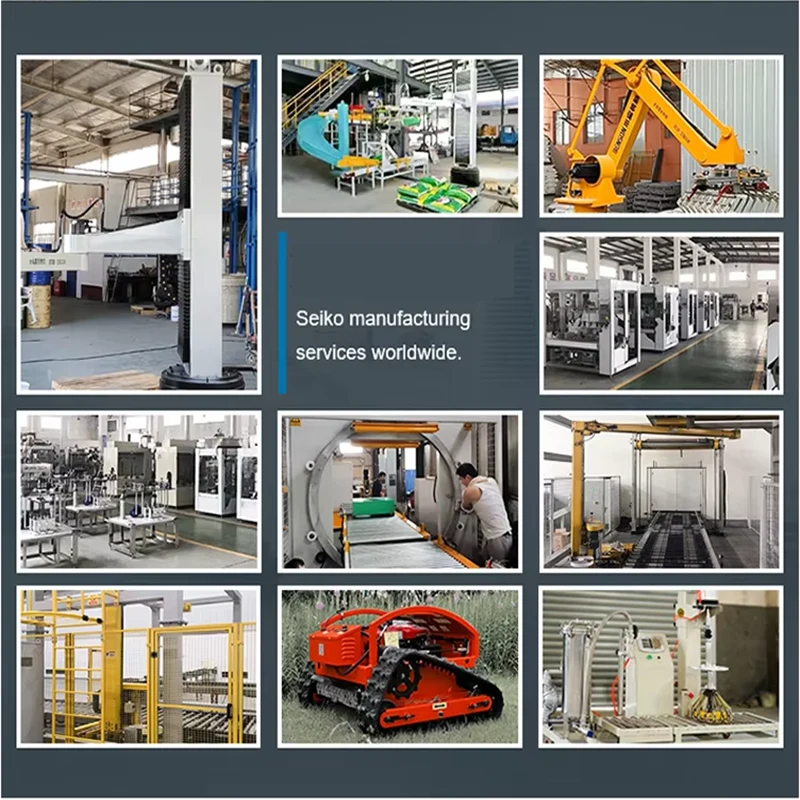

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizers and loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "industry-university-research integration". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. A new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and a large number of high-quality accessories have been adopted, and product quality has been greatly improved. Bensen (Shandong) Machinery Co., Ltd.'s products have been widely used in automobiles, motorcycles, engineering machinery, chemical equipment, chemical product processing, food processing, power equipment, chemical product processing and other industries. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system. , Provide customers with high-quality technical support and after-sales service.

Exhibition

Product Inquiry