It adopts advanced automatic clamping technology, which can ensure the precise positioning of packaging bags on the pallet. When necessary, the packaging bags can be placed in an overlapping manner to enhance the stability of the pallet stack. For example, in the palletizing of chemical raw materials, this technology effectively avoids the risk of raw material leakage caused by unstable stacking. Its palletizing mode can be freely programmed, and up to 70 configurations can be created

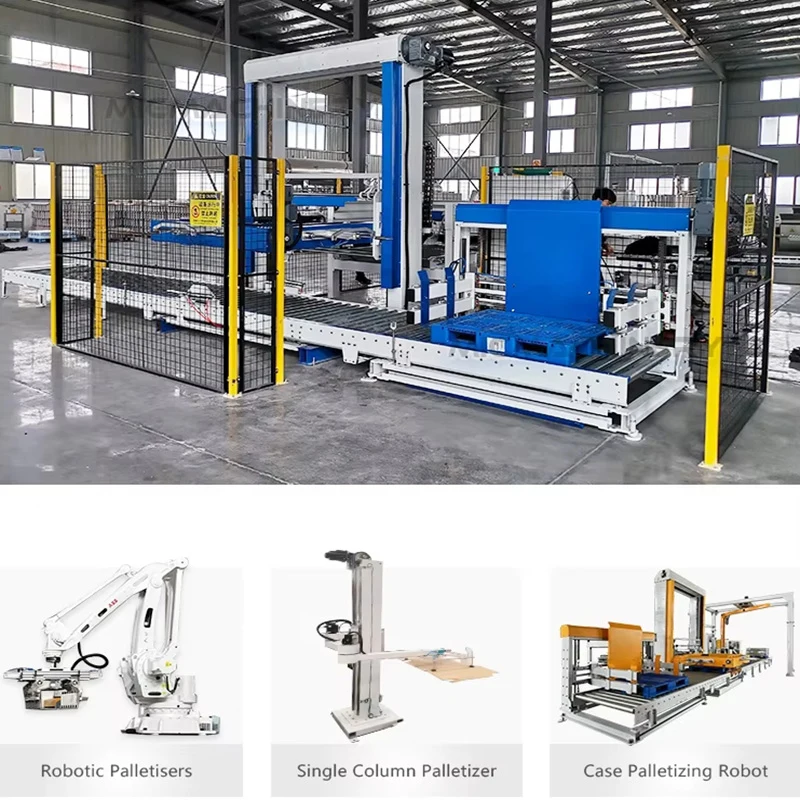

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

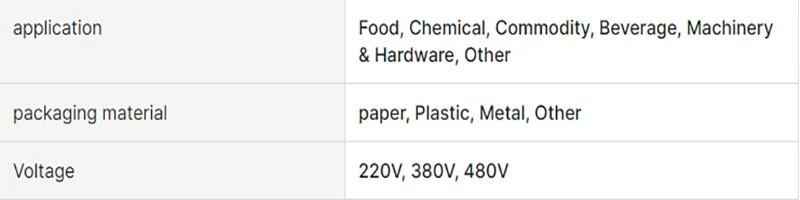

Other attribute

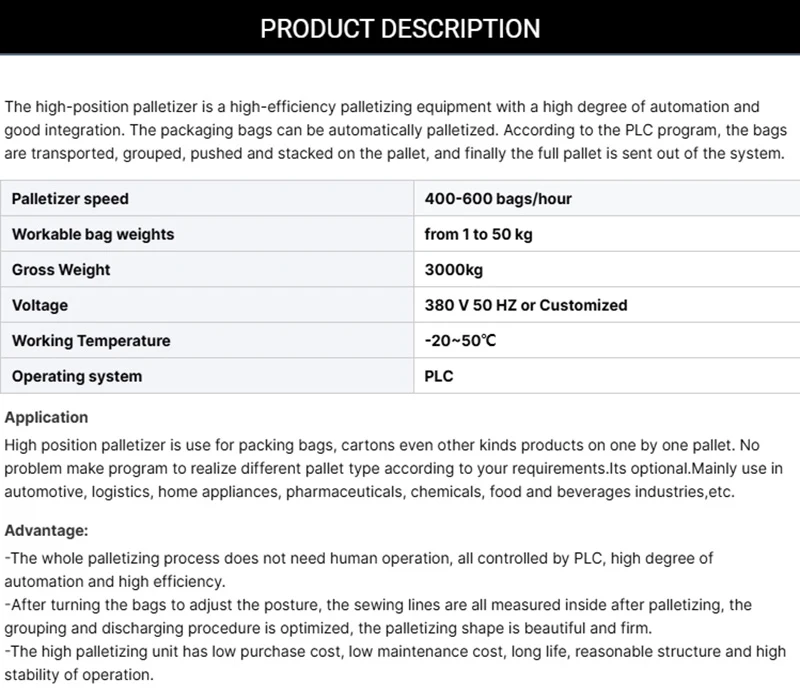

Products Description

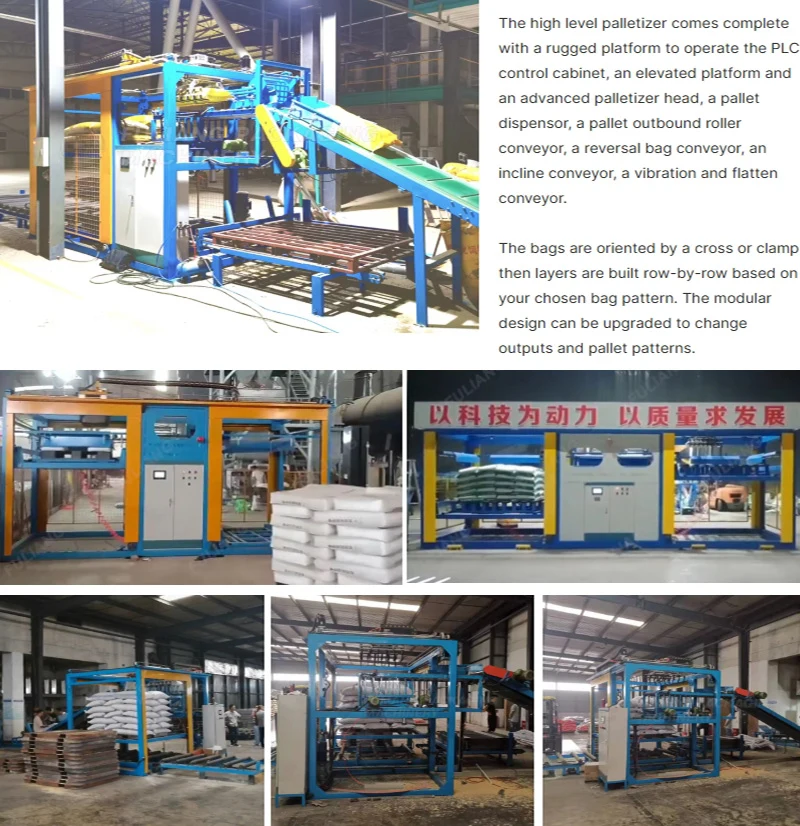

High - level palletizers

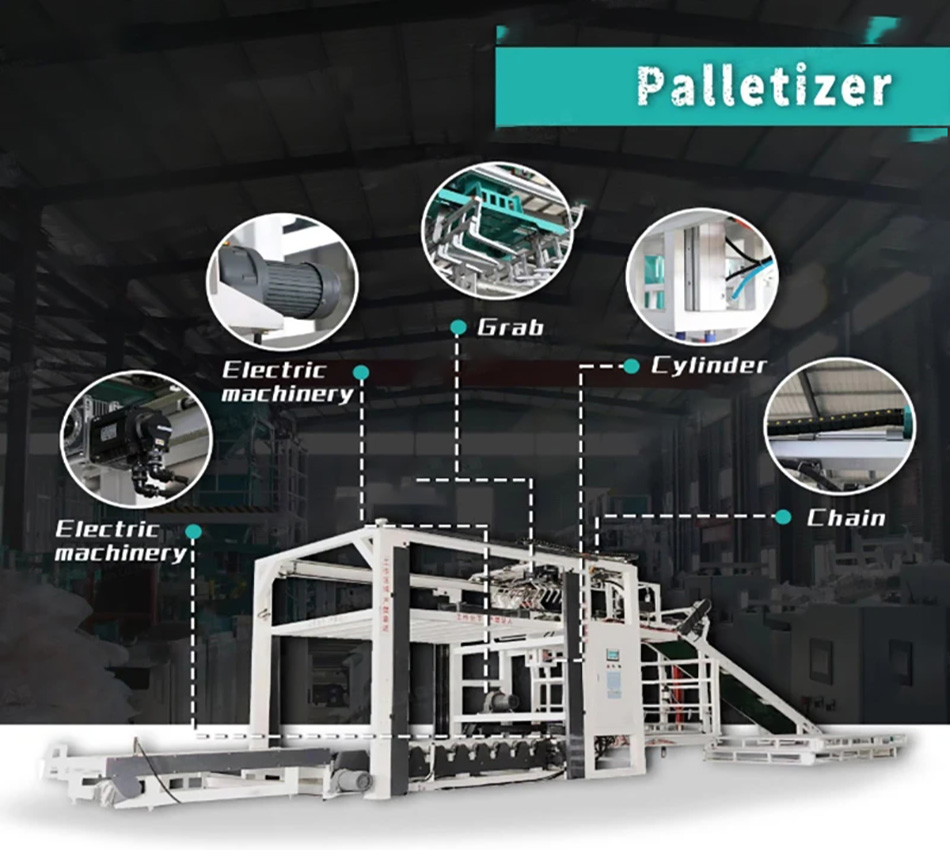

The high - level palletizeris a highly automated industrial equipment. It is mainly used to stack materials with regular packaging such as bags, boxes, and barrels layer by layer into a neat stack shape according to the set arrangement method. It is widely applied in industries such as food, medicine, chemicals, and logistics. Its core structures include the robotic arm system (designed with multiple joints, capable of flexibly grasping materials and accurately positioning), the intelligent control system (through PLC or industrial computer programming, realizing full - process automatic control of the palletizing path, number of layers, and arrangement method), the flexible grasping device (such as suction cups, grippers, etc., adapting to different material characteristics), and the conveying system (connecting the production line and the palletizing area to achieve the automatic transfer of materials and pallets). During operation, high - level palletizerthe materials to be palletized are conveyed to the designated position by the conveyor belt. The sensors detect the position and state of the materials in real - time. The robotic arm precisely grabs the materials under the instructions of the control system and stacks them layer by layer onto the pallet according to the preset stack patterns (such as criss - cross, reverse - cross, etc.). The entire process requires no human intervention and can operate continuously. The palletizing efficiency can reach dozens of pieces per minute, and the stack shape has high stability, effectively avoiding problems such as high labor intensity, low efficiency, and easy errors in manual palletizing. Thefully automatic packaging and palletizing machines, advantages of the high - level palletizer are reflected in its high efficiency (suitable for high - speed production lines and capable of 24 - hour continuous operation), high precision (small positioning error, strict control of the number of palletizing layers and arrangement), flexibility (able to quickly switch different product palletizing programs to meet the production requirements of multiple varieties), and safety (equipped with anti - collision sensors, emergency stop devices, etc., ensuring the safety of equipment and personnel). It is a key equipment for improving storage efficiency and reducing labor costs on modern industrial automated production lines.

The working process of the high - level palletizer is as follows:1. Material Conveying: The materials to be palletized are sent to the feeding station by the production line conveyor, and the empty pallets arrive simultaneously. 2. Detection and Positioning: fully automatic packaging and palletizing machinesThe sensors detect the position and attitude of the materials, and the control system matches the palletizing program. 3. Grasping and Handling: The robotic arm equipped with a suction cup/jaw grasps the materials and transports them to the palletizing area according to the preset trajectory. 4. Layer - by - layer Stacking: Stack the materials layer by layer according to the set stacking pattern (such as criss - cross), and the pallet automatically rises or falls after each layer is completed. 5. Full - pallet Handling: After reaching the preset number of layers, the full - pallet is removed by the conveyor, and a new empty pallet enters the cycle. The manufacturers of automatic palletizerswhole process is automated, highly efficient and accurate, and can be adapted to the rapid switching of multiple varieties.

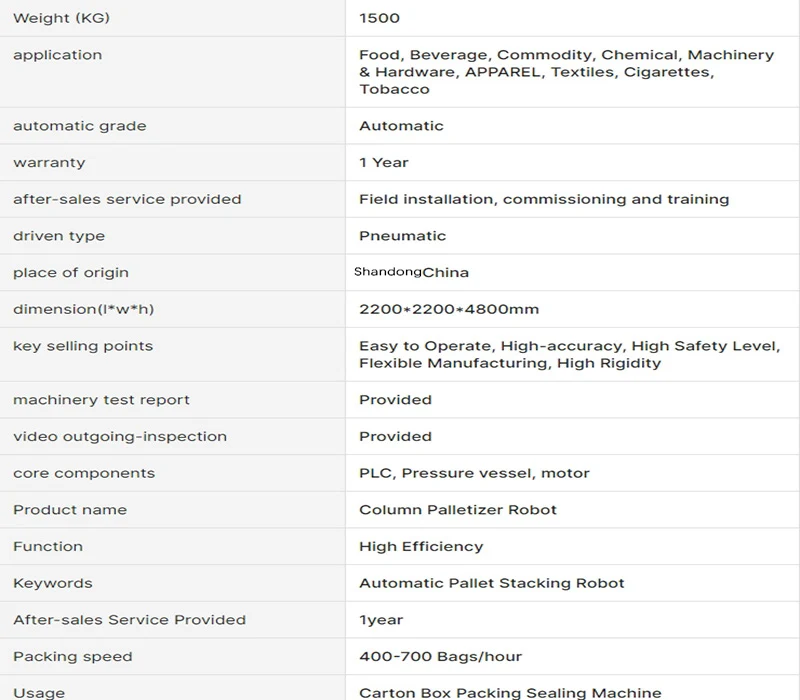

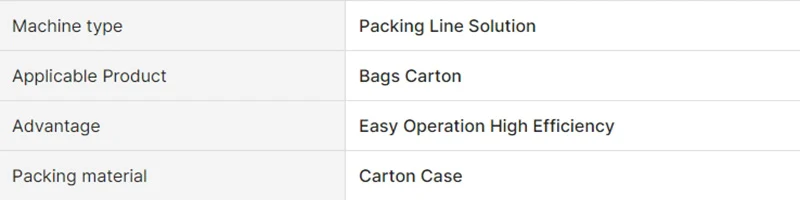

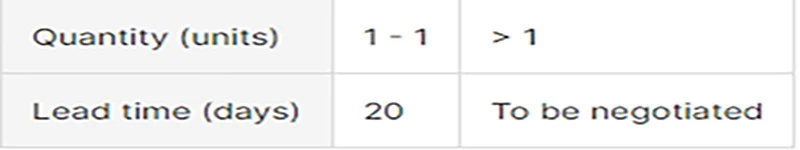

Specification

Advantages of high - level palletizers:

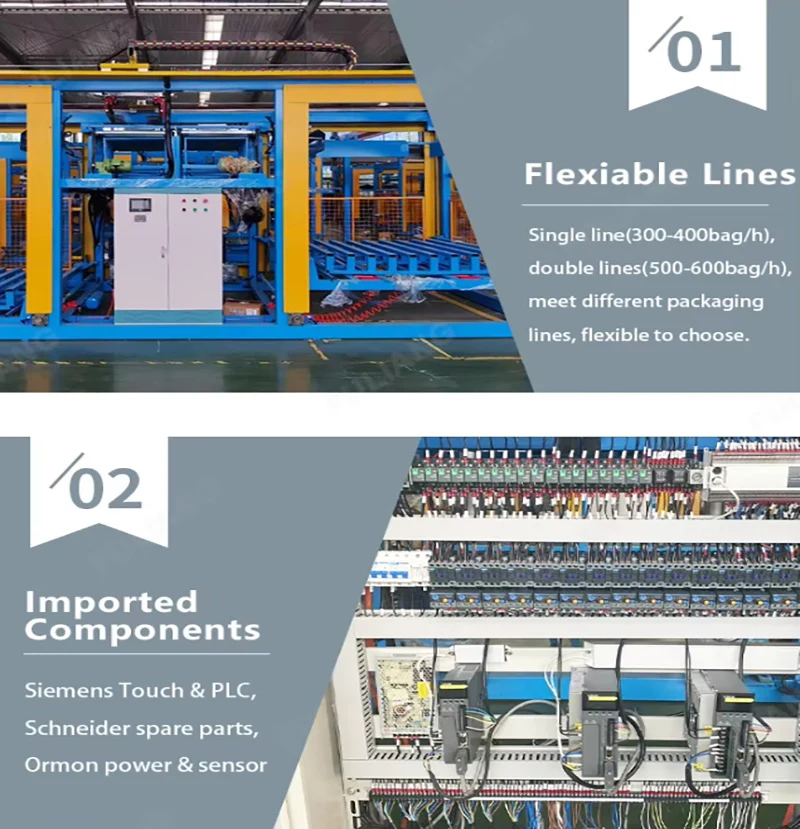

I. High - efficiency Automated Operation1. Improve Production Efficiency: fully automatic packaging and palletizing machines, It can operate continuously for 24 hours. The palletizing speed can reach 10 - 30 layers per minute (depending on the cargo specifications), far exceeding the efficiency of manual palletizing and significantly shortening the production line cycle. 2.Reduce Labor Costs: There is no need for a large number of workers to participate in the stacking process. While reducing labor costs, it also avoids efficiency fluctuations and errors caused by human fatigue. 3. Seamless Docking with the Production Line: It can be linked with front - end conveyor lines, packaging machines and other equipment to form a fully automated production process, improving the overall system coordination.

II. Precision, Stability and Loss Reduction1. High - positioning Accuracy: Servo motors, sensors and control systems are used to ensure accurate cargo stacking positions (usually with an error ≤ 5mm), avoiding the risk of toppling caused by uneven manual placement. 2. Strong Stacking Stability: By optimizing the number of palletizing layers and arrangement methods (such as staggered and overlapping), the goods are stacked tightly and firmly, reducing losses during transportation and storage. 3. Gentle Handling: It is equipped with buffer devices and soft - grasping technologies (such as air - bag fixtures and sponge suction cups), which are friendly to fragile items (such as glass - bottled beverages and ceramic products), reducing the cargo breakage rate.

III. Flexible Adaptation to Multi - scene Requirements1. Compatible with Multiple Cargo Types: manufacturers of automatic palletizersIt can palletize cartons, plastic boxes, pallets, barreled goods, etc. Different cargos can be quickly switched by changing fixtures (such as vacuum suction cups and clamping fixtures). 2. Support Customized Stacking Patterns: According to the height of warehouse shelves, the specifications of transport vehicles and other requirements, the number of stacking layers (usually up to 5 - 10 layers) and arrangement patterns (such as single - row per layer, multi - row staggered per layer) can be freely set. 3. Small Space Occupancy: It adopts a column - type or gantry - type structure with a compact body (usually occupying an area of 3 - 10㎡), which is suitable for small and medium - sized workshops or scenarios with limited space.

IV. Intelligent Management and Maintenance1. Easy to Operate: hrough a touch - screen or PLC control system, palletizing parameters (such as the number of layers, speed, stacking pattern) can be set with one - click, and non - professional technicians can quickly get started. 2. Fault Self - diagnosis: Built - in sensors monitor the running status of the equipment in real - time. When abnormalities occur (such as fixture failure, cargo deviation), it will automatically alarm and stop, facilitating quick problem - checking. 3. Low Maintenance Cost: Key components (such as motors and guide rails) are made of high - wear - resistant materials with a long lifespan (usually ≥ 5 years), and the maintenance cycle is long (a comprehensive maintenance is carried out every six months to one year).

V. Enhance Corporate Image and Competitiveness1. Meet Modern Production Standard: High - level palletizersAutomated equipment reflects the technological advancement and standardized management of the enterprise, meeting customers' requirements for large - scale and standardized production. 2. Adapt to the Industry Upgrade Trend: In the context of increasingly strict environmental protection and safety regulations, it reduces the safety risks in scenarios where workers come into contact with chemicals, heavy objects, etc., meeting the requirements of occupational health. 3. Data - based Management Support: Some high - end models support docking with the factory MES system, which can record data such as the number of palletized goods and equipment operation efficiency in real - time, helping to optimize production decisions.

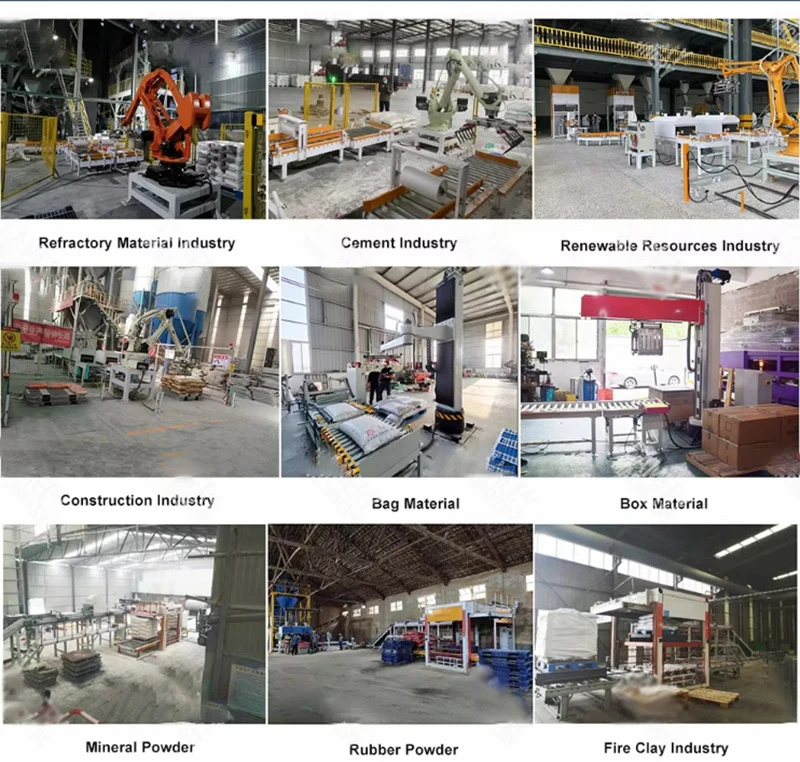

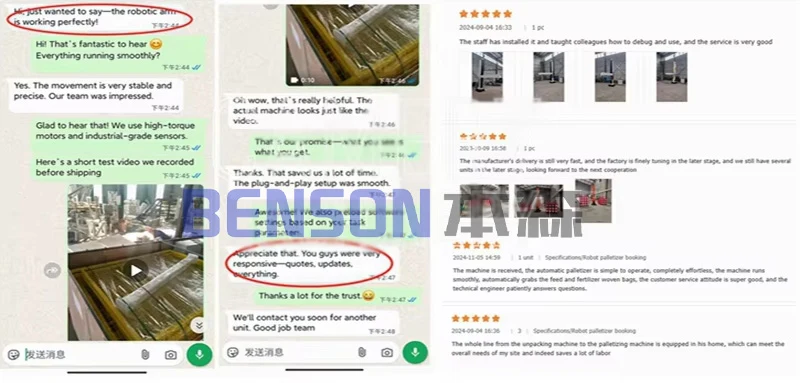

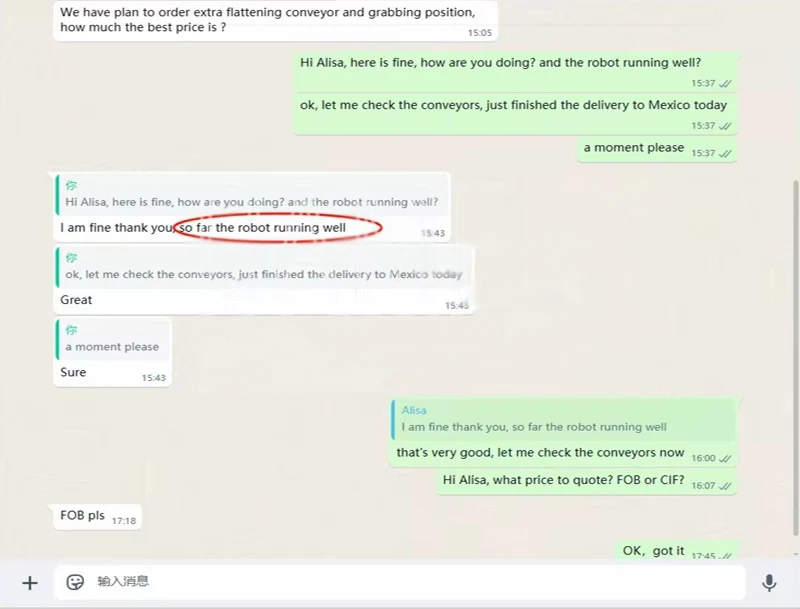

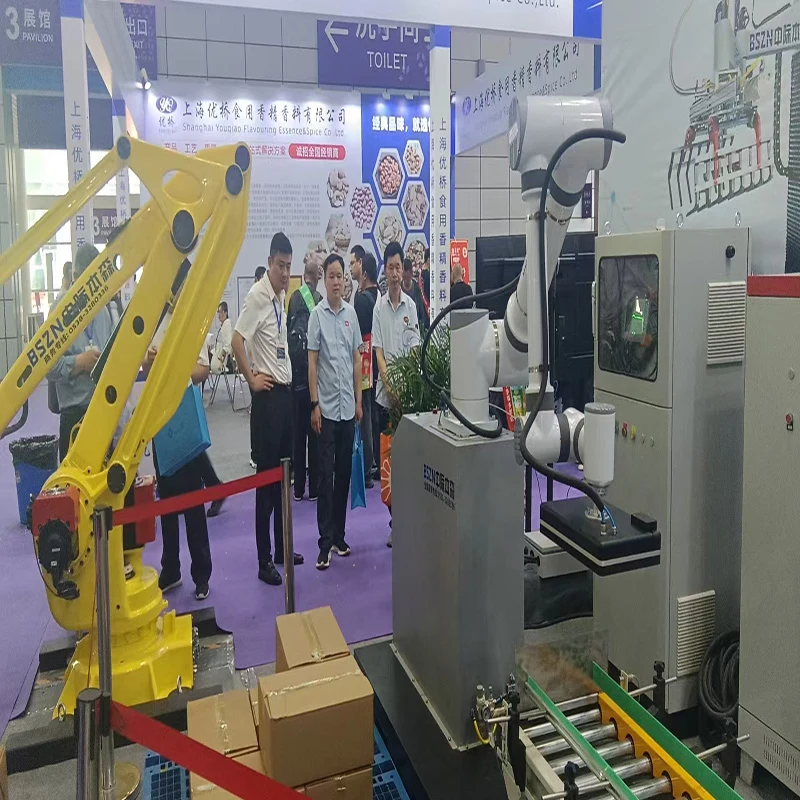

Customer Sites

Company Profile

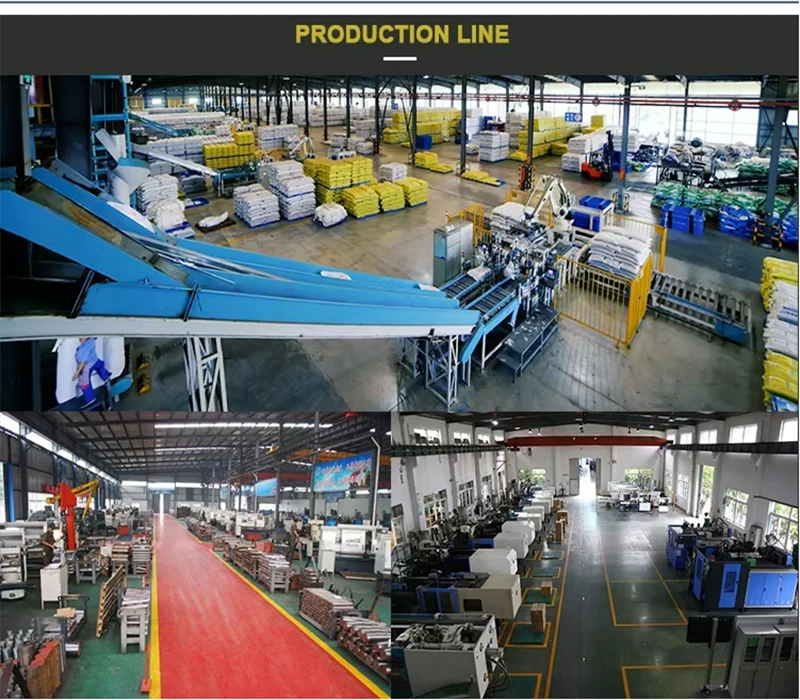

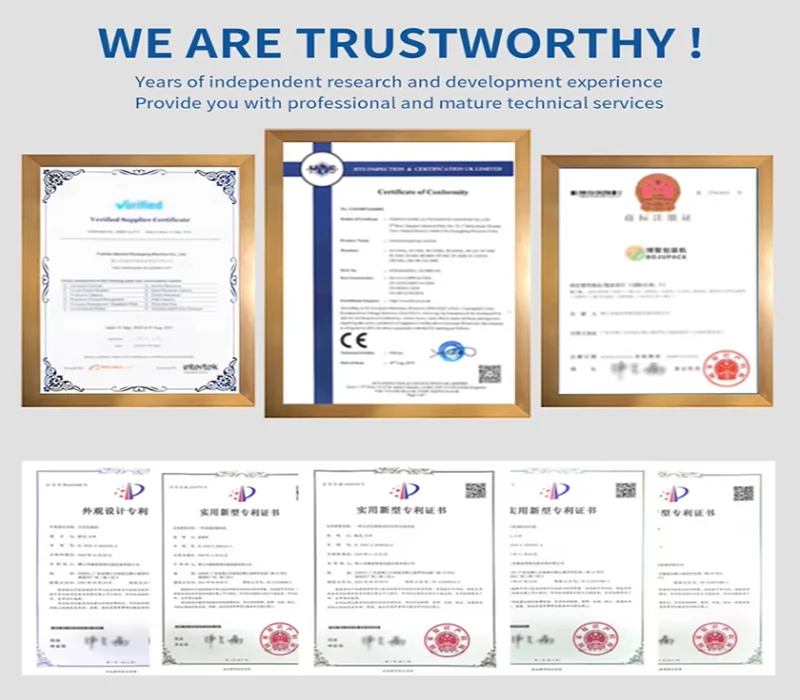

Benson Intelligent Equipment (Shandong) Co., Ltd.was founded in 2013, including self-researching and development, design, production and sales. Benson machinery is committed to the design, production and sales of automatic packaging machine, intelligent palletizing machine, wrapping machine etc. Our products are widely used in food, chemical industry, building materials, feed, warehousing and other industries.Benson has 10 senior technical engineers, more than 20 production workers and 10 senior sales,exporting countries including United States,Mexico, Australia, Russia. Saudi Arabia, Singapore, South Africa etc., all over the world, provided professional solution with efficient and intelligent products to each customer, got the high recognization and compliment from every serviced domestic and foreign client. Benson machinery advocates innovation, professional, efficient, pragmatic business philosophy, to achieve mutual benefit and win-win, continue to provide our customers with high-end products and quality service.

1. Are you factory or trading company?We are the factory, we doing this line for more than 10 years.

2. Can you provide after-sales service for installation?Yes. Before the equipment is shipped, we will install and debug it in the factory to ensure that all components are running stably. After that, the whole set of equipment will be packed in wooden boxes/containers. After receiving the equipment, there is no need for a lot of installation and debugging. At the same time, we will provide corresponding pictures/videos/manuals, and provide telephone consultation online, so that you can ask questions at any time.

If you need to send engineers to the local area to install, debug and train employees, we can also provide you with it. We will provide manuals and detailed videos to help customers install the machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room fees and a daily subsidy of US$150.

3. How long is the warranty on your palletizer robot?We provide a one-year warranty. If there is any problem with the equipment during the warranty period, we will replace it free of charge. If the warranty period expires, we will provide damaged spare parts at cost price. At the same time, our palletizers use brand components such as Schneider and AirTac, which have more stable performance and longer service life. Please rest assured to buy, we are worthy of your trust.

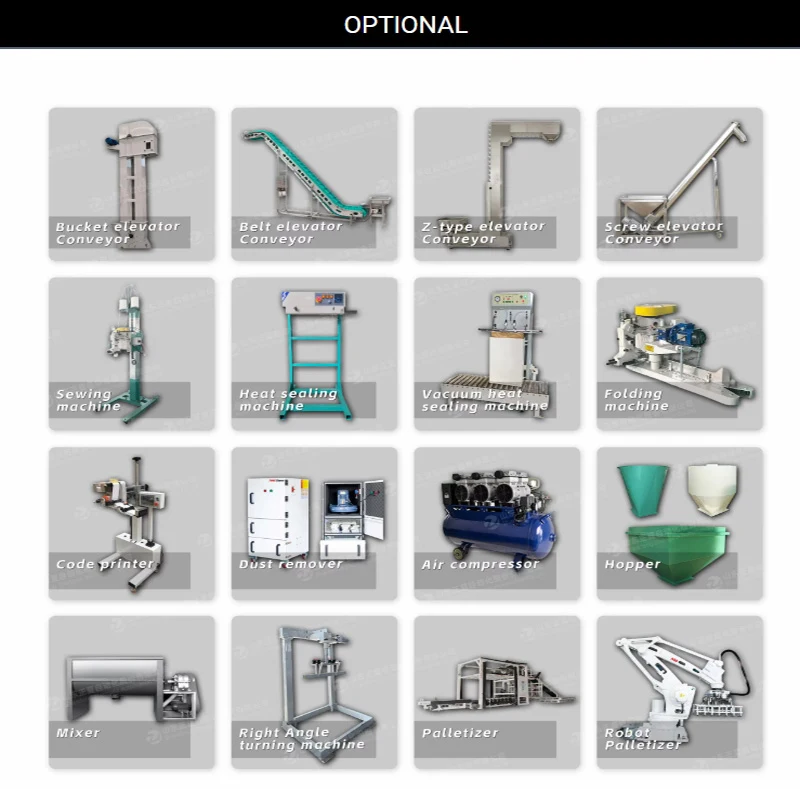

4. Are there any requirements for pallet size and stacking height?It supports a variety of pallet sizes, and the maximum stacking height can reach 1.8 meters to meet different shipping needs.5. Is there a complete solution with a conveyor line?We can provide a complete line: belt conveyor, automatic bag sorting, steering, bag pressing, palletizing, and integrated delivery.

Product Inquiry