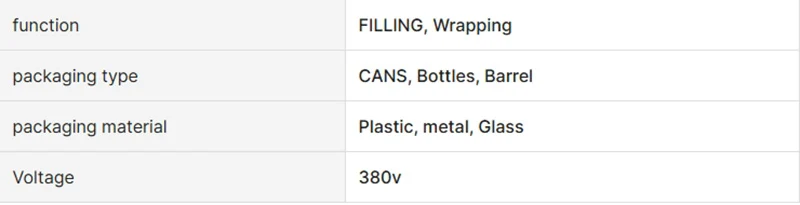

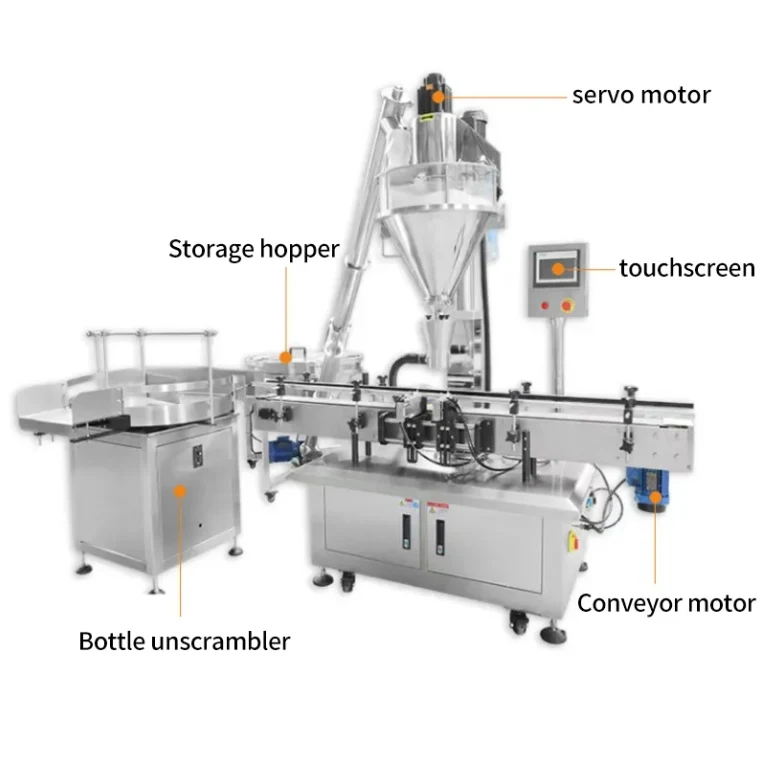

This automatic 100g - 5kg canned packaging machine is specifically designed for food plastic packaging. It integrates advanced automation technology to precisely complete the entire packaging process, including weighing, filling, sealing, and capping. The machine is capable of handling a wide range of food products, from granular and powdered foods to semi - liquid items, ensuring consistent and high - quality packaging results.

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

Automatic 100g-5kg Canned Packaging Machine for Food Plastic PackagingAdvantages

1. High Efficiency: With its automated operation, it can significantly increase production speed, reducing labor costs and improving overall productivity. It can handle a large number of packaging tasks in a short time, meeting the demands of mass production.

2. Accurate Weighing and Filling: Equipped with precise weighing sensors, the machine ensures that each can is filled with the exact amount of product within the 100g - 5kg range, minimizing product waste and ensuring product consistency.

3. Versatility: Suitable for various types of food products and different plastic packaging materials, such as PET, PP, and PE. It can adapt to different can sizes and shapes, providing flexibility for different production requirements.

4. Reliability and Durability: Built with high - quality materials and components, the machine has a long service life and stable performance. It requires less maintenance, reducing downtime and maintenance costs.

5. Hygienic Design: In line with food safety standards, the machine's structure is easy to clean and disinfect, preventing cross - contamination and ensuring the safety and hygiene of food products.

Automatic 100g-5kg Canned Packaging Machine for Food Plastic PackagingApplications

1. Food Industry: Ideal for packaging various food items, including snacks (such as nuts, dried fruits), condiments (like spices, sauces), powdered foods (such as coffee powder, milk powder), and canned foods (such as canned vegetables, canned meats) in plastic containers.

2. Beverage Industry: Can be used for packaging semi - liquid beverages, such as juice concentrates, syrups, etc., in plastic cans.

3. Agricultural and Aquatic Products: Suitable for packaging processed agricultural products (like jams, purees) and aquatic products (such as canned fish, shrimp pastes) in plastic packaging.

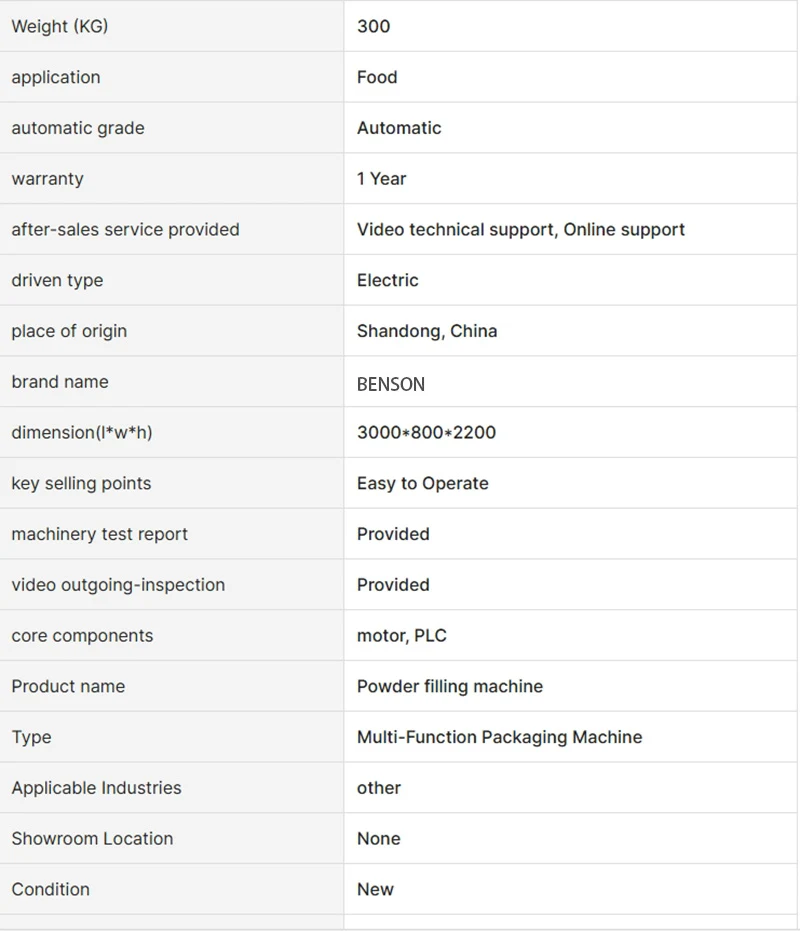

Automatic 100g-5kg Canned Packaging Machine for Food Plastic PackagingFeatures

1. Automated Operation: The machine operates automatically, reducing human intervention and improving the accuracy and stability of the packaging process. It can be programmed to perform different packaging tasks according to specific requirements.

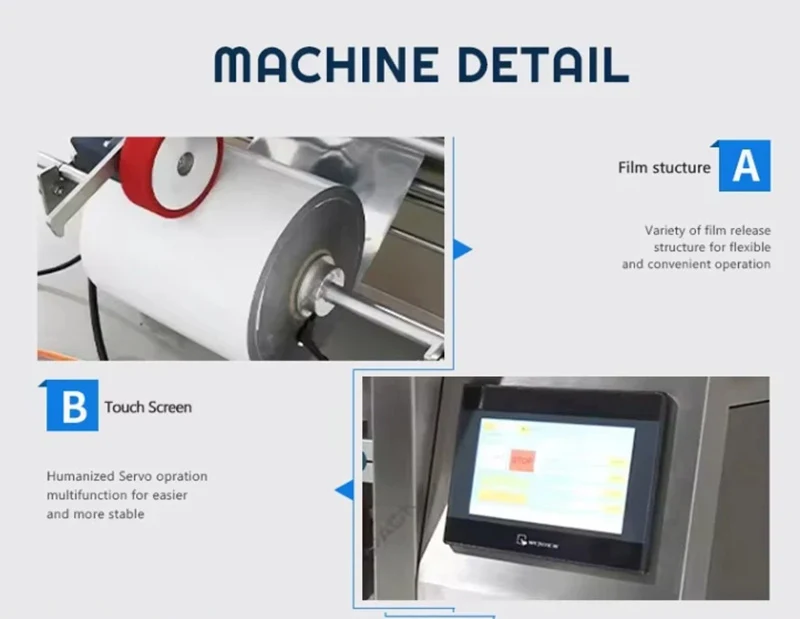

2. Adjustable Parameters: Allows for easy adjustment of various parameters, such as filling weight, sealing time, and capping force, to meet different product and packaging needs.

3. Intuitive Control Panel: Equipped with a user - friendly control panel, operators can easily set up and monitor the packaging process, and receive real - time feedback on machine status and production data.

4. Safety Protection Devices: Fitted with multiple safety protection devices, such as emergency stop buttons, safety sensors, to prevent accidents and ensure the safety of operators and the machine.

5. Compact Design: Despite its powerful functions, the machine has a relatively compact structure, saving floor space in the production workshop and facilitating installation and operation.

Product Inquiry