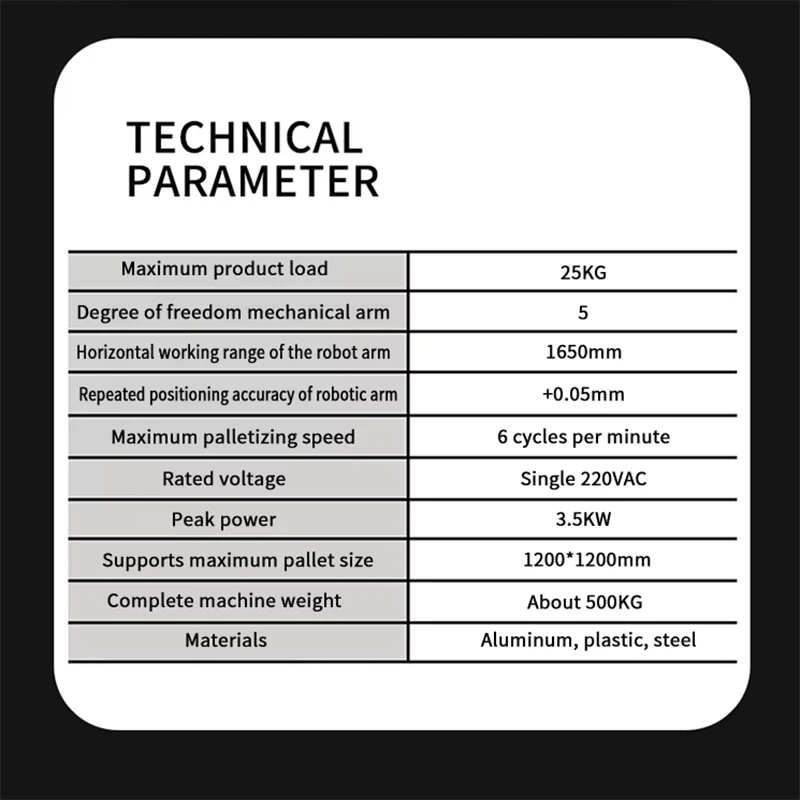

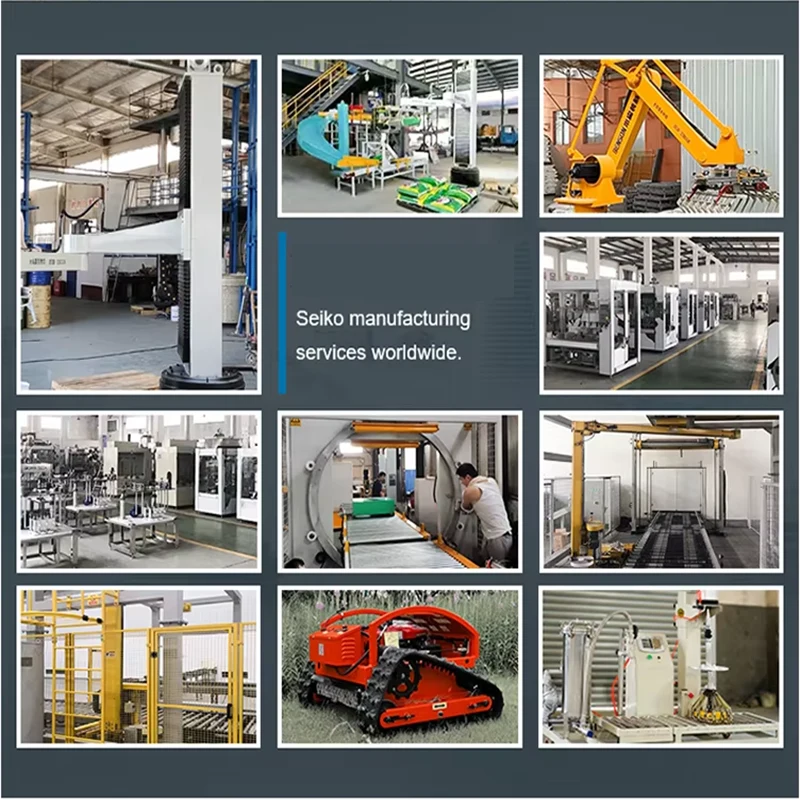

Our automated production collaborative robot is an intelligent device that integrates advanced technology and innovative design, designed for the complex production needs of modern manufacturing. It breaks through the limitations of traditional robots, realizes close human-machine collaboration, greatly improves production efficiency and quality, and helps enterprises transform to intelligent manufacturing.

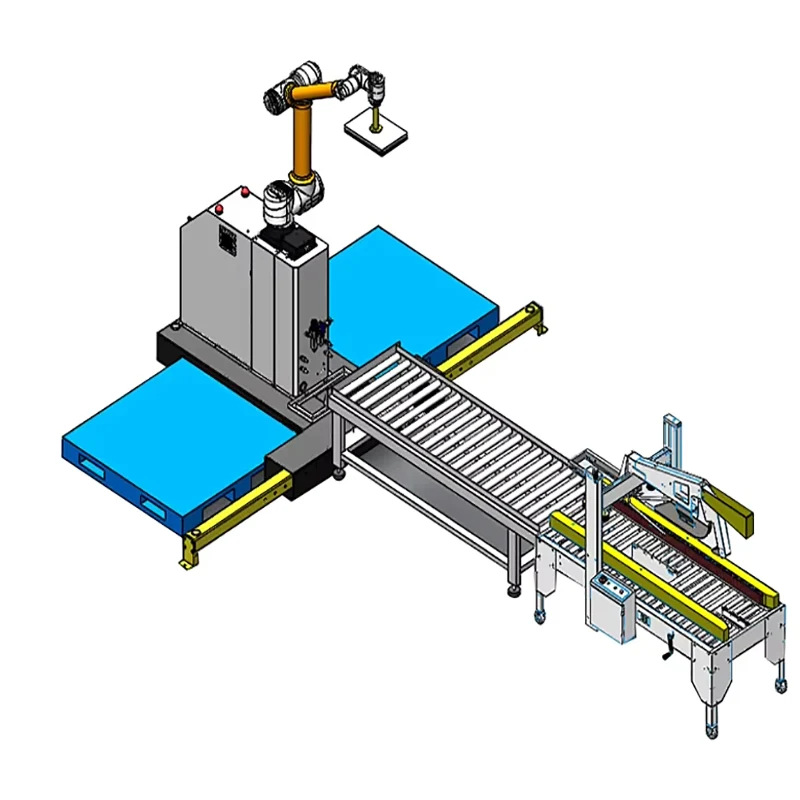

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

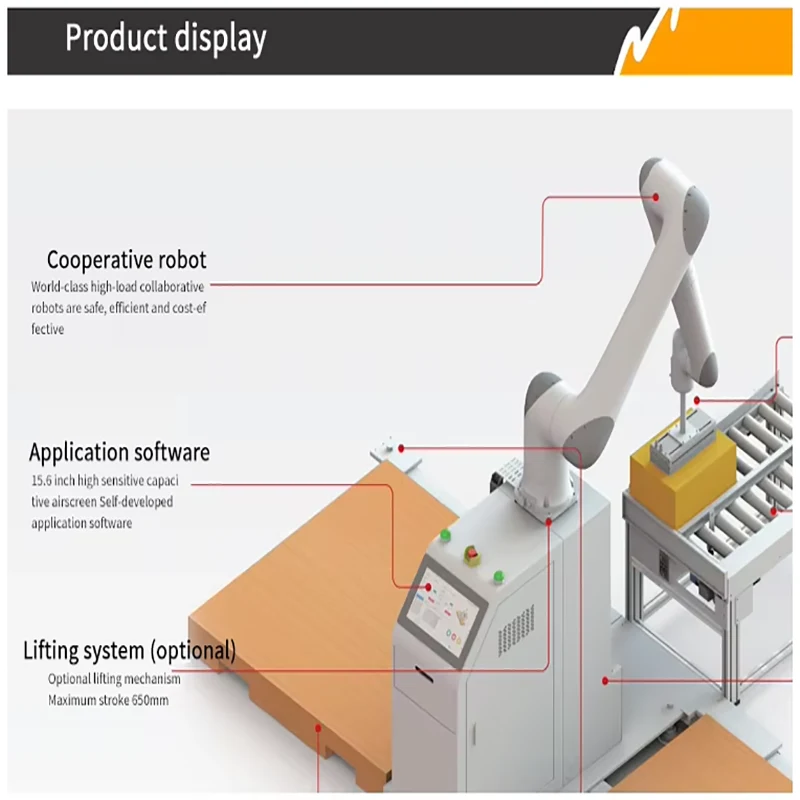

Automated production collaborative robot is easy to operate

Drag teaching: The operator only needs to manually drag the robot arm to the specified position and record the movement trajectory. The robot can quickly learn and repeat the execution without complex programming, which reduces the threshold for use.

Graphical programming interface: Equipped with intuitive graphical programming software, complex task programming can be completed through simple icon dragging and parameter setting, which is convenient for users to adjust the workflow at any time.

Automated production collaborative robot flexible collaboration

Multi-task adaptation: With the 6-axis flexible joint design, it can complete multiple tasks such as assembly, handling, welding, and testing, and easily adapt to different production links.

Rapid deployment: With small size, light weight, and easy installation, it can be quickly integrated into existing production lines without large-scale transformation of production facilities.

Automated production collaborative robot intelligent perception

Visual recognition system: Integrating high-definition visual cameras and advanced visual algorithms, it can quickly identify the shape, size, and position of workpieces, achieve accurate grasping and operation, and adapt to complex and changing production environments.

Force feedback: With force sensing function, it can automatically adjust the force according to the contact force during assembly, grinding and other operations to ensure the quality and stability of operation.

Application scenarios of automated production collaborative robots

3C electronic manufacturing: suitable for the precision assembly, inspection and handling of electronic product parts, such as mobile phone motherboard patch, computer hard disk assembly, etc., to improve production accuracy and efficiency and reduce human errors.

Auto parts production: used for welding, grinding, gluing and handling of auto parts, which can be seamlessly connected with the automobile production line to improve the manufacturing quality and production capacity of parts.

Medical device production: meet the high-precision and high-cleanliness requirements of medical device production, complete the assembly, packaging, quality inspection and other work of the equipment, and ensure product quality and safety.

Food and beverage processing: realize the automation of food sorting, packaging and palletizing, meet food hygiene standards, reduce manual contact and ensure food safety.

Products Description

Company Profile

Bensen (Shandong) Machinery Co., Ltd. is a modern high-tech enterprise engaged in the research and development and production of wrapping machines, packaging equipment, filling machines, industrial robots, palletizing robots, automatic bagging, large-scale production lines, batching equipment, palletizing loaders, material packaging machines and logistics automation production lines. In terms of production, the company has gathered a group of high-level and high-quality professionals. The company actively promotes the development model of "integration of industry, academia and research". The success of this research and development can be widely used in the fields of automated packaging routes, automated logistics engineering, etc. For the new generation of automated assembly lines, the company has introduced various advanced processing equipment to comprehensively enhance its market competitiveness, and has adopted a large number of high-quality accessories, which has greatly improved product quality. It has been widely used in industries such as packaging, packaging, and packaging. From product import to output, from electrical control to mechanical structure design, Bensen (Shandong) Machinery Co., Ltd. can provide comprehensive technical solutions and precision manufacturing of equipment. We have a complete after-sales service system to provide customers with high-quality technical support and after-sales service.

Exhibition

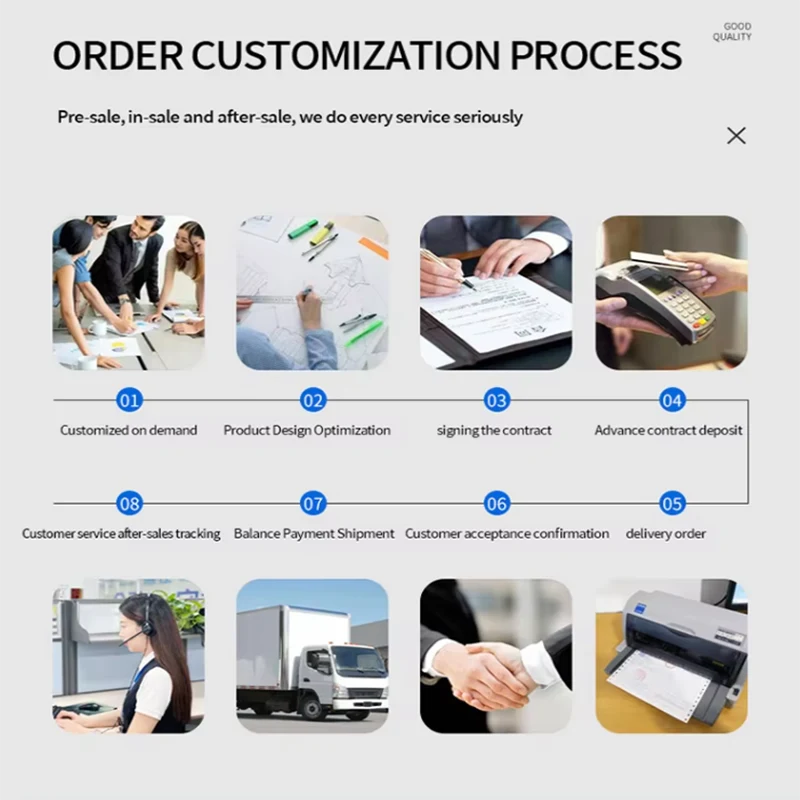

Product Inquiry