The pocket - type bentonite bagging and packaging machine is an automated device specifically designed for the packaging of bentonite. Through automation technology, it realizes the automatic operation of a series of processes, including material conveying, weighing and metering, bagging, and sealing. It usually consists of a feeding device, a high - precision weighing system, a packaging bag conveying and sealing device, etc. During operation, bulk bentonite is conveyed by the feeding device

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Pocket - type Bentonite Bagging and Packaging MachineAdvantages

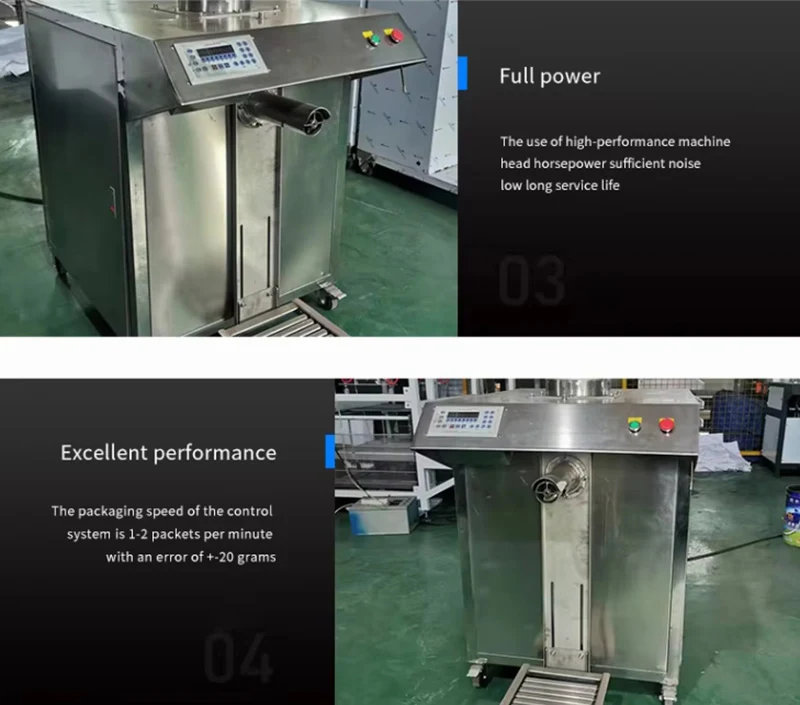

1. Increased production efficiency: With continuous automated operation, it can quickly complete a large number of bentonite bagging and packaging tasks. Compared with manual packaging, it significantly increases production capacity and meets the requirements of large - scale production.

2. Precise metering: Equipped with high - precision weighing sensors and advanced metering control systems, it can accurately control the weight of each bag of bentonite with minimal error, ensuring product weight consistency and enhancing product quality and market competitiveness.

3. Reduced labor costs: By reducing human participation, it lowers labor expenses. At the same time, it reduces errors and losses caused by manual operation, improving production efficiency.

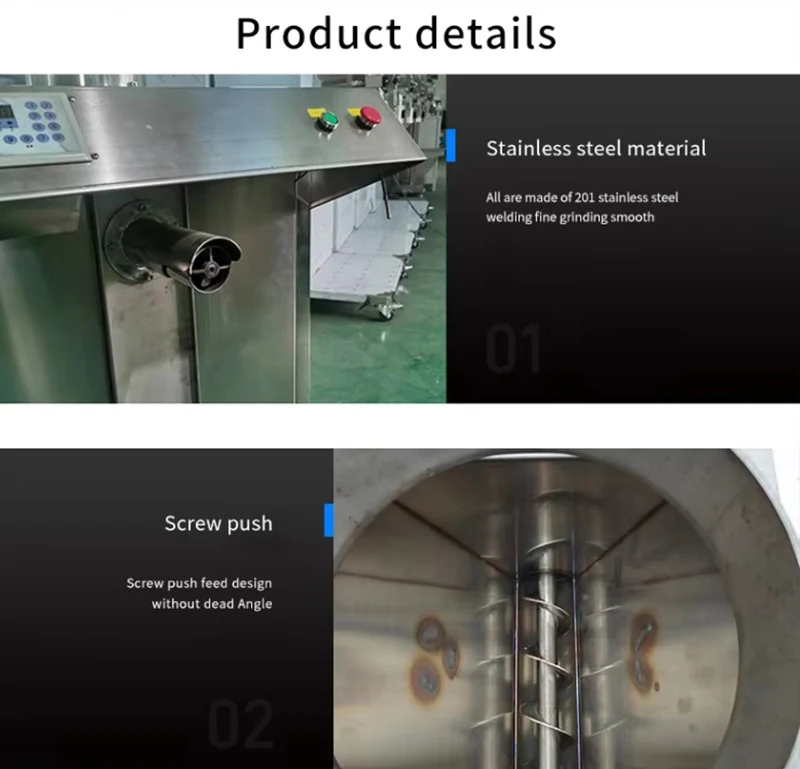

4. Hygienic and environmentally friendly: The fully - enclosed design effectively reduces dust spillage, improving the working environment and meeting environmental protection requirements. The parts in contact with the material mostly use hygienic materials such as stainless steel to prevent material contamination, meeting the usage requirements of industries with high hygiene requirements such as food and medicine.

5. Strong flexibility and adaptability: It can adapt to the packaging requirements of different - sized packaging bags (such as small and large packages) and bentonite with different characteristics (such as powder and granular) by adjusting parameters and replacing components.

Pocket - type Bentonite Bagging and Packaging MachineApplications

1. Building materials industry: As an important component of building materials, bentonite can be packaged in specific proportions by this packaging machine for the production of wall materials, waterproof and sealing materials, etc., providing standardized packaged products for the construction industry.

2. Chemical industry: In oilfield development, bentonite is used as drilling fluid, etc. It is also applied in the production of chemical products such as coatings and adhesives. The packaging machine can meet the packaging needs of bentonite in the chemical field, facilitating storage, transportation, and use.

3. Agricultural field: Bentonite can improve soil, enhancing soil fertility and water and nutrient - retaining capacity. The packaging machine provides a convenient and efficient bentonite packaging solution for agricultural production, making it easier for farmers to use and store.

4. Other industries: In the foundry industry, it is used as a molding sand binder, and in the environmental protection industry, it is used for sewage treatment, etc. The pocket - type bentonite bagging and packaging machine can provide appropriate packaging services for these fields.

Pocket - type Bentonite Bagging and Packaging MachineFeatures

1. High degree of automation: It has functions such as automatic feeding, automatic weighing and metering, automatic bagging, and automatic sealing. It requires little or no human intervention, reducing the influence of human factors and improving the stability and consistency of packaging.

2. Multifunctional filling head: Designed according to the characteristics of bentonite, some are equipped with a vacuum suction - back system to prevent dripping after filling. It can achieve fast and slow dual - speed filling, taking into account both efficiency and prevention of overflow.

3. Good stability: Using high - quality materials and advanced mechanical design, and selecting high - quality components for key electrical and pneumatic controls, it ensures the long - term stable operation of the equipment and reduces the failure rate and maintenance cost.

4. Expandability: It reserves functional expansion interfaces or spaces and can be combined with equipment such as automatic cap sorting and placing machines, inkjet printers, labeling machines, case packers, and palletizers to form a complete automated packaging production line, meeting the needs of enterprises at different development stages.

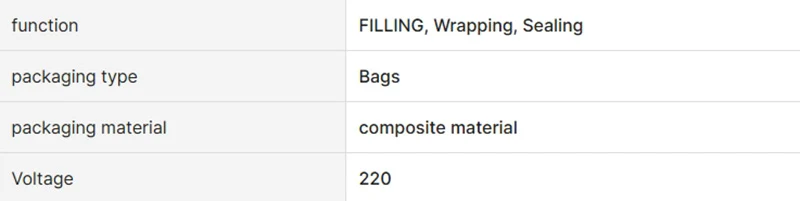

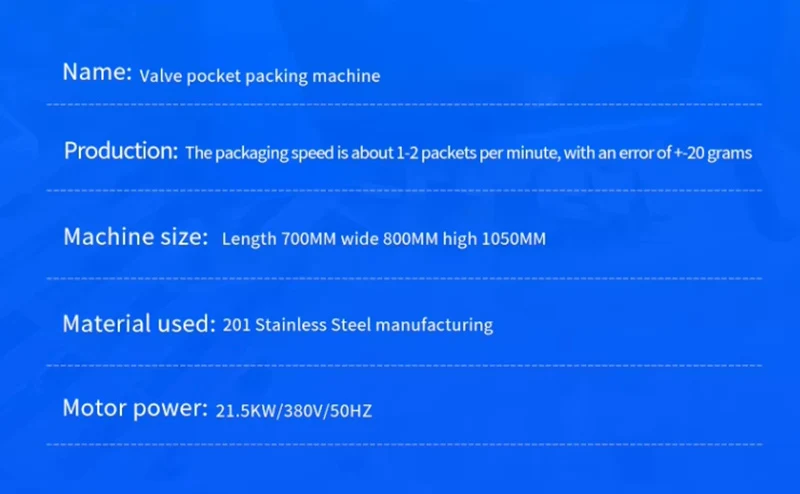

Products Description

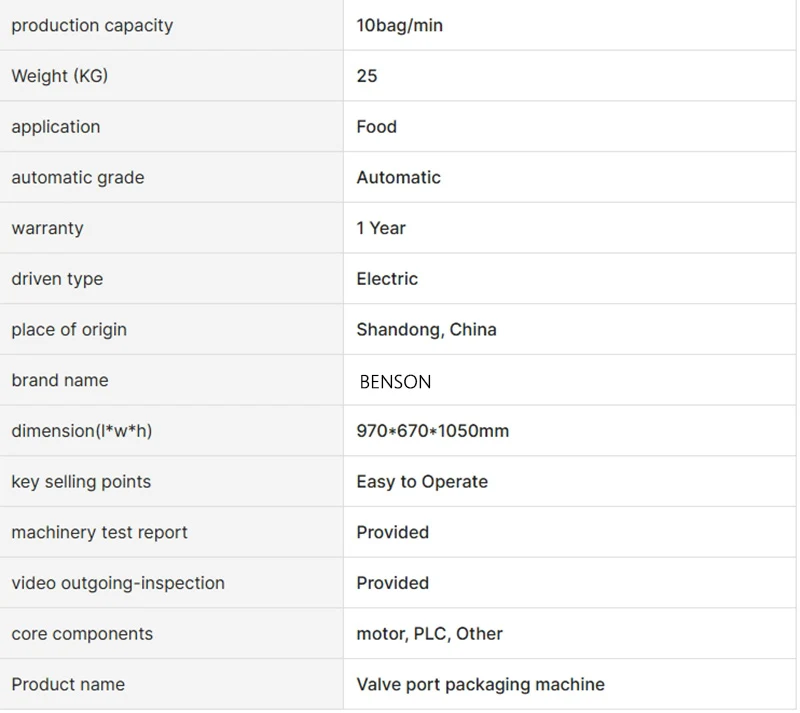

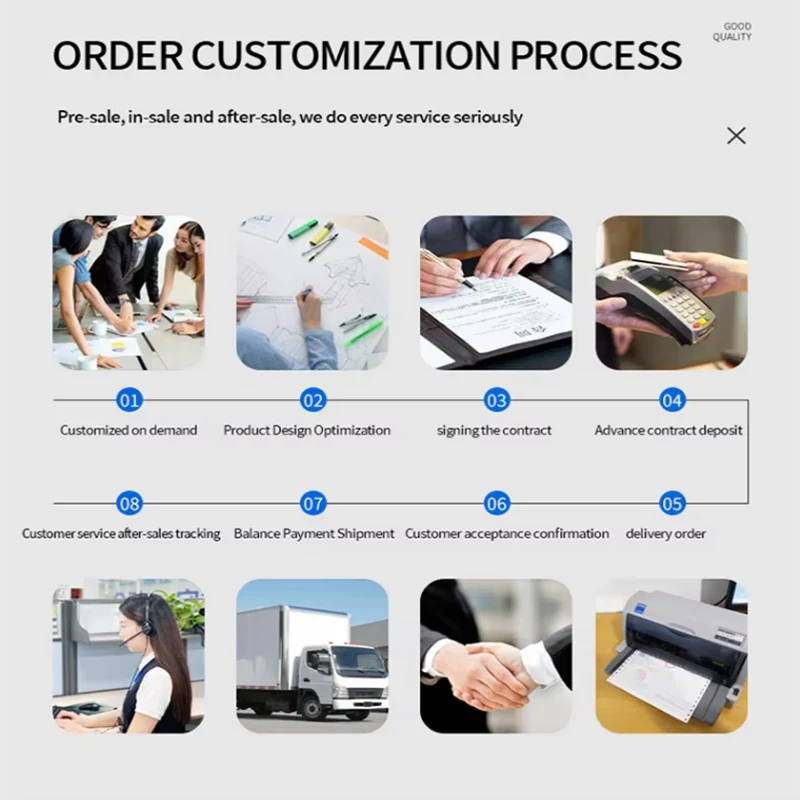

Product Inquiry