Automatic collaborative robots are highly flexible: they can quickly adjust their movements and paths according to different task requirements and working environments, and adapt to the palletizing and loading and unloading of goods of various specifications and shapes.

Strong safety: equipped with a variety of sensors, they can sense the surrounding environment in real time, and automatically stop or adjust their movements when they detect people approaching or obstacles to avoid collision acci

The column palletizer is a compact, space-saving automated palletizing machine....

2025-04-27

As a manufacturer of fully automatic organic fertilizer machinery robots, Benson...

2025-06-29

The 15 - kilogram canned goods vertical stacking robot, the 10 - kilogram chili ...

2025-06-29

The 50-kg intelligent control carton column palletizing robot, high-speed 25-kg ...

2025-06-28

The 15 - kilogram rice vertical palletizing machine packaging production line ca...

2025-06-27

The small 20 - kilogram flour vertical - column palletizing robot is specificall...

2025-06-27

The vertical feed stacker is a key equipment for achieving automation and intell...

2025-06-15

Thegantry - type high - level palletizer, with its stable and robust structure, ...

2025-06-14

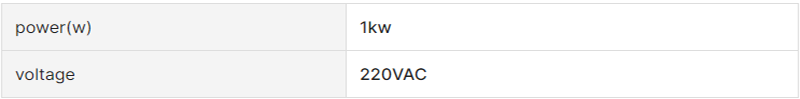

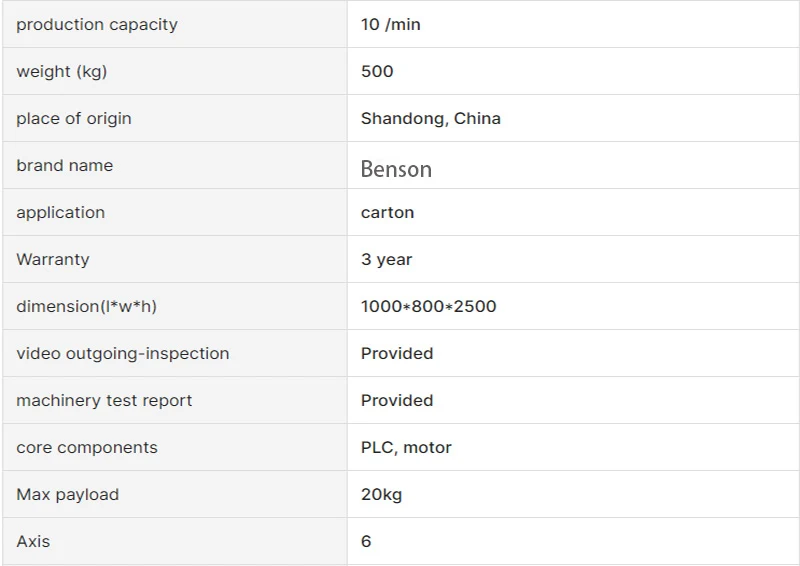

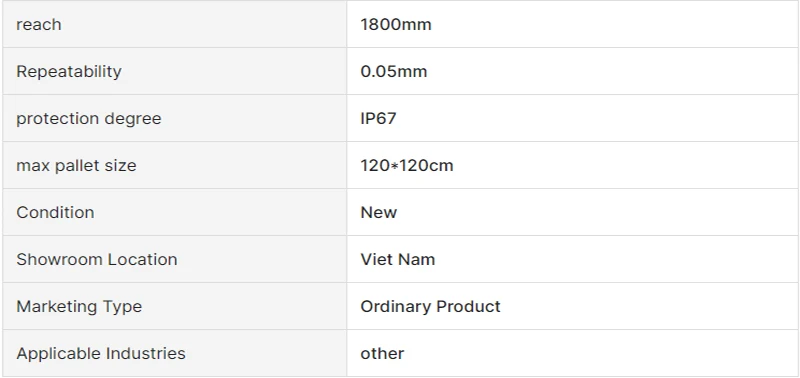

Key attributes

Industry-specific attributes

Other attributes

Packaging and delivery

Products Description

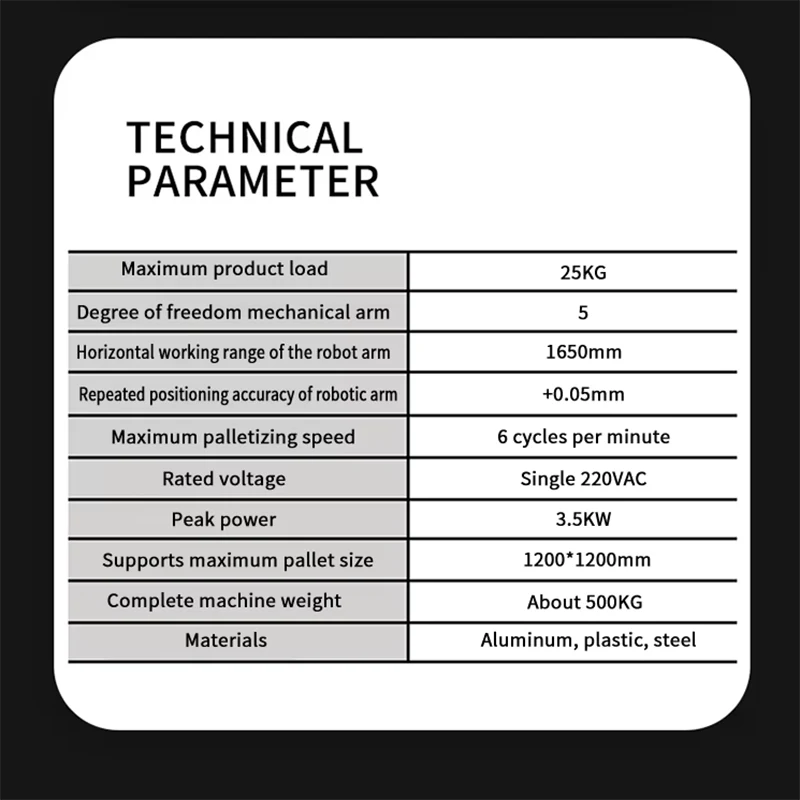

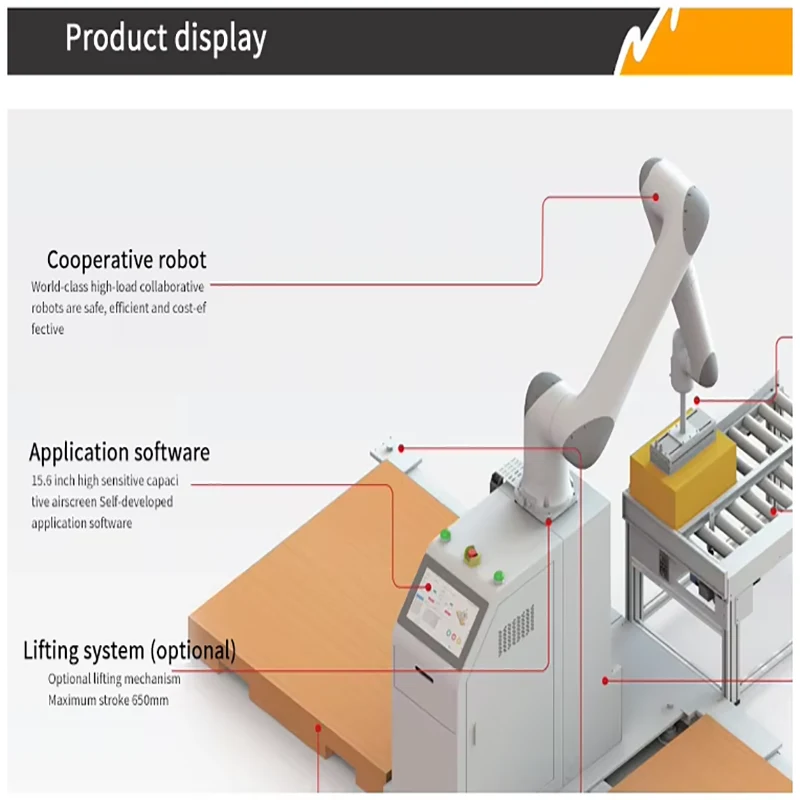

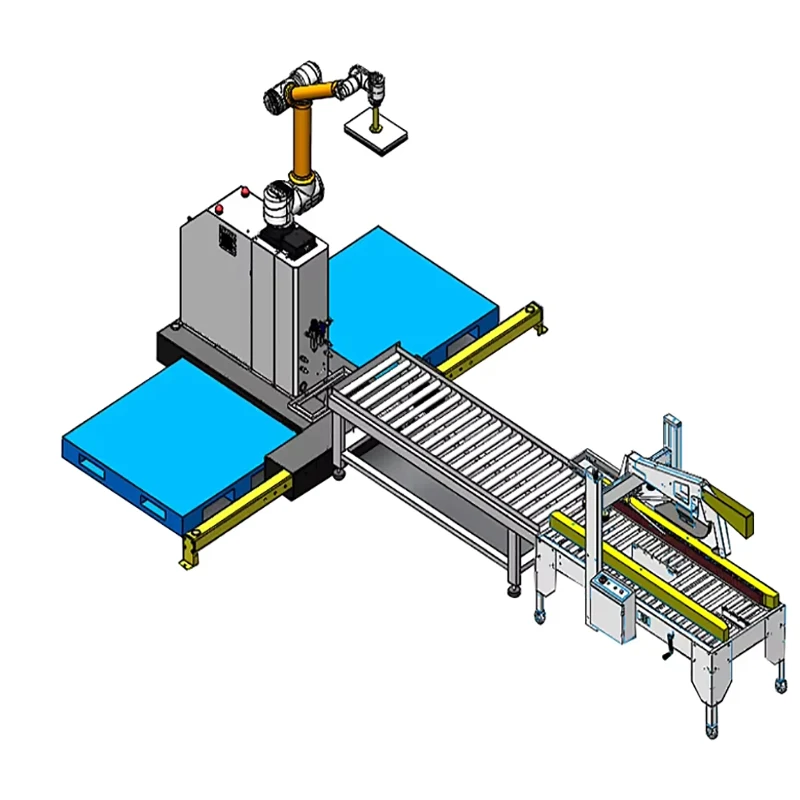

The carton collaborative robot palletizer is an industrial equipment that integrates advanced automation technology and intelligent collaboration concepts. It is designed for efficient completion of cargo palletizing tasks. It breaks the limitations of traditional palletizing operations, can flexibly collaborate with manual and other production equipment, and optimize production logistics.

Features

- Good collaboration: It can work with human workers to complete complex palletizing and loading and unloading tasks, give full play to their respective advantages, and improve work efficiency.

- Efficient and accurate: It can carry out cargo handling at a stable speed and highly accurate operation, reduce manual operation errors, improve palletizing quality and loading and unloading efficiency, and reduce cargo damage rate.

Working principle

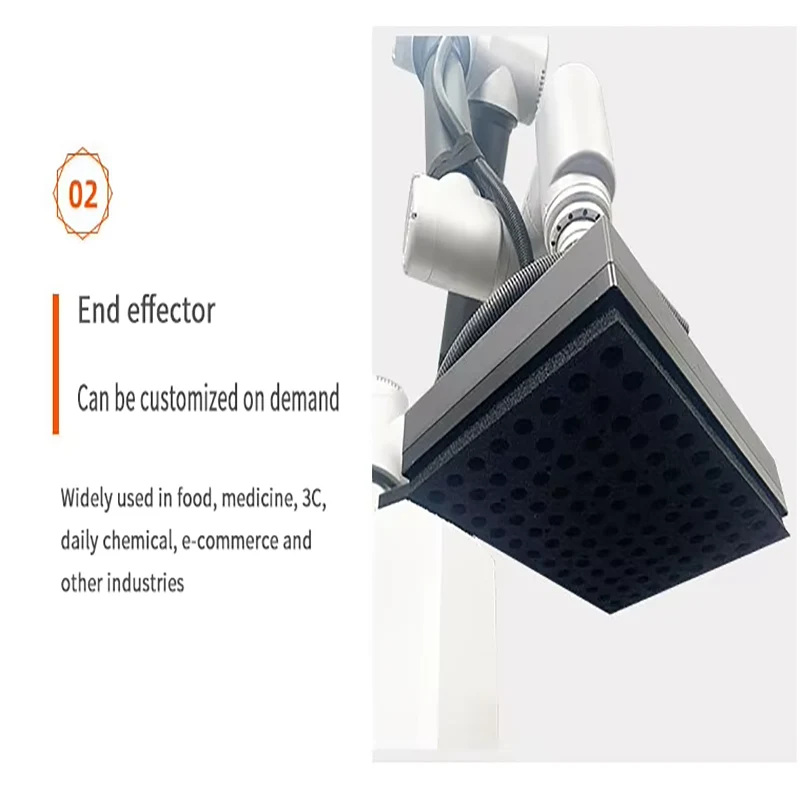

- It is usually based on advanced visual recognition systems to identify the shape, position and posture of the goods, and plan the best grasping and handling path through built-in algorithms. Use robotic arms and end effectors, such as suction cups and grippers, to grasp, carry and place goods. At the same time, with the help of force sensors, precise control of the grasping force is achieved to ensure that the goods can be firmly grasped without damaging them due to excessive force.

Application scenarios

- In logistics warehouses, cartons and packages of various specifications can be quickly palletized and loaded and unloaded to improve the efficiency of goods in and out of the warehouse. In the food and beverage industry, bottled and canned products can be neatly palletized. In the electronics manufacturing industry, it can be used for material handling and finished product palletizing of small electronic products to meet the needs of high-precision and small-batch production.

Development trend

- With the continuous development of artificial intelligence and machine learning technologies, automatic collaborative robots will have stronger autonomous learning capabilities and can continuously optimize their operating processes and decision-making capabilities through the analysis of large amounts of data. At the same time, the intelligence level of robots will be further improved, and more complex task planning and environmental adaptation can be achieved. The integration with the entire production logistics system will also be closer, achieving seamless docking and collaborative operations.

Exhibition

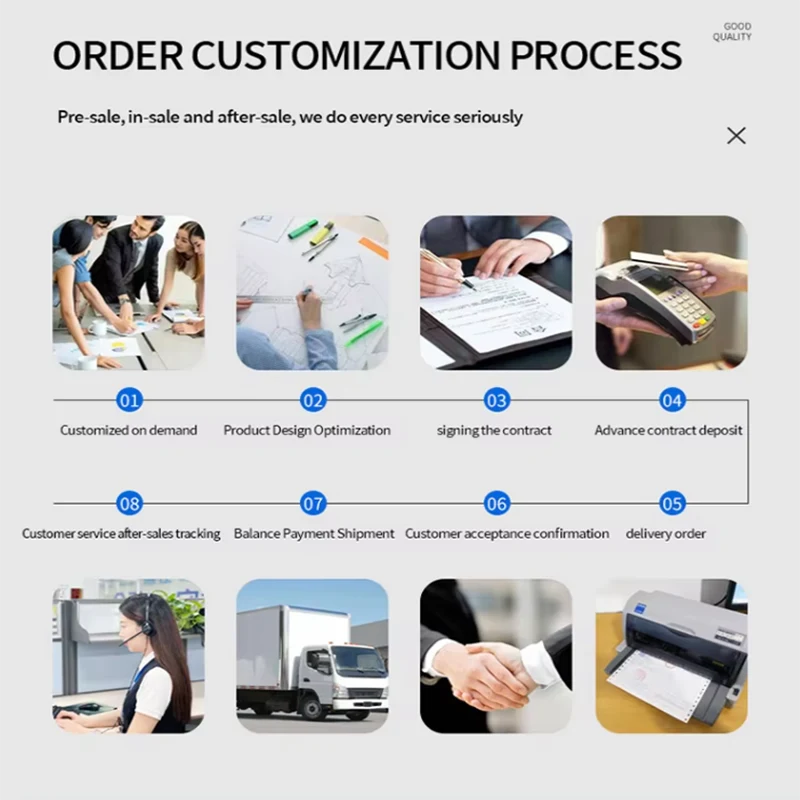

Product Inquiry